Professional Documents

Culture Documents

04 May, 014

Uploaded by

Kailash Rajak0 ratings0% found this document useful (0 votes)

4 views1 pageOriginal Title

04 May,014

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 page04 May, 014

Uploaded by

Kailash RajakCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

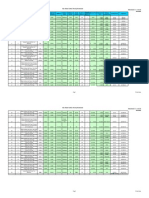

GAMMON INDIA LIMITED (T & D Business) VADADLA GALVANISING SECTION CONTROL CHECKS

F/QAG/014

DATE: 04/05/2012

Degreasing Tank concentration :5% (solution)

Pickling Tank (HCL Acid) Acid Contents (50-210 gm/Lit.)

(5 To 10% ) Acidic degreaser Remarks

FRESH ACID BATH FRESH ACID BATH FRESH ACID BATH FRESH ACID BATH

Iron contents Specific Gravity (120 gm/Lit.) Max. 52 90 89 50

Double rinsing process. Rinsing tank washed and water is replaced.

22.90% 1.18 4.0 5.7 :(20-30%)

Tank no.1 Tank no.2 Tank no.3 Tank no.4

Rinsing Tank (After Pickling )

204 138 124 197

Rinsing Tank No.1 Rinsing Tank No.2 concentration : Specific Gravity: PH

1.21 1.25 1.24 1.20

:(1.16 to 1.24) :(4 to 5) :(10 gm/Lit.Max.)

Fluxing Tank

Iron Content: (Min. once in a week) Acid Contents (Min.once in a week) Temperature Hot Plate Temp. (Once in a day )

0.77 290C

:(2gm/Lire.Max.) Room Temp. To 650C

Pre Heating

(700C to 1000C) Max.1500C

0 0

67 C

Zinc Bath

working Temperature(440 C To 455 C ) concentration : 5% 480C

4480C (Sodium dichromating Solution) 1% to1.5% Temp. should not exceed 650C

Dichromating Tank Temperature

NOTE : Degreasing Tank in the direction addition of Degreaser. For the reason that concentration is going very low down it is not measurable.

PREPARED BY QA & I

GALVANISING IN-CHARGE

You might also like

- Acidizing PresentationDocument55 pagesAcidizing PresentationNaief Javaheri100% (2)

- Pre-Treatment of Crude OilDocument25 pagesPre-Treatment of Crude OilAbhisek AgarwalNo ratings yet

- Mud EngineeringDocument151 pagesMud EngineeringDinesh KumarNo ratings yet

- Acidizing PresentationDocument55 pagesAcidizing PresentationAbhishek Tripathi100% (4)

- 1 DesalterDocument20 pages1 DesalterDucViking80% (5)

- Desalter Salt Balance - 1Document1 pageDesalter Salt Balance - 1Saeid Rahimi MofradNo ratings yet

- BovineDocument26 pagesBovineTapan SharmaNo ratings yet

- Floating Production TechnologyDocument19 pagesFloating Production TechnologyHtin Lin AungNo ratings yet

- Bright Acid Copper For Wire and Grounding Rods: E-Brite 202GDocument6 pagesBright Acid Copper For Wire and Grounding Rods: E-Brite 202GUsman ali Cheema100% (1)

- Water Injection 2011Document113 pagesWater Injection 2011Kosan Namnam100% (1)

- Tekna Heavy Oil Technology For Offshore Applications: Chemistry and Physics of Heavy Oil and Other DispersionsDocument31 pagesTekna Heavy Oil Technology For Offshore Applications: Chemistry and Physics of Heavy Oil and Other DispersionsPrince OmaNo ratings yet

- Water Treatment I Kurang KomplitDocument89 pagesWater Treatment I Kurang KomplitEndarAdeCandraNo ratings yet

- Technical Seminar For Galvanizers March 2012 Mike Ainsley - Update PDFDocument146 pagesTechnical Seminar For Galvanizers March 2012 Mike Ainsley - Update PDFTalal JameelNo ratings yet

- 06b Fluid Loss and Diverting AgentsDocument19 pages06b Fluid Loss and Diverting AgentsErick Carballo CabreraNo ratings yet

- 20T Three Tank Semi-Continuouse Refining Processing LineDocument2 pages20T Three Tank Semi-Continuouse Refining Processing LineWanda OilpressNo ratings yet

- 21-Matrix Treatment and FracturingDocument75 pages21-Matrix Treatment and FracturingDeepak RanaNo ratings yet

- Distillery Industry 7Document15 pagesDistillery Industry 7gundreddy greeshmaNo ratings yet

- Manufacturing Process 1Document18 pagesManufacturing Process 1ARJUNA BATCHNo ratings yet

- FluidsDocument14 pagesFluidsRIFQI SETYA WARDANANo ratings yet

- Biodiesel and Glycerine Purification With Lewatit GF-ResinsDocument65 pagesBiodiesel and Glycerine Purification With Lewatit GF-ResinsJonathan Obando100% (1)

- Conference TAN CrudeDocument61 pagesConference TAN CrudekishoreprithikaNo ratings yet

- The Fundamentals The FundamentalsDocument55 pagesThe Fundamentals The FundamentalsJose PerozoNo ratings yet

- Report On Effluent Treatment Plant ETP ODocument17 pagesReport On Effluent Treatment Plant ETP Omohammed nayeemNo ratings yet

- 1 DesalterDocument20 pages1 Desaltershyam_anupNo ratings yet

- Cement AdditivesDocument16 pagesCement Additivesrendy abbasNo ratings yet

- Attachment A - Pricing PageDocument2 pagesAttachment A - Pricing PagejnmanivannanNo ratings yet

- Ethylene Glycol MonostearateDocument4 pagesEthylene Glycol MonostearateVaibhav NikharNo ratings yet

- Bonderite® 958-EnDocument9 pagesBonderite® 958-EnGabriel BrăbanNo ratings yet

- Technical Report of Formic Acid PlantDocument6 pagesTechnical Report of Formic Acid PlantMuzzamilNo ratings yet

- Desalting Crude OilDocument13 pagesDesalting Crude Oilpardise4000No ratings yet

- Technical Seminar For Galvanizers March 2012 Mike Ainsley - Update PDFDocument146 pagesTechnical Seminar For Galvanizers March 2012 Mike Ainsley - Update PDFМилош Филиповић75% (4)

- 04-Section 04 Pilot Testing & ContaminationsDocument17 pages04-Section 04 Pilot Testing & ContaminationsLazharNo ratings yet

- Process Parameters ChartDocument2 pagesProcess Parameters ChartJabir HussainNo ratings yet

- Major Mechanisms of Formation Damage: Calcium Carbonate Barium SulfateDocument7 pagesMajor Mechanisms of Formation Damage: Calcium Carbonate Barium SulfateMahesh sinhaNo ratings yet

- Desalting of Crude OilDocument19 pagesDesalting of Crude OilaciNo ratings yet

- STEEL Accessories Limited: Effluent Treatment Plant Work Instruction & Standard Operating ProcedureDocument6 pagesSTEEL Accessories Limited: Effluent Treatment Plant Work Instruction & Standard Operating ProcedureMubarak PatelNo ratings yet

- Desalter Salt Balance - 3Document2 pagesDesalter Salt Balance - 3Saeid Rahimi MofradNo ratings yet

- Dairy Waste Water Treatment PlantDocument23 pagesDairy Waste Water Treatment PlantStartechnico TechnocratsNo ratings yet

- Vat Dyes 1Document5 pagesVat Dyes 1natvarlal nirmalNo ratings yet

- By-24 DMR 2013-05-18 G2Document1 pageBy-24 DMR 2013-05-18 G2Iqbal KarimNo ratings yet

- Desalting OverviewDocument9 pagesDesalting OverviewSampat100% (1)

- Reduction Salt Freight Tannery EffluentDocument12 pagesReduction Salt Freight Tannery EffluentEstefano Pacheco PalmaNo ratings yet

- Complete Formulas PDFDocument46 pagesComplete Formulas PDFramu_uppada67% (6)

- DTPMP AcidDocument10 pagesDTPMP AcidJose TerrazasNo ratings yet

- Dip Zinc 7-Tank ProcessDocument3 pagesDip Zinc 7-Tank ProcessAmit Chauhan100% (1)

- Problems Occurring in De-Salter Plant of Crude Oil and Its SolutionDocument6 pagesProblems Occurring in De-Salter Plant of Crude Oil and Its Solutionmustafa abdulhameedNo ratings yet

- Carbonates Acidizing PPTDocument61 pagesCarbonates Acidizing PPTBolsec14No ratings yet

- W E L C O M E: Karthick Poobathi, Kalyanam Sudheer KumarDocument13 pagesW E L C O M E: Karthick Poobathi, Kalyanam Sudheer KumarLê Văn Thế QuangNo ratings yet

- Unitor Chemical Treatment SummaryDocument7 pagesUnitor Chemical Treatment Summaryamirouche15No ratings yet

- 50TD Continuous Physical Refining Equipment ListDocument4 pages50TD Continuous Physical Refining Equipment ListWanda OilpressNo ratings yet

- The Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterFrom EverandThe Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterNo ratings yet