Professional Documents

Culture Documents

Papaya Clarified Frozen

Uploaded by

Sanjay RangrooCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Papaya Clarified Frozen

Uploaded by

Sanjay RangrooCopyright:

Available Formats

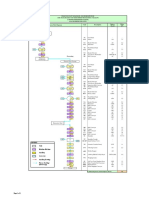

TRICOM AGROCHEM LIMITED Doc.No. TAL/QA/FC-10/00/01.10.

2009

HACCP - FLOW CHART FOR CLARIFIED PAPAYA JUICE CONCENTRATE Page 1 of 1

A1 Receiving of Citric / B1 1 Drum Opening & Cutting Ferrous Trap C1 Receiving of Packaging

Raw water OPRP-4

Ascorbic Acid 13 Material

A2 Clarifier B2 2 Pulp Feeding Tank 14 Sterilizer Balance Tank C2

Inspection & Testing Inspection and Storage

A3 QA Sample

10 Ltr UGR Tank

B3 3 Preheating , 15 Inline Filter (7 mm)

Storage VLO (B03) @ 45-50°C

OPRP-2

A4 Sand Filter

A 16

Pulp Treatment Tank Steritherm M6M

A5 ACF (20KL) E01(98-108°C)

4 CCP-1

IF RECYCLE

A6 A6.1 B

Decanter OPRP-5

5 17

Softner Potable Water Aseptic Filler E02

OPRP-3

QA Sample IF REWORK

Pulp Treatment Tank

A7 Soft Water 6

(20KL) Quick Freezing in Blast

A6.2 18 freezer and then transfer to

A8 Cold Storage@-18°c

Testing Testing Press Paper Filter

7

A6.3

Waste 19

A9 Storage Soft Water Pre-dispatch

Storage of Potable 8 Storage Tank (10 KL) CCP-2 Inspection

Water

A9

UV

Ultrafilteration Buffer Tank Dispatch (In Refrigerated

9 20 Containers, At or below-

C01

Preparation of QA Sample 18°C Only)

A10 Enzyme / Bentonite

Solution with Soft

Water 10 Ultrafilteration C04

OPRP-1

A11

Prepn of Enzyme Overnight Soaking 11 Alfavap (Double effect)

solutions in UV for Bentonite / Fresh D02 A

treated soft water prepn in warm water

12 Brix Balance Tank

A B

Prepared by Approved by Document Status

Food Safety Team Leader Plant Manager

You might also like

- Waste Water Flow SheetDocument7 pagesWaste Water Flow SheetWendra HakaNo ratings yet

- Process Flow Diagram and Horsepower for TSR 10/20 Grades Crumb Rubber Processing FacilityDocument1 pageProcess Flow Diagram and Horsepower for TSR 10/20 Grades Crumb Rubber Processing Facilityhenri joel jrNo ratings yet

- COBAS 6000: C501 Reagent Inventory MONTH/YEARDocument3 pagesCOBAS 6000: C501 Reagent Inventory MONTH/YEARCharmaine Corpuz GranilNo ratings yet

- Diagram alir proses pemurnian tebuDocument4 pagesDiagram alir proses pemurnian tebuMaulana Muhammad IqbalNo ratings yet

- Design of a 100 MTPD IPA and 50 MTPD Acetone Production PlantDocument18 pagesDesign of a 100 MTPD IPA and 50 MTPD Acetone Production PlantTamzidul AlamNo ratings yet

- April Water Balance ChartDocument1 pageApril Water Balance Charttej94No ratings yet

- Flow Chart Dairy & Cheese PowderDocument1 pageFlow Chart Dairy & Cheese PowderDion BrightNo ratings yet

- 106 Primeland, 2218 Market St. Madrigal Business Park, Ayala Alabang, Muntinlupa CityDocument2 pages106 Primeland, 2218 Market St. Madrigal Business Park, Ayala Alabang, Muntinlupa CityJelian GraceNo ratings yet

- Proceso CervezaDocument2 pagesProceso CervezaAngel Ivan Gonzalez MtzNo ratings yet

- C2 OkeDocument6 pagesC2 OkeEndah WinartiNo ratings yet

- Integrated Water Purification System (Type /type ) : Get Type Grade Water From Tap at ONCE !Document2 pagesIntegrated Water Purification System (Type /type ) : Get Type Grade Water From Tap at ONCE !berkahNo ratings yet

- Om012 - Waldnieler Fruit JuiceDocument4 pagesOm012 - Waldnieler Fruit JuiceshekharshindeNo ratings yet

- C391E078-Parts TOCVDocument32 pagesC391E078-Parts TOCVAnderson SilvaNo ratings yet

- A4coa PP19018597 165570-52489363Document14 pagesA4coa PP19018597 165570-52489363bbcdgg1234567No ratings yet

- Water Quality Report - Mr. G. Bharath Chandra, Karlapalem, 19-02-2024Document1 pageWater Quality Report - Mr. G. Bharath Chandra, Karlapalem, 19-02-2024Sai GopiNo ratings yet

- Flowchart AllDocument11 pagesFlowchart Allasri nurulNo ratings yet

- Mercury Contamination RisksDocument78 pagesMercury Contamination RisksguruhnurizalNo ratings yet

- Velcon Aviation Fuel Filter Cartridges ManualDocument2 pagesVelcon Aviation Fuel Filter Cartridges ManualAbdul BasitNo ratings yet

- Flow Proses CPC Plant Rev 2Document2 pagesFlow Proses CPC Plant Rev 2Ahmad MujahidinNo ratings yet

- Quantity of Material (LPBS)Document8 pagesQuantity of Material (LPBS)Billy DNo ratings yet

- PT Daehwa Leather Maintains Wastewater Treatment RecordsDocument2 pagesPT Daehwa Leather Maintains Wastewater Treatment RecordsrismaNo ratings yet

- Water Washing Bleacher: 1 2 3 4 5 6 Temp Press (Bar) Flowrate (KG/H)Document1 pageWater Washing Bleacher: 1 2 3 4 5 6 Temp Press (Bar) Flowrate (KG/H)Tito SinagaNo ratings yet

- Laxit Nirma Presentation 2Document13 pagesLaxit Nirma Presentation 2Alpesh SolankiNo ratings yet

- 360 Reference Tables - Material Specifications and ApplicationsDocument5 pages360 Reference Tables - Material Specifications and ApplicationsGuido BerdinaNo ratings yet

- ChE 391 Process DiagramsDocument4 pagesChE 391 Process DiagramsghanimakNo ratings yet

- Parker Manual 2014-EN 20161202Document68 pagesParker Manual 2014-EN 20161202suresh muthuramanNo ratings yet

- Flow Proses Pocari SweatDocument19 pagesFlow Proses Pocari SweatRamlan nugrahaNo ratings yet

- SWS Process Flow DiagramDocument1 pageSWS Process Flow DiagramNKNo ratings yet

- Book 2Document240 pagesBook 2Caloy CeloyNo ratings yet

- Format RK Lab 2019Document3 pagesFormat RK Lab 2019apotek seltim 2No ratings yet

- Chemical MonitoringDocument1 pageChemical MonitoringShamsuddin SoomroNo ratings yet

- Boiler Pressure PartsDocument1 pageBoiler Pressure PartsMITHUNNo ratings yet

- Technical & Service Manual: Ceiling Cassettes Series PLA R407C/R410ADocument88 pagesTechnical & Service Manual: Ceiling Cassettes Series PLA R407C/R410Apaivinha21No ratings yet

- PT - Ivo Mas Tunggal: Gambar 1: Pengolahan TBS Menjadi Minyak Sawit Kasar (CPO)Document2 pagesPT - Ivo Mas Tunggal: Gambar 1: Pengolahan TBS Menjadi Minyak Sawit Kasar (CPO)jenni sisika ria purbaNo ratings yet

- DMF Relief ValveDocument1 pageDMF Relief ValveRealyn BermejoNo ratings yet

- Trends in High Purity Water Treatment for Nuclear Power PlantsDocument21 pagesTrends in High Purity Water Treatment for Nuclear Power PlantsNoumanIhsanNo ratings yet

- HPLC Columns PackingsDocument26 pagesHPLC Columns PackingsssnoormNo ratings yet

- CPT Flowsheets End SemDocument9 pagesCPT Flowsheets End SemRitvi BartiyaNo ratings yet

- Patient Gas ModuleDocument12 pagesPatient Gas ModuleRobson BarrosNo ratings yet

- H2SO4 Alkylation - Application NoteDocument2 pagesH2SO4 Alkylation - Application NoteFaten BhsNo ratings yet

- Page 1Document1 pagePage 1sharma5544No ratings yet

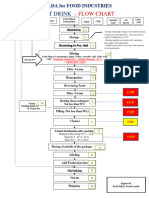

- Flow Chart - Fruit Drink - E - 1Document1 pageFlow Chart - Fruit Drink - E - 1Mohamed HabibNo ratings yet

- Gelatina Bovina 280 Bloom Malla 30 - FT - GEDocument1 pageGelatina Bovina 280 Bloom Malla 30 - FT - GEhannalupeNo ratings yet

- AnnexureDocument391 pagesAnnexureTommy ArjanggiNo ratings yet

- Cavalier 1 of 4Document1 pageCavalier 1 of 4AdriánNo ratings yet

- Feed back breaker and emergency stop switchesDocument1 pageFeed back breaker and emergency stop switchesArnoldo GutierrezNo ratings yet

- Water SystemDocument21 pagesWater SystemAulia RizkhanNo ratings yet

- Европейская фармакопея колонки ВЭЖХDocument26 pagesЕвропейская фармакопея колонки ВЭЖХitzamaraNo ratings yet

- Super Critical Boiler : Construction and WorkingDocument62 pagesSuper Critical Boiler : Construction and WorkingSai Krishna100% (1)

- Equipment I/S AVL PTW Date Ganga Makeup HouseDocument2 pagesEquipment I/S AVL PTW Date Ganga Makeup HouseMohammad AtaullahNo ratings yet

- PCP Sag Pro Pid Lab 401855Document10 pagesPCP Sag Pro Pid Lab 401855Mohd Effiezool YaserNo ratings yet

- Dearation SystemDocument1 pageDearation SystemHilary SmitNo ratings yet

- FCC Reactor Overhead Line Vapor Isolation Valve Gines IMI ZJ FCCU Budapest 2017Document49 pagesFCC Reactor Overhead Line Vapor Isolation Valve Gines IMI ZJ FCCU Budapest 2017vivek_recNo ratings yet

- Halal Control Point HCP in Halal PoultryDocument1 pageHalal Control Point HCP in Halal PoultryBharrathi RagupathyNo ratings yet

- Equipment List Senbal-05 Feb 23Document1 pageEquipment List Senbal-05 Feb 23R.A. AbriantoNo ratings yet

- FM-02 Consumable Material Feb 16 Stock RecordDocument6 pagesFM-02 Consumable Material Feb 16 Stock RecordyogoNo ratings yet

- Foam ConcentratesDocument2 pagesFoam ConcentratesSupakanit LimsowanNo ratings yet

- Water treatment process diagramDocument3 pagesWater treatment process diagramdewi_sartikaNo ratings yet

- Banana Puree Report Food NewsDocument2 pagesBanana Puree Report Food NewsSanjay RangrooNo ratings yet

- Tank DesignDocument2 pagesTank DesignSanjay RangrooNo ratings yet

- List of Cleaning ChemicalsDocument1 pageList of Cleaning ChemicalsSanjay RangrooNo ratings yet

- Food Parks in KarnatakaDocument2 pagesFood Parks in KarnatakaSanjay RangrooNo ratings yet

- Product ListDocument1 pageProduct ListSanjay RangrooNo ratings yet

- Guia 1 Ingles II Periodo Grado NovenoDocument2 pagesGuia 1 Ingles II Periodo Grado NovenoShaihell Zamanta Galicia MolinaNo ratings yet

- Calculating Food Cost and InventoryDocument4 pagesCalculating Food Cost and Inventorygene roy hernandezNo ratings yet

- Penguin Readers - Level 2 - Happy Days and Very Short Stories - Jake AllsopDocument111 pagesPenguin Readers - Level 2 - Happy Days and Very Short Stories - Jake AllsopTomás Abolafia100% (2)

- Lesson 2.2 - 2.4Document5 pagesLesson 2.2 - 2.4brenda herrera peñaNo ratings yet

- MATH183 Answer Key 10Document4 pagesMATH183 Answer Key 10Farrel FathurahmanNo ratings yet

- 4 Digestive System (5th)Document14 pages4 Digestive System (5th)Catherine JeaneNo ratings yet

- Detailed Project Report Foxnut (Makhana) Processing Unit Under Pmfme SchemeDocument27 pagesDetailed Project Report Foxnut (Makhana) Processing Unit Under Pmfme SchemePratik KumarNo ratings yet

- Invasive Threat: How Asian Carp Invaded AmericaDocument7 pagesInvasive Threat: How Asian Carp Invaded AmericaJose DanielNo ratings yet

- Monsales, Maylyn - Case Study 5 Mcdonald's Fast Food RestaurantDocument4 pagesMonsales, Maylyn - Case Study 5 Mcdonald's Fast Food RestaurantMaylyn L. MonsalesNo ratings yet

- Nutritious Millet Recipes for Healthy LivingDocument186 pagesNutritious Millet Recipes for Healthy Livingcharu duaNo ratings yet

- Grade 2 Arabic WsDocument8 pagesGrade 2 Arabic WsAbdur Rahman Sarker (Abid)100% (1)

- Food and Wine Pairing ChartDocument1 pageFood and Wine Pairing Chartjasper bobilesNo ratings yet

- Grade 6 Assessment Quarter 2Document7 pagesGrade 6 Assessment Quarter 2Ebarleen Keith LargoNo ratings yet

- Aedt 2020 2 8Document7 pagesAedt 2020 2 8Ajay lokhandeNo ratings yet

- Two Word - Compound - Words - Open - FormsDocument2 pagesTwo Word - Compound - Words - Open - Formsvo phan nghiemNo ratings yet

- Cow PeasDocument6 pagesCow PeasLawrence KasambaNo ratings yet

- Print Apr InsectophobeDocument272 pagesPrint Apr Insectophobekass100% (7)

- Libro1 BaseDocument88 pagesLibro1 BaseDaniel Felipe Garcia OrozcoNo ratings yet

- SANA - Colldl Silver - Suggtdlbl3Document1 pageSANA - Colldl Silver - Suggtdlbl3Jean VaccaNo ratings yet

- Latih Tubi Upsr 2017 Bahasa Inggeris Lulus PDFDocument312 pagesLatih Tubi Upsr 2017 Bahasa Inggeris Lulus PDFYu AkmaNo ratings yet

- Philippine traditions and cultural influencesDocument5 pagesPhilippine traditions and cultural influencesShanna Marie AndalNo ratings yet

- Nurturing Health and Well-Being Through Organic GardeningDocument8 pagesNurturing Health and Well-Being Through Organic GardeningKinney Rose G. LimNo ratings yet

- VAP Actual Run - Tuna SisigDocument4 pagesVAP Actual Run - Tuna Sisigrowilson reyNo ratings yet

- W 1 Food Where Does It Come From CBSE Class 6 WorksheetDocument3 pagesW 1 Food Where Does It Come From CBSE Class 6 WorksheetForyoutube JobsNo ratings yet

- IOP - Proc - Nutritional and Functional Sorghum - S WidowatiDocument10 pagesIOP - Proc - Nutritional and Functional Sorghum - S WidowatiSwido WatiNo ratings yet

- Culture and Arts CarDocument8 pagesCulture and Arts CarjohnreineNo ratings yet

- 03 Diet Guide PT 2 Self-Customization PDFDocument14 pages03 Diet Guide PT 2 Self-Customization PDFtuliochalb100% (4)

- Assignment 20132014Document13 pagesAssignment 20132014Nabilah NasirNo ratings yet

- Family Trip To Shahpur DamDocument10 pagesFamily Trip To Shahpur DamShaikh Muhammad Ali100% (1)

- ECO249 Lesson Plan 2Document6 pagesECO249 Lesson Plan 221. Dimas Budi PratomoNo ratings yet