Professional Documents

Culture Documents

Is 802 (Part-I, Sec-2) Use of Structural Steel in Overhead T

Uploaded by

Anonymous RXXdbl36A0 ratings0% found this document useful (0 votes)

23 views14 pagesdesign

Original Title

Is 802 (Part-i, Sec-2) Use of Structural Steel in Overhead t

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdesign

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views14 pagesIs 802 (Part-I, Sec-2) Use of Structural Steel in Overhead T

Uploaded by

Anonymous RXXdbl36Adesign

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 14

I S 802 (P a r t 1/Sec 2) : 1992

(Rea ffi r med 1998)

Ed i t i on 4.1

(1998-01)

Indian S tandard

USE OF STRUCTURAL STEEL IN OVERHEAD

TRANSMISSION LINE TOWERS CODE

OF PRACTICE

P ART 1 MATERI AL, LOADS AND P ERMI SSI BLE STRESSES

Sect i on 2 P er mi ssi b le St r esses

( Third Revision )

(Incor por at ing Amendment No. 1)

UDC 621.315.668.2

BIS 2002

B U R E A U O F I N D I A N S T A N D A R D S

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

P r i ce Gr ou p 6

St r uct ur al Engineer ing Sect ional Commit t ee, CED 7

FOREWORD

This Indian St andar d (Thir d Revision) was adopt ed by t he Bur eau of Indian St andar ds, aft er t he

dr aft finalized by t he St r uct ur al Engineer ing Sect ional Commit t ee had been appr oved by t he Civil

Engineer ing Division Council.

This st andar d has been pr epar ed wit h a view t o est ablish unifor m pr act ices for design, fabr icat ion,

t est ing and inspect ion of over head t r ansmission line t ower s. Par t 1 of t he st andar d cover s

r equir ement s in r egar d t o mat er ial, t ypes of t ower s, loading and per missible st r esses apar t fr om

ot her r elevant design pr ovisions. Pr ovisions for fabr icat ion, galvanizing, inspect ion and packing

have been cover ed in Par t 2 wher eas pr ovisions for t est ing of t hese t ower s have been cover ed in

Par t 3 of t he st andar d.

This st andar d (Par t 1) was fir st published in 1967 and subsequent ly r evised in 1973 and 1977. In

t his r evision, t he code has been split in t wo sect ions namely Sect ion 1 Mat er ials and loads, and

Sect ion 2 Per missible st r esses. Ot her major modificat ions effect ed in t his r evision (Sect ion 2) ar e

as under :

a) Per missible st r esses in st r uct ur al member s have been given in t er ms of t he yield st r engt h of

t he mat er ial. Wit h t he inclusion of bolt s of pr oper t y class 5.6 of IS 12427 : 1988, per missible

st r esses for t hese bolt s have also been included.

b) Cr it ical st r ess in compr ession F

cr

has been modified for widt h/t hickness r at io of t he angles

exceeding t he limit ing value for calculat ing t he allowable unit compr essive st r esses.

c) Effect ive slender ness r at ios ( KL/r ) for r edundant member s have been included and

pr ovisions fur t her elabor at ed.

d) Examples for t he det er minat ion of slender ness r at ios have been ext ended t o include K and

X br acings wit h and wit hout secondar y member s.

Designs pr ovisions or ot her it ems not cover ed in t his st andar d shall gener ally be in accor dance

wit h IS 800 : 1984 Code of pr act ice for gener al const r uct ion in st eel ( second revision ).

While pr epar ing t his st andar d, pr act ices pr evailing in t he count r y in t his field have been kept in

view. Assist ance has also been der ived fr om t he Guide for design of st eel t r ansmission line t ower s

(second edit ion) ASCE Manual No. 52, issued by Amer ican Societ y of Civil Engineer s (ASCE)

New Yor k, 1988.

This edit ion 4.1 incor por at es Amendment No. 1 (J anuar y 1998). Side bar indicat es modificat ion of

t he t ext as t he r esult of incor por at ion of t he amendment s.

For t he pur pose of deciding whet her a par t icular r equir ement of t his Code is complied wit h, t he

final value, obser ved or calculat ed, expr essing t he r esult of a t est , shall be r ounded off in

accor dance wit h IS 2 : 1960 Rules for r ounding off numer ical values ( revised ). The number of

significant places r et ained in t he r ounded off value should be t he same as t hat of t he specified

value in t his st andar d.

I S 802 (P a r t 1/Sec 2) : 1992

1

Indian S tandard

USE OF STRUCTURAL STEEL IN OVERHEAD

TRANSMISSION LINE TOWERS CODE

OF PRACTICE

P ART 1 MATERI AL, LOADS AND P ERMI SSI BLE STRESSES

Sect i on 2 P er mi ssi b le St r esses

( Third Revision )

1 SCOP E

1.1 This st andar d (Par t 1/Sec 2) st ipulat es t he

per missible st r esses and ot her design

par amet er s t o be adopt ed in t he design of

self-suppor t ing st eel lat t ice t ower s for over head

t r ansmission lines.

1.1.1 Mat er ials, t ype of t ower s, loading and

br oken wir e condit ions ar e cover ed in Sect ion 1

of t his st andar d.

1.1.2 Pr ovisions on fabr icat ion and t est ing of

t r ansmission line t ower s have been cover ed in

Par t 2 and Par t 3 r espect ively of t he st andar d.

NOTE While for mulat ing t he pr ovisions of t his

st andar d it has been assumed t hat t he st r uct ur al

connect ions ar e t hr ough bolt s.

1.2 This st andar d does not cover guyed t ower s.

These will be cover ed in a separ at e st andar d.

2 REF ERENCES

The Indian St andar ds list ed in Annex A ar e

necessar y adjunct s t o t his st andar d.

3 STATUTORY REQUI REMENTS

3.1 St at ut or y r equir ement as laid down in t he

Indian Electricity Rules, 1956 or by any ot her

st at ut or y body applicable t o such st r uct ur es as

cover ed in t his st andar d shall be sat isfied.

3.2 Compliance wit h t his code does not r elieve

any one fr om t he r esponsibilit y of obser ving

local and st at e byelaws, fir e and safet y laws

and ot her civil aviat ion r equir ement s

applicable t o such st r uct ur es.

4 CONDUCTOR TENSI ON

4.1 The conduct or t ension at ever yday

t emperat ure and wit hout ext ernal load should not

exceed t he following per cent age of t he ult imat e

st r engt h of t he conduct or :

pr ovided t hat t he ult imat e t ension under

ever yday t emper at ur e and full wind or

minimum t emper at ur e and t wo-t hir ds wind

pr essur e does not exceed 70 per cent of t he

ult imat e t ensile st r engt h of t he cable.

5 P ERMI SSI BLE STRESSES

5.1 Axi a l St r esses i n Ten si on

The est imat ed t ensile st r esses on t he net

effect ive sect ional ar eas ( see 9 ) in var ious

member s, shall not exceed minimum

guar ant eed yield st r ess of t he mat er ial.

However in case t he angle sect ion is connect ed

by one leg only, t he est imat ed t ensile st r ess on

t he net effect ive sect ional ar ea shall not exceed

F

y

, wher e F

y

, is t he minimum guar ant eed yield

st r ess of t he mat er ial.

5.2 Axi a l St r esses i n Comp r essi on

5.2.1 The est imat ed compr essive st r esses in

var ious member s shall not exceed t he values

given by t he for mulae in 5.2.2.

5.2.2 The allowable unit st r ess F

a

, in MPa on

t he gr oss cr oss sect ional ar ea of t he axially

loaded compr ession member s shall be:

Init ial unloaded t ension 35 per cent

Final unloaded t ension 25 per cent

a)

and,

b)

I S 802 (P a r t 1/Sec 2) : 1992

2

wher e

5.2.2.1 The for mulae given in 5.2.2 ar e

applicable pr ovided t he lar gest widt h t hickness

r at io b/t is not mor e t han t he limit ing value

given by:

( b/t )

lim

= 210/

wher e

5.2.2.2 Wher e t he widt h t hickness r at io exceeds

t he limit s given in 5.2.2.1, t he for mulae given

in 5.2.2 shall be used subst it ut ing for F

y

t he

value F

cr

given by:

a)

and

b)

NOTE The maximum per missible value of b/t for any

t ype of st eel shall not exceed 25.

5.3 The r edundant member s shall be checked

individually for 2.5 per cent of axial load car r ied

by t he member t o which it suppor t s.

5.4 St r esses i n Bolt s

Ult imat e st r esses in bolt s confor ming t o

pr oper t y class 4.6 of IS 6639 : 1972 and t o

pr oper t y class 5.6 of IS 12427 : 1988 shall not

exceed t he value given in Table 1. For bolt s

confor ming t o IS 3757 : 1985, per missible

st r esses and ot her pr ovisions gover ning t he use

of high st r engt h bolt s r efer ence shall be made

t o IS 4000 : 1992.

5.4.1 Wher e t he mat er ial of bolt and t he

st r uct ur al member ar e of differ ent gr ades, t he

bear ing st r engt h of t he joint shall be gover ned

by t he lower of t he t wo.

6 SLENDERNESS RATI OS

6.1 The slender ness r at ios of compr ession and

r edundant member s shall be det er mined as

follows:

C

e

=

Fy = minimum guar ant eed yield st r ess of

t he mat er ial, MPa

E = modulus, of elast icit y of st eel t hat is

2 10

5

MPa,

KL/r = lar gest effect ive slender ness r at io of

any unbr aced segment of t he

member ,

L = unbr aced lengt h of t he compr ession

member ( see 6.1.1 ) in cm, and

r = appr opr iat e r adius of gyr at ion in

cm.

b = dist ance fr om edge of fillet t o t he

ext r eme fibr e in mm, and

t = t hickness of flange in mm.

2 E/F

y

F

y

Ta ble 1 Ult i ma t e St r esses i n Bolt s, MP a

( Clause 5.4 )

Na t u r e of St r e ss P e r mi ssi b le

St r e s s for Bolt s

of P r op e r t y

Cla ss

Re ma r k s

4.6 5.6

(1) (2) (3) (4)

S hear

Shear st r ess on gr oss

ar ea of bolt s

218 310 For gr oss ar ea of

bolt s ( see 10.4 ).

For bolt s in double

shear t he ar ea t o

be assumed shall

be t wice t he ar ea

defined

Bearing

Bear ing st r ess on

gr oss diamet er of

bolt s

436 620 For t he bolt ar ea in

bear ing ( see 10.5 )

Tension

Axial t ensile st r ess 194 250

Type of Members Value of KL/r

a) Compression Members

i) Leg sect ions or joint

member s bolt ed in bot h

faces at connect ions for

0 < L/r < 120

L/r

ii) Member s wit h

concent r ic loading at

bot h ends of t he

unsuppor t ed panel for

0 < L/r < 120

L/r

iii) Member wit h

concent r ic loading at

one end and nor mal

fr aming eccent r icit y at

t he ot her end of t he

unsuppor t ed panel for

0 < L/r < 120

30 + 0.75 L/r

iv) Member wit h nor mal

fr aming eccent r icit ies

at bot h ends of t he

unsuppor t ed panel for

0 < L/r < 120

60 + 0.50 L/r

v) Member unr est r ained

against r ot at ion at bot h

ends of t he unsuppor t ed

panel for 120 < L/r <

200

L/r

; )

I S 802 (P a r t 1/Sec 2) : 1992

3

NOTE The values of KL/r cor r esponding t o (a) (vi)

and (a) (vii), t he following evaluat ion is suggest ed:

1 The r est r ained member must be connect ed t o t he

r est r aining member wit h at least t wo bolt s.

2 The r est r aining member must have a st iffness fact or

I/L in t he st r ess plane ( I = Moment of iner t ia and L =

Lengt h ) t hat equals or exceeds t he sum of t he

st iffness fact or s in t he st r ess plane of t he r est r ained

member s t hat ar e connect ed t o it .

3 Angle member s connect ed by one leg should have t he

holes locat ed as close t o t he out st anding leg as

feasible. Nor mal fr aming eccent r icit ies at load

t r ansfer connect ion imply t hat connect ion holes ar e

locat ed bet ween t he heel of t he angle end t he

cent r eline of t he fr aming leg.

6.1.1 In calculat ing t he slender ness r at io of t he

member s, t he lengt h L should be t he dist ance

bet ween t he int er sect ions of t he cent r e of

gr avit y lines at each end of t he member .

6.2 Examples showing t he applicat ion of t he

pr ocedur e given in 6.1 and 6.1.1 and met hod of

det er mining t he slender ness r at io of legs and

br acings wit h or wit hout secondar y member s

ar e given in Annex B.

NOTE Wher e t est and/or analysis demonst r at e t hat

any ot her t ype of br acing pat t er n if found t echnically

suit able, t he same can be adopt ed.

6.3 The limit ing values KL/r shall be as follows:

6.4 Slender ness r at io L/r of a member car r ying

axial t ension only, shall not exceed 400.

7 MI NI MUM THI CKNESS

7.1 Minimum t hickness of galvanized and

paint ed t ower member s shall be as follows:

7.2 Gusset plat es shall be designed t o r esist t he

shear , dir ect and flexur al st r esses act ing on t he

weakest or cr it ical sect ion. Re-ent r ant cut s

shall be avoided as far as pr act ical. Minimum

t hickness of gusset shall be 2 mm mor e t han

lat t ice it connect s only in case when t he lat t ice

is dir ect ly connect ed on t he gusset out side t he

leg member . In no case t he gusset shall be less

t han 5 mm in t hickness.

8 NET SECTI ONAL AREA F OR TENSI ON

MEMBER

8.1 The net sect ional ar ea shall be t he least

ar ea which is t o be obt ained by deduct ing fr om

t he gr oss sect ional ar ea, t he ar ea of all holes

cut by any st r aight , diagonal or zigzag line

acr oss t he member . In det er mining t he t ot al

ar ea of t he holes t o be deduct ed fr om gr oss

sect ional ar ea, t he full ar ea of t he fir st hole

shall be count ed, plus a fr act ion par t X, of each

succeeding hole cut by t he line of holes under

consider at ion. The value of X shall be

det er mined fr om t he for mula:

X

.

= 1

wher e

For holes in opposit e legs of angles, t he value of

g should be t he sum of t he gauges fr om t he

back of t he angle less t he t hickness of t he

angle.

vi) Member par t ially

r est r ained against

r ot at ion at one end of

t he unsuppor t ed panel

for 120 < L/r < 225

28.6 + 0.762 L/r

vii) Member par t ially

r est r ained against

r ot at ion at bot h ends of

t he unsuppor t ed panel

for 120 < L/r < 250

46.2 + 0.615 L/r

b) Redundant Members

i) For 0 < L/r < 250 L/r

Leg member s, gr ound wir e peak

member and lower member s of t he

cr oss ar ms in compr ession

120

Ot her member s car r ying comput ed

st r esses

200

Redundant member s and t hose

car r ying nominal st r esses

250

Minimum Thickness,

mm

Galvanized Paint ed

Leg member s, gr ound

wir e peak member and

lower member s of cr oss

ar ms in compr ession

5 6

Ot her member s 4 5

P = longit udinal spacing (st agger ), t hat is

t he dist ance bet ween t wo successive

holes in t he line of holes under

consider at ion;

g = t r ansver se spacing (gauge), t hat is t he

dist ance bet ween t he same t wo

consecut ive holes as for P; and

d = diamet er of holes.

; )

P

2

4gd

----------

I S 802 (P a r t 1/Sec 2) : 1992

4

9 NET EF F ECTI VE AREA F OR ANGLE

SECTI ON I N TENSI ON

9.1 In t he case of single angle connect ed

t hr ough one leg, t he net effect ive sect ion of t he

angle shall be t aken as:

A

1

+ A

2

k

wher e

wher e lug angles ar e used, t he effect ive

sect ional ar ea of t he whole of t he angle member

shall be consider ed.

9.2 In t he case of pair of angles back t o back in

t ension connect ed by one leg of each angle t o

t he same side of gusset , t he net effect ive ar ea

shall be t aken as:

A

1

+ A

2

k

wher e

A

1

and A

2

ar e as defined in 9.1, and

k =

9.3 The angles connect ed t oget her back-t o-back

(in cont act ) or separ at ed back-t o-back by a

dist ance not exceeding t he aggr egat e t hickness

of t he connect ed par t s shall be pr ovided wit h

st ich bolt at a a pit ch not exceeding 1 000 mm.

The slender ness r at io of individual component

bet ween adjacent st ich bolt s shall not be mor e

t han t hat of t he t wo member s t oget her .

9.4 Wher e t he angles ar e back t o back but not

connect ed as per 9.3, each angle shall be

designed as a single angle connect ed t hr ough

one leg only in accor dance wit h 9.1.

9.5 When t wo t ees ar e placed back t o back but

ar e not connect ed as per 9.3, each t ee shall be

designed as a single t ee connect ed t o one side of

a gusset only in accor dance wit h 9.2.

NOTE The ar ea of t he leg of an angle shall be t aken

as t he pr oduct of t he t hickness and t he lengt h fr om t he

out er cor ner minus half t he t hickness, and t he ar ea of

t he leg of a t ee as t he pr oduct of t he t hickness and t he

dept h minus t he t hickness of t he t able.

10 BOLTI NG

10.1 Mi n i mu m Di a met er of Bolt s

The diamet er of bolt s shall not be less t han

12 mm

10.2 P r efer r ed Si zes of Bolt s

Bolt s used for er ect ion of t r ansmission line

t ower s shall be of diamet er 12, 16 and 20 mm.

10.3 The lengt h of bolt s shall be such t hat t he

t hr eaded por t ion does not lie in t he plane of

cont act of member s. The pr oject ed por t ion of

t he bolt beyond t he nut shall be bet ween 3 t o

8 mm.

10.4 Gr oss Ar ea of Bolt

For t he pur pose of calculat ing t he shear st r ess,

t he gr oss ar ea of bolt s shall be t aken as t he

nominal ar ea of t he bolt .

10.5 The bolt ar ea for bear ing shall be t aken as

d t wher e d is t he nominal diamet er of t he

bolt , and t t he t hickness of t he t hinner of t he

par t s joint ed.

10.6 The net ar ea of a bolt in t ension shall be

t aken as t he ar ea at t he r oot of t he t hr ead.

10.7 Holes for Bolt i n g

The diamet er of t he hole dr illed/punched shall

not be mor e t han t he nominal diamet er of t he

bolt plus 1.5 mm.

11 F RAMI NG

11.1 The angle bet ween any t wo member s

common t o a joint of a t r ussed fr ame shall

pr efer ably be gr eat er t han 20 and never less

t han 15 due t o uncer t aint y of st r ess

dist r ibut ion bet ween t wo closely spaced

member s.

ANNEX A

( Clause 2 )

LI ST OF REF ERRED I NDI AN STANDARDS

A

1

= effect ive sect ional ar ea of t he

connect ed leg.

A

2

= t he gr oss cr oss-sect ional ar ea of t he

unconnect ed leg, and

k =

3A

1

3A

1

A

2

+ ( )

-----------------------------

5A

1

5A

1

A

2

+

------------------------

IS No. Title

800 : 1984 Code of pr act ice for use of

st r uct ur al st eel in gener al

building const r uct ion ( revised )

3757 : 1985 High st r engt h st r uct ur al bolt s

( second revision )

IS No. Title

4000 : 1992 Code of pr act ice for high

st r engt h bolt s in st eel

st r uct ur es

6639 : 1972 Hexagonal bolt for st eel

st r uct ur es

12427 : 1988 Tr ansmission t ower bolt s

I S 802 (P a r t 1/Sec 2) : 1992

5

ANNEX B

( Clause 6.2 )

EXAMP LES OF DETERMI NATI ON OF SLENDERNESS RATI OS

B-0 Example of det er mining t he effect ive lengt h of compr ession member s of t ower s based on t he

pr ovision given in 6.1 ar e given below.

B-1 LEG MEMBER USI NG SYMMETRI CAL BRACI NG

B-2 LEG MEMBER USI NG STAGGERED BRACI NG

Method of Loading/

Rigidity of J oints

S lenderness Ratio

Concent r ic loading fr om 0 t o 120

No r est r aint at ends fr om 120 t o 200

Method of Loading/

Rigidity of J oints

S lenderness Ratio

Concent r ic loading or 0.67 fr om 0

t o 120

No r est r aint at ends or 0.67 fr om 120

t o 200

L

r

vv

--------

KL

r

--------

L

r

vv

-------- =

,

_

L

r

vv

--------

KL

r

--------

L

r

vv

-------- =

,

_

L

r

xx

-------- or

L

r

yy

--------

L

r

vv

--------

KL

r

--------

L

r

--- - =

,

_

L

r

xx

-------- or

L

r

yy

--------

L

r

vv

--------

KL

r

--------

L

r

--- - =

,

_

I S 802 (P a r t 1/Sec 2) : 1992

6

B-3 EF F ECT OF END CONNECTI ONS ON MEMBER CAP ACI TY

Method of Loading/Rigidity of

J oints

S lenderness Ratio

Tension syst em wit h compr ession

st r ut (eccent r icit y in cr it ical

axis)

fr om 0 t o 120

Bracing Requirements ( S ingle

Angle Members ):

Single bolt connect ion, no

r est r aint at ends

fr om 120 t o 200

Mult iple bolt connect ion par t ial

r est r aint at bot h ends

fr om 120 t o 250

B-4 CONCENTRI C LOADI NG TWO ANGLE MEMBER

Method of Loading/Rigidity

of J oints

S lenderness Ratio

Tension syst em st r ut compr ession

concent r ic loading

or fr om 0 t o 120

Bracing Requirements ( Two Angle

Member ):

Single bolt connect ion, no

r est r aint at ends

or fr om 120 t o 200

Mult iple bolt connect ion, par t ial

r est r aint at ends

or fr om 120 t o 250

L

r

vv

--------

KL

r

-------- 60 0.5

L

r

---- + =

,

_

L

r

vv

--------

KL

r

--------

L

r

--- - =

,

_

L

r

vv

--------

KL

r

-------- 46.2 0.615

L

r

--- - + =

,

_

L

r

xx

--------

L

r

yy

--------

KL

r

--------

L

r

--- - =

,

_

L

r

xx

--------

L

r

yy

--------

KL

r

--------

L

r

--- - =

,

_

L

r

xx

--------

L

r

yy

--------

KL

r

-------- 46.2 0.615

L

r

--- - + =

,

_

I S 802 (P a r t 1/Sec 2) : 1992

7

B-5 HORI ZONTAL MEMBER OF K-BRACI NG-TWO ANGLE MEMBER

Method of Loading/Rigidity

of J oints

S lenderness Ratio

Tension-compression system

with compression strut:

Mult iple bolt s connect ion

par t ial r est r aint at ends

and int er mediat e

0.5 fr om 120 t o 250

Bracing Requirements ( Two

Angle Member ):

Concent r ic load at ends,

eccent r ic loading at

int er mediat e in bot h

dir ect ions

0.5 fr om 0 t o 120

Concent r ic loading at ends

and int er mediat e

0.5 fr om 0 t o 120

L

r

yy

-------- or

L

r

xx

--------

KL

r

-------- 46.2 0.615

L

r

--- - + =

,

_

L

r

yy

-------- or

L

r

xx

--------

KL

r

-------- 30 0.75

L

r

--- - + =

,

_

L

r

yy

-------- or

L

r

xx

--------

KL

r

--------

L

r

--- - =

,

_

I S 802 (P a r t 1/Sec 2) : 1992

8

B-6 EF F ECT OF SUBDI VI DED P ANELS F OR THE HORI ZONTAL MEMBER AND END

CONNECTI ONS ON MEMBER CAP ACI TY

Method of Loading/Rigidity

of J oints

S lenderness Ratio

Tension system with

compression strut:

Eccent r icit y in cr it ical axis 0.5 fr om 0 t o 120

Bracing Requirements:

Single bolt connect ion, no

r est r aint at ends for

int er mediat e

0.5 fr om 120 t o 200

Mult iple bolt connect ion at

ends. Single bolt connect ion

at int er mediat e point :

Par t ial r est r aint at one end,

on r est r aint at int er mediat e

0.5 fr om 120 t o 225

Par t ial r est r aint at bot h ends fr om 120 t o 250

Mult iple bolt connect ion

Par t ial r est r aint at ends and

int er mediat e

0.5 fr om 120 t o 250

L

r

vv

-------- or

L

r

xx

--------

KL

r

-------- 60 0.50

L

r

--- - + =

,

_

L

r

vv

-------- or

L

r

xx

--------

KL

r

--------

L

r

--- - =

,

_

L

r

vv

--------

KL

r

-------- 28.6 0.762

L

r

--- - + =

,

_

L

r

xx

--------

KL

r

-------- 46.2 0.615

L

r

--- - + =

,

_

L

r

vv

-------- or

L

r

xx

--------

KL

r

-------- 46.2 0.615

L

r

--- - + =

,

_

I S 802 (P a r t 1/Sec 2) : 1992

9

B-7 CONCENTRI C LOADI NG TWO ANGLE MEMBER, SUBDI VI DED P ANELS OF A

HORI ZONTAL MEMBER

Method of Loading/Rigidity

of Panel

S lenderness Ratio

Tension system with

compression strut:

0.5 fr om 0 t o 120

Concent r ic loading

Bracing Requirements:

Single bolt connect ion, no

r est r aint at ends and

int er mediat e

0.5 fr om 120 t o 200

Mult iple bolt connect ion at

ends. Single bolt connect ion

at int er mediat e joint

Par t ial r est r aint at one end,

no r est r aint at int er mediat e 0.5 fr om 120 t o 200

Par t ial r est r aint at bot h ends fr om 120 t o 250

Mult iple bolt connect ion

Par t ial r est r aint at ends

and int er mediat e

0.5 fr om 120 t o 250

L

r

yy

-------- or

L

r

xx

--------

KL

r

--------

L

r

--- - =

,

_

L

r

yy

-------- or

L

r

xx

--------

KL

r

--------

L

r

--- - =

,

_

L

r

yy

--------

KL

r

-------- 28.6 0.762

L

r

--- - + =

,

_

L

r

xx

--------

KL

r

-------- 46.2 0.615

L

r

--- - + =

,

_

L

r

yy

-------- or

L

r

xx

--------

KL

r

-------- 46.2 0.615

L

r

--- - + =

,

_

I S 802 (P a r t 1/Sec 2) : 1992

10

B-8 X-BRACI NGS WI TH AND WI THOUT SECONDARY MEMBERS

S lenderness Ratio Critical of:

B-8.1 AB/r

vv

B-8.2

a)

AC/r

vv

or CB/r

vv

or

*AB/r

xx

or *AB/r

yy

or

*AD/r

vv

b)

AC/r

vv

or CB/r

vv

or

*AD/r

vv

B-8.3

a)

AD/r

vv

or *AF/r

xx

or

DC/r

vv

or *AE/r

vv

or

CB/r

vv

or

*AB/r

xx

or *AB/r

yy

or

EF/r

vv

b)

AD/r

vv

or *AF/r

xx

or

DC/r

vv

or *AE/r

vv

or

CB/r

vv

or

AC/r

xx

or *AC/r

vy

or

EF/r

vv

c)

AD/r

vv

or *AF/r

xx

or

DC/r

vv

or

CB/r

vv

or *AE/r

vv

or

EF/r

vv

B-8.4 AE/r

vv

or *AF/r

xx

or

ED/r

vv

or *AE/r

vv

or

DC/r

vv

or CB/r

vv

*Applicat ion for t ension compr ession syst em only i.e. t ensile st r esses in one br acing must be at least equal t o 75 per cent

of t he compr essive st r ess in t he ot her br acing.

#The cor ner st ay should be designed t o pr ovide lat er al suppor t adequat ely.

I S 802 (P a r t 1/Sec 2) : 1992

11

B-9 K-BRACI NGS WI TH AND WI THOUT SECONDARY MEMBERS

S lenderness Ratio Critical of:

B-9.1 AB/r

vv

B-9.2

a)

AC/r

vv

or

CB/r

vv

or

AB/r

xx

or AB/r

yy

b)

AC/r

vv

or

CB/r

vv

B-9.3

a)

AD/r

vv

or

DC/r

vv

or

CB/r

vv

or

AB/r

xx

or AB/r

yy

b)

AD/r

vv

or

DC/r

vv

or

CB/r

vv

or

AC/r

xx

or AC/r

yy

c)

AD/r

vv

or

DC/r

vv

or

CB/r

vv

B-9.4 AE/r

vv

or

ED/r

vv

or

DC/r

vv

or

CB/r

vv

#The cor ner st ay should be designed t o pr ovide lat er al suppor t adequat ely.

Bu r ea u of I n d i a n St a n d a r d s

BIS is a st at ut or y inst it ut ion est ablished under t he Bureau of Indian S tandards Act, 1986 t o pr omot e

har monious development of t he act ivit ies of st andar dizat ion, mar king and qualit y cer t ificat ion of goods and

at t ending t o connect ed mat t er s in t he count r y.

Cop yr i gh t

BIS has t he copyr ight of all it s publicat ions. No par t of t hese publicat ions may be r epr oduced in any for m

wit hout t he pr ior per mission in wr it ing of BIS. This does not pr eclude t he fr ee use, in t he cour se of

implement ing t he st andar d, of necessar y det ails, such as symbols and sizes, t ype or gr ade designat ions.

Enquir ies r elat ing t o copyr ight be addr essed t o t he Dir ect or (Publicat ions), BIS.

Revi ew of I n d i a n St a n d a r d s

Amendment s ar e issued t o st andar ds as t he need ar ises on t he basis of comment s. St andar ds ar e also

r eviewed per iodically; a st andar d along wit h amendment s is r eaffir med when such r eview indicat es t hat no

changes ar e needed; if t he r eview indicat es t hat changes ar e needed, it is t aken up for r evision. User s of

Indian St andar ds should ascer t ain t hat t hey ar e in possession of t he lat est amendment s or edit ion by

r efer r ing t o t he lat est issue of BIS Cat alogue and St andar ds : Mont hly Addit ions.

This Indian St andar d has been developed fr om Doc : No. CED 7 (4725)

Amen d men t s I ssu ed Si n ce P u bli ca t i on

Amen d No. Da t e of I ssu e Text Affect ed

Amd. No. 1 J anuar y 1998

BUREAU OF I NDI AN STANDARDS

Headquar t er s:

Manak Bhavan, 9 Bahadur Shah Zafar Mar g, New Delhi 110002.

Telephones: 323 01 31, 323 33 75, 323 94 02

Telegr ams: Manaksanst ha

(Common t o all offices)

Regional Offices: Telephone

Cent r al : Manak Bhavan, 9 Bahadur Shah Zafar Mar g

NEW DELHI 110002

323 76 17

323 38 41

East er n : 1/14 C. I. T. Scheme VII M, V. I. P. Road, Kankur gachi

KOLKATA 700054

337 84 99, 337 85 61

337 86 26, 337 91 20

Nor t her n : SCO 335-336, Sect or 34-A, CHANDIGARH 160022 60 38 43

60 20 25

Sout her n : C. I. T. Campus, IV Cr oss Road, CHENNAI 600113 235 02 16, 235 04 42

235 15 19, 235 23 15

West er n : Manakalaya, E9 MIDC, Mar ol, Andher i (East )

MUMBAI 400093

832 92 95, 832 78 58

832 78 91, 832 78 92

Br anches : AH ME DABAD. BAN GAL ORE . BH OP AL . BH U BAN E S H WAR. COI MBAT ORE .

F ARI DABAD. GH AZI ABAD. GU WAH AT I . H YDE RABAD. J AI P U R. KAN P U R.

LUCKNOW. NAGPUR. NALAGARH. PATNA. PUNE. RAJ KOT. THIRUVANANTHAPURAM.

VISHAKHAPATNAM.

'

'

'

'

'

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Saof 0008Document138 pagesSaof 0008Paul CultreraNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Taylorcraft O-57 GrasshopperDocument8 pagesTaylorcraft O-57 GrasshopperAviation/Space History Library100% (1)

- B767 ATA 32 Student BookDocument89 pagesB767 ATA 32 Student BookElijah Paul Merto100% (4)

- Assembly and RiggingDocument121 pagesAssembly and RiggingVv ZoidNo ratings yet

- 4) Handbook of Aeronautical KnowledgeDocument356 pages4) Handbook of Aeronautical Knowledgeleather_nun100% (1)

- Bolted Aluminum Aircraft AirframeDocument14 pagesBolted Aluminum Aircraft Airframeviorelu99100% (2)

- Burnelli AircraftDocument51 pagesBurnelli Aircraftretread1100% (3)

- Pipe SupportsDocument62 pagesPipe Supportscbt_71100% (1)

- Taylorcraft Service Manual BB12Document48 pagesTaylorcraft Service Manual BB12Jessie BechaydaNo ratings yet

- Construction, Repair and ModificationDocument164 pagesConstruction, Repair and ModificationNathaniel LuraNo ratings yet

- Hadley Group Ultrazed and Ultrabeam 63mm System ManualDocument68 pagesHadley Group Ultrazed and Ultrabeam 63mm System ManualTarek-Aziz BihiNo ratings yet

- Method Statement: Loading / Offloading Stations and Metering Skids Installation at Tank Battery / Guebiba Base & TrapsaDocument13 pagesMethod Statement: Loading / Offloading Stations and Metering Skids Installation at Tank Battery / Guebiba Base & TrapsaAkram FerchichiNo ratings yet

- New CDocument1 pageNew CAnonymous RXXdbl36ANo ratings yet

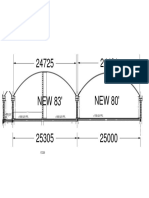

- Old Old: +850 Lev FFL +1000 Lev FFL +1000 Lev FFL +1150 Lev FFLDocument1 pageOld Old: +850 Lev FFL +1000 Lev FFL +1000 Lev FFL +1150 Lev FFLAnonymous RXXdbl36ANo ratings yet

- Water Tank Rev PCC Top Detail at 0.6 LevDocument1 pageWater Tank Rev PCC Top Detail at 0.6 LevAnonymous RXXdbl36ANo ratings yet

- Idtc (Truck Bill)Document2 pagesIdtc (Truck Bill)Anonymous RXXdbl36ANo ratings yet

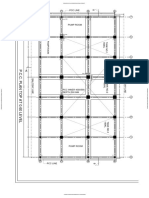

- Footing Details Control BLDDocument1 pageFooting Details Control BLDAnonymous RXXdbl36ANo ratings yet

- To Intrest CertificateDocument1 pageTo Intrest CertificateAnonymous RXXdbl36ANo ratings yet

- Waste2 Steel Making and Beam Design23335555Document5 pagesWaste2 Steel Making and Beam Design23335555Anonymous RXXdbl36ANo ratings yet

- Waste2 Steel Making and Beam DesignDocument4 pagesWaste2 Steel Making and Beam DesignAnonymous RXXdbl36ANo ratings yet

- Waste2 Steel Making and Beam Design2333Document8 pagesWaste2 Steel Making and Beam Design2333Anonymous RXXdbl36ANo ratings yet

- Waste2 Steel Making and Beam Design2333444Document12 pagesWaste2 Steel Making and Beam Design2333444Anonymous RXXdbl36ANo ratings yet

- Sbi Sunita Income TaxwasteDocument2 pagesSbi Sunita Income TaxwasteAnonymous RXXdbl36ANo ratings yet

- Waste2 Steel Making and Beam Design2Document4 pagesWaste2 Steel Making and Beam Design2Anonymous RXXdbl36ANo ratings yet

- Sbi Sunita Income TaxwasteDocument2 pagesSbi Sunita Income TaxwasteAnonymous RXXdbl36ANo ratings yet

- 3 Tundish Well Block High Grog Quality Fire Clay Bulk Density-38 To 42 4 Tundish Bricks IS8 - 58%ALUMINA 230X115X25 230X115X25Document4 pages3 Tundish Well Block High Grog Quality Fire Clay Bulk Density-38 To 42 4 Tundish Bricks IS8 - 58%ALUMINA 230X115X25 230X115X25Anonymous RXXdbl36ANo ratings yet

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument4 pages68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36ANo ratings yet

- Load Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Document31 pagesLoad Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Anonymous RXXdbl36ANo ratings yet

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument4 pages68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36ANo ratings yet

- SR Ingot Footing Was2Document30 pagesSR Ingot Footing Was2Anonymous RXXdbl36ANo ratings yet

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument6 pages68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36ANo ratings yet

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument4 pages68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36ANo ratings yet

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument6 pages68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36ANo ratings yet

- SR Ingot Footing Was2Document31 pagesSR Ingot Footing Was2Anonymous RXXdbl36ANo ratings yet

- Waste 5Document2 pagesWaste 5Anonymous RXXdbl36ANo ratings yet

- Load Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Document31 pagesLoad Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Anonymous RXXdbl36ANo ratings yet

- Steel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K UrlaDocument2 pagesSteel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K UrlaAnonymous RXXdbl36ANo ratings yet

- Waste 6Document2 pagesWaste 6Anonymous RXXdbl36ANo ratings yet

- S.N. Detail NO. NO. L B H/D Std. WTDocument2 pagesS.N. Detail NO. NO. L B H/D Std. WTAnonymous RXXdbl36ANo ratings yet

- S.N. Detail NO. NO. L B H/D Std. WTDocument2 pagesS.N. Detail NO. NO. L B H/D Std. WTAnonymous RXXdbl36ANo ratings yet

- S.N. Description Detail NO. NO. L BDocument2 pagesS.N. Description Detail NO. NO. L BAnonymous RXXdbl36ANo ratings yet

- Waste 2222Document2 pagesWaste 2222Anonymous RXXdbl36ANo ratings yet

- Pa 18 150 - pcv1988Document164 pagesPa 18 150 - pcv1988Jessey StonerNo ratings yet

- Stiffner DesignDocument28 pagesStiffner DesignNisarg TrivediNo ratings yet

- Structural ComponentsDocument29 pagesStructural ComponentsCed SisonNo ratings yet

- Steel BracingsDocument6 pagesSteel BracingsLleiLlei100% (1)

- Antecedents: Codex On The Flight of BirdsDocument13 pagesAntecedents: Codex On The Flight of BirdsJordan MosesNo ratings yet

- ch801 1-60 InstructionsDocument10 pagesch801 1-60 InstructionsStevenNo ratings yet

- Seah 1998Document299 pagesSeah 1998Wallison MedeirosNo ratings yet

- Chapter:1 Historical Developments of AeronauticsDocument44 pagesChapter:1 Historical Developments of AeronauticsAttakaththi DineshNo ratings yet

- Design of The Canada Line Extradosed Transit BridgeDocument10 pagesDesign of The Canada Line Extradosed Transit BridgeAlberto Ruiz-Cabello LópezNo ratings yet

- AirplaneDocument96 pagesAirplaneshubhamvpathade03No ratings yet

- UNIVAIR Pa25 and OthersDocument13 pagesUNIVAIR Pa25 and OthersJessie BechaydaNo ratings yet

- 50" Curtis Jenny Electric Scale ARF Instruction Manual: SpecsDocument16 pages50" Curtis Jenny Electric Scale ARF Instruction Manual: SpecsAntónio OliveiraNo ratings yet

- Lecture 12Document15 pagesLecture 12joshuaNo ratings yet

- 1-Overview of Excavation and Lateral Support System (2022)Document53 pages1-Overview of Excavation and Lateral Support System (2022)Jiajie FENGNo ratings yet

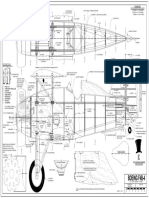

- CG (Initial) : Designed by Plans byDocument1 pageCG (Initial) : Designed by Plans byFarooq AhmadNo ratings yet

- Different Types of Aircraft WingsDocument32 pagesDifferent Types of Aircraft Wingslalit vaishnav100% (1)

- Skybolt ManualDocument72 pagesSkybolt ManualGeorge FarwellNo ratings yet

- Airbus Compound HelicopterDocument15 pagesAirbus Compound Helicopterjorge paezNo ratings yet