Professional Documents

Culture Documents

What Is The DataFlow of MM

Uploaded by

exuser01Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is The DataFlow of MM

Uploaded by

exuser01Copyright:

Available Formats

What Is The DataFlow Of MM?

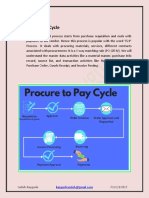

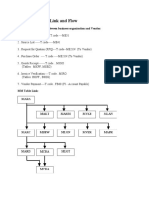

The dataflow as functional process below are the points: 1) Purchasing Requsition -> sent by inventory dept to purcharsing dept 2) Request for Quotation(RFQ)-> Purchasing Dept shall ask the vendors to give the quotation for the requested materials by inventory. 3) Quotation -> Quotation is sent by vendors to the company 4) Purchase order-> Based on all paramers of a quotation sent by vendors. Vendors are selected from whom the material has to be obtained. The company gives purchase order to the vendor. 5) Good's receipt -> vendors sends the goods to the company with goods receipt 6) Invoice verification -> this done based on good's receipt. this means that the ordered goods have reached or not. 7) Payment -> payment is done based on invoice verification. this is (FI/CO) *-Santosh Kumaar.M Full MM Transaction Codes Flow: RFQ to Vendor - ME41 Raising Quotation - ME47 Comparison of Price - ME49 Creation of PO - ME21N Goods Receipt - MIGO Invoice (Bill PAssing) - MIRO Goods Issue - MB1A Physical Inventory - MI01( Create doc) MI04 (Enter Count) MI07 (Post) The FI - MM integration: First you define the g/l master records. 1) Inventry raw material a/c 2) GR/IR clearing a/c 3) Raw material consumption a/c Above like this you define all required g/l accounts then you will go to T.CODE - OBYC Double click BSX (this is transaction key) " GBB " WRX " PRD These are transaction keys important. Then you go to T CODE - OMSY (this is also important) then Material creation T Code MM01 then

1) Purchase order T.code ME21N 2) Goods received " MIGO 3) Invoice verification " MIRO The FI - MM integration finished. *-- Vadlamudi

You might also like

- Full MM Transaction Codes Flow:: The Dataflow of MMDocument1 pageFull MM Transaction Codes Flow:: The Dataflow of MMKalyan ChakravarthyNo ratings yet

- MM Flow in SapDocument4 pagesMM Flow in Sapsankara28No ratings yet

- Procure To Pay (P2P) Process of SAP MMDocument5 pagesProcure To Pay (P2P) Process of SAP MMSwapnil KambleNo ratings yet

- RFQ DocumentDocument9 pagesRFQ DocumentOm BhakreNo ratings yet

- Sap MM T-CodeDocument5 pagesSap MM T-CodeBalakrishna RamayanamNo ratings yet

- Important Transactions in MMDocument2 pagesImportant Transactions in MMJonnalagadda LakshmanNo ratings yet

- Sap MMDocument8 pagesSap MMcnewaskarNo ratings yet

- Code MIGO-Transfer Posting Accounting EntriesDocument3 pagesCode MIGO-Transfer Posting Accounting EntriesShiv P100% (1)

- Stock Transport OrderDocument2 pagesStock Transport OrderTeamsapNo ratings yet

- SAP Purchasing: Prepared by Lavanya .MDocument28 pagesSAP Purchasing: Prepared by Lavanya .MpavankalluriNo ratings yet

- SAP Purchasing: Prepared by Lavanya .MDocument28 pagesSAP Purchasing: Prepared by Lavanya .MBaalu KathirveluNo ratings yet

- MM&SD Flow2Document13 pagesMM&SD Flow2paulusnipponboyNo ratings yet

- 22-SD and MM Flows in SAPDocument6 pages22-SD and MM Flows in SAPKIRANNo ratings yet

- SAP Purchasing: Prepared by Lavanya .MDocument28 pagesSAP Purchasing: Prepared by Lavanya .MZafar KhanNo ratings yet

- P2P PPT (Siddharth Kumar)Document12 pagesP2P PPT (Siddharth Kumar)siddharth.kumarshinNo ratings yet

- P2P ProcessDocument23 pagesP2P ProcessAshish SinghNo ratings yet

- SAP Procure To Pay ScenariosDocument90 pagesSAP Procure To Pay Scenariosislamelshahat100% (1)

- Sarmasoftwareservices-Hyderabad. Mobile:9949210713. MM Process FlowDocument4 pagesSarmasoftwareservices-Hyderabad. Mobile:9949210713. MM Process FlowSARMANo ratings yet

- Consignment ProcessDocument9 pagesConsignment ProcessRama MoorthyNo ratings yet

- SAP Purchasing: Prepared by Lavanya .MDocument28 pagesSAP Purchasing: Prepared by Lavanya .MRaghavendra BetakerurNo ratings yet

- SAP Procure To Pay ProcessDocument61 pagesSAP Procure To Pay ProcessGaphur shaikNo ratings yet

- SAP SD Third Party SalesDocument28 pagesSAP SD Third Party Salesramesh B50% (2)

- P2P Test Scenario ListDocument5 pagesP2P Test Scenario ListSrinivas Muddasani100% (1)

- ERS - Evaluated Receipt SettlementDocument10 pagesERS - Evaluated Receipt SettlementAntonio Addeo MongellaNo ratings yet

- SAP TcodesDocument184 pagesSAP TcodesAshutosh Agarwal100% (1)

- SAP MM 38 SAP Subcontracting Process Semi - Finish ProductDocument7 pagesSAP MM 38 SAP Subcontracting Process Semi - Finish ProductSujan SkNo ratings yet

- Procurement Process Consists The Following ProcessesDocument3 pagesProcurement Process Consists The Following ProcessesNaresh BabuNo ratings yet

- Top 22 SAP MM Interview QuestionsDocument4 pagesTop 22 SAP MM Interview QuestionsTrishul SampathNo ratings yet

- Automatic Purchase Order CreationDocument9 pagesAutomatic Purchase Order CreationMahesh Kumar SahooNo ratings yet

- Fdocuments - in - Vendor Managed Consignment Process Sap MMDocument12 pagesFdocuments - in - Vendor Managed Consignment Process Sap MMSai SachinNo ratings yet

- 22-SD and MM Flows in SAPDocument6 pages22-SD and MM Flows in SAPKIRANNo ratings yet

- Subcontracting Process in SAP MMDocument14 pagesSubcontracting Process in SAP MMPRATAP SAPMMNo ratings yet

- Sap 18Document8 pagesSap 18onkar shindeNo ratings yet

- Concept of ERS in MMDocument9 pagesConcept of ERS in MMnaveenk143100% (2)

- Info From:: Re: SD Flow and MM FlowDocument6 pagesInfo From:: Re: SD Flow and MM FlowPoulomibNo ratings yet

- CM ProcessDocument4 pagesCM Processiphone appleNo ratings yet

- SAP MM Interview Q&ADocument4 pagesSAP MM Interview Q&AUttamNo ratings yet

- Procurement Cycle in Sap MMDocument4 pagesProcurement Cycle in Sap MMtanusreeghoshNo ratings yet

- Material Management Flow: Purchasing RequisitionDocument3 pagesMaterial Management Flow: Purchasing RequisitionAnonymous qjtOiPdTNNo ratings yet

- SAP Purchasing User Training ManualDocument28 pagesSAP Purchasing User Training Manualamit huidrom100% (2)

- 1) Explain What Is SAP MM?Document5 pages1) Explain What Is SAP MM?dudhmogre23No ratings yet

- Concept of ERS in SAP MMDocument10 pagesConcept of ERS in SAP MMmahesh varmaNo ratings yet

- Materials Management Process FlowDocument3 pagesMaterials Management Process FlowwaqarafzalNo ratings yet

- Sap Real Time IssuesDocument4 pagesSap Real Time IssuessowmyanavalNo ratings yet

- Supply Chain Logistics + PurchaseDocument9 pagesSupply Chain Logistics + Purchaseyaswanth1992No ratings yet

- Sap MM2Document113 pagesSap MM2henriqueclaroNo ratings yet

- Concept of ERS in SAP MMDocument9 pagesConcept of ERS in SAP MMARABINDA CHAKRAVARTYNo ratings yet

- Top 21 SAP MM Interview QuestionsDocument9 pagesTop 21 SAP MM Interview QuestionsVishnu Kumar SNo ratings yet

- SAP MM Interview Questions: Contact:-+91 6360959192Document50 pagesSAP MM Interview Questions: Contact:-+91 6360959192Tushar ChaudhariNo ratings yet

- Inter 2Document2 pagesInter 2Sireesha ReddyNo ratings yet

- MM FlowDocument2 pagesMM FlowAshok kumar kethineniNo ratings yet

- SAP MM (Material Management) Transaction Code ListDocument3 pagesSAP MM (Material Management) Transaction Code Listrajuwithualways100% (1)

- Import Purchase ProcessDocument9 pagesImport Purchase Processnbhaskar bhaskar100% (1)

- How To Create Pipeline PO in SAP by Prashant KumarDocument5 pagesHow To Create Pipeline PO in SAP by Prashant Kumarrubber2010No ratings yet

- Material Management ERP-SAPDocument50 pagesMaterial Management ERP-SAPNuman Rox100% (1)

- 12.SAP MM - Procurement Cycle (Creating Purchase Order)Document8 pages12.SAP MM - Procurement Cycle (Creating Purchase Order)Niranjan NaiduNo ratings yet

- Sap S4 Hana MMDocument12 pagesSap S4 Hana MMJosé RoblesNo ratings yet

- Computerised Accounting Practice Set Using MYOB AccountRight - Advanced Level: Australian EditionFrom EverandComputerised Accounting Practice Set Using MYOB AccountRight - Advanced Level: Australian EditionNo ratings yet