Professional Documents

Culture Documents

Sample Engineering Specification: Customer Service

Uploaded by

Pooniam KanjanapatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample Engineering Specification: Customer Service

Uploaded by

Pooniam KanjanapatCopyright:

Available Formats

Spring Check valves are used to prevent back-flow and siphoning. The 1/2 lb.

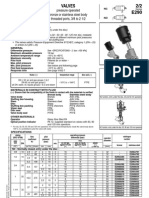

SS spring maintains a positive seal even when no backpressure is present. Suggested applications: pool/spa assemblies and installations, potable water systems. FEATURES AND BENEFITS 2-psi minimum flow pressure required to open valve Pressure rating: 150 psi, non-shock water at 73o F Flow direction indicator molded into body for accurate installation 304 SS spring for corrosion resistance 1/2 - 2" socket (solvent weld) end connections Corrosion-resistant PVC body with EPDM seal Low-cost operation Note: For Foot Valve requirements, see the Colonial Single Union ball check valve.

SAMPLE ENGINEERING SPECIFICATION Thermoplastic spring check valves shall be constructed from PVC Type I, cell class 12454 material conforming to ASTM D-1784. Seal shall be EPDM. Valves shall have socket end connectors for solvent weld installation. All 1/2 - 2" valves shall be pressure rated at 150 psi, non-shock water at 73o F.

SPRING CHECK VALVE

CUSTOMER SERVICE: 6400 Corporate Ave., Portage, MI 49002, Toll-free (800) 374 0234, Phone (269) 323 2495, Fax (269) 323 0630, www.colonialengineering.com

TEMPERATURE CORRECTION FACTORS FOR VALVES & UNIONS (ABOVE 73o F)

Temp (o F) 73 80 90 100 110 120 130 140 150 160 170 180 200 210 240 280

NR: Not Recommended Caution: Colonial recommends a minimum installation distance of 10 X the pipe diameter from a pump or other sources of turbulence.

SPRING CHECK VALVE

PVC 1.00 .88 .75 .62 .50 .40 .30 .22 NR NR NR NR NR NR NR NR

A C B D

COMPONENTS AND MATERIALS

Part Letter A B C D Component Body Connector Seat Spring Seal Quantity 1 1 1 1 Material PVC PVC 304 SS EPDM

DIMENSIONS

Part No. V07221B V08221B V10221B V14221B V17221B V20221B Size 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" A 4-1/8" 4-1/8" 5-1/4" 5-15/16" 5-15/16" 7" D 2-7/32" 2-7/32" 2-7/8" 3-19/32" 3-19/32" 4-7/32" F 11/16" 23/32" 7/8" 1-5/16" 1-1/16" 1-5/32"

COMPRESSED AIR WARNING

The products in this document are only intended for use in transferring or storing chemically compatible pressurized liquids. Do not test or use products in this document with compressed air or other gases. Doing so is dangerous and could cause injury or great bodily harm should a system fail under compressed air. Only use products that are specifically designed for compressed air/gas service. Call Colonial technical service for more information.

You might also like

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Vortex Float ValveDocument3 pagesVortex Float ValveFrancisco Javier Villegas AndersonNo ratings yet

- Type A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")Document2 pagesType A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")thomasoburNo ratings yet

- ValvesDocument6 pagesValvesstevegazeleyNo ratings yet

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- Gate Valve: Standard Features Type P Parts (Sizes 1-1/2" - 6")Document3 pagesGate Valve: Standard Features Type P Parts (Sizes 1-1/2" - 6")MOHAMMAD ASIFNo ratings yet

- WW 770-UDocument4 pagesWW 770-UAhmad NasserNo ratings yet

- FlowCon EVS 15-25mm Plug-in Temperature Control InsertDocument7 pagesFlowCon EVS 15-25mm Plug-in Temperature Control InsertJeff Anderson CollinsNo ratings yet

- Visual Flow Indicator Guide from Flow-MonDocument12 pagesVisual Flow Indicator Guide from Flow-Mondhanu_aquaNo ratings yet

- Manual Pinch Valves BrochureDocument9 pagesManual Pinch Valves BrochureVenkatesh GangadharNo ratings yet

- Series 510 Specification SheetDocument2 pagesSeries 510 Specification SheetFEBCONo ratings yet

- Gate Valve SpecificationDocument1 pageGate Valve SpecificationMarkhey Alberca GarciaNo ratings yet

- SideWinder 40 60 80 CHMCL PMP BrchreDocument4 pagesSideWinder 40 60 80 CHMCL PMP BrchreSH McNo ratings yet

- Irrigation System for Residential ComplexDocument8 pagesIrrigation System for Residential ComplexuddinnadeemNo ratings yet

- Bronze 40 GPM Diaphragm Pump & Pump Out Hose AssemblyDocument4 pagesBronze 40 GPM Diaphragm Pump & Pump Out Hose AssemblyRoger AklNo ratings yet

- BPS09 P PDFDocument4 pagesBPS09 P PDFengp3077No ratings yet

- DCV Spirax PDFDocument2 pagesDCV Spirax PDFVaitheeswaran PalaniNo ratings yet

- Desuperheater That Combines Proven Technologies For Better Operational EconomyDocument4 pagesDesuperheater That Combines Proven Technologies For Better Operational Economyhappale2002No ratings yet

- 08 - SpeckDocument5 pages08 - SpeckSezer CetinNo ratings yet

- Flow Divertor Ball Valve DN20 - DN32 - DN50: DescriptionDocument3 pagesFlow Divertor Ball Valve DN20 - DN32 - DN50: Description윤병택No ratings yet

- Bermad - Filtro en y 70fDocument2 pagesBermad - Filtro en y 70fYadir BojacaNo ratings yet

- VALVULA DE SOLENOIDE HS7 BulletinDocument4 pagesVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve: OGB50FDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve: OGB50FOscar CRNo ratings yet

- Chapter 5Document18 pagesChapter 5arsiajanNo ratings yet

- Alarm ValveDocument6 pagesAlarm ValveAnonymous ZPTCAz9No ratings yet

- RedvalvE 90 01Document4 pagesRedvalvE 90 01Rizal FalevyNo ratings yet

- BallValues PDFDocument12 pagesBallValues PDFDevdatt WaghuleNo ratings yet

- VNotchDocument3 pagesVNotchThiruThirunavukkarasuNo ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- Valve configuration and solenoid directional valvesDocument8 pagesValve configuration and solenoid directional valvesFabinhoTowerNo ratings yet

- Lance Valves quality case studyDocument12 pagesLance Valves quality case studyJaehun YuNo ratings yet

- Catalogo 13 - 2016 EditionDocument12 pagesCatalogo 13 - 2016 EditionHector Manuel Calvo MejiaNo ratings yet

- Gate Valves ManualDocument3 pagesGate Valves ManualMOHAMMAD ASIFNo ratings yet

- RV Valves Product Data SheetDocument16 pagesRV Valves Product Data SheetWaqar DarNo ratings yet

- d200 Control0810-5Document4 pagesd200 Control0810-5Văn Thành NgôNo ratings yet

- Inside Sales For Valves Part 3Document6 pagesInside Sales For Valves Part 3niket honnalliNo ratings yet

- Warning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoDocument6 pagesWarning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoRiky AyalaNo ratings yet

- Accessories BrochureDocument4 pagesAccessories BrochureJERSON KELER TORIBIO BEDONNo ratings yet

- Angle Seat Valve: High Cycle-Life On/Off Control ValveDocument6 pagesAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyNo ratings yet

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonNo ratings yet

- GF System Specification PVC-U BS InchDocument14 pagesGF System Specification PVC-U BS InchDale CokleyNo ratings yet

- WPI-KE-1104-SP141-QM5433 (Datasheet)Document4 pagesWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- EPE AccumulatorsDocument6 pagesEPE AccumulatorsGuru VagaNo ratings yet

- Series 008PCQT Specification SheetDocument2 pagesSeries 008PCQT Specification SheetWattsNo ratings yet

- Butterfly ValveDocument14 pagesButterfly ValveSingSareblakKanaManahNo ratings yet

- Irrigation Solenoid ValveDocument1 pageIrrigation Solenoid ValveAtul KalaskarNo ratings yet

- Flowcon ABM InstructionDocument4 pagesFlowcon ABM InstructionJeff Anderson CollinsNo ratings yet

- 01PV0C01Document4 pages01PV0C01raobabar21No ratings yet

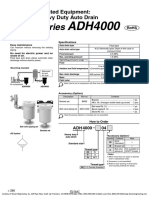

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNo ratings yet

- Standpipe Piezo DatasheetDocument2 pagesStandpipe Piezo DatasheetQoudar RamdhaniNo ratings yet

- Series 767FR Specification SheetDocument4 pagesSeries 767FR Specification SheetFEBCONo ratings yet

- Auto Drain 70APADH4000Document3 pagesAuto Drain 70APADH4000thomasoburNo ratings yet

- Lead Free Series SS009 Specification SheetDocument2 pagesLead Free Series SS009 Specification SheetWattsNo ratings yet

- Series 825YD Specification SheetDocument2 pagesSeries 825YD Specification SheetFEBCONo ratings yet

- Es F 856STDocument4 pagesEs F 856STFEBCONo ratings yet

- System Rated Plus W Sub 150Document1 pageSystem Rated Plus W Sub 150Sattar Al-JabairNo ratings yet