Professional Documents

Culture Documents

Todd Shuder

Uploaded by

ToddShuderCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Todd Shuder

Uploaded by

ToddShuderCopyright:

Available Formats

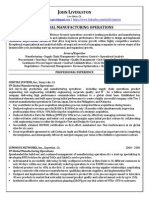

TODD R.

SHUDER

Carlsbad, CA 92011 (760) 431-0301 cell: (760)-712-6496 tshuder@roadrunner.com

OPERATIONS / MANUFACTURING / ENGINEERING

OBJECTIVE

To be a catalyst for a company that seeks growth and operational excellence. To provide leadership and vision. To implement changes conducive to long term value for the company, employees, and shareholders. To champion ideas and projects that will lead the company to be the best in its industry.

PROFESSIONAL STRENGTHS

A positive attitude and management style resulting in high levels of team productivity and profitable breakthroughs. Identifies, analyses and solves complex, systemic issues that hamper profitability. Correlates manufacturing and operational activities to P&L performance to implement cost improvement projects. Utilizes lean manufacturing and six sigma methods to improve product flow, quality and on-time delivery. Diversified multi-plant and international experience. Proven leadership in start-ups, expansions, relocations and rebuilding situations. An agent for change. Strong interpersonal skills; builds teams that function independently. A skillful mentor. Projects solid organizational, presentation and communication skills to elicit teamwork and change as needed. Extensive customer and supplier relationship-building, promoting successful account development and sales volume.

SUMMARY OF QUALIFICATIONS

P&L Experience Business Plans Operations Capital Budgets Presentations Consumer Products Team Solutions Supply Chain Lean Mfg. Startups Turnarounds Six Sigma Composites Metals Adhesives Aerospace Formulations Clean Rooms Electronics Coatings Sales Support Project Mgmt. Medical Devices ISO9002 ISO13485 21 CFR 820 cGMP Shingo Metrics

PROFESSIONAL EXPERIENCE SUMMARY

Manufacturing Engineering Manager, Oncore Manufacturing Services, San Marcos, CA (2008-2011)

(Manufacturer of Electronic assemblies for: Aerospace AS9100; Medical devices - ISO 13485; healthcare; satellite communicationsCOMSEC/ITAR and various consumer products) Process owner of conceptual prototypes, product/process development, work instructions, BOMs, assembly drawings, transition to production, documentation, defect analysis, defect remediation, design for manufacturing ability (DFM) and sustaining activities to meet revenue plans and business plan objectives. Utilizes lean manufacturing and six sigma methods to promote successful continuous improvements programs that meet or exceed cost and quality objectives. Frequent, daily interaction with site leadership, production, quality, program management, and facilities to provide a cohesive and coordinated execution plan. Directed the allocation of resources for concurrent management of multiple projects and priorities. Led a multi-facility team to leverage economy-of-scale purchasing opportunities with suppliers. Implemented VMI (vendor managed inventories) with Kanban pull requirements (JIT) where advantageous . Established point-of use warehousing to eliminate costs associated with setups. Frequent interface with customers to communicate updates on productivity, quality, delivery and supplier issues. Focal point for new customer visits, program definition and scope.. Develops personnel to meet existing and anticipated challenges. Organizes and guides departmental and multi-functional sub-teams to resolve complex problems. Directs equipment maintenance activities, and process/equipment validation protocols (IQ/OQ/PQ). Develops the Cap-Ex budget to augment capabilities to meet existing and future requirements.

Served on a steering committee to attain certifications for the manufacturing of aerospace and medical devices products.. Executed the gap analysis between the requirements of the domestic and international standards (AS9100 and cGMP, 21 CFR Part 820, ISO 13485) to those of the current quality system.. Defined and documented the processes and procedures found lacking in the gap analysis. Was a principle participant in the registration audit. Results: Successfully achieved registration to the ISO13485 standard within 7 months and the AS9100 within 10 months. Manages a staff of 14 to implement Lean Manufacturing techniques (5S, value stream mapping, DMAIC, etc.) and metrics to track progress toward goals ( internal metrics, DPMO, statistical analyses, DOE) Results: Steady, continuous, and sustained progress has been made in all metric categories. Manufacturing cycle time reduced from 14 to 6 days.

Operations/Engineering Manager, Nelco Products Inc., Fullerton, CA (1999-2008)

(Manufacturer of prepreg materials and laminates for the PCB industry - Turnaround; Expansion and Startup, P&L Responsibility) Directed and coordinated plant operations to obtain optimum efficiency and maximize profits. Defines roles and responsibilities of staff to accomplish business and program objectives. Established production standards and metrics; developed budget and cost controls. Developed the facility layout and construction plan for a new manufacturing facility (Park Aircraft Technologies Corp). Participated on a corporate committee that defined and selected the capital equipment through a competitive bidding and design review process. Led efforts to obtain AS9100 certification. Results: Groundbreaking to completion of the 50,000 square foot facility was successfully completed within 14 months. Designed a series of ERP (Oracle) reports to establish a waste metric for the manufacturing managers. Led a manufacturing management team to utilize the reports and apply DMAIC principles to resolve problems contributing to waste. Utilized Cause and Effect (C&E) Matrices to dissect and solve the more complex problems. Results: Waste in the fabrication and finishing departments were reduced by 75% and 20% respectively. Assembled and mentored a multi-functional Value Stream Mapping (VSM) team to wring the value out of production processes by identifying productivity inefficiencies such as: long setup times, excessive handing, wasted motion, queues, and long WIP transactions. The VSM led to the following improvements: 1. 2. 3. 4. 5. Redesigned and reordered the product work flow to eliminate time-consuming counting and kitting of parts. Established barcode capabilities to reduce the average setup time from 15 to 2 minutes. Combined multiple processes into a single process in three different areas. Implemented work cells to minimize non-valued added activities, movements, and queue times. Removed unnecessary authorization procedures that impeded product flow.

Result: The throughput/productivity of each department was improved by an average of 25%. The average factory lead time was reduced from 3 days to less than 24 hours. Operational excellence changed an annual net loss of 15MM into an annual net gain of 6MM. The Finished Goods Inventory area was disorganized and the number one source of customer complaints (wrong shipments, late shipments, non-shipments). 1. 2. 3. 4. 5. 6. Performed Value Stream Mapping of the inventory pull process to identify inefficiencies. Implemented a 5S program to simplify, standardize, and sustain the process: Eliminated palletized storage and dependence on a forklift. Minimized the storage space by converting to smaller bin locations for manual retrieval. Utilized barcode technology to assign bin locations for product stocking and retrieval. Setup a WIFI network to dynamically download the barcode data to the ERP system.

Result: No customer complaints regarding inventory pulls. Manpower in the area was reduced from 5 to 2. The space of the inventory area was reduced from 12,000 to 3,500 square feet.

Director of Engineering and Quality, Cobra Golf Inc., Carlsbad, CA

(Exponential Growth; International Supply Chain Management) 1994 1998 Managed a staff of 12 managers/supervisors and 140 hourly.

(1994-1998)

Exponential growth in sales was causing late deliveries and quality problems with the steel and titanium golf head supply chain. Inventories of unmatched components were growing. Managed the international supply chain (China, Taiwan, Mexico) for quality and delivery problems. Performed product flow mapping at each of the vendors facilities and made the following changes: 1. 2. 3. 4. Implemented smaller batch sizes to reduce queue times and shorten the total process cycle time. Redesigned product flow to process components as matched sets instead of identical parts. Reordered the process steps, inserting AQL inspection at critical process steps. Developed/started up a limited but flexible in-house manufacturing facility to satisfy critical needs.

Results: Average lead times from our supply chain were reduced from eight to three weeks. Inventory levels were reduced by 40%. The improvement in supplier quality allowed us to reduce our incoming inspection labor by 65%. On time supplier deliveries improved from 70 to 95%. Increase the profit margin of an existing, high-volume product line. Targeted the product component with the highest DM cost. Substitutions with lower cost raw materials were made possible with slight design modifications. Result: A cost reduction of $3 per unit; $4.5 million annualized. Performance was equivalent.

Materials & Process Engineering Group Leader, Hexcel Corporation, AZ and CA (1985-1994)

(Manufacturer of Aerospace and Electronic Materials - Product Development, Startup) Part of a small research team that developed and qualified radar absorbing (stealth) materials for the B-2, F117 and YF22, leading to the winning of contracts from Boeing, Northrop and Lockheed resulting in sales totaling in the hundreds of millions of dollars. Supervised the analytical (chemical characterizations) and mechanical/environmental test labs. Utilized DOE (response surface) methods to develop manufacturing processes and chemical formulations for new product development. Startup of a new 270,000 square foot facility to supply composite materials for Air Force stealth programs. Prepreg, printing and lamination equipment were sourced, installed and started up successfully. Start-up completed 3 months ahead of schedule and 10% under budget.

Operations Manager, Wilson Sporting Goods, Saint Vincent, West Indies

(International Relocation and Startup, P&L Responsibility) 1983 1985

Startup Manager for a plant of 120; responsible for P & L and departmental budgets. Directed the manufacturing, engineering, purchasing, quality control, accounting and maintenance departments to meet business plan objectives. Financial oversight of plant operations. Charged with transferring composite tennis racket manufacturing operations from Chicago to the West Indies. systematic plan to transport equipment with minimal impact on production. Results: Plant operations were up and running within five months...shipments on time and no decrease in quality. Established a

Manufacturing Engineer, Westinghouse Electric Corp. Pittsburgh, PA

(Switchgear and Hydroelectric Power Systems ) Manufacturing engineer for the machine shop, electroplating and electroforming shop, painting and assembly operations that supported the switchgear and hydroelectric generator divisions. Machine shop processes included: milling, drilling, hydro-forming, broaching, brazing, welding, grinding, polishing, and lapping of ferrous and non-ferrous (brass, bronze, zinc, aluminum, copper and titanium) parts. Managed a $350K capital project to upgrade the electroplating shop with new, pick and place equipment and a wastewater treatment facility. Installation was completed within budget and 2 months ahead of schedule. Received praise from my mentor and was awarded employee of the year by senior management.

EDUCATION

Grove City College, Grove City, PA B.S. Chemical Engineering

You might also like

- Engineering Manager ResumeDocument10 pagesEngineering Manager ResumeJameel KhanNo ratings yet

- Manufacturing Process Engineering Manager in Huntsville AL Resume Michael FranzeseDocument3 pagesManufacturing Process Engineering Manager in Huntsville AL Resume Michael FranzeseMichaelFranzeseNo ratings yet

- Operations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsDocument2 pagesOperations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsPaulRoberts2No ratings yet

- Mark Knofler: Career OverviewDocument2 pagesMark Knofler: Career OverviewknoflerNo ratings yet

- Manufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczDocument2 pagesManufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczJosephMarkowiczNo ratings yet

- Job Profile and Work ObjectivesDocument3 pagesJob Profile and Work Objectivessunjith.sookdeo7441No ratings yet

- Quality Manager & Production Manager CompetencyDocument6 pagesQuality Manager & Production Manager CompetencyManoj MehraNo ratings yet

- Quality EngineerDocument4 pagesQuality Engineerapi-78526036No ratings yet

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDocument2 pagesProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsNo ratings yet

- Plant Manager Manufacturing Operations in Syracuse NY Resume Samuel BeamanDocument3 pagesPlant Manager Manufacturing Operations in Syracuse NY Resume Samuel BeamanSamuelBeamanNo ratings yet

- Sample Resume Process Engineer Economic RecoveryDocument10 pagesSample Resume Process Engineer Economic RecoveryVijay RajaindranNo ratings yet

- Head Manufacturing - ResumeDocument6 pagesHead Manufacturing - Resumerkgnanduri100% (4)

- Quality Manager or Quality EngineerDocument3 pagesQuality Manager or Quality Engineerapi-77217896No ratings yet

- Lean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichDocument3 pagesLean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichMichaelMakarewichNo ratings yet

- Functional Area:: ManufacturingDocument4 pagesFunctional Area:: ManufacturingHuman ResorceNo ratings yet

- Senior Quality Engineer in Houston TX Resume Frank MedranoDocument2 pagesSenior Quality Engineer in Houston TX Resume Frank MedranoFrankMedranoNo ratings yet

- Juan Fadrique Molina Naranjo RESUME Rev9Document6 pagesJuan Fadrique Molina Naranjo RESUME Rev9juan molinaNo ratings yet

- Chad Vorse Resume AllDocument2 pagesChad Vorse Resume Allapi-253814297No ratings yet

- Engineering Project Manager Continuous Improvement in Richmond VA Resume Richard MestlerDocument2 pagesEngineering Project Manager Continuous Improvement in Richmond VA Resume Richard MestlerRichardMestlerNo ratings yet

- Jaime M. Ramirez: Engineering / Operations / Plant ManagerDocument4 pagesJaime M. Ramirez: Engineering / Operations / Plant ManagerjaimejaimearturoNo ratings yet

- Executive-Level Leadership: Supply Chain Management: Ummary of UalificationsDocument2 pagesExecutive-Level Leadership: Supply Chain Management: Ummary of Ualificationswendy priana negaraNo ratings yet

- Program/Project ManagerDocument3 pagesProgram/Project Managerapi-78753389No ratings yet

- Vice President Manufacturing Operations in Milwaukee WI Resume Dennis ThomasDocument2 pagesVice President Manufacturing Operations in Milwaukee WI Resume Dennis ThomasDennisThomasNo ratings yet

- Hussain CV To The Public PDFDocument2 pagesHussain CV To The Public PDFali hussainNo ratings yet

- Director Operations Apparel Textiles Worldwide Resume Michael Marazzo JRDocument2 pagesDirector Operations Apparel Textiles Worldwide Resume Michael Marazzo JRMichaelMarazzoJrNo ratings yet

- Medical Device Engineer ResumeDocument3 pagesMedical Device Engineer ResumeAbdul samiNo ratings yet

- ! Jon Hobgood Change Agent Lean Ops ResumeDocument4 pages! Jon Hobgood Change Agent Lean Ops ResumerajathhNo ratings yet

- VP Director Manufacturing Operations in NYC Resume Mark IgnatowiczDocument3 pagesVP Director Manufacturing Operations in NYC Resume Mark IgnatowiczMarkIgnatowiczNo ratings yet

- Director VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuDocument3 pagesDirector VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuThomasZhu2No ratings yet

- Program Manager in Denver CO Resume Scott HornDocument2 pagesProgram Manager in Denver CO Resume Scott HornScottHorn2No ratings yet

- Oktoer ResumeNov2009Document3 pagesOktoer ResumeNov2009oktoer0% (1)

- Senior Operations Lean Manager in Dallas Fort Worth TX Resume James BirdDocument2 pagesSenior Operations Lean Manager in Dallas Fort Worth TX Resume James BirdJames BirdNo ratings yet

- Experienced DGM seeks senior roleDocument5 pagesExperienced DGM seeks senior rolekavas26No ratings yet

- VP IT Infrastructure Operations in San Francisco Bay CA Resume Pradeep KumarDocument4 pagesVP IT Infrastructure Operations in San Francisco Bay CA Resume Pradeep KumarPradeepKumar2No ratings yet

- Resume of KarenspahrDocument3 pagesResume of Karenspahrapi-28129161No ratings yet

- VP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonDocument2 pagesVP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonJohn Livingston2No ratings yet

- Naukri VikasMishra (19y 0m)Document7 pagesNaukri VikasMishra (19y 0m)Amit SinhaNo ratings yet

- Program Product Project Quality Manager in Central FL Resume Kevin CampbellDocument2 pagesProgram Product Project Quality Manager in Central FL Resume Kevin CampbellKevinCampbellNo ratings yet

- General Manager Lean Manufacturing in Orlando FL Resume Kevin KelseyDocument2 pagesGeneral Manager Lean Manufacturing in Orlando FL Resume Kevin KelseyKevinKelseyNo ratings yet

- Plant Manager Production in Madison WI Resume Bill StechDocument2 pagesPlant Manager Production in Madison WI Resume Bill StechBillStechNo ratings yet

- Quality Manufacturing Manager Electronics in Boston MA Resume Richard SylvainDocument2 pagesQuality Manufacturing Manager Electronics in Boston MA Resume Richard SylvainRichard SylvainNo ratings yet

- Advanced Operations Management AssignmentDocument3 pagesAdvanced Operations Management AssignmentTop Engineering SolutionsNo ratings yet

- VP Supply Chain Manufacturing in Los Angeles San Diego CA Resume Gary MuellerDocument3 pagesVP Supply Chain Manufacturing in Los Angeles San Diego CA Resume Gary MuellerGaryMueller1No ratings yet

- CV Wendel Almeida InglêsDocument5 pagesCV Wendel Almeida InglêsWendel AlmeidaNo ratings yet

- Rufus Short ResumeDocument3 pagesRufus Short ResumeStacy ElliottNo ratings yet

- Senior Project Manager in Dallas TX Resume Phillip HaugDocument2 pagesSenior Project Manager in Dallas TX Resume Phillip HaugPhillipHaugNo ratings yet

- VP Director Operations Supply Chain in San Jose CA Resume Kevin AmiriDocument2 pagesVP Director Operations Supply Chain in San Jose CA Resume Kevin AmiriKevinAmiriNo ratings yet

- Juan A. Macia: Residencial Bruno Martínez Casa 11 C, CR-SJ 10805Document2 pagesJuan A. Macia: Residencial Bruno Martínez Casa 11 C, CR-SJ 10805Juan Alberto Macia GomezNo ratings yet

- CV of Muhammad Adeel RajputDocument4 pagesCV of Muhammad Adeel RajputFarhan SaghirNo ratings yet

- Job Description: We Are An Equal Opportunities EmployerDocument1 pageJob Description: We Are An Equal Opportunities EmployerVinay KNo ratings yet

- Manager Equipment Engineering Operations in Dallas Houston TX Resume Phillip TapiaDocument3 pagesManager Equipment Engineering Operations in Dallas Houston TX Resume Phillip TapiaPhillip TapiaNo ratings yet

- Pammi Sudhakar CV 2023Document5 pagesPammi Sudhakar CV 2023Pammi SudhakarNo ratings yet

- VP Director Business Operational Excellence in Denver CO Resume Joseph EllinghausDocument2 pagesVP Director Business Operational Excellence in Denver CO Resume Joseph EllinghausJosephEllinghausNo ratings yet

- Ian Catterick's comprehensive resumeDocument6 pagesIan Catterick's comprehensive resumeJojo JacobNo ratings yet

- Controller/Accounting ManagerDocument5 pagesController/Accounting Managerapi-79129010No ratings yet

- Resume 2Document5 pagesResume 2api-334380382No ratings yet

- Director Operations Manufacturing Production in Philadelphia PA Resume Charles AltmanDocument3 pagesDirector Operations Manufacturing Production in Philadelphia PA Resume Charles AltmanCharlesAltmanNo ratings yet

- Experienced Process Engineer Seeking New OpportunitiesDocument2 pagesExperienced Process Engineer Seeking New OpportunitiesdannyNo ratings yet