Professional Documents

Culture Documents

Procedure For Positive Material Identification Pmi

Procedure For Positive Material Identification Pmi

Uploaded by

Rodrigo CarneiroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure For Positive Material Identification Pmi

Procedure For Positive Material Identification Pmi

Uploaded by

Rodrigo CarneiroCopyright:

Available Formats

TCR ENGINEERING SERVICES PVT. LTD.

35, PRAGATI INDUSTRIAL ESTATE, N. M. JOSHI MARG, MUMBAI-400 011, Maharashtra India

PHONE: 2309 7921/2307 3390

FAX : 23080197

Email sales@tcreng.com

Procedure for Positive Material Identification (PMI) for

Alloying Elements in Metals

TYPE OF INSTRUMENT

Portable XRF Alloy Analyzer

Model : XLt 898, Make : NITON

Method

This procedure describes the methods to carryout Positive Material Identification

(PMI) for verification of Grade or Alloy type and Quantitative Analysis of Alloying

Elements present in the material without destroying the material by X-Ray

Fluorescence Techniques.

Surface Preparation of components

The surface of the component subjected to the test shall be free from grease, oil, paint

and oxides. The surface preparation shall be performed with a portable grinding

machine or any other suitable equipment and the same should represent the original

surface of the component.

Calibration of the testing instrument

Calibration of the instrument has been carried out by the manufacturer at their factory

using various types and grades of Standards Reference Materials (SRMs) for various

types of materials. Hence no re-calibration is required to be performed.

VERIFICATION OF INSTRUMENT

Verification shall be performed at site once daily by using standard reference

samples, before commencing the actual testing or as and when required during the

day.

Page 01 of 02

TCR ENGG. SERVICES PVT. LTD.

Continuation Sheet

Testing of Components

On satisfactory verification of the instrument, the actual testing shall be commenced

on individual components and the results shall be recorded.

Acceptance & Rejection

All results within 10% of the requirements of the relevant material specification

shall be considered acceptable and a considerable deviation of alloying elements / or

absence of alloying elements with respect to the required material specification shall

be considered non acceptable. A detailed Chemical analysis may be performed in a

laboratory for the materials having very nominal deviation of Alloying Elements

from the acceptable limits, as a referee method, before rejecting the material. In

such cases a final decision to accept or reject is left to the client and their consultant.

All rejected materials are identified and kept separately.

Documentation of Results

A detailed report shall be made in the prescribed format having all the relevant data

of the material tested.

_____________

Prepared by

_____________

Reviewed by

Page 02 of 02

____________

Approved by

You might also like

- Aws d1.1-UT Procedure For Back Strip T or Corner Joint PDFDocument6 pagesAws d1.1-UT Procedure For Back Strip T or Corner Joint PDFnathgsurendraNo ratings yet

- 4260Document10 pages4260Lipika GayenNo ratings yet

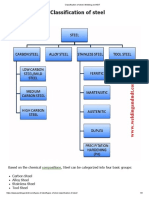

- Classification of Steel - Welding and NDTDocument3 pagesClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- Sae Ams 5518M-2014Document5 pagesSae Ams 5518M-2014Mehdi Mokhtari100% (1)

- Positive Material Identification Procedure: IndexDocument8 pagesPositive Material Identification Procedure: Indexselvakumar100% (1)

- Corrosion Prevention and ControlDocument296 pagesCorrosion Prevention and ControlMaria Delgado100% (3)

- QC Manager-Johnson CVDocument7 pagesQC Manager-Johnson CVShanmuga NavaneethanNo ratings yet

- FM 1112 PDFDocument35 pagesFM 1112 PDFMohamed Nabil100% (3)

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- GE Mentor EM Weld BrochureDocument6 pagesGE Mentor EM Weld BrochuredimachampionNo ratings yet

- Vc-Api 650 PDFDocument6 pagesVc-Api 650 PDFShinta ShowiantariNo ratings yet

- RT Procedure Rev01EDocument20 pagesRT Procedure Rev01ETrương Ngọc SơnNo ratings yet

- QMS-003 Procedure For Quality Control of Materials Issue 5 April 20Document107 pagesQMS-003 Procedure For Quality Control of Materials Issue 5 April 20bmanojkumar16100% (2)

- Engineering Spec For Positive Material IdentificationDocument8 pagesEngineering Spec For Positive Material Identificationcancerian86100% (1)

- 193602csqrop034 00 Manual Ut ProcedureDocument24 pages193602csqrop034 00 Manual Ut Procedureyehia100% (2)

- UT ProcedureDocument14 pagesUT Procedureshifa0% (1)

- Profile Radiography IAEADocument14 pagesProfile Radiography IAEAPaolo Ng100% (1)

- Procedure On Handling Complaints AppealsDocument10 pagesProcedure On Handling Complaints AppealsRajender Kumar BaruaNo ratings yet

- PMI Report May 2019Document19 pagesPMI Report May 2019RifanjshshNo ratings yet

- PMI Just in Case: Measurement of Ferrite Content in Austenitic & Duplex SteelDocument7 pagesPMI Just in Case: Measurement of Ferrite Content in Austenitic & Duplex Steelmahi1437100% (1)

- Improving Wave Soldering MachineDocument49 pagesImproving Wave Soldering MachinedangmiuNo ratings yet

- Positive Material Identification ProcedureDocument6 pagesPositive Material Identification Procedureomar100% (1)

- PMI Report TemplateDocument2 pagesPMI Report TemplateKewell LimNo ratings yet

- Astm 20M PDFDocument33 pagesAstm 20M PDFDee DeeNo ratings yet

- BIX - RT ProcedureDocument36 pagesBIX - RT ProcedureEduard Abastillas100% (1)

- Sms Mockup Testing ProcedureDocument19 pagesSms Mockup Testing ProcedureIksan Adityo Mulyo100% (1)

- API 5CT Scope For Pup JointsDocument3 pagesAPI 5CT Scope For Pup JointsKapil HarchekarNo ratings yet

- Agpl QP RFT 03 PDFDocument8 pagesAgpl QP RFT 03 PDFMaged Ali RaghebNo ratings yet

- Holiday Detection ProcedureDocument4 pagesHoliday Detection Proceduregst ajah100% (1)

- CV 2023Document5 pagesCV 2023AmitNo ratings yet

- 10 NDE ControlDocument6 pages10 NDE ControlShahbaz AlamNo ratings yet

- Check Valve Selection Guide: FCD ADAMS8007-00Document4 pagesCheck Valve Selection Guide: FCD ADAMS8007-00Mohamed NabilNo ratings yet

- 2 - HydroFORM - Mechanical Setup R2Document17 pages2 - HydroFORM - Mechanical Setup R2carlosNo ratings yet

- Classification Exercises Materials PDFDocument6 pagesClassification Exercises Materials PDFmatina14100% (1)

- Pmi Testing ProcedureDocument4 pagesPmi Testing ProcedureDhanushNo ratings yet

- PMI TestingDocument3 pagesPMI TestinghungNo ratings yet

- UT Procedure PDFDocument14 pagesUT Procedure PDFAbhayNo ratings yet

- UT Procedure PDFDocument23 pagesUT Procedure PDFcentaury2013No ratings yet

- Ferrite Meter Manual OPMS FMP30Ferit 902-530 enDocument36 pagesFerrite Meter Manual OPMS FMP30Ferit 902-530 enFmc2100% (1)

- API 1104 ComplateDocument24 pagesAPI 1104 ComplateAwale UdinNo ratings yet

- Pmi Procedure: Superflow Pumps Pvt. LTDDocument6 pagesPmi Procedure: Superflow Pumps Pvt. LTDashish tiwariNo ratings yet

- AWS-UT-2006 Rev 0Document40 pagesAWS-UT-2006 Rev 0Shyam Singh100% (3)

- HardnessTest Examination ReportDocument1 pageHardnessTest Examination ReportUmair AwanNo ratings yet

- PAUT & TOFD Procedure For EOL, VadinarDocument22 pagesPAUT & TOFD Procedure For EOL, Vadinarrupam100% (5)

- Bombardier Aerospace Learjet Suppliers Listing by NameDocument1,420 pagesBombardier Aerospace Learjet Suppliers Listing by NameHari Prasad100% (1)

- Positive Material IdentificationDocument7 pagesPositive Material IdentificationJithesh.k.sNo ratings yet

- Mahesh CV Sept-19Document9 pagesMahesh CV Sept-19Mahesh Pandit100% (1)

- Iso 9712Document19 pagesIso 9712Daniel100% (1)

- NDT Report Check List Appendix 2Document4 pagesNDT Report Check List Appendix 2Adil Hasanov100% (1)

- NDTDocument42 pagesNDTshahazad100% (1)

- Feritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelDocument8 pagesFeritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelBiju_PottayilNo ratings yet

- Ultrasonic ProcedureDocument31 pagesUltrasonic ProcedureChristopher Jones100% (1)

- Radiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0Document13 pagesRadiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0BCE DeNo ratings yet

- Vlosi Holiday Test Report No-16Document1 pageVlosi Holiday Test Report No-16Anonymous uJzSZ5100% (1)

- Dye Pentrant Test ProcedureDocument6 pagesDye Pentrant Test ProcedurePer DCNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Welding of Pipelines and Related Facilities: Api Standard 1104 Nineteenth Edition, September 1999Document62 pagesWelding of Pipelines and Related Facilities: Api Standard 1104 Nineteenth Edition, September 1999Riki AkbarNo ratings yet

- Quality ManagementDocument49 pagesQuality ManagementMuhannad AbdulRaoufNo ratings yet

- Liquid Penetrant Examination ProcedureDocument15 pagesLiquid Penetrant Examination ProcedureANH TAI MAINo ratings yet

- Flaw Detection and Characterization in Welded Samples Used For Ultrasonic System QualificationDocument6 pagesFlaw Detection and Characterization in Welded Samples Used For Ultrasonic System Qualificationcal2_uniNo ratings yet

- MT ReportDocument11 pagesMT Reportel_sharkawy2011100% (1)

- Scan Plan (PAUT) For Taper Joints and K WeldsDocument4 pagesScan Plan (PAUT) For Taper Joints and K WeldsRamakrishnan AmbiSubbiahNo ratings yet

- CV Bhaskar M KaleDocument5 pagesCV Bhaskar M KalebmkaleNo ratings yet

- Saferad ProcedureDocument19 pagesSaferad ProcedureExsan OthmanNo ratings yet

- PAUT Procedure EEISDocument13 pagesPAUT Procedure EEISZakirUllahNo ratings yet

- Ferrite Testing ProcedureDocument6 pagesFerrite Testing ProcedureReadersmo0% (1)

- Ultrasonic Test Procedure: Rev. Date Prepared by Reviewed ApprovedDocument8 pagesUltrasonic Test Procedure: Rev. Date Prepared by Reviewed Approvedkevin desaiNo ratings yet

- Smith PDFDocument6 pagesSmith PDFmaheshv79No ratings yet

- PmiDocument6 pagesPmiSai FujiwaraNo ratings yet

- Flow Coefficients CV Values: Bolted Bonnet Globe Valves API 623 & B 16.34 Class: 150 - 2500 Size: 2" - 18"Document1 pageFlow Coefficients CV Values: Bolted Bonnet Globe Valves API 623 & B 16.34 Class: 150 - 2500 Size: 2" - 18"Mohamed NabilNo ratings yet

- Fe Exam Truths and Tips: o A List Out Your Strongest Subjects, SpendDocument1 pageFe Exam Truths and Tips: o A List Out Your Strongest Subjects, SpendMohamed NabilNo ratings yet

- Order #100002885: Shipping AddressDocument1 pageOrder #100002885: Shipping AddressMohamed NabilNo ratings yet

- StandardMOUlongversion Ar enDocument13 pagesStandardMOUlongversion Ar enMohamed NabilNo ratings yet

- Alu Profile CatalogueDocument17 pagesAlu Profile CataloguePius SchumNo ratings yet

- TA 202: Introduction To Manufacturing Processes: Prof. Sounak K. ChoudhuryDocument25 pagesTA 202: Introduction To Manufacturing Processes: Prof. Sounak K. ChoudhuryZishan MuzeebNo ratings yet

- Loetfibel Ekorrds 040805Document17 pagesLoetfibel Ekorrds 040805Anonymous Kti5jq5EJINo ratings yet

- 2nd Sem ChemestryDocument29 pages2nd Sem ChemestryJayesh khachaneNo ratings yet

- Me101 Engineering Drawing & GraphicsDocument20 pagesMe101 Engineering Drawing & GraphicsKanwar Mansoor Ali KhanNo ratings yet

- A7 STP CTH Type Anchors For Refractory PDFDocument7 pagesA7 STP CTH Type Anchors For Refractory PDFprashant sharmaNo ratings yet

- Manual UTPDocument478 pagesManual UTPjpinto69No ratings yet

- Vdocuments - MX - Aws c53 00 Carbon Arc Gougingpdf PDFDocument29 pagesVdocuments - MX - Aws c53 00 Carbon Arc Gougingpdf PDFSerkan AkşanlıNo ratings yet

- Mpae PDFDocument70 pagesMpae PDFKABADDI RISINGNo ratings yet

- 0170 g11Document19 pages0170 g11Lokesh NarasimhaiahNo ratings yet

- DESIGN AND FABRICATION TURBO WOOD STOVE TIET OriginalDocument71 pagesDESIGN AND FABRICATION TURBO WOOD STOVE TIET OriginalSHIELDNo ratings yet

- Nucor PDFDocument63 pagesNucor PDFJorge ViceNo ratings yet

- SECTION 05730 Ornamental Formed Metal Rev 0Document25 pagesSECTION 05730 Ornamental Formed Metal Rev 0Abdalrahman AntariNo ratings yet

- Competing Values Leadership Second Edition Full ChapterDocument36 pagesCompeting Values Leadership Second Edition Full Chapterwilliam.kellar832100% (22)

- The Wonder Island Boys: The Mysteries of The Caverns by Finlay, Roger ThompsonDocument126 pagesThe Wonder Island Boys: The Mysteries of The Caverns by Finlay, Roger ThompsonGutenberg.orgNo ratings yet

- The Mystery of Molten Metal: Natalia Sobczak, Jerzy Sobczak, Rajiv Asthana and Robert PurgertDocument13 pagesThe Mystery of Molten Metal: Natalia Sobczak, Jerzy Sobczak, Rajiv Asthana and Robert Purgertyosua l.rajaNo ratings yet

- Constant Mesh Manual Transmission Gear BoxDocument33 pagesConstant Mesh Manual Transmission Gear BoxBirhanu AsfawNo ratings yet

- Engineering MetallurgyDocument540 pagesEngineering MetallurgyAMEEEN123No ratings yet

- BS en 573-4-2004 PDFDocument24 pagesBS en 573-4-2004 PDFDILIP VELHALNo ratings yet

- Structural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthDocument8 pagesStructural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthSendi Dwi OktaviandiNo ratings yet

- Stainless Steel GradesDocument8 pagesStainless Steel Gradesnathan1979No ratings yet

- Productinformation MoCheck304316 eDocument1 pageProductinformation MoCheck304316 edsuraj wickramasinghaNo ratings yet

- Uns N06625Document1 pageUns N06625robertNo ratings yet