Professional Documents

Culture Documents

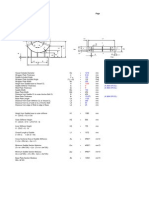

Inputs Astm A36 ASTM A193 Nitrile Rubber O-Ring Reference Document - (From Sec. VIII, Div. I) Gasket/'O-Ring' Type: Elastomer

Uploaded by

Ratnakar PatilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inputs Astm A36 ASTM A193 Nitrile Rubber O-Ring Reference Document - (From Sec. VIII, Div. I) Gasket/'O-Ring' Type: Elastomer

Uploaded by

Ratnakar PatilCopyright:

Available Formats

Inputs

Material of Valve Body

Material of Bolt Material

Gasket/'O-Ring' Type : Elastomer

Reference Document- (From Sec. VIII, Div. I)

ASTM A36

ASTM A193

Nitrile Rubber O-ring

Gasket Factor

Gasket Joint Contact or Unit Seating Loa

1.4

MPa

Inside Diameter Of Gasket

Di

1548

mm

Outside Diameter Of Gasket

Do

1696

mm

Inside Diameter of Flange

1542

mm

Outside Dia. Of Flange

1854

mm

Thickness of Hub at the back of Flange

g1

30

mm

Thickness of Hub at the small end (Shell

g0

16

mm

Hub Length Min

14

mm

Hub stress Correction Factor

3.3

Thickness of Flange (assumed)

38.6

mm

Factor for Integral T

= (g1/g0) Vs (h/h0) =

0.905

Factor for Integral Type Flanges

Factor

(From Sec. VIII, Div. I, 2004 Pg. 356)

Value

V

K

=

=

0.445

1.20

mm

5.49

mm

Factor T

1.84

Factor U

11.69

Factor Y

10.64

Max. Allowable Stress for Body / End Co

Sn

355

MPa

Allowable Bolt Stress Value at atmosphe

Sa

178

MPa

1.1

MPa

2440

mm

M52

Calculations

(Reference. Section II, Part D :2004 Pg. No. 383)

Design Pressure at Room Temperature

PD

( Reference. ANSI B 16.34 Pressure-Temp. Rating )

Bolt Circle Diameter

Size of Bolt / Stud

Stress Area of one Bolt

Atb1

1735.643

No. of Bolts

Nb

52

g1 / g0

1.875

Ratio

Factor

ho

Ratio

Actual Total Tensile Stress Area of Bolts

157.07

mm2

mm

h / ho

0.09

Ab

90253.43

mm2

Diameter at location

1622.00

mm

Total Hydrostatic En

2229735

Actual Width of Gas

( Do - Di ) / 2

74.00

mm

Basic Gasket Seatin

bo

N/2

37.000

mm

or Joint-Contactb

=

Surface Seating

( When bo =< 0.25 inch , b = bo

Hydrostatic End

Force on Area

Inside of Flange

Total Joint Contact

Surface

Compression Load

Load for

OPERATING

bo

=

3.041

mm

OR When bo > 0.25 inch , b = (0.5) * s

HD

= ( 0.785 ) x B2 x PD =

2015210

Hp

2=

x b x 3.14 x G x m x=PD

33447

Wm1

H + Hp

2263183

Minimum Required

Bolt Load for

GASKET SEATING

Wm2

3.14 x b

xGxy

21697

Bolts at root of the

thread for GASKET

Am1

Wm1 / Sa

12750.32

mm2

Bolts at root of the

thread for GASKET

Am2

Wm2 / Sa

122.24

mm2

12750.32

mm2

Am

Total Cross Sectional

= MAX (Am1, Am2) =

( taken as Greater of Am1 and Am2 )

FLANGE MOMENTS

For

OPERATING

Radial

Distance Conditions :from Bolt Circle to

point of

R

=

Intersection of hub

and back of flange

((CB)/2)g1

419

mm

Gasket Load

HG

Wm1 - H

33447

End Force and

Hydrostatic End

HT

H - HD

214525

hD

R + (0.5 x g1)

434.00

mm

hG

(C-G)/2

409.00

mm

hT

= ( R + g1 + hG ) / 2 =

429.00

mm

Moment Arms :-

Flange Moments for OPERATING Conditions :-

MD

HD x hD

###

N-m

MG

HG x hG

###

N-m

MT

HT x hT

###

N-m

Total Flange Moment

For OPERATING Cond Mo

MD + MG + M T

###

N-m

FLANGE STRESSES

Factor e

F / h0

0.01

Factor K

A/B

1.20

Factor d

= (U/V) x h0 x g02 =

###

Factor L

((t

= x e+1) / T) + (t3 / =

d)

0.72

Factor Z

= (K2 + 1) / (K2 - 1) =

5.49

Longitudinal Hub Str

SH

(f x Mo) / (L x g12 x B)

=

=

3239.80

MPa

Radial Flange Stress

SR

2

((1.33xtxe+1)xMo)/(Lxt

=

=

xB)

768.44

MPa

Tangential Flange St

ST

(Y x=Mo / t2 x B) - (Z x S=x R)

321.14

MPa

FLANGE STRESSES INDUCED

Longitudinal Hub

SH

3239.80

<

Radial Flange Stre

SR

768.44

<

Tangential Flange

ST

321.14

<

A = ( SH + SR ) /2

2004.12

B = ( SH + ST ) /2

1780.47

Greater A and B

2004.12

Conclusion :

" Design of Flange is Safe "

<

1.5 x Sf

=

Sf

=

Sf

=

Sf

=

532.5

355

355

355

You might also like

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- 5.7 Asmeviii A-2 & Tema Split Backing RingDocument1 page5.7 Asmeviii A-2 & Tema Split Backing RingpastylNo ratings yet

- Calculo de Brida Segun ASMEDocument29 pagesCalculo de Brida Segun ASMEakarcz6731No ratings yet

- Nozzle TempDocument2 pagesNozzle TempRakeshNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- 2 Inch UCB Lite Cast Joint EfficiencyDocument3 pages2 Inch UCB Lite Cast Joint EfficiencyAnil Krishna JangitiNo ratings yet

- CO2 AbsorberDocument11 pagesCO2 AbsorberDhrumil Gandhi100% (2)

- Flange KOD Vessel Calculation - Actual ConditionDocument21 pagesFlange KOD Vessel Calculation - Actual ConditionPeter PerezNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Blind Flange With Multiplpe Opening (U Stamp) )Document12 pagesBlind Flange With Multiplpe Opening (U Stamp) )Ashish Dhok0% (1)

- Calculation For Sight Glass FlangeDocument4 pagesCalculation For Sight Glass FlangeOmil Rastogi0% (2)

- Flange Analysis - Traditional Method 14sep10Document1 pageFlange Analysis - Traditional Method 14sep10Lava SatNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- Mathcad - Bolt Loading VDI M39 01Document10 pagesMathcad - Bolt Loading VDI M39 01Pete SwiftNo ratings yet

- 17 Asmeviii A-2 Reverse Integral FlangeDocument1 page17 Asmeviii A-2 Reverse Integral FlangepastylNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Blind Flange (10 Bar)Document7 pagesBlind Flange (10 Bar)SyedZainAliNo ratings yet

- Aspen HX Design ReportDocument78 pagesAspen HX Design ReportberylqzNo ratings yet

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- Calculation LugDocument20 pagesCalculation LugKartika ZuhraNo ratings yet

- Design Calculation 4-PadeyesDocument4 pagesDesign Calculation 4-PadeyesMuhammad Yahdiman100% (3)

- 5 Asmeviii A-24 Clamp ConnectionDocument6 pages5 Asmeviii A-24 Clamp ConnectionpastylNo ratings yet

- Flange DesignDocument6 pagesFlange DesignDinesh VaghelaNo ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- 5 Asme Viii A-24 Clamp ConnectionDocument6 pages5 Asme Viii A-24 Clamp ConnectionpastylNo ratings yet

- Cover Plate CalculationDocument1 pageCover Plate CalculationSachin5586No ratings yet

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- Flange DesignDocument26 pagesFlange Designresume Fi-1401No ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- Flange DesignDocument30 pagesFlange Designravielb9873No ratings yet

- RectangularDocument15 pagesRectangularaku9450% (2)

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- Saddle 1Document3 pagesSaddle 1RUDHRA DHANASEKARNo ratings yet

- Lug Support DesignDocument3 pagesLug Support DesignSajal KulshresthaNo ratings yet

- General Criteria For Design Steel StructureDocument12 pagesGeneral Criteria For Design Steel StructureSurat WaritNo ratings yet

- 14Document43 pages14Gautam SharmaNo ratings yet

- Pipe Support CalculationDocument2 pagesPipe Support Calculationjsmnjasmines86% (7)

- Eyab AssignmentDocument8 pagesEyab AssignmentAbnet BeleteNo ratings yet

- Bolt TorqueDocument2 pagesBolt TorqueAzwan Shah100% (1)

- Padeye CalDocument6 pagesPadeye Calhuangjl100% (1)

- Design (Valve)Document12 pagesDesign (Valve)zmetheuNo ratings yet

- Radial Stiffener PDFDocument6 pagesRadial Stiffener PDFsagar1503No ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Ferrofab Fze: Collar Bolt Sizing CalculationDocument2 pagesFerrofab Fze: Collar Bolt Sizing CalculationMohammad Zahid50% (2)

- End Plate Design As Per-Ec3Document18 pagesEnd Plate Design As Per-Ec36j7100% (1)

- Calculation Validation ReportDocument18 pagesCalculation Validation Reportvijay10484No ratings yet

- Blind Flange Calculation11Document3 pagesBlind Flange Calculation11jaymuscatNo ratings yet

- End Plate ConnectionDocument12 pagesEnd Plate ConnectioncklconNo ratings yet

- Wellhead Dual Tubing Hanger RequirementsDocument1 pageWellhead Dual Tubing Hanger RequirementsRatnakar PatilNo ratings yet

- Weir Oil Gas BrochureDocument33 pagesWeir Oil Gas BrochureRatnakar Patil100% (1)

- Part Logic1Document2 pagesPart Logic1Ratnakar PatilNo ratings yet

- Common Valve Casting Materials MetallurgyDocument4 pagesCommon Valve Casting Materials MetallurgyRatnakar PatilNo ratings yet

- Parveen Well Head PDFDocument25 pagesParveen Well Head PDFRatnakar PatilNo ratings yet

- ViN Trunn Mounted BVDocument8 pagesViN Trunn Mounted BVRatnakar PatilNo ratings yet

- Wellhead Products Catalog vFEB2015 PDFDocument20 pagesWellhead Products Catalog vFEB2015 PDFRatnakar PatilNo ratings yet

- Study Successful CalculationDocument58 pagesStudy Successful CalculationRatnakar PatilNo ratings yet

- Company Profile en TORNOSDocument14 pagesCompany Profile en TORNOSRatnakar PatilNo ratings yet

- Universal Company Profile StainlessDocument7 pagesUniversal Company Profile StainlessRatnakar PatilNo ratings yet

- Enquiry Form DataDocument3 pagesEnquiry Form DataRatnakar PatilNo ratings yet

- Ball Joint DesignDocument8 pagesBall Joint DesignRatnakar PatilNo ratings yet

- Control Valve Eng. TipsDocument3 pagesControl Valve Eng. TipsRatnakar PatilNo ratings yet

- Machine Hours RateDocument15 pagesMachine Hours RateRatnakar PatilNo ratings yet

- Student's Holiday - Vi 19619Document1 pageStudent's Holiday - Vi 19619Ratnakar PatilNo ratings yet

- Reverse Flow Cyclones For Tea DustDocument11 pagesReverse Flow Cyclones For Tea DustRatnakar PatilNo ratings yet

- 0324AT Hyu PCGDocument55 pages0324AT Hyu PCGLiz BenhamouNo ratings yet

- Physics Progect On Led As Light SensorDocument10 pagesPhysics Progect On Led As Light SensorShubham KumarNo ratings yet

- Biology Unit PlanDocument10 pagesBiology Unit Planapi-246097943No ratings yet

- Industrial Microbiology Lec 10Document41 pagesIndustrial Microbiology Lec 10Louella ArtatesNo ratings yet

- Influence of Acerola Pulp Concentration On Mead Production by Saccharomyces Cerevisiae AWRI 796Document8 pagesInfluence of Acerola Pulp Concentration On Mead Production by Saccharomyces Cerevisiae AWRI 796mashelyNo ratings yet

- FaienceDocument15 pagesFaienceRenata TatomirNo ratings yet

- Rxn10 - FEMLAB-Fixed Bed ReactorDocument15 pagesRxn10 - FEMLAB-Fixed Bed ReactorvijendranbNo ratings yet

- Baicapil™Document26 pagesBaicapil™HarmonyLife100% (6)

- 01 - Ashrae - AerodynamicsDocument52 pages01 - Ashrae - AerodynamicsAnonymous A8HV1JiN2TNo ratings yet

- Manganese DioxideDocument5 pagesManganese Dioxidemartinusteddy2114No ratings yet

- Advanced in Viscid Problems SolutionsDocument12 pagesAdvanced in Viscid Problems SolutionssalahNo ratings yet

- A101 Design Calculation For Foundation of New VCM Storage TankDocument25 pagesA101 Design Calculation For Foundation of New VCM Storage TankzatenneNo ratings yet

- Comparative Investigation of Traditional and Modern Passive Design Strategies To Reduce The Energy Use in Residential Building of West-Maharashtra RegionDocument17 pagesComparative Investigation of Traditional and Modern Passive Design Strategies To Reduce The Energy Use in Residential Building of West-Maharashtra RegionAnonymous CwJeBCAXp100% (1)

- Unit 2 - Chemical ReactionsDocument9 pagesUnit 2 - Chemical ReactionsNobukhosi NdlovuNo ratings yet

- Chemistry 2 Module 3Document10 pagesChemistry 2 Module 3Joshua James Sanguenza RodriguezNo ratings yet

- 1.2.0 Drilling Ref. PFMEADocument12 pages1.2.0 Drilling Ref. PFMEAMani Rathinam RajamaniNo ratings yet

- Improved Procedures For The Genetic Transformation of Rhodobacter CapsulatusDocument1 pageImproved Procedures For The Genetic Transformation of Rhodobacter CapsulatusSerena XuNo ratings yet

- Chemistry LabDocument49 pagesChemistry LabVishwas VermaNo ratings yet

- Bonding Theories of Coordination CompoundsDocument6 pagesBonding Theories of Coordination Compoundsmark carlo SanorjoNo ratings yet

- Vacuum Super Insulated Heat Storage Up To 400 °C: January 2015Document11 pagesVacuum Super Insulated Heat Storage Up To 400 °C: January 2015Arvin SlayerNo ratings yet

- Source Machinery: REF: SOU/GEN/11-12/21 DATE: 12 December, 2011Document8 pagesSource Machinery: REF: SOU/GEN/11-12/21 DATE: 12 December, 2011Ravi k LavuNo ratings yet

- To Run QC On Absolute Positions: Figure 9-49. Example For Template With Absolute SettingsDocument100 pagesTo Run QC On Absolute Positions: Figure 9-49. Example For Template With Absolute SettingsMaicol EligioNo ratings yet

- MOS Cap SimulationDocument19 pagesMOS Cap SimulationRuchirNo ratings yet

- Inform Energy Sanicube InformationDocument11 pagesInform Energy Sanicube Informationh2odavidNo ratings yet

- Seismic Principles: - Chapter 1Document13 pagesSeismic Principles: - Chapter 1Mahardika Aji KurniawanNo ratings yet

- Composite Leaf SpringDocument23 pagesComposite Leaf SpringVijay AnandNo ratings yet

- Project Work On Water Tank Cleaning MachineDocument2 pagesProject Work On Water Tank Cleaning MachinePrakash Pokhrel100% (1)

- Solar and Stellar Magnetic Activity - ISBN0521582865 PDFDocument402 pagesSolar and Stellar Magnetic Activity - ISBN0521582865 PDFOmar Musalem100% (1)

- Chapter 2 Pharmaceutical Aids and NecessitiesDocument11 pagesChapter 2 Pharmaceutical Aids and NecessitiesZarah Pauline Jimenez100% (2)