Professional Documents

Culture Documents

Lugs Netsc 001

Uploaded by

luis0 ratings0% found this document useful (0 votes)

9 views30 pagesbolt to lung

Original Title

LugsNetsc001

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbolt to lung

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views30 pagesLugs Netsc 001

Uploaded by

luisbolt to lung

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 30

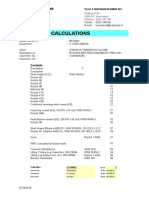

P. DESIGN OF LIFTING AND TAILING LUGS

203

Ad, GH, J, K

B

c

D

D3

F

R

t

bab

N

S,P,E

8

t

t

v

w

Ww

Zz

:

a

oy

o

os

oO

%

ow

Ser Fea

LIST OF SYMBOLS

shackle dimension

width of lug plate

= centroidal distance

lug plate width at the pin.

bolt circle diameter

= lift load at each lug

= talling lug load

vessel wall stress factor

dimensions of lug plate

number of bolts for the nozzle

dimensions of trunnion

lug thickness

lug plate thickness

collar plate thickness

thickness of vessel shell

weld size

weight of vessel

section modulus

angle of vessel from horizontal

stress ratio, o,/o,

allowable bending stress

allowable bearing stress

allowable shear stress,

allowable tensile stress

vessel stress

allowable stress in the weld

bending stress in lug plate due to angle e

angle of lift cable from vert.

204

A. PURPOSE

This design guide describes methods of selecting and designing different types of lifting

and tailing devices for use in the erection of pressure vessels.

B.' CODES AND STANDARDS -

Since lifting or tailing lugs are non pressure retaining structural members, vesse! codes

or Standards are not applicable in the design of these lugs. Good engineering practice

and the recommended procedures given in the AISC Steel Construction Manual are all

that are needed.

C. TYPES OF LIFTING/TAILING LuGs

Besides slings and attachments improvised in the field, lifting lugs for towers, reactors and

other pressure vessels can be broadly classified into (1) the ear type, (2) trunnions, and

(3) the top nozzle blind type. See Fig. 1.

By far the most common are the ear type lifting lugs. These are usually installed at the

top of the vessel and can be used for most vessels, especially large towers. Because of

their location, interference with vessel appurtenances, such as platforms and ladders

below the top head is not very critical. See Section 1.

When a tower is unusually tall, so that lifting it will require a large crane and/or a long

boom, or will produce excessive bending stress in the vessel as a beam, the trunnion

type lifting lugs may be more suitable. ‘These are attached to the vessel shell some

distance down from the top head. In using this type of lugs, the interference of the lifting

cables with external ladders, platforms, nozzles, etc. attached to the vessel above the

lugs, from the tying down to the up-right position of the tower should be carefully checked

and avoided. See Section. 2.

Most heavy wall vessels have a large and strong nozzle located at the center of their top

head. With a special bolted attachment, this nozzle can be used for the erection of the

vessel. This type of lifting blind is especially attractive when there are several vessels

with the same size and rating top nozzles, so that one such lifting blind can be used on

all ofthem. Even if the top nozzles were of different size, a special lifting blind can usually

be designed to adapt it to more than one nozzle size. The advantages of the top nozzle

liting blind are economy, little interference with vessel appurtenances, and elimination of

welding to the vessel which can cause stress risers that are undesirable in some critical

vessels. See Section; 3.

In uprighting @ vessel from the horizontal to its vertical position, a pivot point, which is

also capable of sliding toward the vessel foundation, is needed. This point can be

provided simply and relatively inexpensively by a tailing lug. The design of tailing lugs is

described in Section © 4, .

2l0

You might also like

- Flow Design Formulas For Calculation - Exported From (HTM - 02 - 01 - Part - A)Document8 pagesFlow Design Formulas For Calculation - Exported From (HTM - 02 - 01 - Part - A)wesam allabadi50% (2)

- 101 Problems in AlgebraDocument160 pages101 Problems in AlgebraTrishaii Cuaresma96% (28)

- Business Startup Guides-Preparing Yourself Ver 2Document4 pagesBusiness Startup Guides-Preparing Yourself Ver 2Minh Huỳnh100% (1)

- Excercise in FDocument2 pagesExcercise in FPaz Villahoz100% (2)

- Calculus Cheat Sheet DerivativesDocument4 pagesCalculus Cheat Sheet DerivativesRajatNo ratings yet

- Music To Watch Girls by MJDocument3 pagesMusic To Watch Girls by MJMarvin JongNo ratings yet

- Lifting ClampDocument10 pagesLifting ClampwallachiaNo ratings yet

- Bs 2573 Crane DesignDocument72 pagesBs 2573 Crane DesignAnonymous 1HFV185Sl480% (5)

- Guideline Lifting Lug DesignDocument10 pagesGuideline Lifting Lug Designye-kyaw-aung80% (10)

- Lifting Lug Calculation RefDocument2 pagesLifting Lug Calculation Refmarc_albertoNo ratings yet

- Lug AnalysisDocument15 pagesLug AnalysisAfzalul Karim Nirvick0% (1)

- Lifting LugDocument4 pagesLifting Lugsjkang0226100% (4)

- Anchor Bolt and Base PlateDocument4 pagesAnchor Bolt and Base Platevijaystructural100% (1)

- Calculation Sheet: Padeye Calculations LoadsDocument28 pagesCalculation Sheet: Padeye Calculations Loadsghoshamit4100% (5)

- TrunnionDocument7 pagesTrunnionRUDHRA DHANASEKAR100% (1)

- Heat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataDocument2 pagesHeat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataSteve MoonNo ratings yet

- Shell Lifting AttachmentsDocument12 pagesShell Lifting AttachmentsjesusgameboyNo ratings yet

- Prying ActionDocument8 pagesPrying ActionjoseherreramogollonNo ratings yet

- A Bolts Aci318 05Document6 pagesA Bolts Aci318 05RnD2013No ratings yet

- PADEYE-AISC-360-2005 CalculationDocument6 pagesPADEYE-AISC-360-2005 CalculationsaswattNo ratings yet

- SANS 347:2012: Categorization and Conformity Assessment Criteria For All Pressure EquipmentDocument51 pagesSANS 347:2012: Categorization and Conformity Assessment Criteria For All Pressure EquipmentTshilidzi Irene Netselo100% (3)

- Connection, Stiffeners, Brackets, Curved Beam, Crane, Cutouts, Lifting Lug DesignDocument50 pagesConnection, Stiffeners, Brackets, Curved Beam, Crane, Cutouts, Lifting Lug DesignapirakqNo ratings yet

- Din 28086Document9 pagesDin 28086Fer VF100% (1)

- Design and Verification of Lifting LugsDocument3 pagesDesign and Verification of Lifting LugsFabio Okamoto100% (1)

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document30 pagesMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)fsijest50% (4)

- Lifting Lug DesignDocument7 pagesLifting Lug DesignJens SøndergaardNo ratings yet

- Calculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesDocument7 pagesCalculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesYunizar Putra MahardikaNo ratings yet

- Taita Salasaca - Conga Drums 2Document2 pagesTaita Salasaca - Conga Drums 2Carlos XavierNo ratings yet

- Bolted Flange Joints and Connections - KovesDocument15 pagesBolted Flange Joints and Connections - KovesTshilidzi Irene NetseloNo ratings yet

- Renault Inyección Electrónica Kangoo RL-RN 1.6 1999 Siemens Sirius 32b PDFDocument2 pagesRenault Inyección Electrónica Kangoo RL-RN 1.6 1999 Siemens Sirius 32b PDFOsvaldo LópezNo ratings yet

- PER 2012 - Pressure EquipmentDocument35 pagesPER 2012 - Pressure EquipmentTshilidzi Irene Netselo100% (1)

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 pagesEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosNo ratings yet

- BP Pressure Vessels GS146-2Document66 pagesBP Pressure Vessels GS146-2Tshilidzi Irene Netselo100% (3)

- Hoist and Trolley Full CatalogDocument84 pagesHoist and Trolley Full CatalogAbdul MaminNo ratings yet

- Installation of Underground Petroleum Storage Systems - 4th Edition, 1987 (API 1615)Document38 pagesInstallation of Underground Petroleum Storage Systems - 4th Edition, 1987 (API 1615)Tshilidzi Irene NetseloNo ratings yet

- Renault Inyección Electrónica Clio 1.4 Ac Delco Monopoint P PDFDocument2 pagesRenault Inyección Electrónica Clio 1.4 Ac Delco Monopoint P PDFGood CarNo ratings yet

- Bolted End Plate Moment ConnectionsDocument30 pagesBolted End Plate Moment ConnectionssavanotreborNo ratings yet

- Beam Deflections and Stresses During Lifting PDFDocument10 pagesBeam Deflections and Stresses During Lifting PDFManoj KumarNo ratings yet

- Din 791Document5 pagesDin 791Mizo Hamdy0% (1)

- Lifting Analysis - TrunnionDocument3 pagesLifting Analysis - TrunnionMudasir MughalNo ratings yet

- Custody Transfer Metering Skid - Sea TransportationDocument518 pagesCustody Transfer Metering Skid - Sea Transportationswathi.nayudu2k3No ratings yet

- Most Applications, F.S. 5.0) : Calculation ReferenceDocument5 pagesMost Applications, F.S. 5.0) : Calculation ReferenceParthibanNo ratings yet

- Charles D Ghilani - Paul R Wolf - Elementary Surveying - An Introduction To Geomatics-Pearson Prentice Hall (2012) - ExtractoDocument19 pagesCharles D Ghilani - Paul R Wolf - Elementary Surveying - An Introduction To Geomatics-Pearson Prentice Hall (2012) - ExtractoRodrigo DelBarrioNo ratings yet

- 6periostitisDocument10 pages6periostitisAntonioNo ratings yet

- Planes APIDocument10 pagesPlanes APIManuel FigueroaNo ratings yet

- 113-SEW Brake DetailsDocument10 pages113-SEW Brake DetailsTarak Nath RakshitNo ratings yet

- Ibfc 142 Engenheiro MecanicoDocument16 pagesIbfc 142 Engenheiro MecanicoJosé Maria junior100% (2)

- Los Mareados Arreglo Hernan PossettiDocument2 pagesLos Mareados Arreglo Hernan PossettiteomondejarmusicaNo ratings yet

- 5756867Document1,027 pages5756867Sách Việt Nam50% (2)

- Escort 18 16 ZetecDocument2 pagesEscort 18 16 ZetecOsvaldo LópezNo ratings yet

- Strong Enough - DrumsDocument2 pagesStrong Enough - DrumsКолянсур ИвановNo ratings yet

- Detail (1-1) To R.C. Strip Footing (Sf1) : A B E F H J KDocument1 pageDetail (1-1) To R.C. Strip Footing (Sf1) : A B E F H J KThomas Garcia0% (1)

- Extracto Destinos-Elementos-para-la-gestión-de-destinos-turisticosDocument76 pagesExtracto Destinos-Elementos-para-la-gestión-de-destinos-turisticosEnzo Navarrete UlloaNo ratings yet

- Paradise Violín IIDocument2 pagesParadise Violín IIJavier Rubio PérezNo ratings yet

- Trompeta 1Document2 pagesTrompeta 1Mauricio TorresNo ratings yet

- Tu Me Gustas Trompeta 1Document2 pagesTu Me Gustas Trompeta 1JonathanNo ratings yet

- 2020Document14 pages2020mintrikpalougoudjoNo ratings yet

- What A Wonderful World Eb - Bass Trombone PDFDocument1 pageWhat A Wonderful World Eb - Bass Trombone PDFJose HerreroNo ratings yet

- 01 - Lista de Parametros SimplificadaDocument8 pages01 - Lista de Parametros SimplificadaLuis Felipe VidigalNo ratings yet

- Elec 4 BlackDocument1 pageElec 4 Blackyudo08No ratings yet

- Building ActDocument136 pagesBuilding ActVeronika RaušováNo ratings yet

- El Pastor - VihuelaDocument1 pageEl Pastor - VihuelaDamian Guardia SalazarNo ratings yet

- Fiat CoupeDocument1 pageFiat CoupeJulio FaninNo ratings yet

- Indian Express 19 AugustDocument20 pagesIndian Express 19 AugustTension Dene kaNo ratings yet

- Trompeta 2Document2 pagesTrompeta 2Mauricio TorresNo ratings yet

- Mix Serpiente - BandaDocument53 pagesMix Serpiente - BandaJohn Carlos Vilca VelizNo ratings yet

- Article - Screw Threads DesignDocument7 pagesArticle - Screw Threads DesignjdfdfererNo ratings yet

- Baron enDocument8 pagesBaron enTshilidzi Irene NetseloNo ratings yet

- Adjudication of Disputes in The Construction IndustryDocument2 pagesAdjudication of Disputes in The Construction IndustryTshilidzi Irene NetseloNo ratings yet

- Weld Repair ProcedureDocument6 pagesWeld Repair ProcedureTshilidzi Irene Netselo75% (4)