Professional Documents

Culture Documents

Fit Selection Basic

Fit Selection Basic

Uploaded by

api-3848892Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fit Selection Basic

Fit Selection Basic

Uploaded by

api-3848892Copyright:

Available Formats

1121

H6 H7 H8 H9 Applicable part Functional classification Application example

The part which allows a large clearance space or the part requires Functionally, the part which requires large clearance space Piston ring and piston ring groove

c9 clearance space. The part which can be enlarged to make clearance Expanse. Positioning error is large.

space to make assembly easier. Fit of loosening safety pin

Length of fit is long.

Loose fit

The part which requires proper clearance space in the high temperature.

For reducing Crank web and pin bearing (Side surface)

The part which allows a large clearance space or

d9 d9 Production cost Exhaust valve cage and traveling part of spring sheet

the part requires clearance space.

Safety cost Piston ring and piston ring groove

プレス

The part which allows a slight clearance space or the part requires clearance space(high grade fit). Fit of exhaust valve seat Shoulder Bolts MSB(e9)

The bearing part which has slight clearance space and good lubrication.

e7 e8 e9 The general rotating or traveling part. Main bearing for crankshaft Stopper Bolts STBG(e9)

Light rolling fit

The bearing part which is working under the condition of high temperature, (The condition of good lubrication is required.) General traveling part Puller Bolts PBNT(e9)

high speed and high load(high grade pressure feed lubrication).

Clearance fit

〔Technical Data〕

f7 Fit which can be mobile due to proper clearance space(high grade fit). Ordinary fit parts. Insertion part of cooling exhaust valve cage Return Pins(f6)

f6 f7 (Disassembling is often done.) General shaft and bushing Runner Lock Pins(f6)

Can be moved relatively

f8 The general cold bearing part of grease or oil lubrication. Lever for link system and bushing

The continuous rotary part of light load precision machine. The part which requires precision Pin for link system and lever

g5 g6 Fit which can be mobile in spite of small clearance space Key and key groove

movement without any slack.

rolling fit Rolling fit

(spigot and positioning). Precision traveling part. Valve stem of precision control valve Pusher Pins PSP(g6)

Fit Selection Basics

h7 Fit which can be moved manually with using a lubricator(high grade positioning). Fit of rim and boss

h5 h6 h9 Special precision traveling part. Fit of toothed gear of precision gear mechanism

h8 Stationary part which is not of great importance. Dowel Pins MSTH(h7) Sprue Bushings(h6)

Mounting part which is given a little leeway. Capable of Fit between joint flanges

h5 assembling

js6 High-precision positioning where both are unmobile. Transmission of Governor way and pin

h6 and disas-

Push fit Lubricated fit Precision

Fit which can be assembled and disassembled by wood or lead hammer. power cannot Fit of rim of toothed gear and boss

sembling be done by only

Fit which can be assembled and disassembled by an iron hammer or hand press. Fixation of gear pump shaft and casing

without junction power

js5 k6 (Key or such items are required to prevent other components from rotating). Reamer bolt Press-fit Section of Tapered Pin Sets(k6)

damaging of fit.

High-precision positioning. components.

Transition fit

Reamer bolt Dowel Pins MSTM(m6)

Same as the above for assembling and disassembling

Driving fit

k5 m6 Fixation of piston of hydraulic system and shaft Ball Buttons BBT(k5)

High-precision positioning which does not tolerate any clearance space. Fit of joint flange and shaft

Fit which requires considerable power for assembling and disassembling. Flexible plate coupling and gear(passive side)

m5 n6 High-precision fixed mounting. Precision fit Leader Pins & Bushings(m5)

Small power

Manual for Designing

Insertion of valve guide for inlet valve Angular Pins(m5)

Light press fit

(Key or such items are required for large torque transmission.) can be

Fit which requires much power for assembling and disassembling.(Key or such items are required transmitted by Insertion of valve guide for inlet valve Dowel Pins MST(p6)

n5

p6 for large torque transmission.)However, when non-ferrous components are fitted together, press junction power Fixation of gear and shaft(small torque) Stopper Pins STPN(p6)

n6 fit power will be activated.Standard press fit fixing between iron and iron or between bronze and copper. of fit. Flexible plate coupling and gear(active side)

Cannot be moved relatively

Press fit

Same as the above for assembling and disassembling

p5 r6 Joint and shaft

Shrinkage fit, cooling fit and strong press fit for large dimension compo-nents. Hard to

Excerpt from“Usage of JIS series”

disassemble

(Precision Ver.)

r5 s6 without Fixation of bushing for bearing

Considerable

damaging Insertion of valve guide for inlet valve

t6 Fixed firmly together, so that permanent assembling can be sought with power can be

components.

Interference fit

shrinkage fit, cooling fit and strong press fit for assembling. Press fit for light alloy. transmitted by Fixation of joint flange and shaft(large torque)

u6 junction power

of fit. Fixation of driving gear and boss

x6

Strong press fit・Shrinkage fit・Cooling fit

Fixation of bushing for bearing

Printed in red are listed with applicable examples of mold parts.

1.1 Commonly used hole-basis fits 2.1 Commonly used shaft-basis system of fits

Basic Tolerance zone class of shaft Tolerance zone class of hole

hole Basic shaft

Clearance fit Transition fit Interference fit Clearance fit Transition fit Interference fit

g5 h5 js5 k5 m5 h5 H6 JS6 K6 M6 N6 * P6

H6

f6 g6 h6 js6 k6 m6 n6 * p6 * F6 G6 H6 JS6 K6 M6 N6 P6 *

h6

f6 g6 h6 js6 k6 m6 n6 p6 * r6 * s6 t6 u6 x6 F7 G7 H7 JS7 K7 M7 N7 P7 * R7 S7 T7 U7 X7

H7

e7 f7 h7 js7 E7 F7 H7

h7

f7 h7 F8 H8

H8 e8 f8 h8 D8 E8 F8 H8

h8

d9 e9 D9 E9 H9

d8 e8 h8 D8 E8 H8

H9

c9 d9 e9 h9 h9 C9 D9 E9 H9

〔Technical Data〕

H10 b9 c9 d9 B10 C10 D10

Notice*Fits will make exceptions according to the size steps. Notice*Fits will make exceptions according to the size steps.

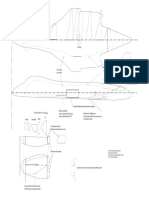

1.2 Mutual relations of tolerance zone in commonly used hole-basis system of fits 2.2 Mutual relations of tolerance zone in commonly used shaft-basis system of fits

Basic hole H6 H7 H8 H9 H10 Basic shaft h5 h6 h7 h8 h9

Clearance fit Transition fit Interference fit Clearance fit

Clearance Transition Clearance Clearance Clearance Transition Interference Clearance Clearance Clearance

fit

Fit Fit

fit fit fit fit fit fit fit fit fit fit

Press fit

Rolling fit

Clearance fit

Driving fit

Transition

Interference fit

Interference fit

Shrinkage fit

Light rolling fit

Loose rolling fit

Strong press fit

Lubricated fit

Tolerance range class of shaft f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9 d8 d9 g8 e9 h8 h9 b9 c9 d9 Tolerance range class of shaft M6 JS6 K5 M6 N6 P6 F6 F7 G6 G7 H6 H7 JS6 JS7 K6 K7 M6 M7 N6 N7 P6 P7 R7 S7 T7 U7 X7 E7 F7 F8 H7 H8 D8 D9 E8 E9 F8 H8 H9 B10 C9 C10 D8 D9 D10 E8 E9 H8 H9

50 200

Dimensional Tolerance and Fits

H10

H9

H7 H8

H6

0 150

−50 100

Variation of tolerance

Variation of tolerance

(μm) (μm)

−100 50

−150 0 h5 h6 h6 h7 h8

h9

Excerpt from JIS B 0401(1986)

−200 −50

*This table shows the case when basic size is over 18mm to 30mm. *This table shows the case when basic size is over 18mm to 30mm.

1122

You might also like

- Critical Thinking Skills Success in 20 Minutes A Day - Lauren StarkeyDocument182 pagesCritical Thinking Skills Success in 20 Minutes A Day - Lauren StarkeyAustin Higgins97% (61)

- LCC M150 500 3 LCCPump Metal PDFDocument8 pagesLCC M150 500 3 LCCPump Metal PDFFrancisco Loyola CarrascoNo ratings yet

- Group 3 Swing Device: 1. StructureDocument11 pagesGroup 3 Swing Device: 1. StructurethierrylindoNo ratings yet

- Rotor Air CoolersDocument8 pagesRotor Air CoolersZainulAbidinNo ratings yet

- Solid Works Drawing and DetailingDocument69 pagesSolid Works Drawing and Detailingapi-3848892100% (1)

- Presentation Asme Sec-Ix Wps PQR Wpq..Document176 pagesPresentation Asme Sec-Ix Wps PQR Wpq..Utkarsh GautamNo ratings yet

- Hydrodynamic Journal Bearings by MFDocument72 pagesHydrodynamic Journal Bearings by MFTanweer Ahmed100% (1)

- ROPS FOPS Test Certificate ST1030Document1 pageROPS FOPS Test Certificate ST1030Ventasde VehiculosNo ratings yet

- Surface Roughness by Different Processing MethodsDocument1 pageSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- Surface Roughness by Different Processing MethodsDocument1 pageSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- HSD PDFDocument3 pagesHSD PDFDavid AguilarNo ratings yet

- PLC Basic Programme BookDocument45 pagesPLC Basic Programme Bookapi-384889275% (4)

- Painting RecordDocument1 pagePainting RecordHimawan Setyarso100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Belt Scale Application GuidelinesDocument25 pagesBelt Scale Application Guidelinesบิ๊ก บิ๊กNo ratings yet

- Linatex Screen O&m ManualDocument23 pagesLinatex Screen O&m ManualsirercksNo ratings yet

- Wear ProtectionDocument6 pagesWear ProtectionRafael CortezNo ratings yet

- Mechanical OPerationDocument10 pagesMechanical OPerationAnshika RajputNo ratings yet

- C1540-683 Recirc-532Document1 pageC1540-683 Recirc-532eaglego00100% (1)

- WL 00200 6 de enDocument200 pagesWL 00200 6 de enaNo ratings yet

- 20X6 Static Rinser: Powerscreen Parts Manual Version 02eg FROM S/N PID00010C76D05004Document59 pages20X6 Static Rinser: Powerscreen Parts Manual Version 02eg FROM S/N PID00010C76D05004Andrey L'vovNo ratings yet

- Finite-Element Design of Concrete Structures - Practical Problems and Their Solutions 2nd - G. A. Rombach PDFDocument372 pagesFinite-Element Design of Concrete Structures - Practical Problems and Their Solutions 2nd - G. A. Rombach PDFWasin WaiyasusriNo ratings yet

- Installation, Operation and Maintenance of Airflex Model VC Grinding Mill ClutchesDocument33 pagesInstallation, Operation and Maintenance of Airflex Model VC Grinding Mill Clutchesdennis_schoonhovenNo ratings yet

- Tolerances FabDocument1 pageTolerances FabAnwarNo ratings yet

- Line Sizing Criteria As Per Different International StandardsDocument12 pagesLine Sizing Criteria As Per Different International StandardsbadelitamariusNo ratings yet

- Kpi-Jci: Tolerances - Unless Noted: NoticeDocument1 pageKpi-Jci: Tolerances - Unless Noted: NoticeRubenNo ratings yet

- Surface RoughnessDocument1 pageSurface Roughnessapi-3848892100% (2)

- Surface RoughnessDocument1 pageSurface Roughnessapi-3848892100% (2)

- Surface RoughnessDocument1 pageSurface Roughnessapi-3848892100% (2)

- Rochi 2019 PDFDocument26 pagesRochi 2019 PDFGautamNo ratings yet

- Introduction To Structural AnalysisDocument32 pagesIntroduction To Structural AnalysisSteven KuaNo ratings yet

- Settlement 1Document16 pagesSettlement 1James Anthony TorresNo ratings yet

- Palla: Vibrating MillDocument16 pagesPalla: Vibrating MillSanjeev AroraNo ratings yet

- Us 12e pr1265 PDFDocument1 pageUs 12e pr1265 PDFAzis AbdNo ratings yet

- Tightening ForceDocument1 pageTightening ForceLuisLauShNo ratings yet

- Flender Technical HandbookDocument79 pagesFlender Technical HandbookKADİR durmazNo ratings yet

- Slurry Pump The KproDocument11 pagesSlurry Pump The Kpro4lk0nNo ratings yet

- L410UVP E20 2021 - WebDocument12 pagesL410UVP E20 2021 - WebCOOPERATIVA RUBEMANo ratings yet

- CR800 Hybrid Low ResDocument8 pagesCR800 Hybrid Low RestappannNo ratings yet

- Socket Head Cap ScrewsDocument1 pageSocket Head Cap Screwsapi-3848892100% (5)

- Socket Head Cap ScrewsDocument1 pageSocket Head Cap Screwsapi-3848892100% (5)

- Gas LiftDocument12 pagesGas LiftLulav BarwaryNo ratings yet

- SEW Compact Constant Speed Reducer MC SeriesDocument195 pagesSEW Compact Constant Speed Reducer MC SeriesDênis DáyolNo ratings yet

- E - 7403-9000 - Table of ContentsDocument4 pagesE - 7403-9000 - Table of Contentsraobabar21No ratings yet

- Basic of FastenersDocument53 pagesBasic of FastenersKomal TagraNo ratings yet

- Analysis of Spiral Power SpringDocument4 pagesAnalysis of Spiral Power SpringMuhd IlhamNo ratings yet

- General Kinematics - UncoalerDocument38 pagesGeneral Kinematics - UncoalerJogesh NarulaNo ratings yet

- NutsDocument49 pagesNutsIshant JaiswalNo ratings yet

- Passingen PDFDocument1 pagePassingen PDFAnonymous Z4Jo4fXVNo ratings yet

- Natural RubberDocument7 pagesNatural RubberFrancis AdrianNo ratings yet

- Wecall CatalogDocument20 pagesWecall Catalogpdoherty100% (2)

- Helical Compressing Spring Calculation PDFDocument4 pagesHelical Compressing Spring Calculation PDFViktor KovtunNo ratings yet

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- Technical Data (Thai) 3Document1 pageTechnical Data (Thai) 3NatKThNo ratings yet

- Is 6051 1970Document15 pagesIs 6051 1970harshal161987100% (1)

- Catálogo RULMECADocument308 pagesCatálogo RULMECArdgmaxiNo ratings yet

- EZG Series Slurry Pump: Excellence Pump Industry Co., LTDDocument6 pagesEZG Series Slurry Pump: Excellence Pump Industry Co., LTDCristobal BernalNo ratings yet

- ASUG Company ProfileDocument1 pageASUG Company ProfileAndre WAGNo ratings yet

- CC07 - ECR Info System-Ecc6Document7 pagesCC07 - ECR Info System-Ecc6NadeemNo ratings yet

- A Study On Tribological & Statistical Investigation of PTFE, Tin Bronze and White MetalDocument9 pagesA Study On Tribological & Statistical Investigation of PTFE, Tin Bronze and White MetalIJRASETPublicationsNo ratings yet

- (17CrNiMo6) 4317 Case Hardening SteelDocument3 pages(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNo ratings yet

- ABB CatalogueDocument6 pagesABB CatalogueNavneet SinghNo ratings yet

- WL 00200 5 T6-8 de enDocument39 pagesWL 00200 5 T6-8 de enrwva20No ratings yet

- md-8 Spring DesignDocument8 pagesmd-8 Spring DesignBharatiyulamNo ratings yet

- SDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Document15 pagesSDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Ali YükselNo ratings yet

- Vertical and Horizontal Screw ConveyorsDocument4 pagesVertical and Horizontal Screw ConveyorsLLNo ratings yet

- Steel Grades Material and Chemical Composition InformationDocument2 pagesSteel Grades Material and Chemical Composition InformationMitesh PhalakNo ratings yet

- Fits BoreDocument1 pageFits BorezzzNo ratings yet

- Flexible Couplings: ElflexDocument8 pagesFlexible Couplings: ElflexSUNIL TVNo ratings yet

- Chemical ChartDocument6 pagesChemical ChartAnurag SarkarNo ratings yet

- Vibration Formula ScribDocument2 pagesVibration Formula ScribiulianstoicaNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Fitting Which Requires Large Force For Assembly/disassembly A Key or Other Device Is Required For High-Torque Transmission Purposes.Document1 pageFitting Which Requires Large Force For Assembly/disassembly A Key or Other Device Is Required For High-Torque Transmission Purposes.Eli BoscanNo ratings yet

- Fit Selection BasicDocument1 pageFit Selection Basicfeni4kaNo ratings yet

- Brochure E20 ENG WebDocument12 pagesBrochure E20 ENG WebEng.Muhammad MisbahNo ratings yet

- SKF WSTU 215-SRB-CRE SpecificationDocument5 pagesSKF WSTU 215-SRB-CRE SpecificationGuess VaughnNo ratings yet

- Rolled Ball Screws / Precision Ball Screws: - Selection ProcessDocument1 pageRolled Ball Screws / Precision Ball Screws: - Selection Process杜文欽No ratings yet

- B-1B 46 Inch Wing Span Fuselage & NacelleDocument1 pageB-1B 46 Inch Wing Span Fuselage & NacelleOkoNo ratings yet

- Calculation of Beam DeflectionDocument1 pageCalculation of Beam Deflectionapi-3848892100% (2)

- Greek Symblos-Atomic SymbolsDocument1 pageGreek Symblos-Atomic Symbolsapi-3848892No ratings yet

- Greek Symblos-Atomic SymbolsDocument1 pageGreek Symblos-Atomic Symbolsapi-3848892No ratings yet

- Claculation of Area, Center of Gravity and Sectional Secondary MomentDocument1 pageClaculation of Area, Center of Gravity and Sectional Secondary Momentapi-3848892No ratings yet

- Examples of Applicable Steels For Typical ProductsDocument1 pageExamples of Applicable Steels For Typical Productsapi-3848892No ratings yet

- Calculation of Beam DeflectionDocument1 pageCalculation of Beam Deflectionapi-3848892100% (2)

- Solidworks Tutorial 07nov06Document13 pagesSolidworks Tutorial 07nov06Robin SanjayaNo ratings yet

- Cosmos SWDocument52 pagesCosmos SWRicardo Vargas GraciaNo ratings yet

- Solid Works AssemblyDocument46 pagesSolid Works Assemblyapi-3848892No ratings yet

- Mastercam Tutorial Surface ModelingDocument4 pagesMastercam Tutorial Surface Modelingapi-3848892100% (1)

- Ug Nx3 TutorialDocument235 pagesUg Nx3 TutorialAJAYKRISHNAA92% (13)

- Prepare For IELTSDocument170 pagesPrepare For IELTSevilinside_me96% (23)

- Conversion Table of HardnessDocument1 pageConversion Table of Hardnessapi-3848892100% (2)

- Fit Selection BasicDocument1 pageFit Selection Basicapi-3848892100% (2)

- Calculation of Beam DeflectionDocument1 pageCalculation of Beam Deflectionapi-3848892100% (2)

- Physics 2017 HSCDocument44 pagesPhysics 2017 HSCSophiaNo ratings yet

- Chapter 8 - FailureDocument6 pagesChapter 8 - FailureThành Phương TấnNo ratings yet

- CK-12 Physics Int Q&T Answer Key (07.25.17)Document345 pagesCK-12 Physics Int Q&T Answer Key (07.25.17)Mridu Jahid MollaNo ratings yet

- EXPERIMENT NO 2 (Aggregate Crushing Value)Document3 pagesEXPERIMENT NO 2 (Aggregate Crushing Value)ADENIRAN firdausNo ratings yet

- Axial Deformation Problems With Solutions PDFDocument2 pagesAxial Deformation Problems With Solutions PDFAngela ElumbaNo ratings yet

- CAPE Chemistry 2014 U2 P2Document18 pagesCAPE Chemistry 2014 U2 P2Unknown userNo ratings yet

- Fluorescence Recovery After Photobleaching (FRAP) Is ADocument6 pagesFluorescence Recovery After Photobleaching (FRAP) Is AYunonNo ratings yet

- Frame Stress CalculationDocument15 pagesFrame Stress CalculationNyein ZawNo ratings yet

- Science & Technology Questions For Competitive Exams PDFDocument7 pagesScience & Technology Questions For Competitive Exams PDFAntarip IndranoojNo ratings yet

- Task 1-Eider Estrada Task 1-Eider EstradaDocument11 pagesTask 1-Eider Estrada Task 1-Eider EstradaMiGue DAzaNo ratings yet

- Pelton Wheel: Muhamad Ridzuan Bin Arifin - CD 060091Document17 pagesPelton Wheel: Muhamad Ridzuan Bin Arifin - CD 060091limakupang_matNo ratings yet

- Objective Questions (01 To 15) : Structural AnalysisDocument380 pagesObjective Questions (01 To 15) : Structural AnalysisJohn andre MarianoNo ratings yet

- Rates of Reaction LabDocument3 pagesRates of Reaction LabHobi and Jimin’s waRM Jinger Tae with Suga KookiesNo ratings yet

- Impulse and Momentum PDFDocument3 pagesImpulse and Momentum PDFEjurango JhaNo ratings yet

- Projectile Motion Lab RevisedDocument7 pagesProjectile Motion Lab RevisedLeznan DayNo ratings yet

- Structural Integrity of Fiber Re InfoDocument13 pagesStructural Integrity of Fiber Re InfoSebastian RocaNo ratings yet

- Advanced Sampling Che210D: Difficult-To-Simulate SystemsDocument10 pagesAdvanced Sampling Che210D: Difficult-To-Simulate SystemsPrasad Uday BandodkarNo ratings yet

- Chemical Engineering Journal: Cintia F. Yamamoto, Elaine I. Pereira, Luiz H.C. Mattoso, Teruo Matsunaka, Caue RibeiroDocument8 pagesChemical Engineering Journal: Cintia F. Yamamoto, Elaine I. Pereira, Luiz H.C. Mattoso, Teruo Matsunaka, Caue RibeiroLeo LopezNo ratings yet

- Task 4 - Soalan KBATDocument3 pagesTask 4 - Soalan KBATFATIMAH BINTI HISHAMUDDIN IPGKTINo ratings yet

- ƒTESTEX Data Sheet TRITON BFET 051721 REVDocument2 pagesƒTESTEX Data Sheet TRITON BFET 051721 REVElyel GonzalezNo ratings yet

- Angelica Junco SOLIDDocument10 pagesAngelica Junco SOLIDAbraham BarrónNo ratings yet

- YZ-Systems - Crude Oil Sampling System - Datasheet - HiResDocument2 pagesYZ-Systems - Crude Oil Sampling System - Datasheet - HiResCuong TranHungNo ratings yet