Introduction: TPM

Presented by Andy Ginder Vice President, ABB Reliability Consulting 281-450-1081 Andy.p.ginder@us.abb.com

1

�Objectives

Learn the main elements and features of TPM Know the stages and steps of a TPM program and their purpose, and appreciate the benefits of the process Understand how preventive maintenance, 5S, SMED and other activities apply to TPM Understand how the feedback process works, and how equipment effectiveness is measured

2

�Total Productive Maintenance

A plant improvement methodology Enables continuous and rapid improvement of the manufacturing process Extensive use of employee involvement, employee empowerment

Small groups

Closed-loop measurement of results.

Key performance measures or indicators provide feedback to the process to support continuous improvement OEE

3

�Equipment Reliability

The probability that equipment or systems will perform required functions satisfactorily under specific conditions within a certain period of time. Intrinsic: based on design

Determined during the design, fabrication, and installation stages.

Operational: determined by the user

Related to how and under what conditions the equipment is operated and maintained.

4

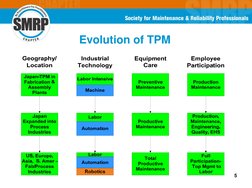

�Evolution of TPM

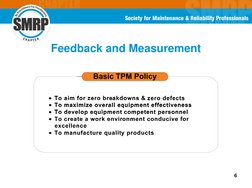

�Feedback and Measurement

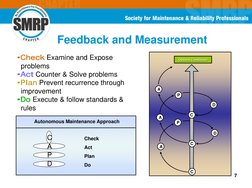

�Feedback and Measurement

Check Examine and Expose problems Act Counter & Solve problems Plan Prevent recurrence through improvement Do Execute & follow standards & rules

Autonomous Maintenance Approach

Optimal Conditions

A P D A P D C

C A P D

Check Act Plan Do

C A C

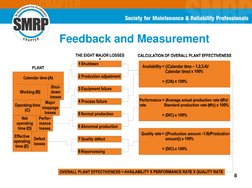

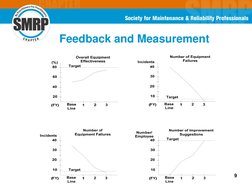

�Feedback and Measurement

�Feedback and Measurement

�Core Elements of TPM

Paradigm shift from the typical perceptions of who is responsible for maintenance. Maximize overall equipment effectiveness. Establish a thorough maintenance system for the entire life span of the equipment. Implement by all departments including engineering, operations, maintenance, environmental, purchasing, accounting, stores, safety, and human resources. Involve every employee, from top management to hourly employees.

10

�TPM Program Stages (4)

Stages I. Preparation II. Preliminary Implementation III. TPM Implementation IV. Stabilization

11

�TPM Program - 12 Steps

Stage I. Preparation 1. Formulate master plan for TPM implementation 2. Announce top managements decision to introduce TPM 3. Launch education program and campaign to introduce TPM 4. Create organizations (teams) to promote TPM 5. Establish basic TPM policies and goals

12

�The TPM Goals/Process

Define the Vision - Should be a Stretch Goal Create the Mission Statement

Minimal: Concise, short and sweet Memorable: A rallying cry Measurable: You know when you have arrived, a concrete step toward attainment of your vision

Define Core Values Develop Strategies Create Key Performance Indicators Define Critical Activities

13

�TPM Program - 12 Steps

Stage II. Preliminary Implementation 6. Hold TPM kick-off Stage III. TPM Implementation 7. Improve effectiveness of each piece of equipment 8. Develop an operator performed maintenance program 9. Develop a scheduled maintenance program for the Operations and Maintenance departments

14

�Sample Operator Tasks

Housekeeping and cleaning equipment Visual checks and inspections Changing filters Dismantling obsolete piping and tubing Removing insulation Tightening loose connections, hardware, belts Repairing steam leaks Adjusting valve packings Greasing valves Installing line clamps Doing minor painting

15

�Criteria for Selecting Operator Tasks

Safety Time requirements Task receptivity Task timing Task complexity Task frequency Task criticality Training requirements Tool and material requirements

16

�Support Tools

Basic hand tools Detailed inspection sheets or checklists Equipment logs Specific written procedures Visual graphics, routes, diagrams

Color coding (marked lube points), equipment numbers

Equipment markings or stamped plates Operator backlogs and performance indicators

17

�TPM Program - 12 Steps

Stage III. TPM Implementation (cont) 10. Conduct training to improve operation and maintenance skills 11. Develop equipment management or maintenance prevention program Stage IV. Stabilization 12. Perfect TPM implementation and raise TPM levels

18

�Sustaining the Process

Self-Sustaining is a Myth. Requirements are: Active Champions and Sponsors Knowledgeable and Motivated People A Holistic Strategic Approach Supported by Tactical Plans Emphasis on Practical (Real-World) Application of Theoretical Concepts Ongoing Internal Reinforcement Integrated with Appropriate Rewards and Incentives Supplemented by Periodic External Interventions Backed by Audit Process

19

�What is 5S?

A process designed to organize the workplace, keep it neat and clean, maintain standardized conditions, and instill the discipline required to enable each individual to achieve and maintain a world class work environment.

20

�What are the 5Ss?

1. SEIRI - Sort 2. SEITON - Set in order 3. SEISO- Shine 4. SEIKETSU - Standardize 5. SHITSUKE- Sustain

21

�Before

After

22

�Evolution Intangible Benefits

Clean Environment

23

�Evolution Intangible Benefits

24

�Evolution Intangible Benefits

25

�Evolution Intangible Benefits

26

� Internal Setup: Operations that are performed while a machine is stopped External Setup: Operations that are performed while a machine is running

SMED: Single-Minute Exchange of Die

SMED

SMED was originally designed to improve die press setups but its principles apply to changeovers in all types of processes 27

�3 Phases of SMED

Separating Internal and External Setup Converting Internal Setup to External Setup Streamlining all Aspect of the Setup Operation

SMED

28

�Preventive Maintenance

PM Analysis Procedure Clarify the problem Conduct a physical analysis of the problem List every condition potentially related to the problem Evaluate equipment, materials, and methods Plan the investigation Investigate malfunctions Formulate improvement plan

29

�Preventive Maintenance and Maintenance Standards

Maintenance Standards A. Equipment maintenance standards 1. Inspection standards for measuring equipment deterioration 2. Overhaul standards for preventing equipment deterioration 3. Repair standards for restoring equipment B. Maintenance work procedures 1. Procedures showing work practices and times

30

�Questions

31