Professional Documents

Culture Documents

3 TB - Dehumidification and The Psychrometric Chart

3 TB - Dehumidification and The Psychrometric Chart

Uploaded by

Karthy GanesanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 TB - Dehumidification and The Psychrometric Chart

3 TB - Dehumidification and The Psychrometric Chart

Uploaded by

Karthy GanesanCopyright:

Available Formats

Technical Bulletin 3

Dehumidification and the

Psychrometric Chart

I

R ELATIVE HUMIDITY

NTRODUCTION

The psychrometric chart has been well documented in a wide

variety of technical textbooks and journals. This technical

bulletin will not attempt to cover the chart in detail, but, will

highlight those features of the chart which apply to refrigerant

type dehumidification applications. It will define the terms

which form the nucleus of properly applying a dehumidifier.

Relative humidity is a misapplied term. It is often used in

place of absolute humidity. The key is the word relative. To

understand this concept, a law of nature must be Reviewed.

Air is a compressible fluid and its volume is represented by

the following equation:

v = K(T/P)

V = Volume

T = Temperature

P = Pressure

K = Constant

HE CHART

49

Figure 1 shows a typical psychrometric chart. Dry Bulb

temperatures are shown on the chart as vertical lines.

The horizontal lines represent Dew Point temperatures. Lines

representing Wet Bulb temperatures are the straight diagonal

lines sloping downward from left to right. The curve forming

the top edge of the chart is called the saturation curve.

Air in a condition that falls on any point along this curve is

totally saturated with moisture. Any additional moisture

added could not be absorbed and would remain in a liquid

state as condensation. The sweeping curved lines that

follow the saturation curve are relative humidity lines

expressed as percentages. These lines represent the

degree of volume displaced by moisture with respect to the

total air volume.

48

80

42

RH

80

%

RH

%

70

RH

id

110

100

90

ulb

120

tB

60

ti v

Hu

130

0%

Te

mp

80

era

RH

tur

es

70

RH

%

40

60

30

RH

50

45

40

13

40

12

20%

RH

35

30

30

25

H

10% R

20

Dew Point Temperatures

10

0

20

25

30

35

40

12.5 CU. FT.

45

50

55

60

13.0 CU. FT.

65

70

DRY BULB F

75

80

13.5 CU. FT.

85

90

95

100

14.0 CU. FT.

105

GRAINS OF MOISTURE PER POUND OF DRY AIR

75

RH

%

90

70

33

32

31

65

it

140

Dry Bulb Temperatures

TIO

RA

TU

38

SA

37

AT

PY

36

AL

35

TH

EN

39

40

(B

41

TU

/L

B)

43

44

45

170

14

12

11

10

9

180

46

47

105

We

60

e

la

Re

100

150

30

29

19

15

95

ti o

rv

90

160

28

27

26

25

24

23

22

21

20

18

17

16

Figure 1

at

a

u5r0

Cu55

14.5 CU. FT.

85

34

As the air temperature increases, its total volume increases

and decreases on reduction of temperature. Pressure has the

opposite effect. As pressure increases volume decreases.

This is important to understand because water damage

occurs at an absolute humidity concentration regardless of its

relative humidity. This is known as the constant Dew Point

Temperature.

Water, however, is not compressible. Therefore given a

specific amount, it will always occupy the same amount of

volume.

S ENSIBLE AND LATENT HEATING AND COOLING

There are four types of energy changes when heat of moisture

is added or removed. Sensible heat occurs when heat is added

without the addition or reduction of moisture. Sensible cooling

is the reverse. Latent heat, also known as humidification, is the

addition of moisture without changing the dry bulb temperature.

Latent cooling or dehumidification is the removal of moisture.

Figure 3 shows how these are displayed on the chart.

49

Figure 2 illustrates how this applies to the psychrometric

chart. As moisture laden air is heated or cooled the air volume

changes but the moisture does not. Thus there is a change in

relative humidity, without a change in actual water content.

48

95

100

105

46

180

170

(B

N

80

42

40

TIO

39

RA

TU

75

38

140

130

35

60

%

90

RH

32

80

%

31

RH

%

70

65

88 GR.

90

25

RH

%

60

24

80

23

%

50

RH

21

%

40

20

18

RH

40

60

50

16

19

17

70

55

30

15

92F

RH

50

40

40

12

10

13

11

12

14

45

20%

RH

35

30

30

25

H

10% R

20

78F

60

70F

27

26

28

29

30

100

22

Figure 2

110

10

0

20

25

30

35

40

12.5 CU. FT.

45

50

55

60

13.0 CU. FT.

65

70

DRY BULB F

75

80

13.5 CU. FT.

85

90

95

100

14.0 CU. FT.

105

GRAINS OF MOISTURE PER POUND OF DRY AIR

RH

80

120

70

33

34

EN

TH

AL

PY

AT

SA

40% RH

37

60% RH

150

36

80% RH

160

41

TU

/L

B)

43

44

45

70F

90

47

92F

78F

14.5 CU. FT.

85

TECHNICAL BULLETIN 3

Dehumidification and the Psychrometric Chart

Rarely will these occur as shown but will rather be a mixture of

them. A refrigerant dehumidification system is a combination of

sensible and latent cooling and sensible heating. First the

system cools the air to reduce the dry bulb temperature to the

dew point. Then latent cooling reduces the absolute humidity

and finally the air is reheated increasing its dry bulb temperature.

Figure 4 graphs this process.

By obtaining the starting and finishing grains per pound, the

amount of moisture to be removed can be calculated. The

amount of moisture to be removed is the difference between

these two values known as GR.

Figure 5 shows how a dehumidification system was sized.

The ambient design was 91F dry bulb and 78F wet bulb. The

desired indoor value was 80F dry bulb and 50% relative

humidity. The outside ambient has a moisture content of

124 grains and the indoor design has 78 grains. Thus the

required moisture removal rate is 124-78 = 46 grains per

pound of dry air.

D EHUMIDIFIER SIZING

49

To properly apply a dehumidification system, the amount

of moisture to be removed must be calculated. For most

applications the only information available is the dry bulb and

relative humidity or dry bulb and wet bulb temperatures. The

psychrometric chart is used to plot these two values by finding

their intersection and then following the horizontal line to the

right to determine the moisture content in grains per pound.

48

14.5 CU. FT.

90

95

100

105

180

46

47

85

(B

N

80

42

40

39

TIO

TU

75

SA

37

AT

PY

AL

35

TH

130

120

80

%

31

RH

32

110

100

RH

%

70

65

29

RH

%

60

25

27

26

28

90

60

24

80

23

%

50

RH

22

70

%

40

60

16

15

30

RH

50

40

40

12

10

13

11

12

14

45

20%

RH

35

30

30

25

H

10% R

20

RH

50

19

17

20

18

21

55

10

0

20

25

30

35

40

12.5 CU. FT.

45

50

55

60

13.0 CU. FT.

65

70

DRY BULB F

75

80

13.5 CU. FT.

85

90

95

100

14.0 CU. FT.

105

GRAINS OF MOISTURE PER POUND OF DRY AIR

RH

90

70

33

34

EN

36

Sensible Heating

Sensible Cooling

Humidification

Dehumidification

140

30

A.

B.

C.

D.

150

38

RA

Figure 3

160

41

TU

/L

B)

43

44

45

170

49

Figure 4

48

14.5 CU. FT.

90

95

100

105

180

46

47

85

170

/L

TU

80

41

(B

N

40

IO

39

AT

UR

38

75

SA

T

37

AT

130

AL

36

PY

140

35

TH

150

120

RH

80

31

RH

32

110

65

70

%

RH

30

100

RH

28

90

60

27

26

QS

25

Entering Air

60

24

80

RH

23

50

22

70

40

16

15

RH

60

Leaving

Evaporator

Coil

45

14

12

30

Reheated

Air (Supply)

RH

WA

GR

WB

50

40

40

13

11

12

10

9

50

19

17

20

18

21

55

GRAINS OF MOISTURE PER POUND OF DRY AIR

90

70

33

34

EN

QL

160

42

B)

43

44

45

Total Cooling A-B

Sensible Cooling C-B

Latent Cooling A-C

Specific Humidity A (room air)

Specific Humidity C (supply air)

Total Temperature Rise B-D

WA-WB

29

=

=

=

=

=

=

=

QT

QT

QS

QL

WA

WB

T

GR

20%

RH

35

30

30

25

10% RH

20

10

0

20

25

30

35

40

50

45

55

60

65

75

70

DRY BULB F

13.0 CU. FT.

80

85

90

95

100

105

14.0 CU. FT.

13.5 CU. FT.

49

12.5 CU. FT.

48

14.5 CU. FT.

90

95

100

105

47

85

180

46

Figure 5

80

40

(B

N

39

TIO

37

75

38

RA

TU

SA

AT

140

130

WA

91F DB/78F WB

35

36

PY

AL

TH

120

RH

80

31

RH

32

110

RH

70

%

65

90

RH

%

60

25

27

26

28

29

30

100

60

24

23

50

50

H

80

80F DB

22

70

40

RH

60

50

16

19

17

20

18

21

55

15

0%

RH

WB

50

40

40

13

12

GR

45

14

12

11

10

9

GRAINS OF MOISTURE PER POUND OF DRY AIR

%

90

70

33

34

EN

Constant

Total Air Volume

WA-WB

7000 GR/LB Air

=

=

=

=

150

20%

RH

35

30

30

25

10% RH

20

4.5

CFM

GR

7000

41

TU

LBS/HR = 4.5 x CFM x GR

7000

160

42

/L

B)

43

44

45

170

10

0

20

25

30

35

40

12.5 CU. FT.

45

50

55

60

13.0 CU. FT.

65

70

DRY BULB F

75

80

85

90

13.5 CU. FT.

95

100

105

14.0 CU. FT.

8300 West Sleske Court

Milwaukee, WI 53223

(414) 357-7400

FAX: (414) 357-8501

103 09/97

You might also like

- Dehumidifier CalculationDocument22 pagesDehumidifier CalculationamitbslpawarNo ratings yet

- Chilled Water Pump Head Calculation-Port-214fDocument6 pagesChilled Water Pump Head Calculation-Port-214fhasanadel88100% (2)

- AWWA M11 Steel Pipe - A Guide For Design and InstallationDocument301 pagesAWWA M11 Steel Pipe - A Guide For Design and InstallationLuis Daniel100% (1)

- Sizing Industrial DehumidifiersDocument7 pagesSizing Industrial DehumidifiersTanveer AzizNo ratings yet

- The Demise of The Primary-Secondary Pumping Paradigm For Chilled Water Plant DesignDocument5 pagesThe Demise of The Primary-Secondary Pumping Paradigm For Chilled Water Plant DesignWayde WillinsNo ratings yet

- Staircase Pressurisation Calculation Rev-04Document36 pagesStaircase Pressurisation Calculation Rev-04Anish KumarNo ratings yet

- Chiller Plant Manager - IO Summary-200219 PDFDocument1 pageChiller Plant Manager - IO Summary-200219 PDFShruti NandNo ratings yet

- Design of Centralized Hot Water Supply SystemDocument36 pagesDesign of Centralized Hot Water Supply SystemAbhik BhattacharjeeNo ratings yet

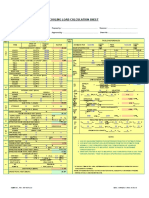

- Cooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/DoorDocument6 pagesCooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/Doorashfaq-matte-799375% (4)

- Chilled Water Pump Design GuideDocument18 pagesChilled Water Pump Design Guidesumanth.n nNo ratings yet

- Optimizing CHW Plants MinnesotaDocument51 pagesOptimizing CHW Plants MinnesotaJasper_HVACNo ratings yet

- Dehumidification Calcs AshraeDocument3 pagesDehumidification Calcs AshraeJojolasNo ratings yet

- Hot Water-Plumbing Lect - 2015 BAUDocument60 pagesHot Water-Plumbing Lect - 2015 BAUAbed BaayounNo ratings yet

- Humidification Load Calculator GuideDocument22 pagesHumidification Load Calculator GuideAnvar Pa100% (1)

- Variable Primary Flow Chilled Water Systems - ASHRAEDocument41 pagesVariable Primary Flow Chilled Water Systems - ASHRAEtrandoreemeNo ratings yet

- Coil LoadDocument13 pagesCoil LoadASK MENo ratings yet

- Stair Pressurization SystemDocument10 pagesStair Pressurization SystemPatel Kalinga100% (1)

- Hvac Pipe SizingDocument1 pageHvac Pipe SizingRaja Antony100% (1)

- HVAC Systems Duct Design-Duct P DropDocument1 pageHVAC Systems Duct Design-Duct P DropmhmdjdgmailcomNo ratings yet

- Air Distribution Engg GuideDocument8 pagesAir Distribution Engg GuideNiong DavidNo ratings yet

- Need For Balancing ValvesDocument12 pagesNeed For Balancing ValvesBubai111No ratings yet

- Car Park Jet FanDocument14 pagesCar Park Jet FanYan Aung50% (2)

- Duct CalculationsDocument38 pagesDuct CalculationsDilnesa EjiguNo ratings yet

- Control Sequences For Chilled Water Systems - Consulting-Specifying EngineerDocument5 pagesControl Sequences For Chilled Water Systems - Consulting-Specifying EngineerNeal JohnsonNo ratings yet

- Shuhail Ibis Hvac ReportDocument61 pagesShuhail Ibis Hvac ReportNikhil TbNo ratings yet

- Pump Room Submersible Pumps CalcDocument1 pagePump Room Submersible Pumps CalcMohamed Adel ElBazNo ratings yet

- Chiller Diversity FactorDocument3 pagesChiller Diversity FactoraadsamudNo ratings yet

- Desiccant Wheel Dehumidification 2Document19 pagesDesiccant Wheel Dehumidification 2ovidiu73No ratings yet

- 00 BLANK - Hot and Cold Water LU Calculation SheetDocument14 pages00 BLANK - Hot and Cold Water LU Calculation SheetrNo ratings yet

- Designing Chilled Water Systems PDFDocument10 pagesDesigning Chilled Water Systems PDFjorge castilloNo ratings yet

- Table 2 - HVAC Design Check FiguresDocument3 pagesTable 2 - HVAC Design Check FiguresEsteban De Vargas CueterNo ratings yet

- Central Water Heating Design: A, This Heat Pump Engineering Project Design Hot Water System IncludeDocument3 pagesCentral Water Heating Design: A, This Heat Pump Engineering Project Design Hot Water System Includehifon1No ratings yet

- Secondary Loop Chilled Water in Super High Rise BLDGDocument11 pagesSecondary Loop Chilled Water in Super High Rise BLDGocean220220No ratings yet

- Engineering Bulletin CDQ Desiccant DehumidificationDocument28 pagesEngineering Bulletin CDQ Desiccant DehumidificationsdvitkoNo ratings yet

- Fcu SizingDocument12 pagesFcu SizingLloydNo ratings yet

- 6 Sequence of OperationsDocument5 pages6 Sequence of OperationsBhagyaraj NPNo ratings yet

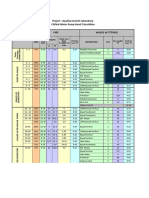

- Project: Quality Control Laboratory Chilled Water Pump Head Calculation Pipe Valves & FittingsDocument15 pagesProject: Quality Control Laboratory Chilled Water Pump Head Calculation Pipe Valves & FittingsZain ShariffNo ratings yet

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDocument6 pagesASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereNo ratings yet

- AC Duct Design PDFDocument6 pagesAC Duct Design PDFkumar123rajuNo ratings yet

- Cooling Unit. Off Coil Temp Room Temp PDFDocument5 pagesCooling Unit. Off Coil Temp Room Temp PDFSundar Ramasamy100% (1)

- ASHRAE Design CriteriaDocument4 pagesASHRAE Design CriteriaJin Fong KuehNo ratings yet

- PressurizationDocument1 pagePressurizationKarthy Ganesan100% (2)

- Plumbing CalculationDocument7 pagesPlumbing CalculationSenghouNo ratings yet

- S&W CalculationDocument10 pagesS&W CalculationSameera LakmalNo ratings yet

- Presurization CalculationsDocument10 pagesPresurization CalculationsvinaygvmNo ratings yet

- Ducts and Diffusers Design PDFDocument106 pagesDucts and Diffusers Design PDFsiroliver39No ratings yet

- Deron Swimming Pool Heat Pump CatalogueDocument19 pagesDeron Swimming Pool Heat Pump Catalogueocean220220No ratings yet

- Ahu DesignDocument17 pagesAhu DesignMohamed Aboobucker Mohamed IrfanNo ratings yet

- Fixture Unit CalculatorDocument14 pagesFixture Unit Calculatorاحمد الجزار2007No ratings yet

- Variable Primary FlowDocument58 pagesVariable Primary FlowAlfredo Merizalde Aviles100% (2)

- Understanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDocument13 pagesUnderstanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDavid O. AlmeidaNo ratings yet

- District Cooling Best Practices: Design Process and Key IssuesDocument19 pagesDistrict Cooling Best Practices: Design Process and Key Issues9810482818No ratings yet

- HVAC Design Manual For Hospitals & Clinics-2003 OrignalDocument6 pagesHVAC Design Manual For Hospitals & Clinics-2003 OrignalAlaa FaiqNo ratings yet

- Heat Recovery For Chilled Water Systems - Applications For Condenserless ChillersDocument20 pagesHeat Recovery For Chilled Water Systems - Applications For Condenserless Chillersfacebook111111100% (2)

- Ventilation Summary For Carpark & VRV System: (M /S) (M /S)Document4 pagesVentilation Summary For Carpark & VRV System: (M /S) (M /S)sachinsaklani23No ratings yet

- VTS FAHU Selected Model - Fin PDFDocument2 pagesVTS FAHU Selected Model - Fin PDFDuxToyNo ratings yet

- CHW Pipe Straight Pressure DropDocument2 pagesCHW Pipe Straight Pressure DropDesigner ForeverNo ratings yet

- Hot Water Heat Pump DesignDocument3 pagesHot Water Heat Pump DesignAdhikar HariramNo ratings yet

- DEhumidification and The Psychrometric ChartDocument4 pagesDEhumidification and The Psychrometric ChartPhyu Mar Thein KyawNo ratings yet

- Effect of Air Velocity in Relative HumidityDocument12 pagesEffect of Air Velocity in Relative HumiditybananaNo ratings yet

- Cooling With Dehumidification PDFDocument9 pagesCooling With Dehumidification PDFKevin TsuiNo ratings yet

- Valve and Actuator CatalogueDocument60 pagesValve and Actuator Catalogueashfaq-matte-79930% (1)

- Specific Areas of Concerns: Inspections of Manufacturers of Sterile ProductsDocument40 pagesSpecific Areas of Concerns: Inspections of Manufacturers of Sterile Productsashfaq-matte-7993No ratings yet

- Controls Tips Tricks Manual For FIFA 07 08Document6 pagesControls Tips Tricks Manual For FIFA 07 08ashfaq-matte-7993100% (1)

- Exercise 10Document4 pagesExercise 10Daniel Francisco Ortiz RosarioNo ratings yet

- E Cel Cables: General Wiring Price ListDocument1 pageE Cel Cables: General Wiring Price ListTauseef Taj KianiNo ratings yet

- Comparison Between Conventional Brickwork Construction Vs Mivan ConstructionDocument5 pagesComparison Between Conventional Brickwork Construction Vs Mivan ConstructionSachin KothvalNo ratings yet

- Box PushingDocument44 pagesBox PushingAnonymous UebIaD8A8C50% (2)

- Physics Project On MagnetismDocument29 pagesPhysics Project On MagnetismChandraneel SinghNo ratings yet

- Emseal Expansion Joint Checklist 1Document1 pageEmseal Expansion Joint Checklist 1Nur Alam SamsieNo ratings yet

- Manufacturing of SteelDocument2 pagesManufacturing of SteelSamuel AntobamNo ratings yet

- Experiment No.8Document5 pagesExperiment No.8Osama RashaydaNo ratings yet

- W06Document1 pageW06erattakoyaNo ratings yet

- 11 ThpaperDocument10 pages11 Thpapertoma97No ratings yet

- Fire Protective Coatings: Reinforced Passive Fire Protection by LapinusDocument18 pagesFire Protective Coatings: Reinforced Passive Fire Protection by LapinusHerbert Aguilargonzalez100% (1)

- Metode PengujianDocument17 pagesMetode Pengujianabraham samadNo ratings yet

- Scientific Background:: Warren TrussDocument2 pagesScientific Background:: Warren TrussMohamed Nour eldenNo ratings yet

- Analysis of RCC Beams Using ABACUSDocument8 pagesAnalysis of RCC Beams Using ABACUSvijjikewlguy7116No ratings yet

- 45IECMC D-Line F Line ContactorsDocument33 pages45IECMC D-Line F Line ContactorsCLAVOTNo ratings yet

- Cold Mounting Systems For All Materialographic ApplicationsDocument6 pagesCold Mounting Systems For All Materialographic ApplicationsDEWI SRIREJEKI LESTARI -No ratings yet

- Advanced ThermodynamicsDocument21 pagesAdvanced ThermodynamicsYash KrishnanNo ratings yet

- HW 1 Solutions 2012Document10 pagesHW 1 Solutions 2012Dustin Brown100% (1)

- Katalog HVAC Polytron 2017 LocalDocument28 pagesKatalog HVAC Polytron 2017 LocalYoga PramudyaNo ratings yet

- Unit5 1Document5 pagesUnit5 1Siva GaneshNo ratings yet

- 4-006 ExplanationDocument6 pages4-006 ExplanationAdam BehielsNo ratings yet

- Vol 6 Tender DrawingsDocument356 pagesVol 6 Tender DrawingsPraveen BNo ratings yet

- Structural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Document38 pagesStructural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Mohammad Yunus Salehi67% (3)

- 2016 HVAC Systems SelectionDocument2 pages2016 HVAC Systems SelectionActiveNo ratings yet

- Hague Fasteners - Special Fasteners & Non Standard Bolts and NutsDocument8 pagesHague Fasteners - Special Fasteners & Non Standard Bolts and Nutsn1ghtfallNo ratings yet

- Ceran - AD - Plus - Calcium Sulfonate Complex PDFDocument1 pageCeran - AD - Plus - Calcium Sulfonate Complex PDFIbrahim MaulanaNo ratings yet

- Kss Cable TieDocument32 pagesKss Cable Tieismail alwainiNo ratings yet

- Kiln Heat Up Optimun Kiln Operation ÖNEMLİ PDFDocument42 pagesKiln Heat Up Optimun Kiln Operation ÖNEMLİ PDFAli HüthütNo ratings yet

- MOE Test Result of Acc ConcreteDocument4 pagesMOE Test Result of Acc ConcreteSabyasachi BangalNo ratings yet