Professional Documents

Culture Documents

IJCER (WWW - Ijceronline.com) International Journal of Computational Engineering Research

Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJCER (WWW - Ijceronline.com) International Journal of Computational Engineering Research

Copyright:

Available Formats

International Journal Of Computational Engineering Research (ijceronline.com) Vol. 2 Issue.

Evaluation of Thermal Properties of E-Glass/ Epoxy Composites Filled By Different Filler Materials

1

K.Devendra1, T. Rangaswamy2

Asst. Professor, Dept. of Mech. Engg., SKSVMACET, Laxmeshwar, KA, India, 2 Professor, Dept. of Mechanical Engineering, GEC, Hassan, KA, India,

Abstract

This paper compares the values of the thermal and fire resistance properties of composites made using the hand layup technique. E-Glass fiber reinforced epoxy composites was fabricated by filling varying concentration of aluminum oxide (Al2O3), magnesium hydroxide(Mg(OH)2), silicon carbide (SiC), and hematite powder. The main aim of this work was to determine the thermal conductivity, thermal expansion coefficient, time to ignition and flame propagation rate of composites. Experimental results show that Al2O3 and Mg (OH)2 filled composites exhibited low thermal conductivities. Composites filled by SiC particles exhibited low thermal expansion coefficient when compared with other filled composites. Fire test results indicated that increase the loading of Al2O3, Mg (OH)2, and hematite powder increase the time to ignition and reduces the flame propagation rate of composites.

Key words: Composites, Fillers, Fire resistance, Properties, Thermal 1. Introduction

The primary field of application for fiber reinforced polymer composites is the aerospace industry. For several years, however, composite materials have been increasingly used for various other technical tasks, where it is beneficial to apply lightweight construction materials which have high strength and stiffness characteristics. The favorable specific properties of fiber reinforced polymer composites are based on the low density of the matrix resins used, and the high strength of the embedded fibers. Fabrication of fiber reinforced polymer composites relatively low cost. These composites are considered as replacements for metal materials. Polymer matrix reinforced by fiber is probably the most commonly used form of composites in structural application, such as air crafts, boats, automobiles[1] etc. For many materials applications, information is needed on their thermal properties [2]. In recent years there have been an increasing number of applications such as communication, satellites, high density electronics, and advanced aircraft requiring more effective and light weight thermal management materials [3]. The temperature fields in composites materials cannot be determined unless the thermal conductivity of the media is known and for any material a low thermal expansion is ideally required [2, 4]. Polymer composites are very flammable due to their chemical structure and they cannot satisfy some applications, which require high flame retardency. H. Dvir et al. [5] have studied the effect of additives such as pentabromobenzyleacryllate (PBBMA) and magnesium hydroxide on mechanical and flame retardant properties of polypropylene composites containing glass fibers. He concluded that addition of PBBMA and Mg (OH2) has a positive effect on flame retardant properties and with minimal negative effect on mechanical properties and optimized the formulation of percentage of matrix and reinforcement. The best formulation obtained was with 38.50% matrix 22.31 % fibers and 15 % PBBMA and 17.99 % Mg (oH2). It has good impact strength 90+ -4 and modulus 6953mpa, Vo UL-94 rating and total flaming time 6sec. A. Shojaei et al. [7] have determined the thermal conductivity of rubber-based composites friction materials. Various thermally conductive fillers including copper, brass chips with two sizes, aluminum chips, aluminum oxide and talc have been selected and the effect of addition of these fillers on the thermal conductivity. It was found that the thermal conductivity of the materials increases continuously by increasing the content of the selected fillers. Maximum thermal conductivity is related to aluminum chips filled composites. Now a variety of inorganic fillers have been used to change the properties of composites. In this work E-glass/epoxy based composites filled with varying concentrations of aluminum oxide (Al2O3), magnesium hydroxide (Mg (OH)2), silicon carbide (SiC), and hematite powder were prepared by hand layup technique. The objective of this work was to investigate the effect of fillers on thermal and fire resistance properties of E-glass fiber reinforced epoxy composites and comparison of results.

2. Materials and Fabrication

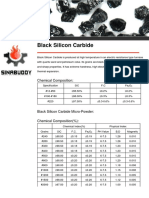

2.1. Materials The composites were made from E-glass fiber and commercially available ARALDITE (L-12) along with hardener K-6. Al2O3, Mg (OH)2, SiC and hematite powder was used as filler materials. Aluminum oxide particles is a ceramic powder commonly used filler, it is also used as an abrasive due to its hardness. Magnesium hydroxide is an inorganic compound and it is a white powder with specific gravity of 2.36, very slightly soluble in water; decomposing at 350o C. Magnesium hydroxide is attracting attention because of its performance, price, low corrosiveness and low toxicity. Silicon carbide exhibits favorable mechanical and chemical properties at high temperatures for many applications. The benefits of using

Issn 2250-3005(online) September| 2012 Page 1708

International Journal Of Computational Engineering Research (ijceronline.com) Vol. 2 Issue.5

SiC as reinforcement are improved stiffness, strength, thermal conductivity, wear resistance, fatigue resistance, reduced thermal expansion and dimensional stability. Hematite is an iron oxide with the same crystal structure as that of corundum (rubies and sapphires). Usually the color varies between a metallic grey and red. Hematite is one of the oldest stones mined in our history. 2.2 Fabrication of Composites The E-glass /Epoxy based composites filled with varying concentrations (0, 10 and 15 Vol %) of aluminum oxide (Al 2O3), magnesium hydroxide (Mg (OH)2), silicon carbide (SiC), and hematite powder were prepared. The volume fraction of fiber, epoxy and filler materials are determined by considering the density, specific gravity and mass. Fabrication of the composites was done at room temperature by hand lay-up techniques. 2.3 Specimen Preparation The prepared slabs of the composite materials were taken from the mold and then specimens were prepared from composite slabs for different thermal and fire resistance tests according to ASTM standards. The test specimens were cut by laminate by using different tools. Three identical test specimens were prepared for different tests.

3. Experimentation

3.1. Thermal Property Tests Thermal conductivity and thermal expansion coefficient of prepared composites was determined according to standard methods. Thermal Conductivity Thermal conductivity measurements are carried out under steady state condition. According to ASTM E1530 disc shaped specimens with diameter of 50mm and thickness of 10mm are used in the instrument for thermal conductivity measurements. A known constant heat is applied from one side of the specimen. When the thermal equilibrium is attained and the system approaches to steady state situation, the temperature of top bottom surfaces were measured by using thermocouples installed on top and bottom of the specimen. Knowing the values of heat supplied, temperatures, and thickness, the thermal conductivity was determined by employing one-dimensional Fouriers law of conduction. All measurements are carried out approximately in the similar temperature range, i.e., 25-90 oC = ------------- (1) Where Q= Heat transfer rate (W) K= Thermal conductivity (W/m oC ) A=Area (m2) T1= temperature at bottom surface of the sample (oC) T2= Temperature at top surface of the sample (oC ) L= Thickness of the sample dT/dx = Temperature gradient

Fig. 1 Thermal conductivity test specimen

Issn 2250-3005(online) September| 2012 Page 1709

International Journal Of Computational Engineering Research (ijceronline.com) Vol. 2 Issue.5

Thermal Expansion Coefficient Measurement

The specimens for the thermal expansion coefficient testing had length and thickness 90mm and 10mm respectively. The linear thermal expansion tests are performed over the temperature range of 25 to 90 oC using electric furnace. The samples are slowly heated from 30 to 90 0C in the electric furnace and kept at 900C for 10 min. Thermal Expansion Coefficient is then given by the relationship ----------- (2) Where =Thermal Expansion coefficient L= Original length of the sample L= Change in length of the sample T= Temperature change

Fig. 2 Thermal expansion coefficient specimen

3.2. Fire Resistance Test The fire properties of composite materials depend on several factors: the type of material, the fire conditions, and the test method used to measure the property. Vertical UL94 (UL94V) Test Rectangular shaped samples with dimensions of 127x12.7x3.2mm are exposed vertically to a methane gas burner flame as required by UL94V. The samples ignited at the bottom and burns upward. The time required for the flame to self extinguish after burner removal is measured and the occurrence of dripping on to a piece of cotton placed underneath the sample is recorded. Test is repeated for different samples. This test also classifies the materials as V-0, V-1 and V-2. V-0 = specimens not burn more than 10 Sec and the drip do not ignite the cotton. V-1= specimens not burn more than 30 Sec and the drip do not ignite the cotton. V-2= specimens not burn more than 30 Sec and the drip ignite the cotton. If the entire sample is consumed the material is classified as non-rated (NR) Time-to-Ignition Time to ignition is the period of time that a combustible material can with stand exposure to a constant heat flux before igniting and undergoing sustained flaming combustion, more simply, it is the time taken for a material to start burning. The ignition time can be used as a rough measure of the flammability resistance of material. Obviously it is desirable to use material with long ignition times in high fire risk applications. Extending the time- to- ignition value reduces the fire hazard of composite material used in an aircraft. The unit of time-to-ignition is seconds (Sec). Flame Propagation Rate The rate of the movement of the flame front is defined as the flame propagation rate.

Fig. 3 UL-94 Vertical test specimen

Issn 2250-3005(online) September| 2012 Page 1710

International Journal Of Computational Engineering Research (ijceronline.com) Vol. 2 Issue.5

4. Results and Discussion

The thermal conductivity, thermal expansion coefficient, time to ignition and flame propagation rate for different composition of composite materials are presented in tables 2- 5 and their variations shown in figures 4 to 7 respectively. 4.1 Thermal Conductivity Thermal conductivity is the property describing a materials ability to transfer heat. It is well known that thermal conductivity of the composite is dependent on such factors as Polymer-filler interaction and filler characteristics, namely type and shape of filler. From the obtained results it is observed that composites filled by (10% Vol) Al 2O3 and Mg (OH)2 exhibited low thermal conductivity it may be due to that while heating of materials slow chemical reaction takes place in Al2O3 and Mg (OH)2 and releases the small amount of water and this released water resist the heat flow and seems possible that there is a fundamental difficult in transferring heat from the matrix to the fibers. Composites filled by (10% Vol.) SiC exhibited maximum thermal conductivity (3.515 W/m oC). From the literature review we can observed that SiC particles having good thermal conductivity property. Hematite filled composites also exhibited high thermal conductivities when compared with Al2O3 and Mg (OH)2 because hematite powder contains the iron particles and these particles enhances the heat transfer rate. Table 2 Comparison of Thermal Conductivity Composite materials Thermal Conductivity(W/m oC) GE 2.89 GEA1 1.32 GEA2 1.72 GEM1 1.565 GEM2 2.38 GESI1 3.515 GESI2 2.765 GEH1 2.45 GEH2 3.06

Fig. 4 Thermal conductivity for different composition of composite materials 4.2Thermal Expansion Coefficient The experimental values of the thermal expansion coefficient of composites are presented in table-3 Table 3 Comparison of Thermal Expansion Coefficient Composite materials Thermal Expansion Coefficient (/oC) GE 1.9610-5 GEA1 2.4010-5 GEA2 1.6610-5 GEM1 2.4410-5 GEM2 1.1110-5 GESI1 7.4010-6 GESI2 3.7010-6 GEH1 1.8510-5 GEH2 1.8510-5

Issn 2250-3005(online)

September| 2012

Page 1711

International Journal Of Computational Engineering Research (ijceronline.com) Vol. 2 Issue.5

From the experimental results it is observed that increase the addition of Al2O3, Mg (OH)2 and SiC to composites reduces the thermal expansion coefficient. It has been noticed that (15% Vol) Al 2O3, Mg (OH)2 and SiC filled composite exhibited less thermal expansion coefficient this may be by adding the more fillers in composite materials providing good filler matrix interaction in the system, the filler binds the matrix and prevents it from expanding as much as it would on its own. Subsequently, this would affect the thermal expansion of the composite system. The many studies have shown that materials with higher filler content leads to a lower thermal expansion coefficient. Composites filled by (15% Vol.) SiC exhibited low thermal expansion coefficient (3.7010-6) when compared with other filled composites this due to that SiC particle having reduced thermal expansion and good dimensional stability. Hematite filled composites exhibited good thermal stability.

Fig.5 Thermal expansion coefficient for different composition of composite materials 4.3Time to Ignition and Flame Propagation Rate A popular method to reduce the flammability of composites is the addition of inert fillers like silica or thermally active fillers like hydrated oxides to the polymer matrix.From the figs 6 and 7 it is observed that increase the loading of Al2O3, and Mg (OH)2 increase the time to ignition and reduces the flame propagation rate because Al 2O3 is active in both the condensed and gas phases of the combustion process and it is remarkably effective in suppressing flaming combustion and smoke. The main condensed phase mechanism of aluminum oxide is the absorption of heat when the filler decomposes. And this is a highly endothermic reaction that absorbs heat; another important aspect of the reaction is the creation of water vapor formed from the hydroxyl groups binded to the aluminum. This water is released into the flame where it hinders combustion by diluting the concentration of flammable gases evolved from the polymer matrix and restricting the access of oxygen to the composite surface. Magnesium hydroxide also acts as flame retardants in a similar manner to Al2O3 with several flame retardant mechanisms occurring in a fire. Magnesium compound undergo a highly endothermic decomposition reaction that slows the heating rate of the host material in a fire. In addition, the hydroxyl groups bonded to the magnesium are converted in the reaction into water vapor, which dilutes the concentration of flammable organic volatiles and H/Oh radicals in the flame. The decomposition of magnesium compounds also yields magnesia (MgO) that has good insulating properties. The flame retardant mechanisms of magnesium hydroxide are effective in prolonging the ignition time and reducing the amount of smoke produced by high temperature polymers. More addition of iron based hematite filler decreases the time to ignition and flame spread rate fe and derivatives are believed to decompose at elevated temperature which promotes the formation of char via a Lewis acid reaction process. The increased char yield reduces the amount of flammable organic volatiles released by decomposing polymer, which lowers the fuel load in the flame. From the obtained results we can concluded that Al2O3, Mg (OH)2 are good flame retardant fillers. All the composites having flame extinguished time more than 30sec and failed to come under UL-94 rating. Table 4 Comparison of Time to Ignition Composite materials Time To Ignition (Sec) GE 08 GEA1 11 GEA2 14 GEM1 12 GEM2 15 GESI1 09 GESI2 11 GEH1 10 GEH2 12

Issn 2250-3005(online)

September| 2012

Page 1712

International Journal Of Computational Engineering Research (ijceronline.com) Vol. 2 Issue.5

Fig.6 Time to ignition for different composition of composite materials

Table 5 Comparison of Flame Propagation Rate Composite materials Flame propagation Rate (mm/sec) GE 0.60 GEA1 0.47 GEA2 0.44 GEM1 0.49 GEM2 0.45 GESI1 0.512 GESI2 0.52 GEH1 0.537 GEH2 0.514

Fig. 7 Flame propagation rate for different composition of composite materials

5. Conclusions

1. From the obtained results it is observed that composites filled by (10% Vol) Al2O3 and Mg (OH)2 exhibited low thermal conductivities. Composites filled by (10% Vol.) SiC exhibited maximum thermal conductivity (3.515 W/m oC). Hematite filled composites exhibited high thermal conductivities when compared with Al2O3 and Mg (OH)2 filled composites. 2.when increase the adding of filler materials to composites reduces the thermal expansion coefficient it is seen from the composites filled by (15% Vol) Al2O3, Mg (OH)2 and SiC when compared with (10% Vol) filled composites. Composites filled by SiC exhibited low thermal expansion coefficient when compared with other filled composites. 3. Fire test results show that increase the loading of Al2O3, Mg (OH)2, and hematite powder increase the time to ignition and reduces the flame propagation rate of composites. From the obtained results we can concluded that Al 2O3 and Mg(OH)2 are good flame retardant fillers. 4. All the specimens having flame extinguish time more than 30 sec and failed to come under UL-94V rating.

Issn 2250-3005(online)

September| 2012

Page 1713

International Journal Of Computational Engineering Research (ijceronline.com) Vol. 2 Issue.5

References

[1] Maries Indicula, Abderrahim Boudenne. Thermopyhsical properties of natural fiber reinforced polyester composites. Composites science and technology, 66, (2006), 2719-2725 [2] Dilek Kumlutas, Ismail H Tavman. Thermal conductivity of particle filled polyethylene composite materials Composites science and technology, 63 (2003), 113-117 [3] M T Assael, K D Antoniadis. The use of the transient hot-wires technique for measurement of the thermal conductivity of an epoxy-resin reinforced with glass fibers and/or corbon multiwall nanotubes. 68, (2008), 31783183 [4] Y LE Bozee , S Kaang , P J Hine. The thermal expansion behavior of hot compacted polypropylene and polyethylene composites. Composites science and technology, 60, (2003), 333-344 [5] H. Dvir, M. Gottlied. Optimization of a flameretarded polypropylene composite. Composites science and technology, 63 (2003), 1865-1875 [6] P K Rohatgi, N. gupta and Simon Alaraj. Thermal expansion of aluminium-flyash cenosphere composites synthesized by pressure infiltration technique. Journal of composite materials, 40, (2006), 1163-1174 [7] A. Shojaei, M Fahimian. Thermally conductive rubber based composite friction materials for rail road brakesThermal conduction characteristics. Composites science and technology, 67, (2007), 2665-2674 [8] Hua Gui. Effect of dispersion of nano-magnesium hydroxide on the flammability of flame retardant ternary composites. Composites science and technology, 61 (2001), 475-490 [9] Suhreta Husic, Ivan Javni. Thermal and Mechanical properties of glass reinforced soy-based polyurethane composites. Composites science and technology, 65 (2005), 19-25 [10] Cedric sauder, Jacques Lamon. Thermo mechanical properties of carbon fibers at high temperatures (upto 2000oc). Composites science and technology, 62 (2002) ,499-504 [11] A.P. Mouritz, Z. Mathys, Post-fire mechanical properties of glass-reinforced polyester composites, Composites science and technology, 61, (2001) ,475-490. [12] Zhongfu Zhao, Jihua Gou. Fire retardancy of clay/carbon nano fiber hybrid sheet in fiber reinforced polymer composites. Composites science and technology, 69, (2009), 2081-2087 [13] A yasmin, J. J. Luo. Mechanical and thermal behavior of clay/epoxy nano composites. Composites science and technology, 66, (2006), 2415-2422 [14] A G Gibson, Y S Wu. Laminate theory analysis of composites under load in fire. Journal of composite materials, 639- 647. [15] Li-ping Gao, De-Yiwang. A flameretardant epoxy resin based on a reactive phosphorous-containing monomer of DODPP and its thermal and flameretardant properties. Polymer Degradation and stability, 93, (2008), 1308-1315 [16] Terese E Glodek, Steven E Boyd. Properties and performance of a fire resistant eco-composites using polyhedral oligomeric silsesquioxane (poss) fire retardants. Composites science and technology, 68, (2008), 2994-3001 [17] James Giancaspro, Christos papakonstantinou. Fire resistance of inorganic saw dust bicomposite. Composites science and technology, 68, (2008), 1895-1902

Issn 2250-3005(online)

September| 2012

Page 1714

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Parametric Study On Analysis and Design of Permanently Anchored Secant Pile Wall For Earthquake LoadingDocument16 pagesParametric Study On Analysis and Design of Permanently Anchored Secant Pile Wall For Earthquake LoadingInternational Journal of computational Engineering research (IJCER)No ratings yet

- Parametric Study On Analysis and Design of Permanently Anchored Secant Pile Wall For Earthquake LoadingDocument16 pagesParametric Study On Analysis and Design of Permanently Anchored Secant Pile Wall For Earthquake LoadingInternational Journal of computational Engineering research (IJCER)No ratings yet

- PCB Faults Detection Using Image ProcessingDocument5 pagesPCB Faults Detection Using Image ProcessingInternational Journal of computational Engineering research (IJCER)No ratings yet

- Conceptual Design and Structural Analysis of Solid Rocket Motor CasingDocument6 pagesConceptual Design and Structural Analysis of Solid Rocket Motor CasingInternational Journal of computational Engineering research (IJCER)No ratings yet

- Relationship Between Refractive Index, Electronic Polarizavility, Optical Energy Gap Optical Electronegativity and Plasmon Energy in I-Iii-Vi2 and Ii-Iv-V2 Groups of Semi Conductors.Document5 pagesRelationship Between Refractive Index, Electronic Polarizavility, Optical Energy Gap Optical Electronegativity and Plasmon Energy in I-Iii-Vi2 and Ii-Iv-V2 Groups of Semi Conductors.International Journal of computational Engineering research (IJCER)No ratings yet

- Optimization of ZLD in Distillery Industry by Reverse Osmosis Process For Prediction of Multi Responses by Taguchi Orthogonal ArrayDocument12 pagesOptimization of ZLD in Distillery Industry by Reverse Osmosis Process For Prediction of Multi Responses by Taguchi Orthogonal ArrayInternational Journal of computational Engineering research (IJCER)No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Manocha 2013Document10 pagesManocha 2013Guido ObandoNo ratings yet

- HWI Ramming PlasticsDocument23 pagesHWI Ramming PlasticsMuhammad victoryan nadezul100% (1)

- An Experimental Investigation On Mechanical Properties of Aluminium-7075 Based Graphite and Bagasse Ash Particles Reinforced Metal Matrix CompositeDocument16 pagesAn Experimental Investigation On Mechanical Properties of Aluminium-7075 Based Graphite and Bagasse Ash Particles Reinforced Metal Matrix Compositelakshmi vennelaNo ratings yet

- MCQ Ceramicsto PrintDocument5 pagesMCQ Ceramicsto PrintChan Myae AungNo ratings yet

- Surface Review and LettersDocument12 pagesSurface Review and LettersSujoy ChakrabortyNo ratings yet

- Module 5: Materials: Presentation On Molten Salt Reactor Technology By: David Holcomb, PH.DDocument27 pagesModule 5: Materials: Presentation On Molten Salt Reactor Technology By: David Holcomb, PH.Dfarshid KarpasandNo ratings yet

- Pump Tutorial 2Document19 pagesPump Tutorial 210teste10No ratings yet

- Machin AbilityDocument7 pagesMachin AbilityAshok KumarNo ratings yet

- Analysis of Stir Die Cast Al-SiC Composite Brake Drums Based On Coefficient of FrictionDocument6 pagesAnalysis of Stir Die Cast Al-SiC Composite Brake Drums Based On Coefficient of FrictionAnonymous PufNjgNo ratings yet

- 2001 AFS - Preconditioning of Gray Iron Melts Using Ferrosilicon or Silicon CarbideDocument12 pages2001 AFS - Preconditioning of Gray Iron Melts Using Ferrosilicon or Silicon Carbidemecaunidos7771No ratings yet

- A Paper-Like Inorganic Thermal Interface Material Composed of Hierarchically Structured Graphene/Silicon Carbide NanorodsDocument8 pagesA Paper-Like Inorganic Thermal Interface Material Composed of Hierarchically Structured Graphene/Silicon Carbide NanorodsFelipe BasquirotoNo ratings yet

- Engineering Materials: Metals and Their Alloys Ceramics Polymers CompositesDocument53 pagesEngineering Materials: Metals and Their Alloys Ceramics Polymers CompositesSyed Muhammad AliNo ratings yet

- Grundfos CR 32-3-2 A F A e HqqeDocument11 pagesGrundfos CR 32-3-2 A F A e Hqqearyantha suathamaNo ratings yet

- How To Increase Power Rating With The Right Cooling StrategyDocument6 pagesHow To Increase Power Rating With The Right Cooling StrategyAydcon SccNo ratings yet

- GrindingDocument60 pagesGrindingGaurav Yadav100% (1)

- Pilot Units From LiqTech - v2 PDFDocument2 pagesPilot Units From LiqTech - v2 PDFGabriel Montoya CorreaNo ratings yet

- AgitatorDocument10 pagesAgitatoragrocel_bhv5591No ratings yet

- Electrical Discharge Machining Characteristics of Aluminium Metal Matrix Composites - A ReviewDocument10 pagesElectrical Discharge Machining Characteristics of Aluminium Metal Matrix Composites - A Reviewwhoam iNo ratings yet

- Master Grinding WheelsDocument82 pagesMaster Grinding WheelsHouariKouadriNo ratings yet

- Review of Magnesium Metal Matrix CompositesDocument19 pagesReview of Magnesium Metal Matrix CompositesGokulraju RangasamyNo ratings yet

- Black Silicon Carbide-AbrasiveDocument2 pagesBlack Silicon Carbide-AbrasiveZai JscNo ratings yet

- PB3 1Document5 pagesPB3 1womini1025No ratings yet

- Clay Bonded Graphite CrucibleDocument4 pagesClay Bonded Graphite Cruciblevasu_nifft9352No ratings yet

- Emerging Applications of Radiation Processing: IAEA-TECDOC-1386Document171 pagesEmerging Applications of Radiation Processing: IAEA-TECDOC-1386Luis Percy VargasNo ratings yet

- Further Product Details: Qty. Description CR 5-3 A-A-A-E-HQQEDocument10 pagesFurther Product Details: Qty. Description CR 5-3 A-A-A-E-HQQEabhe prasetyaNo ratings yet

- Special Ceramic Materials: Hana OvcacikovaDocument44 pagesSpecial Ceramic Materials: Hana OvcacikovaSasi KalaNo ratings yet

- Investigation in To Tribo Potential of Rice Husk (RH) Char Reinforced Epoxy CompositeDocument103 pagesInvestigation in To Tribo Potential of Rice Husk (RH) Char Reinforced Epoxy CompositerafaqatwahNo ratings yet

- Fabrication of Functionally Graded Composite Material Using Powder Metallurgy Route: An OverviewDocument12 pagesFabrication of Functionally Graded Composite Material Using Powder Metallurgy Route: An OverviewTJPRC PublicationsNo ratings yet

- Wall Colmonoy Corp Colmonoy 200 Series TDS April2020Document3 pagesWall Colmonoy Corp Colmonoy 200 Series TDS April2020santiago aguileraNo ratings yet

- Optimization of Dry Sliding Wear Characteristics of Al 25Zn SiC Hybrid Composites by Graphite Reinforcement Using Artificial Neural Network andDocument15 pagesOptimization of Dry Sliding Wear Characteristics of Al 25Zn SiC Hybrid Composites by Graphite Reinforcement Using Artificial Neural Network andPearl IPNo ratings yet