Professional Documents

Culture Documents

GE's New Gas Turbine System: Designed To Change The Game in Power Generation

GE's New Gas Turbine System: Designed To Change The Game in Power Generation

Uploaded by

Katty LapoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GE's New Gas Turbine System: Designed To Change The Game in Power Generation

GE's New Gas Turbine System: Designed To Change The Game in Power Generation

Uploaded by

Katty LapoCopyright:

Available Formats

The Tradition of Excellence Continues

GEs New Gas Turbine System: Designed to Change the Game in Power Generation

GE Power Systems 2707 North Loop West Houston,TX 77008 Telephone 1-713-803-0900 www.gepower.com

GEA13640 (3M, 11/03) CF6-80C2 and CF6-80E1 are trademarks of GE Aircraft Engines, General Electric Co. LMS100 and MS6001 are trademarks of GE Power Systems, General Electric Co. Copyright 2003, General Electric Co. All rights reserved.

Only GE has the Imagination and Ability to Combine the

Best of Both Worlds.

GE Aircraft Engines Technology

GE Power Systems Technology

A New Beginning

The LMS100 is the first intercooled gas Flexible Power: High Efficiency turbine system developed especially for the High Part-Power Efficiency, 50% Power......39% power generation industry, utilizing the best High Simple Cycle Efficiency......46% of two technologies --- heavy-duty frame gas High STIG Efficiency....50% turbine and aeroderivative gas turbine High Combined Cycle Efficiency.....54% technology. The LMS100 will deliver 100MW at 46% thermal efficiency. This efficiency is 10 % higher than GE's highest simple cycle Inlet Collector efficiency gas turbine available today. It is specifically designed for cyclic applications providing flexible To Intercooler power for peaking, mid-range and baseload.

GE's New Gas Turbine Power Generation System

From Intercooler

Only GE Can Bring You the Best of Both Worlds

LM

LMS

MS

The LMS100 features a heavy-duty low pressure LPC compressor derived from GE Power Systems MS6001FA heavy-duty gas turbine compressor; its core which includes the high pressure compressor, combustor and high pressure turbine is derived from GE Aircraft Engines CF6-80C2 and CF680E1 aircraft engines. The design of the new 2-stage intermediate pressure turbine and new 5-stage power turbine is based on the latest aeroderivative gas turbine technology. The exhaust and aft shaft for hot-end drive are designed using heavy-duty gas turbine practices.

Intercooler

Aeroderivative Supercore Exhaust Collector

Combustor

New High Efficiency Gas Turbine For the Power Generation Industry

Output Shaft HPC LPC HPT IPT PT

The compressed air from the Low Pressure Compressor (LPC) is cooled in either an air-to-air or air-to-water heat exchanger (intercooler) and ducted to the High Pressure Compressor (HPC). The cooled flow means less work for the HPC, increased overall efficiency and power output. The cooler LPC exit temperature air, used for turbine cooling, allows higher firing temperatures, resulting in increased power output and overall efficiency.

The Right Solution.

Rugged Design With Proven Components.

LMS100 Addressing Industry Needs

When asked to describe their requirements for future power generation facilities, customers identified the following items as high on their priority list: 100 MW blocks of power High efficiency at full and part-power Cycling capability Fast start Peaking capability Sustained hot-day power Fuel flexibility Low emissions All agreed that a new gas turbine which met these requirements would be an important addition to their generation mix. The LMS100 has been designed to specifically address all of these needs, changing the game in the power generating industry.

The LMS100 features an inlet and an LPC comprised of the first six stages of the MS6001FA compressor. These stages are followed by an aerodynamically designed volute which ducts the low pressure compressed air into the intercooler. This LPC provides high airflow capacity for the LMS100 Gas Turbine System. Cooled air from the intercooler is ducted back through another aerodynamically designed volute into the aero supercore. The high efficiency aeroderivative supercore consists of: a high pressure compressor (HPC) based on the CF6-80C2 aircraft engine compressor, strengthened for the high (42:1) pressure ratio of the LMS100; a combustor which can be either a standard annular combustor (SAC) or an advanced dry low emissions (DLE2) combustor; a high pressure turbine (HPT) derived from the CF6-80E1 aircraft engine; a 2-stage intermediate pressure turbine (IPT) designed to drive the LPC through a mid-shaft and flexible coupling. Following the IPT is a 5-stage aerodynamically coupled power turbine (PT) that has been designed specifically for the LMS100. The exhaust frame and aft drive shaft are based on a rugged heavy-duty gas turbine exhaust design.

LMS100 Product Features

Over 600 Advanced F Technology Units With Nearly 8 Million Fired Hours

The LMS100 is the Right Solution:

Outstanding full- and part-power efficiency Low hot-day lapse rate High availability aero modular maintenance Low maintenance cost Designed for cycling applications No cost penalty for starts and stops Load-following capability 10 Minutes to full power Improves average efficiency in cycling Potential for spinning reserve credits Reduced start-up emissions Synchronous condenser capability

3,786 CF6-80 Engines in Operation With More Than 103 Million Operating Hours

Industrial Example of a Finned Tube Heat Exchanger

The LPC air is ducted to an air-to-air or air-to-water heat exchanger where it is cooled before being ducted to the HPC. Both designs are industry standard heat exchangers with significant operating hours in multiple industries and are designed to the API 660 and TEMA C standards.

Industrial Example of a Tube & Shell Heat Exchanger

Designed for Availability and Maintainability.

Hot End Drive Shaft Coupling LM Aero Supercore High Pressure Collector & Duct From Intercooler To Intercooler

5-Stage Power Turbine

LMS100 Gas Turbine Product Description

Radial Inlet

2-Stage Intermediate Pressure Turbine (Drives LPC) High Pressure Compressor

2-Stage High Pressure Turbine Standard Annular Combustor Turbine Rear Frame

Diffuser

Low Pressure Compressor (LPC) LPC Exit & Diffuser Duct to Intercooler

Rotable Supercore Enhances Power Plant Availability

GE has established a target availability of 97.5% for a mature GE-built LMS100 power plant. Its power plant target reliability is 98.5%. The rotable supercore consists of the HPC, Combustor, HPT and IPT modules. Rotable modules can be installed during on-site maintenance. A lease or spare supercore and a power turbine module can be installed in 24 hours when depot maintenance is required.

Maintainability Features

Modular construction permits replacement of the aero components without total disassembly. Multiple borescope ports allow on-condition monitoring without turbine disassembly. Condition based maintenance and remote diagnostics. Split casing construction of the LPC and aeroderivative compressor allows detailed on-site inspection and blade replacement. Hot-section field maintenance can be done in several days. Accessories are externally mounted for ease of on-site replacement.

LMS100 Service Intervals

The expected service intervals for the LMS100 based upon normal operation include: On-site hot-section replacement.25,000 fired hours* Depot maintenance; overhaul of hot section and inspection of all systems, power turbine overhaul 50,000 fired hours* Next on-site hot section replacement 75,000 fired hours* Depot maintenance.100,000 fired hours* *Note: These are actual fired hours; no multipliers for cycling are needed.

Maintenance Services

All warranty and follow-on services for the LMS100 will be provided by GE Power Systems on-site or at its several depot locations around the world. These services can include Contractual Service Agreements, Lease Engines, Spare Parts, Rotable Modules, Training and Training Tools.

Reliability Designed In .

Configured To Meet Your Needs.

Package Design

The LMS100 gas turbine package system was designed for reliable operation, easy access for maintenance and quick installation. The auxiliary systems are pre-assembled on a single skid and factory tested prior to shipment. The auxiliary skid is mounted in front of the turbine base plate utilizing short flexible connectors reducing mechanical interconnects by 25%. The complete gas turbine driver package can be shipped by truck.

Emissions Control

The LMS100 gas turbine system has all the advantages of an aeroderivative gas turbine in achieving low emissions.The LMS100 gas turbine with the SAC combustor (using water or steam for NOx control) and the advanced DLE combustor (DLE2) are designed to achieve 25 ppm NOx. This represents a 7 to 18% reduction in mass emissions rate (lbs/kwh) vs. the LM6000. In locations where less than 25 ppm NOx is required a low temperature SCR can be used. The high efficiency of the LMS100 results in exhaust temperatures below 800F (427C) which permits the use of low temperature SCRs without tempering air.

Air-to-Air Intercooler

In locations where water is scarce or very expensive, the basic LMS100 power plant will contain a highly reliable air-to-air intercooler. This unit will be a tube and fin style heat exchanger in an A-frame configuration which is the same as typical steam condensing units in general conformance with API 661 standards. Similar units are in service in the Oil and Gas industry today. In high ambient temperature climates, an evaporative cooling system can be added for power augmentation. This system would use a small amount of water for short time periods as required.

Air-to-Air Finned Tube Heat Exchanger VBV Stack and Silencer Inlet Air-to-Air Intercooler

VBV Stack and Silencer Inlet

Bellows Expansion Joints

Cooling Tower

Auxiliaries Skid Exhaust Stack

Air-to-Air Intercooler Air-to-Water Tube and Shell Heat Exchanger Generator

LMS100 Plant System Design

LMS100 Plant System Design

While the actual plant layout will be site dependent, it will contain basic elements which include an inlet, an auxiliaries skid containing a water wash system, lube oil system and starter system, a turbine skid, an intercooling system, a generator, silencers, exhaust system and a control system.

Air-to-Water Intercooler

In locations where water is readily abundant or less expensive the intercooler can be of the air-to-water type also found in many industrial applications. The intercooler would be a tube and shell type heat exchanger. Either type of intercooler will be connected through a system of piping and expansion bellows, from the low pressure compressor volute to the intercooler and upon return to the high pressure compressor inlet volute.

Wind Wall

Noise Control

The gas turbine-generator will be rated at 85 dBA average at 3 feet (1 meter). An option for 80 dBA at 3 feet will be available. Generator The generator is dual rated for 50 or 60 Hz applications. Either an air-cooled or TWAC configuration can be provided.

Control System

Significant emphasis has been placed on controls design for increased reliability of the entire power plant. The LMS100 control system will have dual channel architecture with a cross-channel data link providing redundancy which will allow multiple failures without engine shutdown. A fiberoptic distributed I/O system located outside the module will be unaffected by electromagnetic or radio frequency interference which will eliminate noisy wiring. Site interconnects are reduced by 90% compared to the typical gas turbine control system.

Auxiliaries Skid Exhaust Stack

Moisture Separator Bellows Expansion Joints Generator

LMS100 is Available in a Variety of Configurations

LMS100 SYSTEM CONFIGURATIONS

Product Offerings Fuel Combustor Diluent

Four basic LMS100 configurations are available as this product is introduced. When combined with intercooler selection and duty applications, the LMS100 will offer the customer 20 different configuration choices.

Power Augmentation

NOx Level

Fuels

The LMS100 SAC will be equipped with dual fuel capability so that it can burn either natural gas or distillate fuels. The LMS100 DLE will operate on gas fuel.

LMS100 SAC, 50/60 Hz LMS100 SAC Steam, 50/60 Hz LMS100 SAC STIG, 50/60 Hz LMS100 DLE, 50/60 Hz

Gas, Liquid or Dual Fuel

Gas Gas Gas

Single Annular (SAC) Single Annular (SAC) Single Annular (SAC) DLE2

Water

Steam Steam None

None None

25 ppm 25 ppm 25 ppm 25 ppm

Steam Injection

None

Competitive Over A Wide Output Range.

LMS100 Applications For Power Generation

LMS100 Provides Outstanding Customer Value in 80+ MW Applications

The attributes of the LMS100 make it a versatile power generation system offering customers increased operational flexibility in a wide variety of applications: Simple Cycle / Peaking & Mid-Rangehigh efficiency, low first cost, sustained hot day power, 10-minute starts and no maintenance penalty for cycling, yield the ideal peaking solution. Throw in high part-power efficiency and load following capability to get high dispatch capability for midrange applications. STIG steam injection for power augmentation provides significant efficiency and power improvements, as well as flexibility. With variable STIG, an operator can inject all of the steam into the gas turbine or pass the steam to process to take advantage of electricity prices or process steam value. Combined Cycle the low exhaust temperature leads to lower cost exhaust system materials, smaller steam turbines, condensers and generators, leading to a lower steam plant installed cost.

Another benefit from the lower exhaust temperature is more power from duct firing (up to 30MW). Combined Heat & Power the high power-tosteam ratio allows the LMS100 to meet the steam demand served by 40-50MW gas turbines while delivering more than twice the power. Using both exhaust and air-to-water intercooler energy, an LMS100 plant can reach >85% thermal efficiency. 50Hz and 60Hz Applications the LMS100 can operate at 50Hz and 60Hz operation without a gearbox, reducing system complexity, plot size and cost, while increasing reliability. Off-Frequency Operation the LMS100 will operate with very little power variation for up to 5% reduction in grid frequency, allowing grid support in times of high demand and load fluctuations. When your power generation need exceeds 100MW, the LMS100 can provide an economic solution in a multi-unit arrangement by providing high efficiency power with unmatched flexibility.

LMS100 ISO Performance Data

ISO Performance Data

Simple Cycle Gas Turbine 60Hz Applications

Model

DLE SAC (w/Water) SAC (w/Steam) STIG Conditions:

Performance at the generator terminals NOx = 25 ppm 59F, 60% Relative Humidity Losses: 0/0 inlet/exhaust Fuel: Spec. Gas (LHV = 19000 BTU/lb)

LMS100 ISO Performance Data

Simple Cycle Gas Turbine 50Hz Applications

Model

DLE SAC (w/Water) SAC (w/Steam) STIG Conditions:

Performance at the generator terminals NOx = 25 ppm 15C, 60% Relative Humidity Losses: 0mm/0mm inlet/exhaust Fuel: Spec Gas (LHV = 44.2MJ/KG)

Output

(MWe)

Heat Rate

(BTU/KWH)

Efficiency

%

Output

(MWe)

Heat Rate

(KJ/KWH)

Efficiency

%

98.7 102.6 102.1 112.2

7509 7813 7167 6845

46 44 48 50

99 102.5 102.2 110.8

7921 8247 7603 7263

45 44 47 50

Air Inlet (Loss Not Included)

Cooling Tower

VBV Silencer

Air Inlet (Loss Not Included)

Cooling Tower

VBV Silencer

Air Inlet (Loss Included)

Turbine Skid

Air-to-Water Intercooler (Pressure Loss Included)

Auxiliaries Skid

Air-to-Water Intercooler (Pressure Loss Included)

Auxiliaries Skid Generator (Performance at Generator Terminals) Exhaust Stack (Loss Not Included)

Exhaust Stack (Loss Not Included)

Generator (Performance at Generator Terminals)

GEA13640-1 (11/03)

You might also like

- Case Study - Kanchanjunga ApartmentsDocument18 pagesCase Study - Kanchanjunga ApartmentsFireSwarm92% (64)

- TM2500 Main Equipment Scope of SupplyDocument4 pagesTM2500 Main Equipment Scope of Supplyzhangj5No ratings yet

- SCOPE-1 SECTION-2 CommssinoingDocument109 pagesSCOPE-1 SECTION-2 Commssinoingahmed100% (1)

- Gas Turbine Lm5000 Operations ManualDocument4 pagesGas Turbine Lm5000 Operations ManualMuhammad Ilham Riyadi100% (1)

- Ge Gas Engine 18 MWDocument1 pageGe Gas Engine 18 MW123habib123fikriNo ratings yet

- 8600 Smart Routers Routing Protocols Configuration Guide76.8600-50121HDocument126 pages8600 Smart Routers Routing Protocols Configuration Guide76.8600-50121HCristinaNo ratings yet

- Benteller Pipe Cataloque PDFDocument2 pagesBenteller Pipe Cataloque PDFGarry Bernard NelsonNo ratings yet

- Aero Grid Stability PAPER Sept 2011Document25 pagesAero Grid Stability PAPER Sept 2011igunhakam55No ratings yet

- General Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Document13 pagesGeneral Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Ibilola IbisankaleNo ratings yet

- IDEA Licence - Terms and ConditionsDocument7 pagesIDEA Licence - Terms and ConditionsIngrid MocanuNo ratings yet

- GE's TM2500+ Solution Offers Fast, Mobile and Flexible PowerDocument6 pagesGE's TM2500+ Solution Offers Fast, Mobile and Flexible PowerJorge Armando Acevedo Pinel100% (1)

- The Market For Gas Turbine Electrical Power Generation: Product Code #F646Document30 pagesThe Market For Gas Turbine Electrical Power Generation: Product Code #F646Michael McQueenNo ratings yet

- Contracts ManagementDocument87 pagesContracts Managementarabi2222No ratings yet

- Gas Turbines Siemens Interactive PDFDocument22 pagesGas Turbines Siemens Interactive PDF'Izzad AfifNo ratings yet

- What Is The Function of Turbine DroopDocument48 pagesWhat Is The Function of Turbine Droopanon_246649396100% (1)

- LIST of GTDocument5 pagesLIST of GTSonali BanerjeeNo ratings yet

- Chapter 1 GeneralDocument65 pagesChapter 1 GeneralGloria Del Carmen MuñozNo ratings yet

- cycleCCplant PDFDocument19 pagescycleCCplant PDFJohn Bihag100% (2)

- D 0906-110-E000D - Released: Drawing Sheet & Revision Status Sheet No. Rev. Sym. Sheet No. Rev. Sym. Sheet No. Rev. SymDocument1 pageD 0906-110-E000D - Released: Drawing Sheet & Revision Status Sheet No. Rev. Sym. Sheet No. Rev. Sym. Sheet No. Rev. SymFerdinandjaNo ratings yet

- Solar Turbines Service Bulletin 1-0-116Document2 pagesSolar Turbines Service Bulletin 1-0-116jussmeeeNo ratings yet

- 3 Containerized 7 8MWDocument12 pages3 Containerized 7 8MWnaz-sdeNo ratings yet

- 517Cr1: Variable Inlet Guide Vane SeizingDocument2 pages517Cr1: Variable Inlet Guide Vane SeizingMuhammad Irfan AnwarNo ratings yet

- F Technology StoryDocument16 pagesF Technology StoryTufail Memon100% (1)

- TM2500TM Mobile Gas Turbine G4Document1 pageTM2500TM Mobile Gas Turbine G4Serg MarushkoNo ratings yet

- Alstom Power Ss Gft579aDocument4 pagesAlstom Power Ss Gft579aFaisal Amran100% (1)

- Stator Differential Protection During Transformer Inrush Conditions in The 489Document4 pagesStator Differential Protection During Transformer Inrush Conditions in The 489meraatNo ratings yet

- Temperature Control at 19MW On MS5001Document4 pagesTemperature Control at 19MW On MS5001chdi100% (1)

- 1.HSK78 2MW DatasheetDocument6 pages1.HSK78 2MW Datasheetnunukidsshop 0869478221No ratings yet

- What Is Excitation System - Definition & Types of Excitation System - Circuit GlobeDocument11 pagesWhat Is Excitation System - Definition & Types of Excitation System - Circuit GlobeSabaMannan123No ratings yet

- Abb Cable AccessoriesDocument131 pagesAbb Cable Accessoriesaamir_janjua_3No ratings yet

- Prismic A30Document2 pagesPrismic A30ario2481No ratings yet

- Gea32885 Bouchain Whitepaper Final Aug 2016 PDFDocument8 pagesGea32885 Bouchain Whitepaper Final Aug 2016 PDFMd. Humayun Kabir ChowdhuryNo ratings yet

- Mark Vie-GEH-6721-Vol-III PDFDocument180 pagesMark Vie-GEH-6721-Vol-III PDFRidho HeriyantoNo ratings yet

- Fuel System: PerformanceDocument3 pagesFuel System: PerformanceDenis JimenezNo ratings yet

- IPL Saturn 20Document56 pagesIPL Saturn 20Ranjan Shankar100% (3)

- LTSA-Contract Package 2Document140 pagesLTSA-Contract Package 2adanasporNo ratings yet

- TM2500 and TM2500+ Intro Pages-2Document24 pagesTM2500 and TM2500+ Intro Pages-2abelsg100% (2)

- Pwps Swiftpac BrochureDocument6 pagesPwps Swiftpac BrochureWilfredo Rojo CastañoNo ratings yet

- 9e PDFDocument12 pages9e PDFgayani100% (2)

- 9e Turbine Gea16035b 9e GT HRDocument1 page9e Turbine Gea16035b 9e GT HRFedor Bancoff.No ratings yet

- GTG 1328sc Sw50 50bargeDocument4 pagesGTG 1328sc Sw50 50bargewidyo saptotoNo ratings yet

- 04 - LM2500 OverviewDocument27 pages04 - LM2500 OverviewLudovic LeroyNo ratings yet

- Alstom Gen TOPAIR PDFDocument6 pagesAlstom Gen TOPAIR PDFcynaidu100% (1)

- Installation Checklists 1-2MW-xxHz BBCICL EN r01 D PDFDocument39 pagesInstallation Checklists 1-2MW-xxHz BBCICL EN r01 D PDFEduardo Jr.No ratings yet

- 10-03-2008 Power in MEADocument30 pages10-03-2008 Power in MEAMohammed YusufNo ratings yet

- GT - CC Input PS Standard Presentation - FV - June2007Document21 pagesGT - CC Input PS Standard Presentation - FV - June2007koohestani_afshin100% (2)

- Satyendra ' S ReportDocument24 pagesSatyendra ' S ReportSatyendra Singh100% (1)

- TIL 2373 - 7E Stage 2 Bucket Tip Shroud DistressDocument8 pagesTIL 2373 - 7E Stage 2 Bucket Tip Shroud DistressBouazzaNo ratings yet

- 9076-2 Power Plant Description Feb 2019Document26 pages9076-2 Power Plant Description Feb 2019Микола Лабунець (TAVR2909)No ratings yet

- Mark VI ControlDocument27 pagesMark VI ControlnasirfahimNo ratings yet

- G-SG-TEST-CPD-117 Gas Turbine Water Wash Systems (Rev. 4)Document17 pagesG-SG-TEST-CPD-117 Gas Turbine Water Wash Systems (Rev. 4)Abdelaziz EldeebNo ratings yet

- SGT 800 Factsheet 2017Document2 pagesSGT 800 Factsheet 2017pradeepnair1710% (1)

- PB TM2500 SSDocument9 pagesPB TM2500 SShpfmachineryNo ratings yet

- Lampiran 1 Standar InspectionDocument7 pagesLampiran 1 Standar InspectionFitra SNo ratings yet

- Gas Turbine Inlet Air Cooling System: Bob OmidvarDocument41 pagesGas Turbine Inlet Air Cooling System: Bob OmidvarKangjin ChoNo ratings yet

- FOCUS REPORT: U.S. Shale Gale under Threat from Oil Price PlungeFrom EverandFOCUS REPORT: U.S. Shale Gale under Threat from Oil Price PlungeRating: 2 out of 5 stars2/5 (1)

- GAS TURBINE (50 Hz/60 HZ) : The Most Efficient Combined Cycle/Cogeneration Below 100 MWDocument2 pagesGAS TURBINE (50 Hz/60 HZ) : The Most Efficient Combined Cycle/Cogeneration Below 100 MW82540No ratings yet

- Benchmarks in Efficiency: Siemens SGE-EM Gas EnginesDocument4 pagesBenchmarks in Efficiency: Siemens SGE-EM Gas Enginesmohsen_cumminsNo ratings yet

- 6009 EM 2MW Class Gas Engines Gensets enDocument5 pages6009 EM 2MW Class Gas Engines Gensets enAdnan YakoobNo ratings yet

- Ger 4222a New High Efficiency Simple Cycle Gas Turbine Lms100Document20 pagesGer 4222a New High Efficiency Simple Cycle Gas Turbine Lms100raghavendran raghuNo ratings yet

- Guardian 10 A 16kWDocument6 pagesGuardian 10 A 16kWLeonardo PiñareteNo ratings yet

- 6F.03 Fact Sheet 2016 PDFDocument2 pages6F.03 Fact Sheet 2016 PDFashok33% (3)

- مخطط استراDocument4 pagesمخطط استراFiras AttavilNo ratings yet

- 3 Equilibrium PDFDocument63 pages3 Equilibrium PDFShuaib MohamedNo ratings yet

- A Methodology To Determine Transient Recovery Voltage in Short-Line FaultDocument7 pagesA Methodology To Determine Transient Recovery Voltage in Short-Line FaultLeonardo CamargoNo ratings yet

- Citrix XenServer Administrator GuideDocument223 pagesCitrix XenServer Administrator Guidedumitru ionNo ratings yet

- Process Distillation Tower DiagnosticsDocument8 pagesProcess Distillation Tower Diagnostics徐孝民No ratings yet

- Vol45 4 PDFDocument268 pagesVol45 4 PDFShailesh LohareNo ratings yet

- Assignment On LifiDocument19 pagesAssignment On LifiMushir BakshNo ratings yet

- Block CavingDocument6 pagesBlock CavingArsa Iskaq IchsanNo ratings yet

- WDU 2.5 enDocument14 pagesWDU 2.5 enAhmadBintangNegoroNo ratings yet

- Speed of SoundDocument2 pagesSpeed of SoundEti GoldbergNo ratings yet

- 06IC Sec11 Function-RelaysDocument86 pages06IC Sec11 Function-RelaysBiju MenonNo ratings yet

- DIfferent Types of FootingDocument6 pagesDIfferent Types of Footingluffy monkeyNo ratings yet

- PNOZ s3 Operat Man 21395-En-10Document17 pagesPNOZ s3 Operat Man 21395-En-10Rudi WidjajaNo ratings yet

- Conversion Technology - A Complement To Plastic Recycling - Apr 11Document56 pagesConversion Technology - A Complement To Plastic Recycling - Apr 11Smita Yadav100% (2)

- Poliya ChemicalResistanceGuideDocument33 pagesPoliya ChemicalResistanceGuideHuber AlvaradoNo ratings yet

- 1 s2.0 s1000936120300546 MainDocument11 pages1 s2.0 s1000936120300546 MainPai Gerdin HawkNo ratings yet

- KCLEDocument48 pagesKCLEzacklawsNo ratings yet

- SAP 2000 Reference GuideDocument402 pagesSAP 2000 Reference Guidejoshappy123100% (2)

- Computer Integrated Manufacturing: "Coming Together Is A Beginning .Document18 pagesComputer Integrated Manufacturing: "Coming Together Is A Beginning .Anonymous 7ZYHilDNo ratings yet

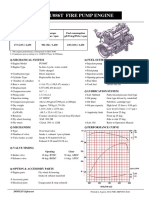

- Pu086T Fire Pump Engine: Power RatingDocument2 pagesPu086T Fire Pump Engine: Power RatingWac MichNo ratings yet

- Anbalagan PDocument217 pagesAnbalagan PMirian SincheNo ratings yet

- Computer Science Ram PresentationDocument11 pagesComputer Science Ram Presentationapi-268896185100% (3)

- ME 355: Compressible Flows, Spring 2016Document3 pagesME 355: Compressible Flows, Spring 2016ashwin josephNo ratings yet

- Tutorial Fail2BanDocument9 pagesTutorial Fail2BanjetbardsNo ratings yet

- Supercapacitor SeminarDocument28 pagesSupercapacitor SeminarDurgeshManeshwar100% (1)

- AirWire Datasheet EnglishDocument4 pagesAirWire Datasheet EnglishAkash PandeyNo ratings yet

- Eo ZDJ WN79 Vow BQu CUFp XDocument5 pagesEo ZDJ WN79 Vow BQu CUFp XShreyansh DuggarNo ratings yet