Professional Documents

Culture Documents

Guide To Annealing

Uploaded by

Ray Faiers0 ratings0% found this document useful (0 votes)

22 views3 pagesguide to annealing of polymers

Original Title

guide to annealing

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentguide to annealing of polymers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views3 pagesGuide To Annealing

Uploaded by

Ray Faiersguide to annealing of polymers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

11012024 ‘Annealing of plastics [SubsTech)

Substances & Technologic

Unequalled Resistance And Durability.

x

Knowledge source on Materials Engineering

to Polymers

Annealing of plastics

Dr. Dmitri Kopeliovich

Annealing of plastics is a heating of a polymeric part to below it’s glass transition temperature in order

to relieve the internal stresses introduced into the part during its fabrication (molding, cooling after

molding, machining, welding)/

In order to mold a plastic it is soften by heating and then forced into a cavity where it cools down and

shrinks. Non-uniform flowing of the soft plastic and non-uniform and relatively fast cooling result in a

formation of internal stresses, which may cause dimensional distortion of the part and even cracking.

Machining of the molded parts introduces additional internal stresses particularly if an improperly designed

tool is used or if the plastic part is locally overheated due to excessive cutting and feed speeds.

Drilling deep holes, uneven thickness reduction and screw thread cutting are the machining operations

producing internal stresses, which should be reduced by annealing

Some polymers (€.g. polycarbonate, polysolfone) are more susceptible to internal stress formation

+ Technology of plastics annealing

+ Annealing temperatures for plastics

Technology of plastics annealing

General annealing process includes the following stages:

= Placing the plastic part in an annealing oven.

+ Heating the part to the annealing temperature at a controlled rate. The heating rate is commonly not

greater than 50-100 F/hour (~30-60 °C/hour).

+ Holding the part at the annealing temperature for 2-4 hours per inch of thickness (except Polyamide-

imide (PAI), which is held for 3-10 days at the annealing temperature)

+ Cooling the part to the ambient temperature at a rate not exceeding 10-50 °F/hour (~6-30 °C/hour)

“substech com/okuwikfdoku, php?id-annealing_of plastics 43

11012024 ‘Annealing of plastics [SubsTech)

There are three technique for annealing of plastics:

* Batch annealing. This is the most common annealing method. The process is performed in a batch

‘oven with forced convection. The plastic parts are placed on the shelves/racks. The main disadvantages

of the method are: batch type (non-continuous) process and a longer annealing operation due to the

restricted air flow.

+ Conveyorized Forced Hot Air Annealing (CFHA). CFHA is a continuous annealing process in which

the plastic parts are placed on the conveyor belt moving through a long tube like oven with forced hot

air convection. The heating process is much faster than In a batch oven. Additionally the continuous

character of the technique is preferable for the industrial implementation

+ Infrared annealing (IR). IR annealing also utilizes a continuous oven but heating method is different.

The plastic parts are heated not by hot air (like in CFHA) but the energy transmitted by infrared

radiation. This is the fastest heating method. However heating Is not always uniform: shadowed

portions of the part heat up slower.

to top

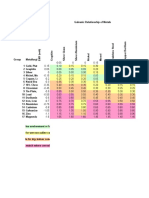

Annealing temperatures for plastics

[Annealing temperature

oF °e

200 93

180 82

320 160

350 177

[High Density Polyethylene (HDPE)| 250 12

Polyvinylidene fluoride (PVDF) 275 135

Nylon 6 300 149

PEEK 375 191

[Polycarbonate (PC) 275 135

Low Density Polyethylene (LDPE) | __175 79

Polyethylene UHMW 220 104

Polypropylene 185 85

Polysterene 170 77

[Polyamide-imide (PAT) 500 260

[Polysulfone 330 166

totop

Related internal links

= Polymer structure

= Glass transition

= Polymer materials (Introduction:

= Elastomers

= Thermoplastics

+ Thermosets

= Tribology of polymers

= Shore (Durometer) hardness test

= Methods of polymers fabrication

“substech com/okuwikfdoku, php?id-annealing_of plastics

srtoz021 ‘Annealing of plates (SubsTech)

+ Vulcanization of rubber

= Plastics recycling

= Combustion, pyrolysis and gasification of scrap tires

* Plastics welding

+ Adhesiv

+ Paints

+ Fluoropolymers

= Ion exchange resins

+ Annealing and stress relief

Related external links

http://www.boedeker.com/anneal.htm [http://www.boedeker.com/anneal.htm]

http://www-annealingplastics.com/ [http://www.annealingplastics.com/]

http://www.bayermaterialsciencenafta.com/faq_pcs/pdf/annealing_batch.pdf

http://www. bayermaterialsciencenafta.com/faq_pcs/pat/annealing_batch-pdf]

http://www.eastcoastmfg.com/plastic_annealing.htm [http://www.eastcoastmig.com/plasti

~_annealing htm]

to Polymers

xcept where otherwise noted, this work is licensed under a Creative Commons Attribution-

Noncommercial-Share Alike 3.0 License

annealing_o_plastics.b¢ + Last mosed: 2013/08/01 by dmitr|_kopelioven

“substech com/okuwikfdoku, php?id-annealing_of plastics 313

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- ORING Hand Book Handbook PDFDocument229 pagesORING Hand Book Handbook PDFBandarSWCC100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Parker O-Ring HandbookDocument287 pagesParker O-Ring Handbookhlusk9neogas100% (4)

- CMI Level 7 Career Development PlanningDocument8 pagesCMI Level 7 Career Development PlanningRay FaiersNo ratings yet

- DNV Bolts Failure Analisys Marine ApplicationDocument34 pagesDNV Bolts Failure Analisys Marine ApplicationBrian Chmeisse100% (2)

- Hallstar Stresscracking Resistance of PolycarbonateDocument9 pagesHallstar Stresscracking Resistance of PolycarbonateRay FaiersNo ratings yet

- Tube Pressure CalculatorDocument4 pagesTube Pressure CalculatorRay FaiersNo ratings yet

- Tufnol Whale SRBF Material DataDocument3 pagesTufnol Whale SRBF Material DataRay FaiersNo ratings yet

- STRESS STRAIN MODEL V2 - AluminumDocument11 pagesSTRESS STRAIN MODEL V2 - AluminumRay FaiersNo ratings yet

- Novel Coronavirus ManualDocument53 pagesNovel Coronavirus ManualXuân Giang NguyễnNo ratings yet

- vs2 Speciality Products Catalogue Lo Res PDFDocument71 pagesvs2 Speciality Products Catalogue Lo Res PDFRay FaiersNo ratings yet

- The Materials Analyst, Part 23 - Stress Cracking - How To Avoid This KillDocument4 pagesThe Materials Analyst, Part 23 - Stress Cracking - How To Avoid This KillRay FaiersNo ratings yet

- Annealing - Chemical TestDocument6 pagesAnnealing - Chemical TestRay FaiersNo ratings yet

- Analysis of Polycarbonate Stress Cracking and Cleaning Solvent Compatibility With Telephone Components Such As Terminal Blocks and ConnectionsDocument3 pagesAnalysis of Polycarbonate Stress Cracking and Cleaning Solvent Compatibility With Telephone Components Such As Terminal Blocks and ConnectionsRay FaiersNo ratings yet

- LM6Document55 pagesLM6Kaio Dos Santos SilvaNo ratings yet

- Solidworks Non Linear Tips and TricksDocument1 pageSolidworks Non Linear Tips and TricksRay FaiersNo ratings yet

- Zyg Anodic Index PDFDocument3 pagesZyg Anodic Index PDFRay FaiersNo ratings yet

- Momi Table PDFDocument1 pageMomi Table PDFEbru Önlü DuralNo ratings yet

- Ta Elastomer Cure DatesDocument3 pagesTa Elastomer Cure DatesRay FaiersNo ratings yet

- Standard Internal Circlips GuideDocument6 pagesStandard Internal Circlips GuideRay FaiersNo ratings yet

- Galvanic Corrosion Chart ExplainedDocument1 pageGalvanic Corrosion Chart Explainedakalp1005No ratings yet

- SolidWorks Simulation - Avoiding SingularitiesDocument6 pagesSolidWorks Simulation - Avoiding SingularitiesAnonymous P8Bt46mk5INo ratings yet

- 19 Rack DesignGuideDocument12 pages19 Rack DesignGuideRay FaiersNo ratings yet

- BucklingDocument6 pagesBucklingZiyad12No ratings yet

- Galvanic Relationship of MetalsDocument2 pagesGalvanic Relationship of MetalsRay FaiersNo ratings yet

- ANSYS ConvergenceDocument24 pagesANSYS ConvergenceRay FaiersNo ratings yet

- Screw TorqueDocument1 pageScrew TorqueRay FaiersNo ratings yet

- Mesh Controls Guide - 50 PagesDocument51 pagesMesh Controls Guide - 50 PagesFernando MarquezNo ratings yet

- Torque SettingsDocument1 pageTorque SettingsRay FaiersNo ratings yet

- Euler S BucklingDocument6 pagesEuler S BucklingRay FaiersNo ratings yet