Professional Documents

Culture Documents

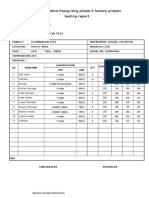

NTPC Quality Inspection

NTPC Quality Inspection

Uploaded by

Abhay TiwariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NTPC Quality Inspection

NTPC Quality Inspection

Uploaded by

Abhay TiwariCopyright:

Available Formats

QUALITY ASSURANCE & INSPECTION

BEST PRACTICES IN QUALITY ASSURANCE & INSPECTION IN NTPC

QUALITY ASSURANCE & INSPECTION

DEVELOPMENT OF QA&I IN NTPC

1975-1980

THE INFANCY : DEVELOPMENT OF STRONG BASICS

1980-1990

ESTABLISHING MATURE SYSTEM. IMPLEMENTATION OF SAME IN POWER PLANTS

1990-1995

ENTRY INTO BULK O&M PHASE OF PLANTS. STRONG BASE OF FQA

1995-2004

AMBITIOUS GENERATION AND CAPACITY ADDITION PLAN. STRONG BASE OF FQA, RIOs & CQA

QUALITY ASSURANCE & INSPECTION

QUALITY ASSURANCE

CONCEPTS

QUALITY ASSURANCE & INSPECTION

QUALITY

QUALITY

IS

FITNESS

FOR

USE

QUALITY ASSURANCE & INSPECTION

QUALITY

THE TOTALITY OF FEATURES AND CHARACTERISTICS (ATTRIBUTES) OF A PRODUCT OR SERVICE THAT BEAR ON ITS ABILITY TO SATISFY A GIVEN NEED

QUALITY ASSURANCE & INSPECTION

INSPECTION

THE PROCESS OF MEASURING, EXAMINING, TESTING, GAUGING OR OTHERWISE COMPARING ONE MORE CHARACTERISTICS OF A PRODUCT OR SERVICE WITH THE SPECIFIED REQUIREMENTS

QUALITY ASSURANCE & INSPECTION

QUALITY CONTROL

THOSE QUALITY ASSURANCE ACTIONS WHICH PROVIDE A MEAN TO CONTROL AND MEASURE THE CHARACTERISTICS OF AN ITEM, PROCESS OR FACILITY TO ESTABLISHED REQUIREMENTS.

QUALITY ASSURANCE & INSPECTION

QUALITY ASSURANCE

ALL THOSE PLANNED & SYSTEMATIC ACTIONS NECESSARY TO PROVIDE ADEQUATE CONFIDENCE THAT AN ITEM OR A FACILITY WILL PERFORM SATISFACTORILY IN SERVICE.

QUALITY ASSURANCE & INSPECTION

QUALITY SYSTEM

QUALITY ASSURANCE & INSPECTION

DEVELOPMENT OF QUALITY SYSTEM STANDARDS

1975 1977

1979

1981

1982

QA-42 DEVELOPED BY CEGB, UK. QUALITY SYSTEM REQUIREMENTS FOR NTPC CONTRACTS. BRITISH STANDARD 5750 ON QUALITY SYSTEMS. BS:5750 ON QUALITY SYSTEMS REVISED.

FIRST INDIAN STANDARD OF MANUAL ON QUALITY ASSURANCE SYSTEMS WAS PUBLISHED AS IS:10201. ISO-9000 SERIES WAS ISSUED FIRST TIME. REVISED ISO-9000 SERIES ISSUED. CURRENT SERIES OF ISO-9000 ISSUED.

1987 1994 2000

QUALITY ASSURANCE & INSPECTION

QA&I MANAGEMENT SET UP

CORPORATE QUALITY ASSURANCE

FIELD QUALITY ASSURANCE

REGIONAL INSPECTION OFFICES

QUALITY ASSURANCE & INSPECTION

CORPORATE QUALITY ASSURANCE

CORPORATE QUALITY ASSURANCE AND INSPECTION IS UNDER ENGINEERING DIVISION LOCATED AT NOIDA , HAVING A STAFF OF 66 ( 53 : QUALITY ASSURANCE + 13 : INSPECTION ). QUALITY ASSURANCE IS HAVING DIFFERENT GROUPS OF MECH., ELECT.+ C&I, CIVIL AND SPECIALIST GROUP.

QUALITY ASSURANCE & INSPECTION

REGIONAL INSPECTION OFFICES

TO FACILITATE PROMPT INSPECTION AT MANUFACTURES WORKS , APPROX. 86 ENGINEERS ARE POSTED AT 10 STRATEGICALLY LOCATED REGIONAL INSPECTION OFFICES SPREAD THROUGHOUT THE COUNTRY. MAJOR EQUIPMENTS FOR POWER PLANTS ARE MANUFACTURED AT BHEL WORKS, HENCE, FIVE OF THESE INSPECTION OFFICES FUNCTION AS RESIDENT INSPECTION OFFICES AT BHELS UNIT AT HARDWAR, TRICHY, RANIPET, HYDERABAD AND BHOPAL. REST OF THE RIOs ARE LOCATED AT KOLKATA, MUMBAI, CHENNAI, BANGLORE, DELHI, THIS ENABLES PROMPT INSPECTION AT MANUFACTURERS WORKS AT DIFFERENT STAGES.

QUALITY ASSURANCE & INSPECTION

FIELD QUALITY ASSURANCE

ALL TWENTY THREE PROJECTS OF NTPC (INCLUDING NTPC MANAGED PROJECTS) ARE HAVING FIELD QUALITY ASSURACE GROUPS, EACH HAVING STRENGTH OF THREE TO NINE EXECUTIVES. THIS GROUP IMPLEMENTS QA MANAGEMENT SYSTEM FOR ERECTION AS WELL AS O&M RELATED ACTIVITIES.

QUALITY ASSURANCE & INSPECTION

ORGANISATION STRUCTURE OF CQA&I

HEAD (QA&I)

HOD(CQA) MECHANICAL M1 SG & PIPING M2-STST & AUX. HOD(CQA) ELECTRICAL & C&I E1 TURBO GENERATOR & ROTATING MACHINES HOD(CQA) CIVIL HOD(CQA) SPECIALIST GROUP IT SUPPORT STANDARDISATION SUPPORT FOR REFERENCE QUALITY PLANS (RQPs)/ STANDARD QUALITY PLANS (SQPs) MANPOWER PLANNING BUDGETING TRAINING STATUS / PROGRESS REPORTING ISO ACTIVITIES WELDING & NDT CONSULTANCY JOBS AUDITS VENDOR ASSESSMENT VENDOR PRFORMANCE FEEDBACK VENDOR DATA BANK INSPECTION SERVICES CORPORATE INSPECTION OFFICE RIO DELHI RIO HARDWAR REGIONAL INSPN. OFFICES (RIOs) BANGLORE BHOPAL MUMBAI KOLKATTA HYDERABAD CHENNI RANIPET TRICHY FIELD QUALITY ASSURANCE (FQA) GROUPS AT PROJECT SITES/ STATIONS

M2-GT GT/HT ASSO. AUX.

M3-A M3-B MATERIAL HANDLING & Misc. M4 MECHANICAL AUXILLIARIES

E2 TRANSFORMER & SWITCHYARD

E3 SWITCHGEAR & PANELS POWER CABLES E4 C&I PKGS. INST. CABLE CONT. CABLE

QUALITY ASSURANCE & INSPECTION

SUCCESS STORY OF QA&I

QA&I HAS A VERY SPECIAL SIGNIFICANCE IN NTPCs SUCCESS. NTPC ANALYSED THE REASONS OF POOR PERFORMANCE OF POWER PLANTS IN THE COUNTRY AND ENVISAGED MANY STATE OF THE ART MANAGEMENT CONCEPTS.

QUALITY ASSURANCE & INSPECTION

SUCCESS STORY OF QA&I

NTPCS EXPERIENCE OF PLAYING A COMPLEMENTARY ROLE WITH THE EQUIPMENT MANUFACTURER IN ENSURING THE QUALITY OF EQUIPMENT HAS BEEN WELL PROVEN AND DIRECTLY REFLECTS IN THE RELIABILITY AND AVAILABILITY OF THE POWER PLANTS

QUALITY ASSURANCE & INSPECTION

FEATURES THAT MAKE QA&I EFFECTIVE

INVOLVEMENT OF QA&I AT EVERY STAGE AS AN INTEGRATED APPROACH TO ASSURE QUALITY. IN BUILT CHECKS AND EFFECTIVE CONTROLS. BALANCES ENSURE

SOME UNIQUE FEATURES OF NTPC SYSTEM ARE ELABORATED AHEAD.

QA&I

QUALITY ASSURANCE & INSPECTION

ANY CHAIN IS AS STRONG AS THE WEAKEST LINK

LINKS OF THE CHAIN ARE :

RIGHT AND PROVEN TECHNOLOGY RIGHT EQUIPMENT RIGHT SOURCES RIGHT MANUFACTURING PROCESS RIGHT SYSTEMS - MANUFACTURING QUALITY - FIELD QUALITY IN BOTH ERECTION / CONSTRUCTION AND O&M PHASE

RELIBILITY CHAIN

QUALITY ASSURANCE & INSPECTION

ENSURING HEALTHY LINKS

RELIABILITY BY SYSTEM APPROACH ENGINEERING QUALITY SYSTEMS CONTRACTUAL PROVISIONS INSPECTION FIELD QUALITY

- IN ERECTION / CONSTRUCTION - IN OPERATION & MAINTENANCE

QUALITY ASSURANCE & INSPECTION

UNIQUE FEATURES

SYSTEMS APPROACH

PREAWARD TIE -UPS POST AWARD TIE-UPS

QUALITY ASSURANCE & INSPECTION

UNIQUE FEATURES

PRE-AWARD TIE-UPS : QA REQUIREMENTS IN TECHNICAL SPECIFICATION. EVALUATION OF BIDS w.r.t. QA REQUIREMENTS. TIE-UP OF QA REQUIREMENTS DURING PRE-AWARD. FINALISATION OF LIST OF ITEMS REQUIRING QP AND SUB-VENDOR APPROVAL.

QUALITY ASSURANCE & INSPECTION

CQA ROLE IN SPECIFICATION FINALISATION AND PRE-AWARD AGREEMENT

QA REQUIREMENTS IN MODULAR SPECIFICATION BID EVALUATION VALIDATION FOR PACKAGE CONTRACT SPECIFICATION

C Q A

BID EVALUATION REPORT

E N G G

PRE-AWARD AGREEMENT WITH IDENTIFIED VENDORS/ MAIN CONTRACTORS FEEDBACK OF SUBVENDOR PERFORMANCE BY RIO / SITE

(I) LIST OF ITEMS REQUIRING QP AND SUB-VENDOR APPROVAL (II) QA&I CO-ORDINATION PROCEDURE (III) SUB-VENDOR ASSESSMENT PROCEDURE (IV) QUALITY AUDIT REQUIREMENTS TO CS & FORM PART OF LOA

ANALYSIS OF PREVIOUS NON-CONFORMITIES (NCRs)

QUALITY ASSURANCE & INSPECTION

UNIQUE FEATURES

P0ST-AWARD APPROVAL OF QUALITY PLANS.

INSPECTION AND CHP CLEARANCE SYSTEM.

DEVIATION DISPOSITIONING SYSTEM. MDCC LINKED TO RELEASE OF PAYMENT

QUALITY ASSURANCE & INSPECTION

CQA INTERACTION AT POST AWARD STAGE

QUALITY PLAN APPROVAL IDENTIFYING: -ACCEPTABLE VENDORS FOR BOIs -IN-PROCESS CHECKS -FINAL INSPECTION

FIELD QUALITY PLAN APPROVAL IDENTIFYING RECEIPT, STORAGE AND ERECTION CHECKS SUB-VENDOR ASSESSMENT : DETAILS FROM MAIN CONTRACTOR MANUFACTURING DEVIATION DISPOSITIONING ERECTION DEVIATION DISPOSITIONING

C Q A

1. MAIN CONTRACTOR 2. RIOs

1. 2.

MAIN CONTRACTOR FQA

ACCEPTANCE / REJECTION TO MAIN CONTRACTOR

1. 2. 1. 2.

MAIN CONTRACTOR RIO MAIN CONTRACTOR FQA

QUALITY ASSURANCE & INSPECTION

MANUFACTURING QUALITY PLAN

MANUFACTURERS NAME AND ADDRESS MFGR.s LOGO

MANUFACTURING QUALITY PLAN

ITEM : SUB-SYSTEM: QP NO.: REV.NO.: DATE: PAGE: . OF.

QUANTUM OF CHECK 6. M/C N REFERENCE DOCUMENT 7. ACCEPTANCE NORMS 8.

PROJECT PACKAGE

: :

CONTRACT NO. : MAIN-SUPPLIER:

FORMAT OF RECORD 9. D* AGENCY M ** C 10. N 11. REMARKS

SL. NO 1.

COMPONENT & OPERATIONS 2.

CHARACTERISTICS

CLASS

TYPE OF CHECK 5.

3.

4.

DOC. NO.:

REV CAT..

MANUFACTURER/

MAIN-SUPPLIER

MANUFACTURER/ SUB-SUPPLIER

MAIN-SUPPLIER

SIGNATURE FORMAT NO.: QS-01-QAI-P-09/F1-R0

* RECORDS, INDENTIFIED WITH TICK ( ) SHALL BE ESSENTIALLY INCLUDED BY SUPPLIER IN QA DOCUMENTATION. ** M: MANUFACTURER/SUB-SUPPLIER C: SUPPLIER/NOMINATED INSPECTION AGENCY, N: NTPC P: PERFORM W: WITNESS AND V: VERIFICATION. AS APPROPRIATE, CHP: NTPC SHALL IDENTIFIED IN COLUM N

LEGEND:

DOC. NO.:

REV CAT..

FOR NTPC USE

REVIEWED BY

APPROVED BY

APPROVAL SEAL

1/1

ENGG. DIV./QA&I

QUALITY ASSURANCE & INSPECTION

FIELD QUALITY PLAN

SUPPLIERS NAME AND ADDRESS

FIELD QUALITY PLAN

ITEM : SUB-SYSTEM : QP NO.: REV.NO.: DATE: PAGE: . OF.

TYPE O F CHEC K 5. QUANTUM O FCHEC K 6. REFER ENC E DOCUMENT 7.

PROJECT PACKAGE

: :

MFGR.s LOGO

CONTRACT NO. : MAIN-SUPPLIER:

ACC EPTANC E NO RMS 8. FO RMAT O F RECO RD 9. D* REMARKS 10.

SL. NO 1.

AC TIVITY AND OPERATIO N 2.

CHARAC TERISTIC S / INSTRUMENTS

C LASS# O F CHEC K 4.

3.

MANUFACTURER/ SUB-SUPPLIER

MAIN-SUPPLIER

SIGNATURE FORMAT NO.: QS-01-QAI-P-09/F2-R0

LEGEND: * RECORDS, INDENTIFIED WITH TICK () SHALL BE ESSENTIALLY INCLUDED BY SUPPLIER IN QA DOCUMENTATION. LEGEND TO BE USED: CLASS # : A = CRITICAL, B=MAJOR, C=MINOR; A SHALL BE WITNESSED BY NTPC FQA, B SHALL BE WITNESSED BY NTPC ERECTION / CONSTRUCTION DEPTT. AND C SHALL BE WITNESSED BY ERECTION SUPPLIER (A & B CHECK SHALL BE NTPC CHP STAGE)

DOC. NO.:

REV

FOR NTPC USE

REVIEWED BY

APPROVED BY

APPROVAL SEAL

1/1

ENGG. DIV./QA&I

QUALITY ASSURANCE & INSPECTION

CERTIFICATE OF CONFORMANCE

MAINSUPPLIERS LOGO

(NAM E & ADDRESS OF T HE M AIN SUPPLIER)

M/S.................................................................................................................................... ....... ........................................................................................................................................... .....

Ref. No. : ..................................... ..........................

Date:

CERTIFICATE OF CONFORMANCE Contract Name & Project Contract No./P.O. No. Sub Supplier's Name

Sl. No. Descripti on of item/ Equi pment

: : :

___________________________ ___________________________ ___________________________

Make NTPC DRG. NO. / GFR. DRG. NO. Qty Offe red Bal. Qty BBU Ref. Identi fication Mark

Specification Size/Type/ Rating

It is hereby confirmed that above mentioned component/item/equipment was/were manufactured and tested in accordance with drawings/data sheets as referred above and found acceptable. Signature Name Design : : :

Note:

FORMAT NO. : QS-01-QAI-P-13/ F2-R0

1/1

ENGG. DIV/QAI

QUALITY ASSURANCE & INSPECTION

INSPECTION CALL FORMAT

us'kuy FkeZy ikoj dkiksZjs'ku fy0

NATIONAL THERMAL POWER CORPORATION LTD.

(Hkkjr ljdkj dk midze)

(A Government of India Enterprise)

PROJECT NAME PROJECT NAME :__________________________________ :__________________________________

MAIN-SUPPLIER : M/S____________________________ Address: _________________________________________ ____________________Email________________________ Contact Person : __________________________________ Ph.:_______________Fax(off)________________________ Manufacturer:M/s______________________________________

(Place of Inspection)

INSPECTION CALL FORMAT

(FOR SUBMISSION BY VENDORS)

CONTRACT/PO NO. :__________________________________ DATE PROPOSED :__________________________________

NO. OF DAYS REQUIRED:______________________________ WEEKLY OFF

(For NTPC use) I/C No. Sl. No.

Address: ______________________________________________ _________________________Email________________________ Contact Person : _______________________________________ Ph.:____________________Fax(off)________________________ Mob./Res.:____________________Email____________________

Unit Cat Insp (*) REFERENCE DOCUMENT REMARKS/ UNDERTAKING

:__________________________________

BBU No. ITEM DESCRIPTION / TESTS As in BBU QUANTITY Already Offered Supplied

QP No.

1. 2

Material internally inspected, in line with NTPC QP and found satisfactory. All Reference Documents including latest revisions of NTPC approved QP /Drawing / BBU in original are available and shall be made available during inspection. All stage inspection requirements if applicable has been cleared and relevant CHPs are available. (Applicable for bought out items) Inspection by Main supplier is completed and material is cleared. OR Joint inspection along with Main supplier proposed.

Drg/Data sheet No.

3

4. 5.

Type test Approval from NTPC /Obtained / Pending / Not available.

Engg.

Material shall not be Despatched without Despatch clearance from

SIGNATURE:_____________________ NAME :_____________________ DESIGNATION :__________________ Insp. Cat (*) : Enter 0 for Stage Insp. 1 for Final Physical Insp. 2 for Review of MTCs based on QP 3 for Non-QP cases based on COC.

QUALITY ASSURANCE & INSPECTION

CHP REPORT

RI O --- ---- --

NATIONAL THERMAL POWER CORPORATION LTD

PROJECT_NAME

( A Go v ern men t o f Ind i a Ent erp ri se )

CONTRACTOR

PACKAGE NAM E

C.H.P. CLEARANCE / INTERIM INSPECTION REPORT SOBCONTRACTOR

CONTRACT_NO: CHP_NO: - ---- INSPE CTION DATE I/C NO DESCRI PTI ON OF MATERIAL / QU ANIT IT Y SL OF F ERED TEST NO

Pa g e ---QU ANIT IT Y ACCEPT ED QU ARANTI NE D/R EJECTED QT Y UNITT

PLACE

DISPOS REF ERANCE AL DOCUMENT S CODE REMARKS

MDCC NO:

/ /ANNEXURE

FOR CONTRACT OR/SUBCONTRACTOR

Fo r and beha lf o f NATIONAL T HERMAL POW ER CORP ORAT ION L T D NAME : DESI GNAT ION : FORM AT NO: QS-01 -QAI-P-13 / F3 REV '0'

QUALITY ASSURANCE & INSPECTION

MATERIAL DESPATCH CLEARANCE CERTIFICATE (MDCC)

QUALITY ASSURANCE & INSPECTION

BEST PRACTICES IN QA &I

WELL DEFINED VENDOR ASSESSMENT SYSTEM STANDARDISATION REVIEW & APPROVAL OF QUALITY PLANS THROUGH DREAMS SOFT WARE AND FORWARDING TO CONTRACTORS BY EMAIL. RECIVING INSPECTION CALLS THROUGH INTERNET AND GENERATING CHP AND MDCC THROUGH WINDSOR X SOFT WARE.

BEST PRACTICES IN QA&I

SYSTEM OF FEEDBACK QUALITY SYSTEM AUDITS OF MANUFACTURERS / SUPPLIERS AND PROJECTS SITES. PREPARATION OF TRAINING CALANDER TO CATER NEEDS OF QA,FQA AND INSPECTION EXECUTIVES, ISO 9001-2000 CERTIFICATION TO ALL INSPECTION OFFICES AND CQA

QUALITY ASSURANCE & INSPECTION

BEST PRACTICES

SUB-VENDOR ASSESSMENT SYSTEM

AT NTPC, FOR BOUGHT OUT ITEMS SUB-VENDORS ARE ACCEPTED BASED ON MAIN CONTRACTORS PROPOSAL ON PACKAGE TO PACKAGE BASIS AS PER TECHNICAL SPECIFICATION REQUIREMENTS. AS SUCH, AT PRESENT, THERE IS NO SYSTEM OF SUBVENDOR REGISTRATION OR ENLISTMENT. DETAILS OF EARLIER ASSESSED SUB-VENDOR IS KEPT IN THE FORM OF SUB-VENDOR FILES. VENDOR ASSESSMENT IS CARRIED OUT FOR SUBVENDORS IDENTIFIED IN DR (DETAILS REQUIRED ) CATEGORY DURING PRE-AWARD WITH MAIN CONTRACTOR.

QUALITY ASSURANCE & INSPECTION

BEST PRACTICES

STANDARDISATION

MODULAR AUTOMATED TECHNICAL SPECIFICATION

FINALISATION OF REFERENCE QUALITY PLAN & STANDARD QUALITY PLAN

MODEL LIST OF ITEMS REQUIRING QP APPROVAL AND SUB-VENDOR APPROVAL

INCORPORATION OF QA REQUIREMENTS IN STANDARD CHECK-LISTS PREPARED BY PROJECT ENGINEERING FOR DRAWING & DATA-SHEET APPROVAL

QUALITY ASSURANCE & INSPECTION

BEST PRACTICES

SYSTEM OF FEEDBACK

THE FEEDBACK OF INSPECTION IS USED FOR UPGRADATION OF QA REQUIREMENTS AND TIE-UPS FOR FUTURE PROJECTS

DEVIATION DISPOSITIONING DURING MANUFACTURING / ERECTION AT SITE NOT ONLY ENSURES PROPER RESOLUTION TO THE PROBLEM BUT ALSO PROVIDES FEEDBACK FOR FUTURE WORK.

FEEDBACK FROM OPERATING UNITS IS ALSO ANALYSED AND TAKEN INTO ACCOUNT FOR FUTURE PROJECTS.

QUALITY ASSURANCE & INSPECTION

BEST PRACTICES

QUALITY SYSTEM AUDITS

QUALITY SYSTEM AUDITS OF MANUFACTURING UNITS OF REGULAR SUPPLIERS W.R.T REQUIREMENTS OF ISO & OTHER QUALITY SYSTEM MANUALS IS TAKEN UP . ALSO, QUALITY SYSTEM AUDIT OF NTPC PROJECT SITES W.R.T. NTPC FQA MANUAL & CONSTRUCTION MANUAL IS TAKEN UP. FOLLOW UP FOR NECESSARY CORRECTIVE AND PREVENTIVE ACTION IS MADE BY CQA.

BEST PRACTICES

QUALITY ASSURANCE & INSPECTION

You might also like

- Current Issues in National DevelopmentDocument5 pagesCurrent Issues in National Developmentjetzon202275% (4)

- Anchor Bolt MSDocument7 pagesAnchor Bolt MSGaneshNo ratings yet

- Crap Hound No.5 (Clip Art, Stock Illustration)Document88 pagesCrap Hound No.5 (Clip Art, Stock Illustration)Fred Seibert94% (17)

- Method Statement For Lightning Protection SystemDocument14 pagesMethod Statement For Lightning Protection Systemshareyhou80% (5)

- QAP MHFrameCoversDocument4 pagesQAP MHFrameCoversAnonymous ciKyr0t100% (1)

- Baofeng Uv-5r Ce Certificate 18-211428Document3 pagesBaofeng Uv-5r Ce Certificate 18-211428anshadNo ratings yet

- Construction of Acid Proof LiningDocument4 pagesConstruction of Acid Proof LiningHiren ThakkarNo ratings yet

- Requirement of Bitumen (VG & PMB)Document5 pagesRequirement of Bitumen (VG & PMB)Veeresh SharmaNo ratings yet

- Basics of Quality Control & Quality AssuranceDocument40 pagesBasics of Quality Control & Quality AssuranceDipNo ratings yet

- VWR Binder DRY-Line Drying Oven With Natural Convection DL 53, DL 115 - EN - 301115 - User Manual PDFDocument39 pagesVWR Binder DRY-Line Drying Oven With Natural Convection DL 53, DL 115 - EN - 301115 - User Manual PDFNuno BoticaNo ratings yet

- NTPC Quality InspectionDocument39 pagesNTPC Quality InspectionPower Power60% (5)

- Chimney NotesDocument3 pagesChimney NotesmonojitdeyNo ratings yet

- Typical QAPDocument4 pagesTypical QAPhemantmech09No ratings yet

- MQP 2Document10 pagesMQP 2prithvirajd20No ratings yet

- 04-2-TS vOL-II, Sec-IV, FQP R1 PDFDocument20 pages04-2-TS vOL-II, Sec-IV, FQP R1 PDFsanjeevchhabraNo ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- C 143 - C 143M - 03 Slump TestDocument4 pagesC 143 - C 143M - 03 Slump TestHaris Alam100% (1)

- Inward Material Inspection Report: Project Name: Job Code: LocationDocument2 pagesInward Material Inspection Report: Project Name: Job Code: LocationTarun GodiyalNo ratings yet

- Testing - Concrete - FinalDocument94 pagesTesting - Concrete - FinalParvatham SubbuNo ratings yet

- Concrete Trial Mix Checklist - 01.09.2022Document5 pagesConcrete Trial Mix Checklist - 01.09.2022Pandiaraj VNo ratings yet

- Copq TemplateDocument2 pagesCopq TemplateMelissa MurrayNo ratings yet

- Itp FinalDocument5 pagesItp Finalchristopher Adajo100% (1)

- 01 - Codes ListDocument6 pages01 - Codes ListSanthoshKumarSharmaCHNo ratings yet

- QAP CI Flsnged PipesDocument11 pagesQAP CI Flsnged PipesNaveen NagisettiNo ratings yet

- Brochure - NDT QA-QC TrainingDocument2 pagesBrochure - NDT QA-QC TrainingsureinNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Welding Procedures (Overview)Document11 pagesWelding Procedures (Overview)Luis LugoNo ratings yet

- Utility Material Table (QCS 2014) PDFDocument1 pageUtility Material Table (QCS 2014) PDFSinan İcikNo ratings yet

- Welding Terms PDFDocument4 pagesWelding Terms PDFsivacwiNo ratings yet

- Weekly Safety Inspection Report: SampleDocument3 pagesWeekly Safety Inspection Report: SampleAviects Avie JaroNo ratings yet

- Tuffkote Protective CoatingsDocument2 pagesTuffkote Protective CoatingsioginevraNo ratings yet

- QAP Plan Elect.Document2 pagesQAP Plan Elect.insap_dineshNo ratings yet

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- Nitobond EP2Document4 pagesNitobond EP2Sanjeev KumarNo ratings yet

- 4 - MS-Installation GI Cable Tray, Trunking & PipesDocument7 pages4 - MS-Installation GI Cable Tray, Trunking & PipesAraf KalamNo ratings yet

- ConduitsDocument10 pagesConduitsSiddiqui Abdul KhaliqNo ratings yet

- Specification For Hot Dip GalvanizingDocument10 pagesSpecification For Hot Dip GalvanizingKyaw Kyaw Aung100% (1)

- Draft QPADocument3 pagesDraft QPASams Romantiz S'bontothlzNo ratings yet

- Is 9417 1989Document15 pagesIs 9417 1989Ganesh RajaNo ratings yet

- Procedure For Erection of Pipings and StructuresDocument10 pagesProcedure For Erection of Pipings and StructuresraviNo ratings yet

- Field Quality Plan - Civil - Rev 1 - 24 (1) .04.09Document13 pagesField Quality Plan - Civil - Rev 1 - 24 (1) .04.09Sandeep JoshiNo ratings yet

- Dinesh Qa-Qc EngineerDocument6 pagesDinesh Qa-Qc EngineerDinesh SomwanshiNo ratings yet

- Tested by Type of Material: Date of TestingDocument1 pageTested by Type of Material: Date of TestingAmit MaityNo ratings yet

- 1363-Hexagonal Head Bolts, Screws & Nuts of Product Grade - CDocument13 pages1363-Hexagonal Head Bolts, Screws & Nuts of Product Grade - CsdmelNo ratings yet

- BK-HH-QAC-MS-0017 - Foundation of Central Control Room & Switch Gear BuildingDocument12 pagesBK-HH-QAC-MS-0017 - Foundation of Central Control Room & Switch Gear BuildingSyed Abbas AliNo ratings yet

- Ref FQP ErectionDocument12 pagesRef FQP ErectionSaurabh HimkarNo ratings yet

- Masterprotect 190: A Two Component Solvent Free High Build Flexible Epoxy Polyurethane Resin Coating SystemDocument3 pagesMasterprotect 190: A Two Component Solvent Free High Build Flexible Epoxy Polyurethane Resin Coating SystemEngTamer100% (1)

- Speed Control System With Rfid Equipped VehicleDocument27 pagesSpeed Control System With Rfid Equipped VehicleAnonymous L9fB0XUNo ratings yet

- Quality ControlDocument30 pagesQuality ControlkhanNo ratings yet

- Illumination Test ReportDocument1 pageIllumination Test ReportSói XámNo ratings yet

- JEE Advanced SC/ST Certificate FormatDocument1 pageJEE Advanced SC/ST Certificate FormatNishit kumar100% (1)

- 8 Field Quality PlanDocument18 pages8 Field Quality Plangeorge_hem100% (1)

- Manoj Kumar QC (C.V)Document4 pagesManoj Kumar QC (C.V)HeartyscorpionNo ratings yet

- Internal Test ReportDocument4 pagesInternal Test ReportAvishek ChowdhuryNo ratings yet

- Audit Notification - EmersonDocument2 pagesAudit Notification - Emersonnisha_khanNo ratings yet

- Specifications of Painting WorksDocument7 pagesSpecifications of Painting WorksSiddharth Gamare100% (1)

- Field Quality Plan For LgfsDocument7 pagesField Quality Plan For LgfsUday PratapNo ratings yet

- The Tata Power Company LimitedDocument10 pagesThe Tata Power Company LimitedSinumalathi MathiNo ratings yet

- Quantum of Check of Material&WorkmanshipDocument35 pagesQuantum of Check of Material&Workmanshipsanjay vidhateNo ratings yet

- QAP VerticalDocument8 pagesQAP VerticalNischay GuptaNo ratings yet

- QAQCDocument43 pagesQAQCsandeep sharmaNo ratings yet

- Certified Qa QC Engineer CivilDocument8 pagesCertified Qa QC Engineer CivilN P Srinivasarao0% (1)

- Effective Implementation of an ISO 50001 Energy Management System (EnMS)From EverandEffective Implementation of an ISO 50001 Energy Management System (EnMS)Rating: 4 out of 5 stars4/5 (1)

- Best Practices in Quality Assurance & Inspection IN NTPCDocument39 pagesBest Practices in Quality Assurance & Inspection IN NTPCbunyi gitarNo ratings yet

- Simple PendulumDocument3 pagesSimple Pendulumhittaf_05100% (1)

- Crash 2024 04 04 - 15.12.27 ClientDocument23 pagesCrash 2024 04 04 - 15.12.27 Clientdpi61317No ratings yet

- Reles 21Document32 pagesReles 21José Ignacio SarasolaNo ratings yet

- Bunsen BurnerDocument28 pagesBunsen BurnerMac SensNo ratings yet

- Nelson & Quick: Conflict at WorkDocument24 pagesNelson & Quick: Conflict at WorkberitahrNo ratings yet

- Chapter 3 (Methodology)Document7 pagesChapter 3 (Methodology)BYO KOSMETIKNo ratings yet

- SL No Package Cost/Sft Remarks Amount (INR) : PROJECT: Indore-Licious General Contract WorksDocument22 pagesSL No Package Cost/Sft Remarks Amount (INR) : PROJECT: Indore-Licious General Contract WorksChaitanya IdateNo ratings yet

- Configuring MPLS VPNs - Troubleshooting Any Transport Over MPLS Based VPNsDocument19 pagesConfiguring MPLS VPNs - Troubleshooting Any Transport Over MPLS Based VPNsAnonymous 6PurzyegfXNo ratings yet

- Onestop Qamaker: Extract Question-Answer Pairs From Text in A One-Stop ApproachDocument8 pagesOnestop Qamaker: Extract Question-Answer Pairs From Text in A One-Stop ApproachSV PRNo ratings yet

- Kelly, Louise Lings, IanDocument40 pagesKelly, Louise Lings, IanLiya liyaNo ratings yet

- Lecture 2 Materials and Methods 2Document30 pagesLecture 2 Materials and Methods 2Jefferson AltarNo ratings yet

- Muskingam Routing PDFDocument35 pagesMuskingam Routing PDFDario PrataNo ratings yet

- Example of An Analytic RubricDocument2 pagesExample of An Analytic RubricAngelica W. PetinesNo ratings yet

- GQ Curtain Wall Catalogue - 2015Document28 pagesGQ Curtain Wall Catalogue - 2015Pham LamNo ratings yet

- My Google Docs Book ListDocument3 pagesMy Google Docs Book ListYadira JohnsonNo ratings yet

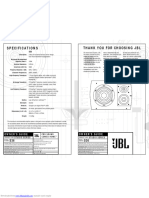

- JBL-Studio S36 SpecsDocument2 pagesJBL-Studio S36 SpecsJhasmani VillegasNo ratings yet

- Implementing Switch Debounce by Code in Embedded System DesignDocument3 pagesImplementing Switch Debounce by Code in Embedded System DesignOliver DennisNo ratings yet

- (BS en ISO 6245-2002) - Methods of Test For Petroleum and Its Products. BS 2000-4 - Determination of Ash.Document16 pages(BS en ISO 6245-2002) - Methods of Test For Petroleum and Its Products. BS 2000-4 - Determination of Ash.CHOUCHENE ELYES100% (2)

- LM359 Dual, High Speed, Programmable, Current Mode (Norton) AmplifiersDocument24 pagesLM359 Dual, High Speed, Programmable, Current Mode (Norton) Amplifierswilliamjamir2295No ratings yet

- PLTW AR IntroToMechanismsPowerPointDocument39 pagesPLTW AR IntroToMechanismsPowerPointAbdulsalam OmotoshoNo ratings yet

- Chimei Innolux N101BGE Datasheet PDFDocument29 pagesChimei Innolux N101BGE Datasheet PDFMichelle BoorNo ratings yet

- NEWTRAININGTEMPLETEDocument149 pagesNEWTRAININGTEMPLETESheenuNo ratings yet

- Choosing A Recruitment AgencyDocument2 pagesChoosing A Recruitment Agencyanis_kasmani9880No ratings yet

- Mbajtesi Kryesor, Prerjet KritikeDocument4 pagesMbajtesi Kryesor, Prerjet KritikeRilind KuçiNo ratings yet

- 17 Batch Seminar MarksDocument9 pages17 Batch Seminar MarksSujana KalyanNo ratings yet

- Optical Lecture 3 NUDocument36 pagesOptical Lecture 3 NUPhon PhannaNo ratings yet