Professional Documents

Culture Documents

Tech Brief 3

Tech Brief 3

Uploaded by

Afzalul Karim NirvickOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tech Brief 3

Tech Brief 3

Uploaded by

Afzalul Karim NirvickCopyright:

Available Formats

Tech brief #3

MSES 5100 Section 001

Md. Afzalul Karim 14/02/2012

Source: Wang Wei, Zhu Di, D. M. Allen, H. J. A. Almond, "Non-traditional Machining Techniques for Fabricating Metal Aerospace Filters"-Chinese Journal of Aeronautics 21(2008) 441447

Thrust: Due to the necessity of precise and cost-effective way to manufacture aerospace filter ,some of the non-traditional machining process overcome the conventional machining processes. Photochemical machining (PCM), photo electroforming (PEF) or laser beam machining (LBM) are the methods that are selected for three aerospace filters to analysis the most efficient and convenient one among them. Several hydraulic and pneumatic parts of the aerospace using these filter to maintain contamination level. That's why the comparison between those NTM method with traditional one is necessary. Traditional fabrication method such as punching, stamping, drilling are used for stronger perforated metal plates but to made Etched disk filter which is advanced fluid filter need to make with Ti generally use PCM for bur free and variable edge profile capabilities. To make Ultra fine micro filters from 2D design PEF is best suitable rather than PCM because of its unique multi level features. But for considering the operating life Titanium propellant filter manufactured by LBM process is best suitable because of its high aspect ratio, precision and accuracy. So these are the way to accomplish the demand of making aerospace filter considering the manufacturing aspect.

You might also like

- Padeye Calculation For Lifting AnalysisDocument3 pagesPadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- V65 N2 P3 C822 KafaliDocument16 pagesV65 N2 P3 C822 KafalimaheshNo ratings yet

- 1 s2.0 S2212671612001813 MainDocument6 pages1 s2.0 S2212671612001813 MainMarcelo SantanaNo ratings yet

- Laser Cutting ItsrDocument31 pagesLaser Cutting Itsrpavi32No ratings yet

- Assignment 5Document1 pageAssignment 5utkarshtyagi2307No ratings yet

- Ucmp-Question Bank - NewDocument4 pagesUcmp-Question Bank - New9966197483No ratings yet

- Syllabus - SEM VI-DE 1 (ME-AE) - Advanced Manufacturing ProcessesDocument3 pagesSyllabus - SEM VI-DE 1 (ME-AE) - Advanced Manufacturing ProcessesAnonymous gvikC9AsDNo ratings yet

- State of The Art On Chemical and Electrochemical Based Finishing Processes For Additive Manufactured FeaturesDocument28 pagesState of The Art On Chemical and Electrochemical Based Finishing Processes For Additive Manufactured FeaturesDaris BaihaqiNo ratings yet

- Untitled DocumentDocument2 pagesUntitled DocumentVivek Rampure KNo ratings yet

- MMP NotesDocument81 pagesMMP NotestatiNo ratings yet

- MEPE34 Additive Manufacturing: Dr. N. Siva ShanmugamDocument17 pagesMEPE34 Additive Manufacturing: Dr. N. Siva ShanmugamJoe AllanNo ratings yet

- 2015 Laser-Beam-Welding-of-Tit-Add Manufd-PartsDocument6 pages2015 Laser-Beam-Welding-of-Tit-Add Manufd-PartsbhaskarNo ratings yet

- NtmpmechDocument144 pagesNtmpmechRajdeep Kr DekaNo ratings yet

- Cem-3 PCBDocument6 pagesCem-3 PCBjimyxtNo ratings yet

- Electrochemical Machining PDFDocument5 pagesElectrochemical Machining PDFBasavaraj HosurNo ratings yet

- Accepted Manuscript: MeasurementDocument37 pagesAccepted Manuscript: Measurementsuneetha suniNo ratings yet

- PTC 2009 1.2 FokensDocument7 pagesPTC 2009 1.2 Fokenskaliappan45490No ratings yet

- Electrical Discharge Machine (Edm) PDFDocument65 pagesElectrical Discharge Machine (Edm) PDFsujayan2005100% (3)

- Atm 2022 1 004Document5 pagesAtm 2022 1 004joskov71No ratings yet

- Study of Sharp Corner Cutting in Wire EDM - Muhammad Iswan Ismail - TJ1191.M58 2008Document27 pagesStudy of Sharp Corner Cutting in Wire EDM - Muhammad Iswan Ismail - TJ1191.M58 2008asdfghjklNo ratings yet

- EDM Process Optimisation Via Predicting A Controller Model: Computational Materials Science and Surface EngineeringDocument7 pagesEDM Process Optimisation Via Predicting A Controller Model: Computational Materials Science and Surface EngineeringNalla MohamedNo ratings yet

- Supporting Document For Report - Wire Edm - HCHCR - For MuzammilDocument63 pagesSupporting Document For Report - Wire Edm - HCHCR - For MuzammilMUJA ICSNo ratings yet

- UE22EExxx Class1Document58 pagesUE22EExxx Class1Suspicious-Nobody-05No ratings yet

- A 11Ghz Narrow Band Pass Filter Design With Lumped Elements, em Sight and Axeim TechniquesDocument9 pagesA 11Ghz Narrow Band Pass Filter Design With Lumped Elements, em Sight and Axeim TechniquesPramod PuttaNo ratings yet

- Silicon NitrideDocument8 pagesSilicon NitrideVikas KharbNo ratings yet

- Opportunities and Challenges of Profile Extrusion Dies Produced by Additive Manufacturing ProcessesDocument6 pagesOpportunities and Challenges of Profile Extrusion Dies Produced by Additive Manufacturing ProcessesNate MercerNo ratings yet

- WEDM of MG/CRT/BN Composites: Effect of Materials and Machining ParametersDocument36 pagesWEDM of MG/CRT/BN Composites: Effect of Materials and Machining ParametersAlagar SamyNo ratings yet

- ECDMDocument8 pagesECDMSaurabhBhardwajNo ratings yet

- Dump FileDocument12 pagesDump FileMADHESWARAN SNo ratings yet

- O. Blatnik, H. Orbanic, C. Masclet, H. Paris, M. Museau, J. Valentincic, B. Jurisevic and M. JunkarDocument5 pagesO. Blatnik, H. Orbanic, C. Masclet, H. Paris, M. Museau, J. Valentincic, B. Jurisevic and M. JunkarAmrik SinghNo ratings yet

- Mech Vi Non Traditional Machining (10me665) NotesDocument45 pagesMech Vi Non Traditional Machining (10me665) Notesnikhil0% (1)

- Photochemical MachiningDocument15 pagesPhotochemical MachiningHeineken Ya Praneetpongrung0% (1)

- Optimal Control Parameters A Machining in CNC Wire EDM For TitaniumDocument20 pagesOptimal Control Parameters A Machining in CNC Wire EDM For TitaniumMarish KannanNo ratings yet

- An Examination of Additive Manufacturing ProcessesDocument12 pagesAn Examination of Additive Manufacturing ProcessesShashank PhansikarNo ratings yet

- Document 3Document4 pagesDocument 3kavithraNo ratings yet

- Ucmp First Mid Course FileDocument160 pagesUcmp First Mid Course FileAraveetiCSReddyNo ratings yet

- Ecm, CM, Edm, PVD, CVDDocument78 pagesEcm, CM, Edm, PVD, CVDAmit DevNo ratings yet

- Review of Electrochemical and Electrodischarge MachiningDocument14 pagesReview of Electrochemical and Electrodischarge Machiningdinesh veerNo ratings yet

- 1.1 Introduction To Conventional and Non Conventional MachiningDocument42 pages1.1 Introduction To Conventional and Non Conventional MachiningDida KhalingNo ratings yet

- Mechanical Characterization of 3D Rinted Porous Turbo Machinary Components-Final (24-08-2019)Document8 pagesMechanical Characterization of 3D Rinted Porous Turbo Machinary Components-Final (24-08-2019)Zeeshan HaiderNo ratings yet

- Photo Chemical Machining (PCM)Document10 pagesPhoto Chemical Machining (PCM)ashishsinglaNo ratings yet

- Effect of Support Structures On The Deformation of Alsi10Mg Aircraft Parts Made Using DmlsDocument15 pagesEffect of Support Structures On The Deformation of Alsi10Mg Aircraft Parts Made Using Dmlssai charanNo ratings yet

- Near Net Shape CastingDocument3 pagesNear Net Shape CastingNURNo ratings yet

- Filter Basics Part 5 - Lumped Element and Distributed Element Filter ConstructionDocument7 pagesFilter Basics Part 5 - Lumped Element and Distributed Element Filter ConstructionAnonymous 0qYv7WpgNo ratings yet

- International Journal of Machine Tools & Manufacture: Yan Zhang, Zhengyang Xu, Di Zhu, Jun XingDocument9 pagesInternational Journal of Machine Tools & Manufacture: Yan Zhang, Zhengyang Xu, Di Zhu, Jun XingSudhir KumarNo ratings yet

- NTM Module 1Document19 pagesNTM Module 1RishiJpNo ratings yet

- Effect of WEDM Process Parameters On Surface Morphology of NitinolDocument14 pagesEffect of WEDM Process Parameters On Surface Morphology of NitinollarryNo ratings yet

- Preliminary ProposalDocument21 pagesPreliminary Proposalafridi cmNo ratings yet

- 316L Muchos Resultados FFF Tensile StrengthDocument10 pages316L Muchos Resultados FFF Tensile StrengthJuan JimenezNo ratings yet

- A Review On Laser Beam Machining Process ModelingDocument9 pagesA Review On Laser Beam Machining Process Modelingnitin kumar halduniyaNo ratings yet

- Defense University, College of Engineering Project Proposal OnDocument15 pagesDefense University, College of Engineering Project Proposal OnGODNo ratings yet

- GuidelinesDocument8 pagesGuidelinesRohammed CastilloNo ratings yet

- 1 s2.0 S2212827116005060 MainDocument5 pages1 s2.0 S2212827116005060 MainKundanNo ratings yet

- Nishant Sharma PDFDocument79 pagesNishant Sharma PDFRommyNo ratings yet

- Chapter 1: Nontraditional MachiningDocument6 pagesChapter 1: Nontraditional MachiningTran Tien AnhNo ratings yet

- Cold Metal Transfer: A Revolution in Mechanised Root Pass Pipeline WeldingDocument3 pagesCold Metal Transfer: A Revolution in Mechanised Root Pass Pipeline Weldingargentino_ar01No ratings yet

- Chemical Treatment - 90% Dimethylketone and 10% Water - ABS PartsDocument4 pagesChemical Treatment - 90% Dimethylketone and 10% Water - ABS Partsadityakashyap.pdm22No ratings yet

- HW 5Document5 pagesHW 5Neel NadparaNo ratings yet

- Ecm PDFDocument29 pagesEcm PDFSukhvir SinghNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Nanoelectronics Devices: Design, Materials, and Applications (Part I)From EverandNanoelectronics Devices: Design, Materials, and Applications (Part I)No ratings yet

- SSGB Cert InsertDocument12 pagesSSGB Cert InsertAfzalul Karim NirvickNo ratings yet

- Choitrer Ditio Dibos by Humayun AhmedDocument188 pagesChoitrer Ditio Dibos by Humayun AhmedAfzalul Karim NirvickNo ratings yet

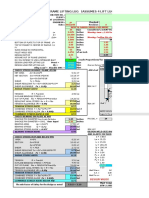

- Unlocked Copy LiftingLugStress Rev 1.5 Modified YH 10.21.2015Document20 pagesUnlocked Copy LiftingLugStress Rev 1.5 Modified YH 10.21.2015Afzalul Karim NirvickNo ratings yet

- New Discovery Sport: Created For MD Afzalul KarimDocument20 pagesNew Discovery Sport: Created For MD Afzalul KarimAfzalul Karim NirvickNo ratings yet

- DFW Imam Advisory PDFDocument2 pagesDFW Imam Advisory PDFAfzalul Karim NirvickNo ratings yet

- Thunder Laser Software RDWorksV8.0 USER MANUAL PDFDocument64 pagesThunder Laser Software RDWorksV8.0 USER MANUAL PDFAfzalul Karim NirvickNo ratings yet

- Chart Title: Item No Subject % Work Done End Date Release Date Comments Note 1 Note 2Document3 pagesChart Title: Item No Subject % Work Done End Date Release Date Comments Note 1 Note 2Afzalul Karim NirvickNo ratings yet

- 234 Thermodynamics: Deceleration of Air in A DiffuserDocument2 pages234 Thermodynamics: Deceleration of Air in A DiffuserAfzalul Karim NirvickNo ratings yet

- 2017 PatriotDocument427 pages2017 PatriotAfzalul Karim NirvickNo ratings yet

- Sample Data Table From 2017 Fundamentals Ch14Document2 pagesSample Data Table From 2017 Fundamentals Ch14Afzalul Karim NirvickNo ratings yet

- Am ChartsDocument1 pageAm ChartsAfzalul Karim NirvickNo ratings yet

- Heat Transfer Checklist For The PE ExamDocument2 pagesHeat Transfer Checklist For The PE ExamAfzalul Karim NirvickNo ratings yet

- Shob Jatra by Humayun Ahmed WWW - Bdbooks24.co - CCDocument7 pagesShob Jatra by Humayun Ahmed WWW - Bdbooks24.co - CCMohammad Anisul HoqueNo ratings yet

- Lug AnalysisDocument15 pagesLug AnalysisAfzalul Karim Nirvick0% (1)

- January February March January February MarchDocument1 pageJanuary February March January February MarchAfzalul Karim NirvickNo ratings yet