Professional Documents

Culture Documents

Pictorial Guide To DIY PCB Making (Page 1 of 6)

Pictorial Guide To DIY PCB Making (Page 1 of 6)

Uploaded by

caddish12Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pictorial Guide To DIY PCB Making (Page 1 of 6)

Pictorial Guide To DIY PCB Making (Page 1 of 6)

Uploaded by

caddish12Copyright:

Available Formats

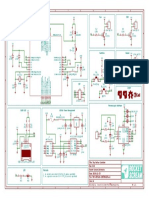

Pictorial Guide to DIY PCB Making [Page 1 of 6] By Basir Atan (basir.atan@gmail.

com)

The PCB design, using Eagle Software (www.cadsoft.com)

The PCB design printed actual size (mirror image) using normal laser printer

Inkjet Glossy Photo Paper glued over the PCB artwork. Just glue the side going into the laser printer

Items required: Blank PCB, iron, scouring pad (stainless steel), paint thinner

Pictorial Guide to DIY PCB Making [Page 2 of 6] By Basir Atan (basir.atan@gmail.com)

Blank PCB cleaned using the scouring pad. Clean using circular motion

Iron-on the artwork (temp setting to wool) for about 4 mins Keep even pressure until artwork start to appear

Soften the paper with running water

After initial removal then gently remove remaining paper

Pictorial Guide to DIY PCB Making [Page 3 of 6] By Basir Atan (basir.atan@gmail.com)

Clean the remainder with soft toothbrush, ensure all clay is removed Note the shiny copper (clean) and translucent copper (not cleaned)

Double check holes & gaps. Clay turns white when dry. If required, clean with wet toothbrush again

Homemade etching tank (FeCl) with aquarium air pump FeCl stains everything. Exercise caution.

Etch the board for about 5-10 mins (depends on FeCl strength)

Pictorial Guide to DIY PCB Making [Page 4 of 6] By Basir Atan (basir.atan@gmail.com)

Etched board ready for drilling

Double check for shorts, breaks, etc

Drilled board ready reading for toner removal

Top view of drilled board

Pictorial Guide to DIY PCB Making [Page 5 of 6] By Basir Atan (basir.atan@gmail.com)

Remove the toner using paint thinner

Ensure all holes are clear of toner residues

Wire jumpers installed and soldered

Board populated with components

Pictorial Guide to DIY PCB Making [Page 6 of 6] By Basir Atan (basir.atan@gmail.com)

Solder side view

Additional component attached

Additional off-board component attached

Board populated & ready for testing

You might also like

- Intelligent Platform Management Interface Specification v1.0Document205 pagesIntelligent Platform Management Interface Specification v1.0alexchuah100% (1)

- TX Brief of AppellantDocument27 pagesTX Brief of AppellantTheresa Martin100% (1)

- Digital Thermometer Circuit.Document2 pagesDigital Thermometer Circuit.elvergonzalez1100% (1)

- Functions in Real LifeDocument34 pagesFunctions in Real LifeMhae Pot100% (1)

- Making of IR Sensor ModuleDocument18 pagesMaking of IR Sensor ModuleGhigoarta Sergiu DanielNo ratings yet

- Eagle TutorialDocument7 pagesEagle Tutorialsfrancois21No ratings yet

- PCB Presentation DraftDocument19 pagesPCB Presentation Draftsanjay sharma100% (1)

- Analisis Kontrastif Nominalisasi Dalam Bahasa Inggris, Bahasa Indonesia, Dan Bahasa JawaDocument17 pagesAnalisis Kontrastif Nominalisasi Dalam Bahasa Inggris, Bahasa Indonesia, Dan Bahasa JawaZelda NameNo ratings yet

- Smart IC Tester PDFDocument8 pagesSmart IC Tester PDFhexapodo2No ratings yet

- Tutorial EagleDocument20 pagesTutorial EagleleydicaliNo ratings yet

- Wired RoboCarDocument17 pagesWired RoboCarAmish SharmaNo ratings yet

- 555 Pulse Generator Circuit (Autoguardado)Document5 pages555 Pulse Generator Circuit (Autoguardado)jhonnygarcia634No ratings yet

- PCB Design Using Cadsoft EAGLE SoftwareDocument22 pagesPCB Design Using Cadsoft EAGLE SoftwareAmarenderNo ratings yet

- Altium Designer PCB Design Tutorial - PCBCartDocument11 pagesAltium Designer PCB Design Tutorial - PCBCartpapirojedecNo ratings yet

- EN 45545-2 NotesDocument2 pagesEN 45545-2 NotesDeepak KumarNo ratings yet

- Fuji Electricalcomponants Industrialrelays Industrialcontrolrelays Annunciatorrelays Timedelayrelays Cat 20thedition 03Document67 pagesFuji Electricalcomponants Industrialrelays Industrialcontrolrelays Annunciatorrelays Timedelayrelays Cat 20thedition 03Anonymous wRhGOUBeNo ratings yet

- IPMI Errata and Clarifications Intelligent Platform Management Interface Specification v1.0, Revision 1.1Document12 pagesIPMI Errata and Clarifications Intelligent Platform Management Interface Specification v1.0, Revision 1.1alexchuahNo ratings yet

- 12V Battery Level Indicator CircuitDocument27 pages12V Battery Level Indicator Circuitjayris2060049No ratings yet

- ESP32 Troubleshooting GuideDocument8 pagesESP32 Troubleshooting GuideAnirudh nandiNo ratings yet

- Export Orcad Design Into Adobe PDFDocument2 pagesExport Orcad Design Into Adobe PDFAngelNo ratings yet

- EDJ16002 Lab 8 PCB Design & FabricationDocument26 pagesEDJ16002 Lab 8 PCB Design & FabricationpreethikaNo ratings yet

- PCB Lab Manual Iiisem Ece PDFDocument46 pagesPCB Lab Manual Iiisem Ece PDFkathirdcnNo ratings yet

- OrCAD Altium Migration Guide PDFDocument8 pagesOrCAD Altium Migration Guide PDFElafanNo ratings yet

- PIFA Planar Inverted F AntennaDocument4 pagesPIFA Planar Inverted F AntennaAhsan AltafNo ratings yet

- Getting Started With Wokwi-IDocument18 pagesGetting Started With Wokwi-IShashikaNo ratings yet

- Introduction To Altium Designer PDFDocument47 pagesIntroduction To Altium Designer PDFMuhammad Amir AmirNo ratings yet

- 160SP Maintenance Manual v.1.0Document174 pages160SP Maintenance Manual v.1.0funfx6575No ratings yet

- PCB Layout and ArtworkDocument59 pagesPCB Layout and ArtworkPhil GainNo ratings yet

- Altium PCB Project Template PDFDocument5 pagesAltium PCB Project Template PDFduchaundh1No ratings yet

- Arduino PPT AkhilDocument15 pagesArduino PPT Akhilakhil gharuNo ratings yet

- LC22-24LE250 - 17MB95S SM - June2013 PDFDocument106 pagesLC22-24LE250 - 17MB95S SM - June2013 PDFAnonymous h80fVWNo ratings yet

- Adafruit TCS34725 Library Documentation: Release 1.0Document23 pagesAdafruit TCS34725 Library Documentation: Release 1.0arijit_ghosh_18No ratings yet

- PCB DesignerDocument70 pagesPCB Designeram1liNo ratings yet

- Pick A PIC ProjectDocument21 pagesPick A PIC ProjectZlatko GrgicNo ratings yet

- R11um0146eu0100 FSP v100 PDFDocument1,444 pagesR11um0146eu0100 FSP v100 PDFChử HoàngNo ratings yet

- Arduino: Potentiometer Diagrams & CodeDocument11 pagesArduino: Potentiometer Diagrams & CoderadosavNo ratings yet

- Microcontroilador ArduinoDocument21 pagesMicrocontroilador ArduinohfguerracNo ratings yet

- How To Solder The Chip ComponentsDocument19 pagesHow To Solder The Chip ComponentsjackNo ratings yet

- Coding The Arduino: "Embedded Systems"Document21 pagesCoding The Arduino: "Embedded Systems"thap_dinhNo ratings yet

- A Ldo Primer - Part I: A Review On Pass Element: Drop SAT BE BEDocument5 pagesA Ldo Primer - Part I: A Review On Pass Element: Drop SAT BE BEChristina ReyesNo ratings yet

- Tiny Reflow ControllerDocument1 pageTiny Reflow Controller31482100% (1)

- Altium Workshop BasicDocument44 pagesAltium Workshop BasicHumberto RiveiroNo ratings yet

- Labcenter Electronics - Proteus VSM - SPICE Co-Simulation - Debugging Benefits For PIC, 8051, AVR, HC11 and ARMDocument2 pagesLabcenter Electronics - Proteus VSM - SPICE Co-Simulation - Debugging Benefits For PIC, 8051, AVR, HC11 and ARMmohuddinNo ratings yet

- Lecture No-02 Course PCB Manufacturing IE-236 & Electronic Simulation and PCB Manufacturing (Repeaters Only)Document22 pagesLecture No-02 Course PCB Manufacturing IE-236 & Electronic Simulation and PCB Manufacturing (Repeaters Only)Ravi Shankar 31No ratings yet

- Manual enDocument341 pagesManual enSimona KonyarNo ratings yet

- PCB Design in 45 MinutesDocument28 pagesPCB Design in 45 MinutesvinNo ratings yet

- Assembly of Flexible Circuits With Lead - Free Solder AlloyDocument16 pagesAssembly of Flexible Circuits With Lead - Free Solder AlloyBorad AlpeshNo ratings yet

- Smart Mirror Using Raspberry Pi: AbstractDocument4 pagesSmart Mirror Using Raspberry Pi: AbstractKannihya MishraNo ratings yet

- Soldering & The Tinning Process: Electronics 1Document22 pagesSoldering & The Tinning Process: Electronics 1Gilbert TamayoNo ratings yet

- Arduino "Getting Started" Tutorial: HardwareDocument7 pagesArduino "Getting Started" Tutorial: HardwareMax dos santos ramosNo ratings yet

- Orcad To EdifDocument16 pagesOrcad To EdifonafetsNo ratings yet

- Make Your Own PCBs Form A To ZDocument17 pagesMake Your Own PCBs Form A To Zbaliza1405No ratings yet

- Manual Osciloscopio Portatil Mini Micro Dso138Document9 pagesManual Osciloscopio Portatil Mini Micro Dso138tandre111No ratings yet

- DC Motor Speed ControlDocument7 pagesDC Motor Speed ControlSinggih Candra PrayogaNo ratings yet

- Altium Tutorial Version24March2014 FinalDocument33 pagesAltium Tutorial Version24March2014 FinalSaima KanwalNo ratings yet

- How To Solder ElectronicsDocument6 pagesHow To Solder ElectronicsjackNo ratings yet

- Altium - Creating Library ComponentsDocument32 pagesAltium - Creating Library Componentseaa603100% (1)

- Adafruit Si5351 Clock Generator BreakoutDocument25 pagesAdafruit Si5351 Clock Generator BreakoutDirson Volmir WilligNo ratings yet

- AVR Project - Remote Controlled Fan Regulator.Document23 pagesAVR Project - Remote Controlled Fan Regulator.nadaratNo ratings yet

- Advanced Home Automation Using Raspberry Pi: Building Custom Hardware, Voice Assistants, and Wireless NodesFrom EverandAdvanced Home Automation Using Raspberry Pi: Building Custom Hardware, Voice Assistants, and Wireless NodesNo ratings yet

- (CE-PHFH-017) - Transportation Validation Report-1.0Document23 pages(CE-PHFH-017) - Transportation Validation Report-1.0Viqar Inamdar100% (1)

- Progress in Electromagnetics Research B, Vol. 44, 241-259, 2012Document19 pagesProgress in Electromagnetics Research B, Vol. 44, 241-259, 2012nur narangNo ratings yet

- Impacts of Global Energy Prices On Businesses in Nigeria.Document10 pagesImpacts of Global Energy Prices On Businesses in Nigeria.OGHENEKARO OMOKERENo ratings yet

- Sp2019 CS509 Exercise Sheet 2Document5 pagesSp2019 CS509 Exercise Sheet 2fakhruldeenNo ratings yet

- Intake and Output MonitoringDocument12 pagesIntake and Output MonitoringJacqueline de Asis100% (2)

- Research Paper Common CoreDocument16 pagesResearch Paper Common Coreapi-356964760No ratings yet

- Movie Worksheet TED - Reporting Crisis Via TextingDocument1 pageMovie Worksheet TED - Reporting Crisis Via TextingAdam SzymaszekNo ratings yet

- Scripture App Builder 02 Building AppsDocument93 pagesScripture App Builder 02 Building AppsFavour badmusNo ratings yet

- California Connections Academy: Biology 2020-2021 Course SyllabusDocument5 pagesCalifornia Connections Academy: Biology 2020-2021 Course Syllabusapi-432540779No ratings yet

- 10 Fitness Social Media Influencers You Should Follow For MotivationDocument3 pages10 Fitness Social Media Influencers You Should Follow For MotivationJulia Marie ReformaNo ratings yet

- CalculationDocument12 pagesCalculationKim EllaNo ratings yet

- Seminar On Zumba Dance Activity Design MainDocument5 pagesSeminar On Zumba Dance Activity Design MainMae Biñas AngelesNo ratings yet

- Strategic Alliances in Distribution: Chapter#8Document17 pagesStrategic Alliances in Distribution: Chapter#8Rafaat ShaeerNo ratings yet

- What Is Grass?Document2 pagesWhat Is Grass?RonNo ratings yet

- Absit by Angélica GorodischerDocument7 pagesAbsit by Angélica Gorodischerae045296No ratings yet

- YXY-25A User ManualDocument7 pagesYXY-25A User ManualEdwin ThieroffNo ratings yet

- FortiGate I Student Guide-OnlineDocument478 pagesFortiGate I Student Guide-OnlinepbougoinNo ratings yet

- 4MA1 2HR Que 20210304Document24 pages4MA1 2HR Que 20210304Sadman SlenderNo ratings yet

- Moonmoon Class Đề 35Document7 pagesMoonmoon Class Đề 35Bùi Tiến VinhNo ratings yet

- Job Interviews Student's VersionDocument6 pagesJob Interviews Student's VersionCarolina LuisaNo ratings yet

- Diabetes Mellitus Type II & Its Repertorial View: Dr. Subhash Chand Yadav and Dr. Sunil Kumar SinghDocument4 pagesDiabetes Mellitus Type II & Its Repertorial View: Dr. Subhash Chand Yadav and Dr. Sunil Kumar SinghDR.SUBHRA SANKAR SINHANo ratings yet

- Session 2Document5 pagesSession 2Viana JarahianNo ratings yet

- The Pentagrams' Grammar and VocabularyDocument72 pagesThe Pentagrams' Grammar and VocabularyRichter, JoannesNo ratings yet

- ReportDocument3 pagesReportAnshuman Pratap Singh ChauhanNo ratings yet

- FOUNDATIONS 2 Web 1Document40 pagesFOUNDATIONS 2 Web 1Gabriel Santiago Santa Cruz AlvaroNo ratings yet

- New China Cybersecurity Guidelines For Registration of Networked Medical Devices - Insight - Baker McKenzieDocument5 pagesNew China Cybersecurity Guidelines For Registration of Networked Medical Devices - Insight - Baker McKenzieMayank KakkarNo ratings yet

- Jockey PumpDocument5 pagesJockey PumpBrandon LeonardNo ratings yet

- Silica Plastic BlockDocument5 pagesSilica Plastic Blockdharshini deivasigamaniNo ratings yet