Professional Documents

Culture Documents

Surface Finish Chart

Uploaded by

bmsschlotterbeckCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surface Finish Chart

Uploaded by

bmsschlotterbeckCopyright:

Available Formats

MARYLAND METRICS

The one-stop source for all your METRIC HARDWARE needs!

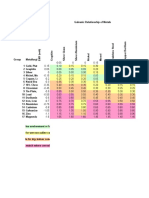

SURFACE ROUGHNESS TABLES

AND U.S. TO METRIC COMPARISON CHARTS

General guidelines for feasible roughness R a for different processing methods

METRIC SURFACE ROUGHNESS VALUES ARE INDICATED BY THE

UNIT: MICROMETER ( m).

Material removing or

separating operations

SYMBOLS: There are a number of symbols in use, all of which have a

specific meaning. A symbol generally consists of 2 lines, one of which

is longer than the other. The angle between the lines is 60 degrees.

Basic symbol (without top line) should not be used alone.

Either the processing method or the surface roughness

should be listed with it.

milled

If written as per this example: it means

machining optional. The surface roughness

should be 3.2 m (0.0032 mm)

Symbol (with top line) means: machining mandatory

(surface roughness 3.2 m).

roughness Ra

R a in um

0.012 0.025 0.05 0.1

0.2

0.4

0.8

1.6

3.2

6.3

13

25

50

flame cutting

sawing

planing

punching

chemical treatment

spark erosion machining

drilling

3.2

boring

milling

turning

broaching

3.2

reaming

filing

3.2

Symbol (with circle in the vee) means: machining

prohibited (surface roughness 3.2 m).

grinding

barreling

brushing

electrolytic grinding

honing

polishing

lapping

The data in the right hand table is furnished only for practical

information and to provide an idea of the achievable roughness

for different processing methods.

superfinishing

Non material

removing operations

sandcasting

This data is primarily for metal surfaces. Other materials may show

differences.

AVERAGE ACHIEVABLE

ROUGHNESS

FINER

hot rolling

die forging

gravity die casting

COARSER

investment casting

extruding

cold rolling

Roughness values in micro-inches

are 40 times the values in micrometers

Ra

Ra

micrometer micro-inch

die casting

in

Roughness

Grade Numbers

(New)**

50

25

2000

1000

N12

N11

12.5

6.3

500

250

N10

N9

32

3.2

1.6

125

63

N8

N7

16

8

0.8

0.4

32

16

N6

N5

4

2

0.2

0.1

8

4

N4

N3

1

0.5

0.05

N2

0.25

0.025

N1

Notes: 1. Triangles,

Rz

Roughness

Grade Numbers

(Old)***

Rt

(R a )

Old

Style

6.3

32

3.2

8

1.6

0.8

0.4

0.2

0.5

0.1

0.25

0.05

250

125

63

32

16

8

4

**Use this symbology on drawings for international suppliers,

and for new designs.

***Old surface roughness

symbols which are still found

on older metric drawings.

They should not be used on

new designs.

Examples of how the

new system is used:

N9

6.3

=

OLD

NEW N6

0.8

=

, or R t on a drawing indicates peak to valley roughness measurements

in micrometers (microns). (one micron = 0.001 mm)

2.

, Ra on a drawing indicates AVERAGE roughness rather than peak to valley values.

(R a is the unit of measurement in micrometers)

3.

American

standard

In certain circumstances, it

will be necessary to

indicate the method of

manufacturing:

precision ground

Example:

N7

is the American standard per ASA B46.1. (average roughness in micro-inches)

filename: SURFRUFF.CDR8 http://mdmetric.com SECTION: TECHDATA

Mail to: P.O. BOX 261,

OWINGS MILLS, MARYLAND 21117

Phones: (800) 638-1830 (410) 358-3130

PAGE:

VERSION: kk21e

techinfo@mdmetric.com copyright 1998, 2014 maryland metrics

Warehouse: 6119 OAKLEAF AVENUE, BALTIMORE, MARYLAND 21215

FAXes:(800) USA-9-FAX=[800-872-9329]

(410) 358-3142

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Tube Pressure CalculatorDocument4 pagesTube Pressure CalculatorRay FaiersNo ratings yet

- Material Data Sheet: Tufnol WhaleDocument3 pagesMaterial Data Sheet: Tufnol WhaleRay FaiersNo ratings yet

- Annealing - Chemical TestDocument6 pagesAnnealing - Chemical TestRay FaiersNo ratings yet

- STRESS STRAIN MODEL V2 - AluminumDocument11 pagesSTRESS STRAIN MODEL V2 - AluminumRay FaiersNo ratings yet

- Guide To AnnealingDocument3 pagesGuide To AnnealingRay FaiersNo ratings yet

- The Materials Analyst, Part 23 - Stress Cracking - How To Avoid This KillDocument4 pagesThe Materials Analyst, Part 23 - Stress Cracking - How To Avoid This KillRay FaiersNo ratings yet

- Analysis of Polycarbonate Stress Cracking and Cleaning Solvent Compatibility With Telephone Components Such As Terminal Blocks and ConnectionsDocument3 pagesAnalysis of Polycarbonate Stress Cracking and Cleaning Solvent Compatibility With Telephone Components Such As Terminal Blocks and ConnectionsRay FaiersNo ratings yet

- Zyg Anodic Index PDFDocument3 pagesZyg Anodic Index PDFRay FaiersNo ratings yet

- Solidworks Non Linear Tips and TricksDocument1 pageSolidworks Non Linear Tips and TricksRay FaiersNo ratings yet

- vs2 Speciality Products Catalogue Lo Res PDFDocument71 pagesvs2 Speciality Products Catalogue Lo Res PDFRay FaiersNo ratings yet

- Galvanic Relationship of MetalsDocument2 pagesGalvanic Relationship of MetalsRay FaiersNo ratings yet

- Hallstar Stresscracking Resistance of PolycarbonateDocument9 pagesHallstar Stresscracking Resistance of PolycarbonateRay FaiersNo ratings yet

- Circlip Data PDFDocument6 pagesCirclip Data PDFRay FaiersNo ratings yet

- ANSYS ConvergenceDocument24 pagesANSYS ConvergenceRay FaiersNo ratings yet

- Ta Elastomer Cure DatesDocument3 pagesTa Elastomer Cure DatesRay FaiersNo ratings yet

- Zero PivotDocument5 pagesZero PivotRay FaiersNo ratings yet

- CMI Level 7 ExamplesDocument8 pagesCMI Level 7 ExamplesRay FaiersNo ratings yet

- LS-PrePost Intro 2016Document138 pagesLS-PrePost Intro 2016Ray FaiersNo ratings yet

- What Is The Singularity Elimination FactorDocument2 pagesWhat Is The Singularity Elimination FactorRay FaiersNo ratings yet

- CorrectionsDocument1 pageCorrectionsRay FaiersNo ratings yet

- Asme - Stress Classification Lines Straight Through SingularitiesDocument10 pagesAsme - Stress Classification Lines Straight Through SingularitiesRay FaiersNo ratings yet

- ANSYS Fluent Theory GuideDocument814 pagesANSYS Fluent Theory GuideEnrique Flores100% (2)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rule 1020 Form (DOLE Registry of Establishment)Document1 pageRule 1020 Form (DOLE Registry of Establishment)Diyames RamosNo ratings yet

- 10-Personnel Cost PlanningDocument52 pages10-Personnel Cost PlanningWenny HuNo ratings yet

- Resume of Shakil-Bhaladar Sw-Engg Java 1.6 Yrs-Exp MSC CS PUNE-2Document3 pagesResume of Shakil-Bhaladar Sw-Engg Java 1.6 Yrs-Exp MSC CS PUNE-2Rohan Singh RathodNo ratings yet

- Gear Geometry & Profile TheoryDocument24 pagesGear Geometry & Profile Theoryansh1983100% (2)

- Review - Module I - Understanding ValueDocument72 pagesReview - Module I - Understanding ValueRavi RakeshNo ratings yet

- Q1 Reconciliation by SKUsDocument38 pagesQ1 Reconciliation by SKUsErineNo ratings yet

- Case Study-Digital RevolutionDocument3 pagesCase Study-Digital RevolutionJagmohanNo ratings yet

- Data Mining NotesDocument178 pagesData Mining NotesSangeetha Bajanthri100% (1)

- Cost Confirmation Table: Final Exams Assignment ModelDocument7 pagesCost Confirmation Table: Final Exams Assignment ModelJewelyn C. Espares-CioconNo ratings yet

- Email Gillespie Home Advisor Referrals Solar PanelsDocument30 pagesEmail Gillespie Home Advisor Referrals Solar PanelsNeil GillespieNo ratings yet

- Case Study Tanuj K Khard Rev2Document12 pagesCase Study Tanuj K Khard Rev2TanujNo ratings yet

- EClerx Corporate Presentation - KMDocument15 pagesEClerx Corporate Presentation - KMSantanu S JoshiNo ratings yet

- Modern Cold StorageDocument6 pagesModern Cold Storageडा. सत्यदेव त्यागी आर्यNo ratings yet

- Paper 02Document18 pagesPaper 02Crystal MurrayNo ratings yet

- Máquina Moer Alumina PDFDocument36 pagesMáquina Moer Alumina PDFDulce GabrielNo ratings yet

- BS 5588 Part 4 1978Document46 pagesBS 5588 Part 4 1978Kirsty Elliston0% (1)

- Public Procuement Rule of NepalDocument147 pagesPublic Procuement Rule of NepalShreeNo ratings yet

- Shaktivell M.letchumanan Dd160012 ReportDocument56 pagesShaktivell M.letchumanan Dd160012 ReportShaktivell LetchumananNo ratings yet

- IKEA Industry Energy Saving Handbook PDFDocument133 pagesIKEA Industry Energy Saving Handbook PDFMARIUS GOVOREANUNo ratings yet

- Computer Science Exam PreviousDocument12 pagesComputer Science Exam PreviousAmanSaroyNo ratings yet

- Ropeway SystemsDocument16 pagesRopeway SystemsSripuja MishraNo ratings yet

- Air Cadet Publication: FlightDocument62 pagesAir Cadet Publication: FlightMarcus Drago100% (1)

- Practical Transformer DesignDocument148 pagesPractical Transformer Designعمر محمود100% (6)

- KPI's - CUTE Handbook PDFDocument19 pagesKPI's - CUTE Handbook PDFpatriciolaria100% (1)

- CHAITANYA KAMBOJ - ProductDocument2 pagesCHAITANYA KAMBOJ - Productchaitanya kambojNo ratings yet

- Surface Lift Distribution-Francisco Miguel Acevedo GonzalezDocument7 pagesSurface Lift Distribution-Francisco Miguel Acevedo GonzalezJesus DominguezNo ratings yet

- Er. Shivam KR CVDocument6 pagesEr. Shivam KR CVBulk WeighingNo ratings yet

- Rahul ResumeDocument7 pagesRahul ResumeMohit GautamNo ratings yet

- Gantt Chart Implementasi ISO 14001 2015Document19 pagesGantt Chart Implementasi ISO 14001 2015hermintonNo ratings yet

- E Cat Prosp 2009 Low ResDocument35 pagesE Cat Prosp 2009 Low ResRahman MoushumiNo ratings yet