WORKPLACE SAFETYCOMMITTEE

Initial & Re-Certification

PPT-057-06

�Technical Assistance Manual

[Link]

Click on Workers

Compensation icon

Click on Health & Safety

Division

Click on HandS System

Click on Workplace Safety

Committee Technical

Assistance Manual

PPT-057-06

�Learning Objectives

Understand the role and functionality of a safety

committee

Understand basic hazard detection and inspection

methods

Understand (and apply) basic accident & incident

investigation techniques

Gain basic awareness of how drug & alcohol

abuse/addiction impacts the workplace

PPT-057-06

�Program Purpose

Educate new committee members

Refresher training for existing members

Most important:

Help prevent accidents &

illnesses in the workplace!

PPT-057-06

�Hidden Costs of Accidents

Total Costs = Direct + Indirect Expenses

Direct (insured) = e.g. wage loss, medical

Indirect (uninsured, cost to company) = e.g.

downtime, property damage, morale of injured

worker and others in department, hiring,

training, possible OSHA citations

PPT-057-06

�Workplace Safety Committees

Role

and

Functionality

PPT-057-06

�Safety Committee Purpose

Improve safety & health in the workplace

Involve employees in the safety function

Generate ideas for improving safety & health

Improve employee/management relations

Stimulate interest among employees

PPT-057-06

�Safety Committee Pitfalls

Busy supervisors can refer problems to

the Committee they should solve themselves

Only a small percentage of employees

participate on the Committee

Timeframe from when problem discovered to

meeting may be lengthy

PPT-057-06

�Safety Committee Pitfalls

Members may not be qualified to handle complex

issues and may only address superficial problems

Recommendations may be expensive or time

consuming and as a result may be overlooked

May create large workloads for the management

representative if only identification of hazards

occur

PPT-057-06

�Safety Committee Authority

Extent should be determined and communicated to

all employees; e.g.:

Empowered and endorsed by top management

Acts as a recommending body

Investigate accidents/incidents

Implement changes

PPT-057-06

10

�Safety Committee Structure

Single - One workplace, one committee

Centralized More than one workplace

One committee in a central location with

representation for each outlying workplace location

Multiple - More than one workplace

Separate individual committees at each workplace

PPT-057-06

11

�Safety Committee Structure

Committee Member Composition

- Minimum of 2 employer and 2 employee

representatives

- Number of employer representatives CANNOT

exceed number of employee representatives

- Quorum = 1/2 Plus 1

PPT-057-06

12

�Safety Committee Structure

Committee Members

Employer Authority to do one or more:

Select or hire an employee

Remove or terminate an employee

Direct the manner of employee performance

Control the employee

Employee Does not possess any authority or

responsibility described for the Employer

A person cannot function

as both of the above

PPT-057-06

13

�Safety Committee Function

Purpose: to detect hazards and prevent accidents

& illnesses

Must have formal (documented) monthly

meetings with Agenda & Minutes:

- Review & update safety training

- Develop safety work practices

- Recommend use of safety equipment/devices

- Accident/incident report reviews

- Action items from reports & safety inspections

- Avenue for employee safety-related issues

PPT-057-06

14

�Members Responsibilities

Attend meetings

Notify all employees in your area that you

are their representative on the Committee

Be watchful for unsafe conditions and acts

and report them

Be responsive to peoples concerns; follow up

Ask employees for safety suggestions and

concerns

Discuss safety issues with employees

Offer solutions not just problems

PPT-057-06

15

�Managements Responsibilities

Provide support (time, effort, money)

Resolve scheduling and personal conflicts

Provide realistic dates for correcting safety and

health concerns

Support training for Committee members

Provide leadership and direction

Attend Committee meetings

PPT-057-06

16

�Managements Responsibilities

Promote positive effects of Committee activities

on individual basis or at group meetings

Respond to recommendations in a timely manner

Promote safety within the organization

PPT-057-06

17

�Employees Responsibilities

Identify safety and health hazards

Report all unsafe conditions and practices

Make suggestions for improving workplace

safety

Participate in Committee activities/initiatives

Follow safe practices/procedures

Cooperate with Committee members

Consider becoming a Committee member

PPT-057-06

18

�Committee Chairperson

Accountable to top management

Sets the agenda

Coordinates meetings

Facilitates meetings

Ensures agenda is followed

Ensures everyone is heard

PPT-057-06

19

�Committee Chairperson

Options:

Safety person serves as Chairperson

Management and union co-chairs

Rotating Chairperson (yearly; each meeting)

PPT-057-06

20

�Safety Committee Certification

Can be done on-line using HandS system

Initial certification:

- After 6 months of functional committee

operation

- Within 30-90 days of insurance policy renewal

-Submit Form LIBC-372

Annual re-certification:

- Within 15-90 days of insurance policy renewal

- Submit Form LIBC-372R

PPT-057-06

21

�HandS

Health and Safety Divisions

online processing system

PPT-057-06

22

�Accessing the HandS System

Go to our website

[Link]

Click Workers

Compensation

then

Health & Safety

Division

then

HandS System

PPT-057-06

23

�Review/Audit Overview

Random/Target Audits

30 day notification

Opening conference

Table top on-site audit

Information verification

Closing conference

Issue Compliance/Non-compliance Rating

(Preliminary)

Non-Compliance issues explained

PPT-057-06

24

�Successful Safety Committees

Competent -- dedicated

Support goals & objectives

Demonstrate team effort

Develop mutual trust, respect & support

PPT-057-06

25

�Objectives

Objectives should be: SMART

Specific

Measurable

Attainable

Relevant

Time-limited

PPT-057-06

26

�Workplace Safety Committees

Hazard Detection

and

Identification

Is this safe?

PPT-057-06

27

�Hazard Detection & Identification

The following list shows the main ways to

identify hazards:

Walkthrough Surveys

Inspection Checklists

Past Records

Accident Investigations

Consultation

Documentation

PPT-057-06

28

�Risk vs. Hazard

Risk: The measure of the

probability and severity of

an adverse effect caused by

a hazard

Hazard: What causes the

risk; administrative or

physical (causes or has the

potential to cause a loss)

PPT-057-06

29

�Purpose of Safety Inspections

Identify potential hazards so they are corrected

before an injury occurs

Implement or improve safety

programs

Increase safety awareness

Display concern for workers safety

Communicate safety standards of performance

PPT-057-06

30

�Inspection vs. Audit

Are you AUDITING or INSPECTING?

Safety Inspections examine physical facilities

looking for unsafe conditions, unsafe acts,

housekeeping issues, etc.

Safety Audits examine procedures & policies

PPT-057-06

31

�Hazard Detection & Inspection

What is a hazard?

What should I look for?

What standards do I reference?

How do I perform the inspection?

How do I document the inspection?

PPT-057-06

32

�What is a Hazard?

An act or a condition in the workplace that has

the potential to cause injury, illness, or death to

a person and/or damage to company property,

equipment and materials

PPT-057-06

33

�What to Look for

High Hazard Areas: Equipment and operations

that involve energy transfer including: chemical,

mechanical, pneumatic, physical, electrical,

gravitational, etc. (Unsafe Conditions)

Procedures and behaviors, including: Use of

protective equipment, safe operating speeds,

following proper procedures, horseplay,

inattentive behavior, etc. (Unsafe Acts)

PPT-057-06

34

�Standards to Reference

OSHA

- Federal Regulations (29 CFR 1910)

- Available at [Link]

PA Department of Labor & Industry

[Link]

PA Department of Environmental Protection

[Link]/portal/[Link]

Other technical standards

(NFPA, ANSI, ASTM, ASME, etc.) get help

if necessary!

PPT-057-06

35

�How to Conduct an Inspection:

Observe processes, equipment, and work

locations for unsafe conditions

Obtain comments and suggestions from

employees

Review Records such as training, Safety

Data Sheets, Accident Reports, etc.

Formulate recommendations

Report findings to management

Follow-up for implementation

PPT-057-06

36

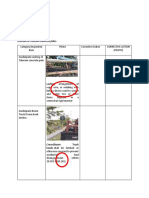

�Any Problems Here?

Chemical

storage

underneath

cabinet

Not all

chemicals

properly

labeled

Are chemicals

compatible

No lip on shelf

PPT-057-06

37

�What About Here?

Fire door held

open by fire

extinguisher

Location of

extinguisher

could be trip

& fall hazard

PPT-057-06

38

�Is this Okay?

No shoring

in trench

NO!

Working

below

unstable

rock

Unstable

soil in

trench

PPT-057-06

39

�What About This?

Storage next

to hot water

heater

Combustible

storage in

mechanical

room

Unsafe

storage

could fall on

somebody

PPT-057-06

40

�Any Issues Here?

Door possibly

closes on cord

damage to

cord

Cord across

walkway trip &

fall hazard

PPT-057-06

41

�What About Here?

Exit

blocked/obstructed

Exit access/aisle

blocked/obstructed

Storage creates trip

& fall hazard

Access to fire

extinguisher

blocked

PPT-057-06

42

�Do you see any Problems?

Electrical

cord frayed,

insulation

missing

PPT-057-06

43

�How to Document the Inspection

In Writing, In Writing, In Writing!

Email

Checklists.

Memorandums.

Written inspection reports..

PPT-057-06

Safety

Inspections

44

�Safety Inspection Checklist

PPT-057-06

45

�Workplace Safety Committees

Accident/Incident

Investigation

and

Reporting

PPT-057-06

46

�Incident Ratio Model

Most Accident

Investigations

Conducted

1

29

Minor Injury

Few Investigations

Conducted

300

Near Miss

Death or Serious Injury

Bi

in gg

ju es

ry t

ca per

us c e

i n nt

g ag

po e

te of

nt

ia

l!

3,000

Unsafe Acts, Behaviors or Conditions

PPT-057-06

47

�Near Miss

What is a near miss?

How does it differ from an accident?

How does it differ from a hazard?

PPT-057-06

48

�What Is A Near Miss?

PPT-057-06

49

�Near Miss

We will read the definition of an accident

We call an accident an actual

We looked at the definition of a hazard

We call a hazard a potential

PPT-057-06

50

�Near Miss

Remembering the definition of a near miss

We would call it an ?????

PPT-057-06

51

�Near Miss

RIGHT --We call a near miss an almost

How does it resemble an accident?

It must be investigated immediately

PPT-057-06

52

�Near Miss

Near misses also have

a cause and effect

What would you say

was the cause of this

almost? What might

be the effect?

What changes would

you make?

PPT-057-06

53

�Near Miss

What impact would

changes make in the

slide?

previous

How would you prevent

from becoming an

this

actual?

PPT-057-06

54

�Reporting Near Miss Incidents

Why report near misses?

PPT-057-06

55

�Near Miss

Always remember, if you:

Eliminate or reduce all hazards

Investigate all near misses immediately

and make changes

You WILL reduce actuals

PPT-057-06

56

�Incident Investigation & Reporting

What is an accident?

What are the causes of an accident?

How do I investigate an accident?

What should I put in my report?

Whats next?

PPT-057-06

57

�Incident Investigation & Reporting

What is an accident?

An uncontrolled and/or unplanned release of

energy that causes or contributes to illness,

injury, death and/or damage to property,

equipment, or materials.

All accidents have a cause and effect!

PPT-057-06

58

�Incident Investigation & Reporting

What are the causes of an accident?

There are two basic causes of accidents:

Unsafe Acts

and

Unsafe Conditions

PPT-057-06

59

�Unsafe Acts vs. Unsafe Conditions

Behaviors

- Account for the vast

Environment

Represent only a

small fraction of

injuries

Cant

Recognize & Remedy

majority of injuries

Wont

Encourage & Enforce

PPT-057-06

60

�Unsafe Acts - Unsafe Conditions

Inadequate

Ventilation

Operating at

Improper Speed

Failure to Warn

Congested Area

Defective Tools,

Equipment or

Materials

Noise Exposure

Inadequate Guards

Inadequate PPE

Improper Lifting

Horseplay

Using Defective

Equipment

(Adapted from Bird & Germain, 1985)

PPT-057-06

61

�Unsafe Acts - Unsafe Conditions

Temperature

Extremes

Influence of Drugs

or Alcohol

Fire/Explosion

Hazard

Operating Without

Authority

Poor Illumination

Improper Loading

Inadequate Warning

System

Failure to Secure

Removing Safety

Devices

File Drawer Left

Open

(Adapted from Bird & Germain, 1985)

PPT-057-06

62

�Unsafe Act or Unsafe Condition?

Act: No guarding on

scaffold; unsafe set-up

for scaffold; no PPE

Condition: Items

stored in exit access,

obstructs exit width

PPT-057-06

63

�Unsafe Act or Unsafe Condition?

Act: Unsafe

ladder setup; no PPE

PPT-057-06

64

�Unsafe Act or Unsafe Condition?

Excessive

sawdust

on floor

Condition

No guard

on blade

PPT-057-06

65

�Unsafe Act or Unsafe Condition?

Act: Unsafe

set-up;

individual in

unsafe position

PPT-057-06

66

�Unsafe Act or Unsafe Condition?

Condition

Exposed wires

PPT-057-06

67

�Unsafe Act or Unsafe Condition?

Act

Man standing

on moveable

stairs being

raised by

forklift

PPT-057-06

68

�Accident/Incident Investigation

Review all reported

incidents causing

injury, damage or a

near miss

What happened

Identify the root

cause

Recommend

corrective measures

PPT-057-06

69

�Who Should do the Investigation?

First Line supervisor

Safety Committee

Safety Director/Safety Person

All of the above

A combination of the above

PPT-057-06

70

�Incident Investigation & Reporting

HOW DO I INVESTIGATE AN ACCIDENT/INCIDENT?

1. Call for first aid/emergency response

2. Secure the scene

3. Photograph the scene

4. Interview witnesses

5. Collect physical evidence

PPT-057-06

71

�Investigation Go Bag

Some suggestions:

Camera

Flashlight

Tape Measure

Surgical Gloves

Necessary PPE

Note Pad/Tablet

Sticky Notes

Pens

PPT-057-06

72

�Goal of the investigation

IS NOT TO:

Exonerate individuals or management

Satisfy insurance requirements

Defend a position for legal argument

Assign blame

Remember, fact finding not fault finding

PPT-057-06

73

�Interviewing Victims & Witnesses

Interview as soon as possible after the incident

Do not interrupt medical care to interview

Interview each person separately

Do not allow witnesses to confer prior to interview

PPT-057-06

74

�The Interview

Put the person at ease

People may be reluctant to discuss the incident

particularly if they think someone will get in

trouble

Reassure them that this is a fact finding

only

Remind them these facts will be used

prevent a recurrence of the incident

PPT-057-06

process

to

75

�The Interview

Take notes!

Do not make suggestions:

If the person is stumbling over a

word or concept, do not help them out.

Ask open ended questions:

What did you see?

What happened?

PPT-057-06

76

�The Interview

Summarize what you have been told

Correct misunderstandings of the events

between you and the witness

Ask the witness/victim for recommendations

to prevent recurrence

These people will often have the best solution

to the problem

PPT-057-06

77

�Incident Investigation & Reporting

WHAT SHOULD I PUT IN MY REPORT?

1.

All the facts, statements, documents, photos,

etc. that were obtained during the investigation

2.

Remember, no opinions (e.g. I think that, I

believe that)

3.

Analysis of the cause

4.

Corrective actions

PPT-057-06

78

�Corrective Action

Told to be more careful

Explained safety rule on lifting

Instructed employee to read Safety Data

Sheet (SDS)

Had co-worker review proper procedures

ARE THESE EFFECTIVE MEANS OF CORRECTIVE

ACTION? WHAT DO YOU THINK?

Hint: Not really! These actions

do not really correct anything.

PPT-057-06

79

�Good Corrective Action

Met with employee to discuss accident and

reviewed proper procedures and then...

Observed employee perform the procedure

Showed employee SDS, reviewed how to

interpret; use of appropriate PPE

Checked for understanding

Plan to discuss with all employees in

department at next meeting

PPT-057-06

80

�Incident Investigation & Reporting

Whats next?

Follow-up!

Follow-up!

Follow-up!

Ensure that corrective actions are being

implemented.

PPT-057-06

81

�Incident Investigation - Summary

Accident & Incident Investigations

First Aid & Emergency Response

Secure Scene

Photograph/Document Scene

Interviews/Statements

Review Records

Prepare a Report:

Include Causes & Effects

Include Corrective Actions

Follow-up!

PPT-057-06

82

�Root Cause(s)

The cause of a problem which, if

adequately addressed, will prevent

a recurrence of that problem

PPT-057-06

83

�WEED OUT THE CAUSES OF INJURIES

AND ILLNESSES

Strains

Burns

Ung

ua

rded

m ac

n too

ls

Chemic

al spill

Conditions

Untrained

play

Horse

hine

Broke

Defectiv

e

Cuts

PPE

worker

Lack of time

Too much work

Create a h

azard

t injury

r

o

p

e

r

Fails to

Fails to inspect

Surface Causes of

the Accident

Behaviors

Fails to enforce

Fails to train

Inadequate training

No discipline procedures

No orientation process

DIRECT CAUSES OF

INJURY/ILLNESS

No recognition

Outdated Procedures

Inadequate training plan

No accountability policy

No inspection policy

PPT-057-01

PPT-057-06

Root Causes of the

86

Accident

84

�Drug-Free Workplaces in PA

Employee

Substance

Abuse

Awareness &

Prevention

(ESAAP)

PPT-057-06

85

�The Unseen Reality

Think PAs workplaces are

drug free? Think again.

75% of drug users are employed

Almost one in ten employees has

a substance abuse problem

24% of workers admit to drinking

during the workday at least once in

the past year

15% of U.S. workers report using

alcohol or being impaired on the

job in the past year

PPT-057-06

86

�The Cost of Substance Abuse

Increased Health Care Costs

Increased Workers

Compensation Premiums

Increased Workplace Violence

PPT-057-06

87

�Substance Abuse

Individuals who abuse drugs

or alcohol are three and a

half times more likely to be

involved in a workplace

accident compared to

individuals who do not

abuse drugs or alcohol

47% of industrial injuries

are directly related to

alcohol abuse or alcoholism

PPT-057-06

88

�Reasons for Not Implementing ESAAPs

Substance abuse is not a problem

Insufficient time to develop & maintain a policy

The policy would be too costly

Too much uncertainty about liability

Lack of information

REALIT

Y=

PPT-057-06

89

�Incentive to Implement ESAAPs

Only 1 out of every 5 Pennsylvania employers

plans to address substance abuse in the

workplace.

The number increased to 2 out of every 3 when

workers compensation premium discounts were

mentioned.*

*While PA presently has no provisions

for granting financial consideration for

implementing an ESAAP, this may be

legislatively addressed in the future

PPT-057-06

90

�ESAAP is an Effective Solution

Southern Pacific Railroad reports after they

implemented an ESAAP accidents dropped by

71%.

One electric supply company documents a

39% decrease in absenteeism after

implementation of an ESAAP.

PPT-057-06

91

�Substance Abuse

When someone has an addiction or abuses alcohol

and other drugs it affects themselves as well as

other people around them:

Emotionally

Behaviorally

Physically

PPT-057-06

92

�Emotional Effects

Aggression

Burnout

Anxiety

Depression

Paranoia

Denial

PPT-057-06

93

�Behavioral Effects

Slow reaction time

Impaired coordination

Slowed or slurred speech

Irritability

Excessive talking

Inability to sit still

Limited attention span

Poor motivation or lack of energy

PPT-057-06

94

�Physical Effects

Common performance problems may

include:

Poor attendance

- Tardiness

- Unexplained absences

- Long lunches

Co-workers or customer complaints

Mistakes

Missed deadlines

PPT-057-06

95

�Drugs of Abuse

Alcohol

Narcotics

Marijuana

Hallucinogens

Inhalants

Designer Drugs

Stimulants

Over the counter

Depressants

(OTC)

PPT-057-06

96

�Drug-Free Workplace Policy

Accomplishes two major things:

1. Sends a clear message that use of

alcohol and drugs in the workplace

is prohibited

2. Encourages employees who have

problems with alcohol and other

drugs

to voluntarily seek help

PPT-057-06

97

�Elements of ESAAPs

PPT-057-06

98

�A Safer, Drug-Free Workplace

Recognize the impact of alcohol and drug abuse on the

workplace

Understand and follow the Drug-Free Workplace Policy

Know the types of assistance available

Visit [Link], the website for the Substance

Abuse and Mental Health Services Administration

(SAMHSA), maintained by the US Department of Health

and Human Services

PPT-057-06

99

�Additional Resources

To assist you in your program development, you can

contact us for your own PowerPoint copy of:

1. Drug & Alcohol Awareness-Employee and

2. Drug & Alcohol Awareness-Supervisor

Department of Labor and Industry

Bureau of Workers Compensation

Email: RA-LI-BWC-Safety@[Link]

Phone: (717) 772-1635

PPT-057-06

100

�PATHS

PA Training for Health and Safety

PATHS is a no fee state-wide service providing

Pennsylvania employers and employees with

coordinated Health and Safety resources through

easy access and affordability

PPT-057-06

101

�PATHS

At the PATHS Website you can:

View . . . Health & Safety Training PowerPoint briefings

Access Safety Talks (Toolbox Talks)

Review . . . Course descriptions, objectives, and

schedules

Employers can register online to participate in webinars

and training sessions. Most sessions are free and are

open to everyone

PPT-057-06

102

�PATHS

PPT-057-06

103

�PATHS

To Access PATHS

[Link]/PATHS

or

[Link]

Workers Compensation

icon

Health & Safety Division

PATHS

PPT-057-06

104

�Contact Information

To contact a Health & Safety Training

Specialist:

Bureau of Workers Compensation

1171 South Cameron Street Room 324

Harrisburg, PA 17104-2501

717-772-1635

RA-LI-BWC-Safety@[Link]

PPT-057-06

105

�HandS Tech Manual

Sample Programs found on following pages:

Safety Committee Compliance Checklist

Sample Bylaws

Sample Safety Policy

Sample Meeting Agenda

Sample Meeting Minutes

49

51

54

55

56

Sample Training Documentation

Sample Incident Investigation Report

PPE Program Checklist

Workplace Inspection Checklist

Safety Orientation

57

58-60

61-67

68-74

75

PPT-057-06

106

�Questions

PPT-057-06

107