Professional Documents

Culture Documents

LV AL Cables

Uploaded by

rocky198255Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LV AL Cables

Uploaded by

rocky198255Copyright:

Available Formats

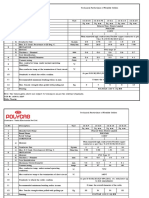

LV 2C AL

DESCRIPTION UNIT REFERENCE 2C X 16 2C X 25 2C X 35 2C X 50 2C X 70 2C X 95 2C X 120 2C X 150 2C X 185

1 Name of Manufacturer #

2 Manufacturing Process CCV/VCV

3 Cable Type A2XWy / A2XFy

4 No. of Conductors 2

5 Applicable Indian Standard #

6 Voltage Grade kV 1.1

7 Permissible Voltage &Frequency Variation for Satisfactory operation ±10%, ±5%

8 Max.rated conductor temp for cont. operation °C 90°C

9 Max.allowable conductor temp.during short circuit °C 250°C

10 Continuous current carrying capacity When Laid in

a) In air A #

b) In Ground A #

c) In duct A #

11 CONDUCTOR

i) Material -- Aluminium

ii) Shape -- Stranded Circular or sector shaped

iii) Cross Sectional area

a) Main conductor mm2 #

b) Neutral conductor mm2 #

iv) Number & Dia of wires mm #

12 INSULATION

i) Material XLPE

ii) Nominal Thickness of insulation

a) Main core mm #

b) Neutral core mm #

iii) Calculated dia over Insulation mm #

13 Calculated laid up diameter mm #

14 INNER SHEATH

i) Material PVC

ii) Extruded or wrapped Extruded

iii) Min. Thickness mm #

iv) Calculated dia over Inner Sheath mm #

15 ARMOUR

i) Material Galvanised Steel

ii) Type of Armouring Round Wires or strips

iii) Nom.Strip

iv) Minimum thickness mm #

v) Calculated dia over armour mm #

vi)Short Ckt. Withstand Capacity kA/Sec #

16 OUTER SHEATH

i) Material PVC FR

ii) Nom.Thickness mm #

17 Appr.Overall Dia. Of Cable mm #

18 Appr.Weight of Cable kg/km #

19 I)Drum Material Steel

II)Max. Length of cable per drum m #

(Tolerance of +3% M) NO NEGATIVE TOLERANCE

20 Recommended min.Bending radious mm #

21 Recommended temp. below which installation of cable should not be carried out #

22 Marking on cables and cable drums as per MR #

23 Design Life #

24 Loss Tangent at 20 °C #

25 Max. Tensile strength #

i) for Cables pulled with stocking Kg #

ii) for Cables pulled with pulling eyes Kg #

Electrical Parameters

26 Short ckt. Current for 1 Sec kA #

27 Max. DC Resistance at 20 °C

a) Main Conductor Ohm/km #

b) Neutral Conductor Ohm/km #

28 Max.AC Resistance at 90 °C Ohm/km #

29 Calculated Star Reactance Ohm/km #

30 Calculated Impedence Ohm/km #

31 Appr.Capacitance mfd/km #

32 Insulation Resistance at 20 °C kΩ #

33 FR Propetrties on outer sheath

Critical Oxygen Index Min. 29%

Temparature Index °C Min. 250 °C

NOTE: " # " - Vendor to furnish as per IS Page 1 of 7

LV 3C AL

DESCRIPTION UNIT REFERENCE 3C X 16 3C X 25 3C X 35 3C X 50 3C X 70 3C X 95 3C X 120 3C X 150 3C X 185 3C X 240 3C X 300

1 Name of Manufacturer #

2 Manufacturing Process CCV/VCV

3 Cable Type A2XWy / A2XFy

4 No. of Conductors 3

5 Applicable Indian Standard #

6 Voltage Grade kV 1.1

7 Permissible Voltage &Frequency Variation for Satisfactory operation ±10%, ±5%

8 Max.rated conductor temp for cont. operation °C 90°C

9 Max.allowable conductor temp.during short circuit °C 250°C

10 Continuous current carrying capacity When Laid in

a) In air A #

b) In Ground A #

c) In duct A #

11 CONDUCTOR

i) Material -- Aluminium

Stranded Circular or sector

ii) Shape --

shaped

iii) Cross Sectional area

a) Main conductor mm2 #

b) Neutral conductor mm2 #

iv) Number & Dia of wires mm #

12 INSULATION

i) Material XLPE

ii) Nominal Thickness of insulation

a) Main core mm #

b) Neutral core mm #

iii) Calculated dia over Insulation mm #

13 Calculated laid up diameter mm #

14 INNER SHEATH

i) Material PVC

ii) Extruded or wrapped Extruded

iii) Min. Thickness mm #

iv) Calculated dia over Inner Sheath mm #

15 ARMOUR

i) Material Galvanised Steel

Single Layer/Double Layer, Round

ii) Type of Armouring

Wires/ strips

iii) Nom.Strip

iv) Minimum thickness mm #

v) Calculated dia over armour mm #

vi)Short Ckt. Withstand Capacity kA/Sec #

16 OUTER SHEATH

i) Material PVC FR

ii) Nom.Thickness mm #

17 Appr.Overall Dia. Of Cable mm #

18 Appr.Weight of Cable kg/km #

19 I)Drum Material Steel

II)Max. Length of cable per drum m #

(Tolerance of +3% M) NO NEGATIVE TOLERANCE

20 Recommended min.Bending radious mm #

21 Recommended temp. below which installation of cable should not be carried out #

22 Marking on cables and cable drums as per MR #

23 Design Life #

24 Loss Tangent at 20 °C #

25 Max. Tensile strength #

i) for Cables pulled with stocking Kg #

ii) for Cables pulled with pulling eyes Kg #

Electrical Parameters

26 Short ckt. Current for 1 Sec kA #

27 Max. DC Resistance at 20 °C

a) Main Conductor Ohm/km #

b) Neutral Conductor Ohm/km #

28 Max.AC Resistance at 90 °C Ohm/km #

29 Calculated Star Reactance Ohm/km #

30 Calculated Impedence Ohm/km #

31 Appr.Capacitance mfd/km #

32 Insulation Resistance at 20 °C kΩ #

33 FR Propetrties on outer sheath

Critical Oxygen Index Min. 29%

Temparature Index °C Min. 250 °C

NOTE: " # " - Vendor to furnish as per IS Page 2 of 7

LV 3C AL

DESCRIPTION 3C X 400

1 Name of Manufacturer

2 Manufacturing Process

3 Cable Type

4 No. of Conductors

5 Applicable Indian Standard

6 Voltage Grade

7 Permissible Voltage &Frequency Variation for Satisfactory operation

8 Max.rated conductor temp for cont. operation

9 Max.allowable conductor temp.during short circuit

10 Continuous current carrying capacity When Laid in

a) In air

b) In Ground

c) In duct

11 CONDUCTOR

i) Material --

ii) Shape --

iii) Cross Sectional area

a) Main conductor

b) Neutral conductor

iv) Number & Dia of wires

12 INSULATION

i) Material

ii) Nominal Thickness of insulation

a) Main core

b) Neutral core

iii) Calculated dia over Insulation

13 Calculated laid up diameter

14 INNER SHEATH

i) Material

ii) Extruded or wrapped

iii) Min. Thickness

iv) Calculated dia over Inner Sheath

15 ARMOUR

i) Material

ii) Type of Armouring

iii) Nom.Strip

iv) Minimum thickness

v) Calculated dia over armour

vi)Short Ckt. Withstand Capacity

16 OUTER SHEATH

i) Material

ii) Nom.Thickness

17 Appr.Overall Dia. Of Cable

18 Appr.Weight of Cable

19 I)Drum Material

II)Max. Length of cable per drum

(Tolerance of +3% M) NO NEGATIVE TOLERANCE

20 Recommended min.Bending radious

21 Recommended temp. below which installation of cable should not be carried out

22 Marking on cables and cable drums as per MR

23 Design Life

24 Loss Tangent at 20 °C

25 Max. Tensile strength

i) for Cables pulled with stocking

ii) for Cables pulled with pulling eyes

Electrical Parameters

26 Short ckt. Current for 1 Sec

27 Max. DC Resistance at 20 °C

a) Main Conductor

b) Neutral Conductor

28 Max.AC Resistance at 90 °C

29 Calculated Star Reactance

30 Calculated Impedence

31 Appr.Capacitance

32 Insulation Resistance at 20 °C

33 FR Propetrties on outer sheath

Critical Oxygen Index

Temparature Index

NOTE: " # " - Vendor to furnish as per IS Page 3 of 7

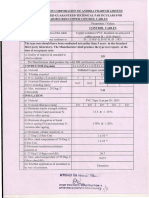

LV 3.5C AL

DESCRIPTION UNIT REFERENCE 3.5C X 25 3.5C X 35 3.5C X 50 3.5C X 70 3.5C X 95 3.5C X 120 3.5C X 150 3.5C X 185 3.5C X 240 3.5C X 300 3.5C X 400

1 Name of Manufacturer #

2 Manufacturing Process CCV/VCV

3 Cable Type A2XWy / A2XFy

4 No. of Conductors 3.5

5 Applicable Indian Standard #

6 Voltage Grade kV 1.1

7 Permissible Voltage &Frequency Variation for Satisfactory operation ±10%, ±5%

8 Max.rated conductor temp for cont. operation °C 90°C

9 Max.allowable conductor temp.during short circuit °C 250°C

10 Continuous current carrying capacity When Laid in

a) In air A #

b) In Ground A #

c) In duct A #

11 CONDUCTOR

i) Material -- Aluminium

Stranded Circular or

ii) Shape --

sector shaped

iii) Cross Sectional area

a) Main conductor mm2 #

b) Neutral conductor mm2 #

iv) Number & Dia of wires mm #

12 INSULATION

i) Material XLPE

ii) Nominal Thickness of insulation

a) Main core mm #

b) Neutral core mm #

iii) Calculated dia over Insulation mm #

13 Calculated laid up diameter mm #

14 INNER SHEATH

i) Material PVC

ii) Extruded or wrapped Extruded

iii) Min. Thickness mm #

iv) Calculated dia over Inner Sheath mm #

15 ARMOUR

i) Material Galvanised Steel

Single Layer/Double

ii) Type of Armouring Layer, Round Wires/

strips

iii) Nom.Strip

iv) Minimum thickness mm #

v) Calculated dia over armour mm #

vi)Short Ckt. Withstand Capacity kA/Sec #

16 OUTER SHEATH

i) Material PVC FR

ii) Nom.Thickness mm #

17 Appr.Overall Dia. Of Cable mm #

18 Appr.Weight of Cable kg/km #

19 I)Drum Material Steel

II)Max. Length of cable per drum m #

(Tolerance of +3% M) NO NEGATIVE TOLERANCE

20 Recommended min.Bending radious mm #

21 Recommended temp. below which installation of cable should not be carried out #

22 Marking on cables and cable drums as per MR #

23 Design Life #

24 Loss Tangent at 20 °C #

25 Max. Tensile strength #

i) for Cables pulled with stocking Kg #

ii) for Cables pulled with pulling eyes Kg #

Electrical Parameters

26 Short ckt. Current for 1 Sec kA #

27 Max. DC Resistance at 20 °C

a) Main Conductor Ohm/km #

b) Neutral Conductor Ohm/km #

28 Max.AC Resistance at 90 °C Ohm/km #

29 Calculated Star Reactance Ohm/km #

30 Calculated Impedence Ohm/km #

31 Appr.Capacitance mfd/km #

32 Insulation Resistance at 20 °C kΩ #

33 FR Propetrties on outer sheath

Critical Oxygen Index Min. 29%

Temparature Index °C Min. 250 °C

NOTE: " # " - Vendor to furnish as per IS Page 4 of 7

LV 4C AL

DESCRIPTION UNIT REFERENCE 4C X 16 4C X 25 4C X 35 4C X 50 4C X 70 4C X 95 4C X 120 4C X 150

1 Name of Manufacturer #

2 Manufacturing Process CCV/VCV

3 Cable Type A2XWy / A2XFy

4 No. of Conductors 4

5 Applicable Indian Standard #

6 Voltage Grade kV 1.1

7 Permissible Voltage &Frequency Variation for Satisfactory operation ±10%, ±5%

8 Max.rated conductor temp for cont. operation °C 90°C

9 Max.allowable conductor temp.during short circuit °C 250°C

10 Continuous current carrying capacity When Laid in

a) In air A #

b) In Ground A #

c) In duct A #

11 CONDUCTOR

i) Material -- Aluminium

Stranded Circular or sector

ii) Shape --

shaped

iii) Cross Sectional area

a) Main conductor mm2 #

b) Neutral conductor mm2 #

iv) Number & Dia of wires mm #

12 INSULATION

i) Material XLPE

ii) Nominal Thickness of insulation

a) Main core mm #

b) Neutral core mm #

iii) Calculated dia over Insulation mm #

13 Calculated laid up diameter mm #

14 INNER SHEATH

i) Material PVC

ii) Extruded or wrapped Extruded

iii) Min. Thickness mm #

iv) Calculated dia over Inner Sheath mm #

15 ARMOUR

i) Material Galvanised Steel

ii) Type of Armouring Round Wires or strips

iii) Nom.Strip

iv) Minimum thickness mm #

v) Calculated dia over armour mm #

vi)Short Ckt. Withstand Capacity kA/Sec #

16 OUTER SHEATH

i) Material PVC FR

ii) Nom.Thickness mm #

17 Appr.Overall Dia. Of Cable mm #

18 Appr.Weight of Cable kg/km #

19 I)Drum Material Steel

II)Max. Length of cable per drum m #

(Tolerance of +3% M) NO NEGATIVE TOLERANCE

20 Recommended min.Bending radious mm #

21 Recommended temp. below which installation of cable should not be carried out #

22 Marking on cables and cable drums as per MR #

23 Design Life #

24 Loss Tangent at 20 °C #

25 Max. Tensile strength #

i) for Cables pulled with stocking Kg #

ii) for Cables pulled with pulling eyes Kg #

Electrical Parameters

26 Short ckt. Current for 1 Sec kA #

27 Max. DC Resistance at 20 °C

a) Main Conductor Ohm/km #

b) Neutral Conductor Ohm/km #

28 Max.AC Resistance at 90 °C Ohm/km #

29 Calculated Star Reactance Ohm/km #

30 Calculated Impedence Ohm/km #

31 Appr.Capacitance mfd/km #

32 Insulation Resistance at 20 °C kΩ #

33 FR Propetrties on outer sheath

Critical Oxygen Index Min. 29%

Temparature Index °C Min. 250 °C

NOTE: " # " - Vendor to furnish as per IS Page 5 of 7

LV 1C AL AMOURED

DESCRIPTION UNIT REFERENCE 1C X 240 1C X 300 1C X 400 1C X 630 1C X 1000

1 Name of Manufacturer #

2 Manufacturing Process CCV/VCV

A2XWay/A2XWaWay/A

3 Cable Type

2XFay/A2XFay

4 No. of Conductors 1

5 Applicable Indian Standard #

6 Voltage Grade kV 0.66

7 Permissible Voltage &Frequency Variation for Satisfactory operation ±10%, ±5%

8 Max.rated conductor temp for cont. operation °C 90°C

9 Max.allowable conductor temp.during short circuit °C 250°C

10 Continuous current carrying capacity When Laid in

a) In air A #

b) In Ground A #

c) In duct A #

11 CONDUCTOR

i) Material -- Aluminium

Stranded Circular or

ii) Shape --

sector shaped

iii) Cross Sectional area

a) Main conductor mm2 #

b) Neutral conductor mm2 #

iv) Number & Dia of wires mm #

12 INSULATION

i) Material XLPE

ii) Nominal Thickness of insulation

a) Main core mm #

b) Neutral core mm #

iii) Calculated dia over Insulation mm #

13 Calculated laid up diameter mm #

14 INNER SHEATH

i) Material NA

ii) Extruded or wrapped NA

iii) Min. Thickness mm NA

iv) Calculated dia over Inner Sheath mm NA

15 ARMOUR

i) Material Aluminum

Single Layer or Double

ii) Type of Armouring

Layer Round Wires

iii) Nom.Strip

iv) Minimum thickness mm #

v) Calculated dia over armour mm #

vi)Short Ckt. Withstand Capacity kA/Sec #

16 OUTER SHEATH

i) Material PVC FR black colored

ii) Nom.Thickness mm #

17 Appr.Overall Dia. Of Cable mm #

18 Appr.Weight of Cable kg/km #

19 I)Drum Material Steel

II)Max. Length of cable per drum m #

(Tolerance of +3% M) NO NEGATIVE TOLERANCE

20 Recommended min.Bending radious mm #

21 Recommended temp. below which installation of cable should not be carried out #

22 Marking on cables and cable drums as per MR #

23 Design Life #

24 Loss Tangent at 20 °C #

25 Max. Tensile strength #

i) for Cables pulled with stocking Kg #

ii) for Cables pulled with pulling eyes Kg #

Electrical Parameters

26 Short ckt. Current for 1 Sec kA #

27 Max. DC Resistance at 20 °C

a) Main Conductor Ohm/km #

b) Neutral Conductor Ohm/km #

28 Max.AC Resistance at 90 °C Ohm/km #

29 Calculated Star Reactance Ohm/km #

30 Calculated Impedence Ohm/km #

31 Appr.Capacitance mfd/km #

32 Insulation Resistance at 20 °C kΩ #

33 FR Propetrties on outer sheath

Critical Oxygen Index Min. 29%

Temparature Index °C Min. 250 °C

NOTE: " # " - Vendor to furnish as per IS Page 6 of 7

LV 1C AL UNARMOURD

DESCRIPTION UNIT REFERENCE 1C X 16 1C X 25 1C X 35 1C X 50 1C X 70 1C X 95 1C X 150 1C X 185 1C X 240

1 Name of Manufacturer #

2 Manufacturing Process CCV/VCV

3 Cable Type AYy

4 No. of Conductors 1

5 Applicable Indian Standard #

6 Voltage Grade kV 0.66

7 Permissible Voltage &Frequency Variation for Satisfactory operation ±10%, ±5%

8 Max.rated conductor temp for cont. operation °C 90°C

9 Max.allowable conductor temp.during short circuit °C 250°C

10 Continuous current carrying capacity When Laid in

a) In air A #

b) In Ground A #

c) In duct A #

11 CONDUCTOR

i) Material -- Aluminium

Stranded Circular or

ii) Shape --

sector shaped

iii) Cross Sectional area

a) Main conductor mm2 #

b) Neutral conductor mm2 #

iv) Number & Dia of wires mm #

12 INSULATION

i) Material XLPE

ii) Nominal Thickness of insulation

a) Main core mm #

b) Neutral core mm #

iii) Calculated dia over Insulation mm #

13 Calculated laid up diameter mm #

14 INNER SHEATH

i) Material NA

ii) Extruded or wrapped NA

iii) Min. Thickness mm NA

iv) Calculated dia over Inner Sheath mm NA

15 ARMOUR NA

i) Material NA

ii) Type of Armouring NA

iii) Nom.Strip NA

iv) Minimum thickness mm NA

v) Calculated dia over armour mm NA

vi)Short Ckt. Withstand Capacity kA/Sec NA

16 OUTER SHEATH

PVC FR Green Colored

i) Material

with Yellow Strip

ii) Nom.Thickness mm #

17 Appr.Overall Dia. Of Cable mm #

18 Appr.Weight of Cable kg/km #

19 I)Drum Material Steel

II)Max. Length of cable per drum m #

(Tolerance of +3% M) NO NEGATIVE TOLERANCE

20 Recommended min.Bending radious mm #

21 Recommended temp. below which installation of cable should not be carried out #

22 Marking on cables and cable drums as per MR #

23 Design Life #

24 Loss Tangent at 20 °C #

25 Max. Tensile strength #

i) for Cables pulled with stocking Kg #

ii) for Cables pulled with pulling eyes Kg #

Electrical Parameters

26 Short ckt. Current for 1 Sec kA #

27 Max. DC Resistance at 20 °C

a) Main Conductor Ohm/km #

b) Neutral Conductor Ohm/km #

28 Max.AC Resistance at 90 °C Ohm/km #

29 Calculated Star Reactance Ohm/km #

30 Calculated Impedence Ohm/km #

31 Appr.Capacitance mfd/km #

32 Insulation Resistance at 20 °C kΩ #

33 FR Propetrties on outer sheath

Critical Oxygen Index Min. 29%

Temparature Index °C Min. 250 °C

NOTE: " # " - Vendor to furnish as per IS Page 7 of 7

You might also like

- Cable GTPDocument1 pageCable GTPAnwar HussainNo ratings yet

- GTP - 1.1kv 1c Copper Xlpe Armd CableDocument1 pageGTP - 1.1kv 1c Copper Xlpe Armd CableShivam DwivediNo ratings yet

- TDS-Solar CableDocument1 pageTDS-Solar CableJaks JaksNo ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- 1C 500 MM (A2xHSYRa2Y) 18 30 (36) KV CABLESDocument3 pages1C 500 MM (A2xHSYRa2Y) 18 30 (36) KV CABLESanamulk-1No ratings yet

- 11kV AbcDocument2 pages11kV AbcJeetendra Dev ChhetriNo ratings yet

- Puvvnl GTPDocument3 pagesPuvvnl GTPshivam dwivediNo ratings yet

- GTP atDocument3 pagesGTP atdeepanshu singh vishenNo ratings yet

- Technical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataDocument4 pagesTechnical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataNikhil KarkeraNo ratings yet

- Technical Data Sheets & Cross Sectional Details of 33kV XLPE CablesDocument4 pagesTechnical Data Sheets & Cross Sectional Details of 33kV XLPE CablesRamaKrishna ANo ratings yet

- 33 KV Single Core Copper XLPE CableDocument3 pages33 KV Single Core Copper XLPE CableSai KumarNo ratings yet

- GTP-LT-AB-CableDocument3 pagesGTP-LT-AB-Cablesandeep kumar pattnaikNo ratings yet

- LVIS09CXSFYL004C010SA001SDocument1 pageLVIS09CXSFYL004C010SA001Ssuvir VigneshNo ratings yet

- Thermocouple Cable: Guaranteed Technical Particulars 382500621BDocument2 pagesThermocouple Cable: Guaranteed Technical Particulars 382500621Bmohan babuNo ratings yet

- GTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding CableDocument1 pageGTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding Cableshivam dwivedi100% (1)

- LT XLPE Cable Technical DataDocument1 pageLT XLPE Cable Technical DataVishal SharmaNo ratings yet

- 8.06.1 GTP - 33 KV Off-Load Isolator Without EarthDocument2 pages8.06.1 GTP - 33 KV Off-Load Isolator Without EarthkaranNo ratings yet

- 16 X 1 Core Cu Flex FR Wire PDFDocument1 page16 X 1 Core Cu Flex FR Wire PDFChandu GowdaNo ratings yet

- 2c x1.5 FAS CableDocument1 page2c x1.5 FAS CableSanjay KumarNo ratings yet

- 1C 240 MM (NYYF-FRLS YYF-FRLS) 0.6 1.0 (1.2) KV CABLESDocument2 pages1C 240 MM (NYYF-FRLS YYF-FRLS) 0.6 1.0 (1.2) KV CABLESanamulk-1No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Anonymous SDeSP1No ratings yet

- Datasheet CableDocument2 pagesDatasheet CableVyrax FalconNo ratings yet

- 132KV TRANSMISSION LINE SPECIFICATIONDocument259 pages132KV TRANSMISSION LINE SPECIFICATIONravindra50% (2)

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVBS09CXSWY2003C004SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVBS09CXSWY2003C004SA002S Date: Rev No.bharathNo ratings yet

- 33 KV 3 Core Aluminium XLPE CableDocument3 pages33 KV 3 Core Aluminium XLPE CableSai KumarNo ratings yet

- Polycab 2C X 4 SQMMDocument1 pagePolycab 2C X 4 SQMMHiteshChauhanNo ratings yet

- Polycab 16mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 16mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- LT XLPE Cable Data SheetDocument2 pagesLT XLPE Cable Data SheetAteebNo ratings yet

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- 0 5PX1CBLKFLX100Document4 pages0 5PX1CBLKFLX100P.p. Arul IlancheeranNo ratings yet

- Polycab Wire PDFDocument4 pagesPolycab Wire PDFMAYUR GENSETNo ratings yet

- Polycab WireDocument4 pagesPolycab WireMAYUR GENSET100% (1)

- Polycab Wire PDFDocument4 pagesPolycab Wire PDFMAYUR GENSET100% (1)

- 1.5sqmm X 3C Arm DatasheetDocument2 pages1.5sqmm X 3C Arm DatasheetAshwin SupeNo ratings yet

- GTP For DPDC HTDocument2 pagesGTP For DPDC HTjamilNo ratings yet

- CMIT 796 ELE 15.17!10!0010 - 0 - Data Sheet For PowerDocument4 pagesCMIT 796 ELE 15.17!10!0010 - 0 - Data Sheet For PowerELE FutureWillNo ratings yet

- Spec NYFGbY 4 X 10, 4 X 50, 4 X 70, 4 X 95Document6 pagesSpec NYFGbY 4 X 10, 4 X 50, 4 X 70, 4 X 95zaki mubarrokNo ratings yet

- 10X4 A2xfy Alum - ArmdDocument2 pages10X4 A2xfy Alum - ArmdParth DhobiNo ratings yet

- Technical Particulars of HT XLPE CablesDocument3 pagesTechnical Particulars of HT XLPE CablesManohar Potnuru100% (1)

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.rajesh1200100% (1)

- Data Sheet Control CableDocument1 pageData Sheet Control CableGunturNo ratings yet

- 220kv 132kv Unarmoured CablesDocument3 pages220kv 132kv Unarmoured CablesArif AhmedNo ratings yet

- 0.75PX1TSCNARMDDocument2 pages0.75PX1TSCNARMDnmpkumarNo ratings yet

- FRLS 1.5 X 2 CoreDocument1 pageFRLS 1.5 X 2 CorerhladiNo ratings yet

- FICHA TECNICA - 3X 35+50 SQ - MM AB CableDocument1 pageFICHA TECNICA - 3X 35+50 SQ - MM AB Cablejohana leonNo ratings yet

- Specification for 3kV Bonding and Earth Continuity CableDocument4 pagesSpecification for 3kV Bonding and Earth Continuity Cablebachtiar ramadhanNo ratings yet

- Nexans_Anti-Theft-Power-Cable-PVC-in...Document5 pagesNexans_Anti-Theft-Power-Cable-PVC-in...abdulkawi alasharyNo ratings yet

- Fsis09cxswyl004c006sa (FR LSH)Document1 pageFsis09cxswyl004c006sa (FR LSH)pkNo ratings yet

- LT Shackle Insulators SpecificationDocument4 pagesLT Shackle Insulators SpecificationJayapriya PNo ratings yet

- 16PX1CYELFLX100Document1 page16PX1CYELFLX100kavin bhagavathy100% (1)

- 4C X 10 EPR PCP Rubber GTPDocument1 page4C X 10 EPR PCP Rubber GTPsyamprasadNo ratings yet

- CMP A2Document1 pageCMP A2mohd darusNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22No ratings yet

- Cable Tray & Conduit SizingDocument2 pagesCable Tray & Conduit SizingSavy PhanethNo ratings yet

- CMP Products Cable Gland CatalogueDocument1 pageCMP Products Cable Gland CataloguemiftahNo ratings yet

- CMP A2 Single Seal Industrial Cable Gland-AKBAR TRADINGDocument1 pageCMP A2 Single Seal Industrial Cable Gland-AKBAR TRADINGGIBUNo ratings yet

- YyyDocument2 pagesYyyŽarko MočnikNo ratings yet

- CSC-XII 1 C Is 7098 Part 2Document8 pagesCSC-XII 1 C Is 7098 Part 2Ashish bhattNo ratings yet

- Cable GTPDocument1 pageCable GTPtukaram.pawarNo ratings yet

- Basic EE AssignmentDocument5 pagesBasic EE AssignmentJohn Arvin EscoteNo ratings yet

- 2019 Higher School Certificate Year 11 Yearly Examination PhysicsDocument11 pages2019 Higher School Certificate Year 11 Yearly Examination PhysicsSyed Hasan100% (1)

- Met 2019Document9 pagesMet 2019nellaiNo ratings yet

- Sensors 18 03445 PDFDocument23 pagesSensors 18 03445 PDFadfasfdafssafNo ratings yet

- APS FM305-ELC - printer-ELoad-cutter-3-inch PDFDocument1 pageAPS FM305-ELC - printer-ELoad-cutter-3-inch PDFLaychoNo ratings yet

- Basic Ee Hw1Document2 pagesBasic Ee Hw1mon patrick pradoNo ratings yet

- Scicent AB TE U8 eDocument40 pagesScicent AB TE U8 erayckng2No ratings yet

- Power Cable SizingDocument8 pagesPower Cable SizingPagdi Srini100% (1)

- Installation Instructions: Model Icp-B6 Intelligent Control PointDocument8 pagesInstallation Instructions: Model Icp-B6 Intelligent Control PointMiguel CoronadoNo ratings yet

- Electrical Upgrading Course Review for Master ElectriciansDocument3 pagesElectrical Upgrading Course Review for Master ElectriciansMark John DrilonNo ratings yet

- Gen Physics Midterm ReviewerDocument13 pagesGen Physics Midterm ReviewerKiyoshi TakeuchiNo ratings yet

- Lect 1 IntroductionDocument57 pagesLect 1 IntroductionAqiaf Khan SikandriNo ratings yet

- Electrical Engineering Practice ProblemsDocument4 pagesElectrical Engineering Practice ProblemsJj JumawanNo ratings yet

- Camco DX BrochDocument6 pagesCamco DX BrochAhmedić-Kovačević KrigeNo ratings yet

- Resistors PDFDocument12 pagesResistors PDFNdambuki DicksonNo ratings yet

- Lineprotection 1600CT RatiDocument13 pagesLineprotection 1600CT RatiAnonymous W9VINoTzaNo ratings yet

- Lebanese International University School of EngineeringDocument12 pagesLebanese International University School of EngineeringHassan RashedNo ratings yet

- Sm50Txxay, Sm50Txxcay: Automotive 5000 W Tvs in SMCDocument15 pagesSm50Txxay, Sm50Txxcay: Automotive 5000 W Tvs in SMCUmesh KirantNo ratings yet

- Electricity Note DC Current PDFDocument8 pagesElectricity Note DC Current PDFSolomonNo ratings yet

- Position Control of A Pneumatic Levitation SystemDocument2 pagesPosition Control of A Pneumatic Levitation SystemJuan Jo MonrroyNo ratings yet

- HGT-1L V 1.1 - FinalDocument3 pagesHGT-1L V 1.1 - FinalAshwini PradhanNo ratings yet

- Electric Circuit CalculationsDocument28 pagesElectric Circuit Calculationsanon gg100% (1)

- Service Manual: Digital HD Video Camera RecorderDocument86 pagesService Manual: Digital HD Video Camera RecorderDanNo ratings yet

- Current LimitingDocument3 pagesCurrent Limitingmessage4guruNo ratings yet

- PO1541 - Ojas Infra - GSF MV TDS-v1.1Document16 pagesPO1541 - Ojas Infra - GSF MV TDS-v1.1Sanjay GadhaveNo ratings yet

- 3 1 5c Ohms Law WorksheetDocument3 pages3 1 5c Ohms Law Worksheetapi-291536841No ratings yet

- IR Insulation Resistance ValuesDocument11 pagesIR Insulation Resistance ValuesBenabidNo ratings yet

- PWR221T-30 Series Power Resistor: Features ApplicationsDocument4 pagesPWR221T-30 Series Power Resistor: Features ApplicationsVehid ParićNo ratings yet

- ALGEBRA FORMULAS AND CONCEPTSDocument151 pagesALGEBRA FORMULAS AND CONCEPTSjohn benedict orbeNo ratings yet

- Kakasa Ka Ba Sa B.E.EDocument5 pagesKakasa Ka Ba Sa B.E.EDennis DaleNo ratings yet