Professional Documents

Culture Documents

DPS Softwareentwicklung GMBH PDF KMMApproved 9.11

DPS Softwareentwicklung GMBH PDF KMMApproved 9.11

Uploaded by

vijay410Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DPS Softwareentwicklung GMBH PDF KMMApproved 9.11

DPS Softwareentwicklung GMBH PDF KMMApproved 9.11

Uploaded by

vijay410Copyright:

Available Formats

Sheet Metal Design

5.0

The SolidWorks partner solution

for optimum cooperation with

the TRUMPF production systems

of the TruTops-series

www.topsworks.com 5.0

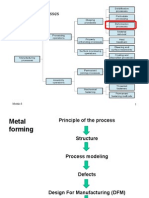

Sheet Metal Design From the Idea to the Product

Today, the key to producing high-quality sheet metal components efficiently is not only a question of how it

has been manufactured. More important, is that all of the steps in the complete process chain from the idea

to the finished product are optimally coordinated. This holistic approach ensures that

the design needs of manufacturing are taken into consideration.

the programming is technology-oriented.

the production makes full use of the entire machine technology.

This is achieved by

re-implementing empirical values derived from experience.

transferring data directly from SolidWorks to TruTops.

SolidWorks in the Design Process for Sheet Metal

Especially for small and ever-changing lot sizes, it is important that the CAD system is flexible to ensure an

optimum cooperation with production. With the parametric 3D CAD System SolidWorks it is possible to easily

create sheet metal parts in the context of an assembly as well as making logical and fast changes. SolidWorks

thereby supports specific sheet metal features for a practice oriented and intuitive construction. That is why

so many customers from the sheet metal industry are counting on SolidWorks and are taking advantage of

the open system philosophy with all the relevant interfaces.

TruTops production systems in the Design Process for Sheet Metal

TruTops: Technology-oriented-production system

TRUMPF offers a fully integrated concept for flexible production

- The machines and production system are from one source.

TruTops Punch is the

production system for

punching and

combination machining

TruTops Bend is the

production system

for bending.

Advantages with ToPsWorks

Integration in SolidWorks

ToPsWorks has been completely integrated into SolidWorks,

this makes ToPsWorks easy to use and learn. Access to the TruTops Bend Technology

Access to the

Interface to the TruTops Production Systems TruTops Punch Technoloy

ToPsWorks retrieves information directly from the TruTops

production systems TruTops Punch and TruTops Bend data-

bases. As a result, all the relevent data necessary to design

a correct sheet metal part and its flat pattern are available

during the design process. This ensures that there are no

rejects, reduces the number of necessary samples, shortens

the cycle time and increases flexibility.

Processing SolidWorks Sheet Metal Parts Inserting a Punch Feature from

The bends of a SolidWorks sheet metal part are analyzed the TruTops Punch Tool Database

according to sheet metal thickness, bend type and bend

angle. The corresponding parameters such as materials and

tools are provided by the TruTops Bend database. According

to these parameters, the bends are adjusted with the cor-

rect radii and shortening values. This ensures that the sheet

metal part that is handed over to production contains all the

correct bend information.

ToPsWorks makes it possible to insert punching Features

based on the TruTops Punch database. That way information

about the available tools is provided during the design pro-

cess. For a series of punching-features the TruTops specific

parameters can be transferred to the GEO-file and can be

used by the technology module from TruTops Punch without

the user having to make any further modifications.

ToPsWorks allows you to display processing samples with

SolidWorks formingtools. In this way repetitive machining

operations in TruTops Punch can be displayed through Solid-

Works formingtools. Thus no additional programming is Implemeting the TruTops Bend Technology on the Sheet Metal Part

necessary. TruTops-specific processing samples for a series

of Punch feature can be transferred to the GEO-file and with

no further steps can be used in the TruTops Punch techno-

logy module.

Inserting a Bend Table on the Drawing

Using ToPsWorks, a bend table with the bend parameter from

the sheet metal part can be placed on the drawing. Infor-

mation such as the sheet metal thickness, the material, the

tools and the parameters of each bend can be displayed.

Bend Table on the SolidWorks Drawing

GEO-Import to create 3D Sheet metal parts from the

GEO-file

Through this funtion it is possible to migrate historical data GEO-Import to create

direktly back to SolidWorks as a native sheet metal part. If 3D-Model

the GEO-file contains the bend line information a sheet metal

part can be created. The user can thus convert his 2D infor-

mation to 3D SolidWorks sheet metal parts.

Exporting the Sheet Metal Part as a TRUMPF GEO-file

Sheetmetal parts that have been processed with ToPsWorks,

can be exported to GEO-Format directly for the TruTops pro-

duction systems Laser, Bend, Punch. Thus, the user saves

having to create a drawing of the flattened part, export this

to DXF format, import this DXF to TruTops, make potential

contour preparation and insert the bend information. The

GEO-files created contain the contour information for the

flat pattern, the process data for the bends, as well as the

material information and sheet metal thickness. Further, spe-

cial attributes can be included in the GEO-format to account

for punch features.

Support of metadata during GEO-Export

ToPsWorks now allows you to include certain metadata

directly in the GEO-file. The user may configure this himself.

For example he can create SolidWorks properties that are

extracted and included in the GEO-file (for example Part ID

Number, Drawing note, Programmer).

Further technicaldata is supported

Bendline information (such as position, radius, angle), bend-

lines, bend type and bending methodare transferred.

Tool information and tool type are supported

Standard elements such as rectangle, round, square but also

special tools such as single hole tool and single hole tool

center punch are transferred.

Export options

Table editor to customize the ToPsWorks database of ToPsWorks

ToPsWorks supplies you with an Editor to edit and modify the

userdefined bendtables. The user has the ability to make cor-

rections with having Microsoft access on his machine. This is

an enhancement to the SolidWorks bend table functions.

Support 64 Bit

By supporting 64bit, ToPsWorks can now be used in the con-

text of extremely large assemblies.

API-interface to automate repetivie processes

This interface offers the user a better integration to his pro-

duct development process. Through this automation for

repetive operations the user saves time. It is possible for

example to take GEO-files from SolidWorks sheet metal parts

and check these in to the PDM system.

Development Programming Production

TruTops Laser, Bend, Punch

GEO-file

production system Laser

(TruLaser 5030 classic)

technology

data from

TruTops Punch TruTops Punch

Database Punching /

Combination

technology data from (TruMatic 6000)

TruTops Bend

TruTops Bend Database Bending

(TruBend 5130)

empirical data

data is compared

5.0

www.topsworks.com

Direct usage of the Geo-file

Propagation of

technology data,

for example tools

and dot mark

points according

to TruTops

Implementation

in TruTops Bend

ToPsWorks World Wide

ToPsWorks is being used world wide.

ToPsWorks is supported by TRUMPF and being implemented by TRUMPF.

Technical data to ToPsWorks

System requirements: Operating system: Windows XP

SolidWorks: from SolidWorks 2007 and SolidWorks 2007 (64 bit) DPS Softwareentwicklung GmbH

Esslinger Strae 7

Supported TruTops Databases: all current metric TruTops Bend and TruTops

70771 Leinfelden - Echterdingen

Punch databases from TRUMPF

Germany

Installation programm: Windows installation and updates are conform

Tel.: +49 711 7973100

with Windows.

Fax: +49 711 79731029

The centralization of Software installation and

updates is supported

e-Mail: info@topsworks.com

Available in the following languages: German, English and French Internet: www.topsworks.com

You might also like

- TruTops HelpDocument395 pagesTruTops HelpVlad Grigorean86% (7)

- Vendaxo - Trumpf TrumaBend V50 CNC Press Brake Machine - 500 KNDocument2 pagesVendaxo - Trumpf TrumaBend V50 CNC Press Brake Machine - 500 KNHalász Attila0% (1)

- Trubend 7000 Operator ManualDocument182 pagesTrubend 7000 Operator Manualcoronaqc100% (1)

- HRB-4 KULLANIM KILAVUZU - Tr.enDocument73 pagesHRB-4 KULLANIM KILAVUZU - Tr.enHaidar Sareeni0% (1)

- 22 Twist Barrel Derringer - Upload by SteyrDocument6 pages22 Twist Barrel Derringer - Upload by SteyrRadek Bust100% (1)

- Byspeed 3015 BA V010 enDocument524 pagesByspeed 3015 BA V010 enΈλσαΟγκρένιNo ratings yet

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryFrom EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNo ratings yet

- Bystar Datasheet Eng OriginalDocument2 pagesBystar Datasheet Eng OriginalAmer FatićNo ratings yet

- Cutting Know HowDocument18 pagesCutting Know Howlugarx100% (1)

- Press BrakesDocument19 pagesPress Brakeszivkovic brankoNo ratings yet

- Casing LeatherDocument3 pagesCasing LeatherPeter DrummenNo ratings yet

- Assembly ProcessDocument169 pagesAssembly Processlabo123No ratings yet

- 6 - Durma Laser User InterfaceDocument30 pages6 - Durma Laser User Interfacesciuc0% (1)

- 05 01 Bytubework V01 enDocument14 pages05 01 Bytubework V01 enVojkan MilenovicNo ratings yet

- Brake Applications CatalogDocument159 pagesBrake Applications Catalogvidarlovik100% (1)

- Help Tops 1130Document312 pagesHelp Tops 1130telonic2006No ratings yet

- FIBER LASER TechnologiesDocument30 pagesFIBER LASER Technologieschathuranga chandrasekaraNo ratings yet

- The Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalDocument1 pageThe Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalSM TECH SRLNo ratings yet

- Quick Guide To Bysoft 7: Installation Installation Designer DesignerDocument1 pageQuick Guide To Bysoft 7: Installation Installation Designer DesignerGunnie PandherNo ratings yet

- TRUMPF Bending Tools Catalog EN PDFDocument261 pagesTRUMPF Bending Tools Catalog EN PDFjulio xNo ratings yet

- ByStar Fiber Datasheet Eng OriginalDocument2 pagesByStar Fiber Datasheet Eng OriginalDamir Merima MuslicNo ratings yet

- TruBend enDocument24 pagesTruBend endg_lentzNo ratings yet

- Adjustment Oscillator and Regulator Board: 1. Adjusting The OffsetDocument5 pagesAdjustment Oscillator and Regulator Board: 1. Adjusting The OffsetRomanProfilNo ratings yet

- Laser Machine ManualDocument110 pagesLaser Machine ManualmokaNo ratings yet

- Eng - DNM Ii - 1401 - Su - E20Document20 pagesEng - DNM Ii - 1401 - Su - E20Nikolat840% (1)

- 2361Document103 pages2361Alen AnušićNo ratings yet

- 1325 Portable CNC Cutting MachineDocument9 pages1325 Portable CNC Cutting MachineJorge Ligeti LandersNo ratings yet

- Top Solid Cam 2006 UsDocument12 pagesTop Solid Cam 2006 Usapi-3725036100% (2)

- Metalix Cnckad Brochure PDFDocument2 pagesMetalix Cnckad Brochure PDFSuwandi LimNo ratings yet

- Countersink Tool Downward - WZ19enDocument10 pagesCountersink Tool Downward - WZ19enBebe Ionuț AnițaNo ratings yet

- AS ING Rev0 PDFDocument38 pagesAS ING Rev0 PDFNguyen Quyet ThangNo ratings yet

- Mpr4x Format UsDocument65 pagesMpr4x Format UsLucas PegasNo ratings yet

- Econoline Sandblasting CatalogDocument20 pagesEconoline Sandblasting Catalogcoke31No ratings yet

- Quotation Form: Camso LoadstarDocument1 pageQuotation Form: Camso Loadstarchathuranga chandrasekaraNo ratings yet

- Library Bending TechnologyDocument103 pagesLibrary Bending TechnologyTrilok Chand Gupta100% (1)

- Top Solid Integration 2003 UsDocument12 pagesTop Solid Integration 2003 Usapi-3725036No ratings yet

- Multiblade MachiningDocument41 pagesMultiblade Machiningwilian_carNo ratings yet

- Preparation For The Fiber Laser Machine InstallationDocument2 pagesPreparation For The Fiber Laser Machine InstallationLuis Fernando ValenciaNo ratings yet

- BySmart Fiber (New) Datasheet Eng OriginalDocument2 pagesBySmart Fiber (New) Datasheet Eng Originalaaa a sadNo ratings yet

- Quotation For Fiber Laser Cutting Machines 4 KW: NF - PRO 315 VentoDocument25 pagesQuotation For Fiber Laser Cutting Machines 4 KW: NF - PRO 315 VentobeemasundarNo ratings yet

- Bend TrainingDocument4 pagesBend TrainingbdaneshvarNo ratings yet

- Userguide en SmallDocument142 pagesUserguide en Smallrudolf_laszlokNo ratings yet

- CNC Machine Tools and Control SystemsDocument39 pagesCNC Machine Tools and Control Systemsp_a_jeevaNo ratings yet

- 350 Laser Machine Operating ManualDocument109 pages350 Laser Machine Operating ManualLee RomanNo ratings yet

- BCL MUser Manual Bodor Laser PDFDocument38 pagesBCL MUser Manual Bodor Laser PDFJose LozanoNo ratings yet

- Haas Mill WIPS Probe Training ManualDocument44 pagesHaas Mill WIPS Probe Training ManualpocerilloNo ratings yet

- 96ENSIS AJ 3kW - Fibre Laser Cutting MachineDocument8 pages96ENSIS AJ 3kW - Fibre Laser Cutting MachineXuan Phuong HuynhNo ratings yet

- SolidCAM 2014 IMachining Training CourseDocument222 pagesSolidCAM 2014 IMachining Training Coursesammy stiltner100% (1)

- TruServices Ersatzteilkatalog 2014Document76 pagesTruServices Ersatzteilkatalog 2014alecandro_90No ratings yet

- Amada Turret PunchDocument9 pagesAmada Turret PunchPriyansh Tiwari100% (1)

- EDM Wire CutingDocument31 pagesEDM Wire Cutingmallpraxis100% (2)

- Plasma Arc Cutting System: Service Manual 802280 - Revision 4Document94 pagesPlasma Arc Cutting System: Service Manual 802280 - Revision 4jr100% (1)

- Wireedm ManualDocument110 pagesWireedm ManualJunaid YNo ratings yet

- Trumpf Tube Replacement Guide - English 2005Document12 pagesTrumpf Tube Replacement Guide - English 2005Amged KhattabNo ratings yet

- CNC Programming Systems PDFDocument22 pagesCNC Programming Systems PDFSurendra SainiNo ratings yet

- InTech-Optimization - of - Additive - Manufacturing - Processes - Focused - On - 3d - PrintingDocument29 pagesInTech-Optimization - of - Additive - Manufacturing - Processes - Focused - On - 3d - PrintingAndy De La CruzNo ratings yet

- Lantek Flex3d Steelwork 1p (EN-UK)Document2 pagesLantek Flex3d Steelwork 1p (EN-UK)LantekNo ratings yet

- Creative Woodworks & Crafts-097-2004-01Document104 pagesCreative Woodworks & Crafts-097-2004-01Peter Drummen83% (6)

- Manual - FX UniversalDocument13 pagesManual - FX UniversalPeter Drummen100% (1)

- ThermocouplesDocument8 pagesThermocouplesRakesh NayakNo ratings yet

- Vietnam Manufacturing Supporting Industry Yearbook 2014 2015Document211 pagesVietnam Manufacturing Supporting Industry Yearbook 2014 2015Pike Andrew100% (1)

- Flow Forming of Thin-Walled Precision ShellsDocument16 pagesFlow Forming of Thin-Walled Precision Shellsehtisham khanNo ratings yet

- Automotive SectorV2 PDFDocument34 pagesAutomotive SectorV2 PDFashuNo ratings yet

- Handout-8a-Metal Forming BasicDocument23 pagesHandout-8a-Metal Forming BasicAmardhianaNo ratings yet

- Harvester and Slasher Bars: The Legend ReturnsDocument8 pagesHarvester and Slasher Bars: The Legend Returnsmauricio1barrientos1No ratings yet

- Steel Data ChartDocument2 pagesSteel Data Chartsmartcad60No ratings yet

- Metal SizesDocument2 pagesMetal Sizesjohnphilip1No ratings yet

- Free Form Origami TessellationsDocument10 pagesFree Form Origami TessellationsSegundo DeferrariNo ratings yet

- SAE J1392-2001 Stabilized 2017Document10 pagesSAE J1392-2001 Stabilized 2017ALEX MURPHYNo ratings yet

- Design Study of Progressive Tool DesignDocument34 pagesDesign Study of Progressive Tool Designsudheer9289% (9)

- Method Statement With Jsa For Heat Insulation Work (Final) (12-08-2019)Document56 pagesMethod Statement With Jsa For Heat Insulation Work (Final) (12-08-2019)Pradip PaulNo ratings yet

- Glysantin G48: Data SheetDocument4 pagesGlysantin G48: Data SheetninzauNo ratings yet

- Rule 17 - Sheet Metal Paint Spray Booths (Book Format)Document2 pagesRule 17 - Sheet Metal Paint Spray Booths (Book Format)Thea Abelardo100% (1)

- Yamaha - Training & Dev. Quality ControlDocument119 pagesYamaha - Training & Dev. Quality ControlSami Zama100% (1)

- ER308 Weld Wire 2 PDFDocument2 pagesER308 Weld Wire 2 PDFJ. BangjakNo ratings yet

- Wilson Tool Trumpf Forming Tools - HP and BasixDocument7 pagesWilson Tool Trumpf Forming Tools - HP and BasixSM TECH SRLNo ratings yet

- Actcut-Laser enDocument2 pagesActcut-Laser ensathiya priyaNo ratings yet

- An Introduction To Pro/SHEETMETAL: A Project Based ApproachDocument47 pagesAn Introduction To Pro/SHEETMETAL: A Project Based ApproachMirek BlaszkoNo ratings yet

- Catalog - PL Mounting System and CarportDocument2 pagesCatalog - PL Mounting System and CarportLaura WuNo ratings yet

- Company Profile Sapphire Auto TechDocument8 pagesCompany Profile Sapphire Auto Techmayank0738No ratings yet

- Tononoka. Company Profile Product CatalogueDocument32 pagesTononoka. Company Profile Product CatalogueInsta PumpsNo ratings yet

- Nepal School BuildingDocument10 pagesNepal School BuildingRaj PalNo ratings yet

- Mechanical One Line NotesDocument35 pagesMechanical One Line NotesVikky DhapodkarNo ratings yet

- Joglekar Estimating and ValuationDocument133 pagesJoglekar Estimating and Valuationrafay100% (1)

- Mutual Industries LTD - CorporateDocument40 pagesMutual Industries LTD - CorporateKool LeisureNo ratings yet

- Magna-505-Display InforDocument2 pagesMagna-505-Display InforLee Chong EeNo ratings yet

- MTS TurningDocument62 pagesMTS TurningCnc Page100% (2)

- D 1748 PDFDocument9 pagesD 1748 PDFyuliaNo ratings yet