Professional Documents

Culture Documents

5s Audit Methodology

5s Audit Methodology

Uploaded by

sandeep dabhade0 ratings0% found this document useful (0 votes)

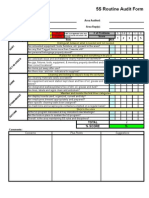

12 views9 pages1) The document proposes a scoring system from 1 to 5 to evaluate three areas: systems available for 5S, actual work practices followed, and personal habits.

2) For systems available, scores are given based on the level of 5S structure, training, methodology definition and maintenance, progress tracking, and sustainability.

3) For work practices, problems are categorized as minor, major, or critical based on types of items and safety issues. Scores are given according to the number of problems identified in each category.

4) For personal habits, scores are assigned based on the level of 5S awareness, understanding of responsibilities, following of disciplines and standards, and ability to sustain practices independently.

Original Description:

it explains 5S Methodology which is widely used in Industry for Visual Impact

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document proposes a scoring system from 1 to 5 to evaluate three areas: systems available for 5S, actual work practices followed, and personal habits.

2) For systems available, scores are given based on the level of 5S structure, training, methodology definition and maintenance, progress tracking, and sustainability.

3) For work practices, problems are categorized as minor, major, or critical based on types of items and safety issues. Scores are given according to the number of problems identified in each category.

4) For personal habits, scores are assigned based on the level of 5S awareness, understanding of responsibilities, following of disciplines and standards, and ability to sustain practices independently.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views9 pages5s Audit Methodology

5s Audit Methodology

Uploaded by

sandeep dabhade1) The document proposes a scoring system from 1 to 5 to evaluate three areas: systems available for 5S, actual work practices followed, and personal habits.

2) For systems available, scores are given based on the level of 5S structure, training, methodology definition and maintenance, progress tracking, and sustainability.

3) For work practices, problems are categorized as minor, major, or critical based on types of items and safety issues. Scores are given according to the number of problems identified in each category.

4) For personal habits, scores are assigned based on the level of 5S awareness, understanding of responsibilities, following of disciplines and standards, and ability to sustain practices independently.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 9

Prepared By:Rameshs Upadhe

a)

We suggest scoring methods as :Scores will be given in the range of 1 - 5.

It is suggested to give 1 - 5 ratings for:I.

Systems Available

II.

Actual work practices followed

III.

Personal habits.

Scoring Method:- Range 1 - 5

A Systems available.

1 5S Detailed Structure & Roll out plan , Displays

2 Training of All employees & Awareness for 5S

5S Methodology for Each S is defined &

3

maintained

Progress status as per Roll out plan & scope for

4

Continues improvement

5 Sustaining methodology & motivation techniques

B Actual work practices Followed:-

The identified problems can be sub categorized as follows:1) Minor

2) Major

3) Critical

Definition for defining criticality:a) Minor - All C class items, all non production small items like

sockets, O rings etc., General waste e.g.. Polythene bags, wooden

waste, paper waste etc.

b) Major - All A & B class production items, tools & equipments,

fixtures, material movement trolleys & equipments etc.

c) Critical Leakages around hydraulic equipments, hazardous waste

not disposed properly, unsafe conditions etc.

The criteria for defining Minor problems are:Scores

No. of Problems identified

13 and above

9 to 12

6 to 8

3 to 5

0 to 2

The criteria for defining Major problems are:Scores

No. of Problems identified

5 & above

1 to 2

The criteria for defining Critical problems are:Scores

No. of Problems identified

3 & above

The scoring methodology could be

summarized as follows:

0

1

2

3

4

5

Needs Substantial Improvement

Not Evident

Evident

Significant

Complete

Sustaining

C Personal habits:-

I.

5S Awareness training is understood

Everybody knows his responsibility &

role to play

General things such as use of PPE,

appearance, uniform, etc

General discipline about time, work, etc

Sustaining is done without any effort

II.

III.

IV.

V.

You might also like

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- 5S Audit ChecklistDocument5 pages5S Audit ChecklistZahid Hussain100% (3)

- ISO 2015 Int Auditor TestDocument10 pagesISO 2015 Int Auditor Testsamir100% (2)

- Management Review TemplateDocument15 pagesManagement Review TemplateHaslayati Hashim100% (1)

- Quality Management Iso9001:2015 Changes: A Guide to ImplementationFrom EverandQuality Management Iso9001:2015 Changes: A Guide to ImplementationRating: 5 out of 5 stars5/5 (1)

- EMS - Check ListDocument10 pagesEMS - Check ListTom Carpenter0% (1)

- Prepared By: Mr. Prashant S. Kshirsagar B.E.Metallurgist (SR - Manager-QA Dept.)Document21 pagesPrepared By: Mr. Prashant S. Kshirsagar B.E.Metallurgist (SR - Manager-QA Dept.)komaltagraNo ratings yet

- WSE Unit 3 TheoryDocument13 pagesWSE Unit 3 TheoryVishal MeenaNo ratings yet

- Bebba 3Document2 pagesBebba 3Sunil VemulaNo ratings yet

- Autonomous Operator Training Step 0Document17 pagesAutonomous Operator Training Step 0JESUSAA36No ratings yet

- CIA New Content2Document7 pagesCIA New Content2Ahmed Adel AttiyaNo ratings yet

- Igc - 1 Questions and Answer (1) (Vist)Document16 pagesIgc - 1 Questions and Answer (1) (Vist)rajesh_viper100% (3)

- ABC Sdn. BHD.: First (1S) Audit ChecklistDocument2 pagesABC Sdn. BHD.: First (1S) Audit ChecklistRamesh KumarNo ratings yet

- BTEC National Level 3 IT Maintaining Computer Systems Assignment 1Document8 pagesBTEC National Level 3 IT Maintaining Computer Systems Assignment 1trey0% (1)

- Unit III: Life Cycle Testing ApproachDocument27 pagesUnit III: Life Cycle Testing ApproachmadhanNo ratings yet

- Phase 1: Systems Planning: Analyzing The Business CaseDocument47 pagesPhase 1: Systems Planning: Analyzing The Business Caseد.عمر بلولةNo ratings yet

- Updated Feasibility StudyDocument23 pagesUpdated Feasibility StudySakibNo ratings yet

- Assignment 1Document3 pagesAssignment 1Mina JouvanyNo ratings yet

- IEM Syllabus With Front Page-FinalDocument43 pagesIEM Syllabus With Front Page-Finalpammy313No ratings yet

- CIA New Content 2013Document7 pagesCIA New Content 2013John MuchabiNo ratings yet

- Word SITXMGT001 Monitor Work Operations 1 Assessment TaskDocument9 pagesWord SITXMGT001 Monitor Work Operations 1 Assessment TaskVirajkanwal KanwalNo ratings yet

- 5S Audit Checklist - Workplace EvaluationDocument5 pages5S Audit Checklist - Workplace EvaluationDaniel2116No ratings yet

- Please Give This FAX To Mr. Dr. Green: Athens 8.2.99Document2 pagesPlease Give This FAX To Mr. Dr. Green: Athens 8.2.99invatorNo ratings yet

- HRM Final Review Cue CardsDocument30 pagesHRM Final Review Cue CardsHelen LuNo ratings yet

- Auditoria Com Abordagem de ProcessoDocument5 pagesAuditoria Com Abordagem de ProcessoANTONIO CARLOS LINO MACHADONo ratings yet

- Process-Based Auditing - ASQDocument5 pagesProcess-Based Auditing - ASQSelvaraj SimiyonNo ratings yet

- Advance Research Methods: Salman Ahmed Rabbani Spring, 2012 Tuesdays 6:30 - 9:30 PMDocument24 pagesAdvance Research Methods: Salman Ahmed Rabbani Spring, 2012 Tuesdays 6:30 - 9:30 PMWacky SunNo ratings yet

- Marking N ReportingDocument57 pagesMarking N ReportingSchahyda Arley100% (3)

- CMRP Sample PapersDocument5 pagesCMRP Sample PapersPRANAY SINGH THAKUR100% (3)

- Industrial Engineering LabDocument20 pagesIndustrial Engineering Labajainb239No ratings yet

- Systems Audit WorkplanDocument3 pagesSystems Audit Workplandixman007No ratings yet

- Chapter 3 - IsD PrinciplesDocument5 pagesChapter 3 - IsD PrinciplesluckyhookNo ratings yet

- MOSH Health & Safety 14-01-2021Document31 pagesMOSH Health & Safety 14-01-2021Mahmood AliNo ratings yet

- 6S - 5S - Evaluation and Implementation Tool - LeanDocument8 pages6S - 5S - Evaluation and Implementation Tool - LeanShekhar RaviNo ratings yet

- Phase 2: Systems AnalysisDocument15 pagesPhase 2: Systems AnalysisSamuel AssefaNo ratings yet

- Lear-75-GM Quality System Basics Audit FormDocument12 pagesLear-75-GM Quality System Basics Audit FormalexrferreiraNo ratings yet

- 5S Audit Form PCI MasterDocument2 pages5S Audit Form PCI MasterTengku SmyNo ratings yet

- HR AuditDocument36 pagesHR AuditTarandeep Singh100% (1)

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaNo ratings yet

- 5S AuditDocument7 pages5S Auditjorge.kemelNo ratings yet

- O LEVEL Project GuideDocument9 pagesO LEVEL Project GuideAnthonyNo ratings yet

- C. Inception ReportDocument7 pagesC. Inception ReportSrinath VenkatNo ratings yet

- Câu 1: Describe The Job Analysis Process? Giving The Example Collecting Informalion 107 Job AnalysisDocument2 pagesCâu 1: Describe The Job Analysis Process? Giving The Example Collecting Informalion 107 Job AnalysisTrần Thị PhươngNo ratings yet

- IT Environment Work PlanDocument2 pagesIT Environment Work Plandixman007No ratings yet

- Systems Analysis and DesignDocument48 pagesSystems Analysis and DesignmaryamNo ratings yet

- T.A. Blakelock Market Research Project: The SituationDocument2 pagesT.A. Blakelock Market Research Project: The SituationRaju SharmaNo ratings yet

- Method Study in Production and Operation ManagementDocument13 pagesMethod Study in Production and Operation ManagementSameer KhanNo ratings yet

- Streamlining Re EngineeringDocument13 pagesStreamlining Re EngineeringAzril RazaliNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- 5s Project dt-03-05-2013Document23 pages5s Project dt-03-05-2013Ashish SwainNo ratings yet

- Six Sigma Study GuideDocument7 pagesSix Sigma Study GuideMoideen NaseerNo ratings yet

- Quality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NameDocument7 pagesQuality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NamewentropremNo ratings yet

- MODULE 2 Training Need AnalysisDocument36 pagesMODULE 2 Training Need AnalysisGanesh Kumar. RNo ratings yet

- Unit III: Life Cycle Testing ApproachDocument28 pagesUnit III: Life Cycle Testing ApproachSanthosh NaniNo ratings yet

- 5S Audit SheetDocument4 pages5S Audit SheetJohn Robert StoneNo ratings yet

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- IELTS Writing Section (Academic) - How To Achieve A Target 8 Score!From EverandIELTS Writing Section (Academic) - How To Achieve A Target 8 Score!Rating: 3.5 out of 5 stars3.5/5 (7)