Professional Documents

Culture Documents

CHDWM - 0802 - Arctic Pure DF - Sept08 PDF

Uploaded by

shuvo134Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHDWM - 0802 - Arctic Pure DF - Sept08 PDF

Uploaded by

shuvo134Copyright:

Available Formats

CREATING VALUE

CASE HISTORY DWM 08 | 02

Arctic Pure Drilling Fluid Recycling Drill Cuttings into Drilling Fluids

Simon Wait and Asbjorn Dysvik

In 2006, Norsk Hydro was drilling in the Barents Sea, a highly sensitive zero discharge environment. Water-based drilling fluids was utilised in all hole sections and drill cuttings shipped to shore for disposal. In order to reduce the impact of shipping drill cuttings to shore, Scomi Oiltools, in consultation with Norsk Hydro, proposed to use the drill cuttings to produce a spud mud for wells where discharge of water-based drilling waste is allowed.

INTRODUCTION Scomi Oiltools successfully developed Arctic Pure spud mud from drill cuttings collected from a previously drilled Norsk Hydro Barents Sea well. The drilling fluid had to meet stringent requirements, given that all the drilling fluid additives had to be green as detailed in the PLONOR list of chemicals. Furthermore, the spud mud had to be stable for a minimum of 12 weeks after production to ensure that settling and bacterial degradation did not occur during transportation and storage at the new drilling location. PROCEDURE Water-based drill cuttings from the Barents Sea were slurrified on the rig in situ with fresh water and PLONOR green list chemicals added to formulate a spud mud stable to settling and bacterial growth. The slurry was reduced in particle size to less than 140 microns using a proprietary new grinding technique. The spud mud was stored for 12 weeks prior to being used and discharged in the Norwegian continental shelf.

THE PROJECT DETAILS Cuttings were collected and slurrified to formulate Arctic Pure spud mud during the first three months of 2007 on the Polar Pioneer. The Arctic Pure spud mud was stored for 12 weeks and then successfully run as a kill mud due to a shallow gas situation.

DRILLING WASTE MANAGEMENT

KEY PERFORMANCE INDICATORS Planned Actual Performance Remarks

Health and Safety None Total Compliance

1. Lost time incidents and non-lost None time incidents Environmental

2. Arctic Pure made from 100% 100% Total Compliance green list PLONOR chemical only Operational New grinding technology 100% successful

Norsk Hydro advertising their success

3. Particles ground to <140 100% 100% microns 4. Spud mud must be stable for up to 12 weeks Spud mud stored for 12 weeks prior to use as a kill fluid

Stored for 100% 12 weeks successful with no stability or degredation issues

CONCLUSION Arctic Pure is a novel type of spud mud produced by recycling water-based drill cuttings; thus, reducing the impact of waste disposal. Scomi Oiltools developed Arctic Pure at its Global Research and Technology Centre (GRTC), in Kuala Lumpur, within a short timescale in order to meet the tight project deadline. Arctic Pure has been used to date to successfully kill a shallow gas situation and has been positively marketed by Norsk Hydro.

Despite the technical challenges of stabilising the fluid and avoiding bacterial degradation using only Green chemicals from the PLONOR list, the fluid was successfully stored over 12 weeks and utilised without any signs of degradation or major change in properties. The total operation was regarded as a great success and the preparation of Arctic Pure has now been used on a second occasion in 2007.

Scomi Oiltools Offices

Europe Middle East Americas Asia West Africa T T T T T +44 1224 719 200 +9714 8838 236 +1281 260 6016 +603 2080 5080 +234 803 402 8010 F F F F F +44 1224 708 677 +9714 8838 920 +1281 260 6969 +603 2080 5083 +1952 674 8453 E aberdeen.sales@uk.scomioiltools.com E dubai.sales@ae.scomioiltools.com E houston.sales@us.scomioiltools.com E kl.sales@my.scomioiltools.com E nigeria.sales@my.scomioiltools.com

Printed on environmental friendly paper CHDWM-Rev0908

You might also like

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Scope Newsletter 144Document13 pagesScope Newsletter 144Ronei de AlmeidaNo ratings yet

- Underwater Technology: Offshore PetroleumFrom EverandUnderwater Technology: Offshore PetroleumL. AtteraasNo ratings yet

- SPE 94511 Production Enhancement From Sand Management Philosophy: A Case Study From Statfjord and GullfaksDocument12 pagesSPE 94511 Production Enhancement From Sand Management Philosophy: A Case Study From Statfjord and GullfaksClaudia Luz Carrillo NiñoNo ratings yet

- 2010 Environmental Report ENDocument20 pages2010 Environmental Report ENIdea Development ID OyNo ratings yet

- Navigator 5Document11 pagesNavigator 5Westshore ShipbrokersNo ratings yet

- Recent Advances in The Biox Technology: Jan Van NiekerkDocument13 pagesRecent Advances in The Biox Technology: Jan Van NiekerkPAULINA AGUIRRENo ratings yet

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryFrom EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryNo ratings yet

- Ichthys Off Shore Win 01 13Document2 pagesIchthys Off Shore Win 01 13sapreswapnil8388No ratings yet

- OTC 18816 AKPO: A Giant Deep Offshore DevelopmentDocument9 pagesOTC 18816 AKPO: A Giant Deep Offshore DevelopmentGabrielNo ratings yet

- 002+Statoil+rev+-Norwep+nettverksmøte+080317+KJ Eik F ScibiliaDocument31 pages002+Statoil+rev+-Norwep+nettverksmøte+080317+KJ Eik F ScibiliaCalomir TudorNo ratings yet

- Avapolyoil PresentationDocument31 pagesAvapolyoil Presentationomul01No ratings yet

- Offshore Track Records PDFDocument13 pagesOffshore Track Records PDFfructoraNo ratings yet

- Spe 94511Document12 pagesSpe 94511merkyworksNo ratings yet

- Welding News 02-08Document7 pagesWelding News 02-08skisharkNo ratings yet

- December 2022 Quarterly Activity Report: Asx AnnouncementDocument26 pagesDecember 2022 Quarterly Activity Report: Asx AnnouncementsummerNo ratings yet

- Revista E&P - Noviembre 2012Document144 pagesRevista E&P - Noviembre 2012jpsi6No ratings yet

- ScieChimiche GeoMap-WMinfoDocument115 pagesScieChimiche GeoMap-WMinfoemoscribdNo ratings yet

- Affiliated To VTU, Belagavi, Approved by AICTE, New Delhi, Recognized by UGC With 2 (F) & 12 (B) Accredited by NBA & NAACDocument21 pagesAffiliated To VTU, Belagavi, Approved by AICTE, New Delhi, Recognized by UGC With 2 (F) & 12 (B) Accredited by NBA & NAACAfnan AnsariNo ratings yet

- Precaster 66 PDFDocument6 pagesPrecaster 66 PDFariNo ratings yet

- Precaster 66 PDFDocument6 pagesPrecaster 66 PDFariNo ratings yet

- PF LP Mud Gun - Rev 01Document2 pagesPF LP Mud Gun - Rev 01saa6383No ratings yet

- Inspiration Booklet: Reusing Water Sector ResidualsDocument37 pagesInspiration Booklet: Reusing Water Sector ResidualsEbenezer OforiNo ratings yet

- AbstractAltaEWTProductionGeosciences2018 11 06 - FINALDocument5 pagesAbstractAltaEWTProductionGeosciences2018 11 06 - FINALJeffGreenNo ratings yet

- 242 01 Silicate Bonded Moulding SandDocument7 pages242 01 Silicate Bonded Moulding Sandlandlamber100% (1)

- Using Polyurea Coatings For Commercial Marine ApplicationsDocument4 pagesUsing Polyurea Coatings For Commercial Marine ApplicationsTuấn Nguyễn VănNo ratings yet

- Canada's Oil Sands: Issues and OpportunitiesDocument13 pagesCanada's Oil Sands: Issues and OpportunitiesharoldliezlNo ratings yet

- Tech - Manual CSM PDFDocument157 pagesTech - Manual CSM PDFPelangi IkhtiarNo ratings yet

- Subsea Processing FunctionsDocument4 pagesSubsea Processing Functionsrylar999No ratings yet

- History of Petronas Floating Liquefied Natural Gas: (CITATION PET17 /L 17417)Document8 pagesHistory of Petronas Floating Liquefied Natural Gas: (CITATION PET17 /L 17417)M Asrar SidonNo ratings yet

- Total Deep Offshore (Brochure)Document12 pagesTotal Deep Offshore (Brochure)dhruvarora0% (1)

- Navigator 4Document8 pagesNavigator 4Westshore ShipbrokersNo ratings yet

- FPSO PresentationDocument30 pagesFPSO Presentationmechmonkey007100% (1)

- Navigator 6Document8 pagesNavigator 6Westshore ShipbrokersNo ratings yet

- CS0102 P DustbanDocument2 pagesCS0102 P DustbanDaneAoneNo ratings yet

- Paint Coatings ONBOARD Magazine Autumn 16Document8 pagesPaint Coatings ONBOARD Magazine Autumn 16Javier Gómez DíezNo ratings yet

- Non-Consolidating Plugging Material For Wellbore and AnnulusDocument18 pagesNon-Consolidating Plugging Material For Wellbore and AnnulusSLACKENGINEERNo ratings yet

- Descaling Liquid 25 LTR: Marine ChemicalsDocument3 pagesDescaling Liquid 25 LTR: Marine ChemicalsSajin JoyNo ratings yet

- B9 Environment - 2021 SDocument16 pagesB9 Environment - 2021 Sgiannyp0paNo ratings yet

- Functionalities of NalcoDocument26 pagesFunctionalities of NalcoSmrutiranjan ParidaNo ratings yet

- REB COMPANY PROFILE Ver 2024Document32 pagesREB COMPANY PROFILE Ver 2024Anggun RushNo ratings yet

- Publication - Painting, Coating & Corrosion Protection - AkzoNobel - International Paints - Mining and Minerals ApplicationsDocument44 pagesPublication - Painting, Coating & Corrosion Protection - AkzoNobel - International Paints - Mining and Minerals Applicationszinha_alNo ratings yet

- Chemical Sand Consolidation Trials (Shell)Document33 pagesChemical Sand Consolidation Trials (Shell)Nur Syaffiqa Mohamad RuzlanNo ratings yet

- WPX 1210Document1 pageWPX 1210Herik AziziNo ratings yet

- Oil Chem Oil Chem: Surfact Tants Bringing Chemical IORDocument31 pagesOil Chem Oil Chem: Surfact Tants Bringing Chemical IORAamir ShahzadNo ratings yet

- Darwin LNG: Photo GalleryDocument2 pagesDarwin LNG: Photo GalleryjiokoijikoNo ratings yet

- Compro Pertamina Inggris Februari 2014 IsiDocument20 pagesCompro Pertamina Inggris Februari 2014 IsiSyifa FauziyahNo ratings yet

- Epcon - Tech (CFU)Document5 pagesEpcon - Tech (CFU)achmadh_2010No ratings yet

- Dubbo Zirconia ProjectDocument9 pagesDubbo Zirconia ProjectsangjuraganNo ratings yet

- Commissioning of BFPLDocument11 pagesCommissioning of BFPLsaravananknpcNo ratings yet

- Finance Project Report On Ice Plant PDFDocument13 pagesFinance Project Report On Ice Plant PDFDinesh Kumar50% (2)

- Asian Oil and Gas-January-February 2014Document54 pagesAsian Oil and Gas-January-February 2014Roslan HamidNo ratings yet

- p.psh.0363 Final ReportDocument12 pagesp.psh.0363 Final ReportRahul Ranjan SinghNo ratings yet

- 337TO 003 World's Largest FLNG PreludeDocument9 pages337TO 003 World's Largest FLNG PreludeRamNo ratings yet

- An 023 Final ReportDocument115 pagesAn 023 Final ReportShubhendu Tiwari100% (1)

- ISGA Land-Based Report 2015Document57 pagesISGA Land-Based Report 2015Robertas KupstasNo ratings yet

- Stack Magic EcofDocument3 pagesStack Magic Ecofmukua100% (1)

- By 16 - DDR - 2012 11 03Document5 pagesBy 16 - DDR - 2012 11 03shuvo134No ratings yet

- By-15 Drilling Report 17.04.2012Document2 pagesBy-15 Drilling Report 17.04.2012shuvo134No ratings yet

- By-16 Drilling Monitoring Report 05.11.2012Document3 pagesBy-16 Drilling Monitoring Report 05.11.2012shuvo134No ratings yet

- By 16 - DDR - 2012 11 02Document5 pagesBy 16 - DDR - 2012 11 02shuvo134No ratings yet

- By 16 - DDR - 2012 11 04Document5 pagesBy 16 - DDR - 2012 11 04shuvo134No ratings yet

- Daily Drilling Monitoring Report Bibiyana-18Document2 pagesDaily Drilling Monitoring Report Bibiyana-18shuvo134No ratings yet

- Daily Monitoring Report SummaryDocument1 pageDaily Monitoring Report Summaryshuvo134No ratings yet

- (NPT Incident Investigation Report) CUVC Board 12-06-08 To 11Document1 page(NPT Incident Investigation Report) CUVC Board 12-06-08 To 11shuvo134No ratings yet

- 32 DMLR - By-20 - 01 - 03 - 2014Document2 pages32 DMLR - By-20 - 01 - 03 - 2014shuvo134No ratings yet

- By 18 - DDR - 2014 03 02Document5 pagesBy 18 - DDR - 2014 03 02shuvo134No ratings yet

- Bonafide Sal CertificateDocument1 pageBonafide Sal CertificatebhismaladNo ratings yet

- Why Printing Money Is So Easy For The FedDocument2 pagesWhy Printing Money Is So Easy For The Fedshuvo134No ratings yet

- 34 DMLR - By-19 - 28 - 01 - 2014Document2 pages34 DMLR - By-19 - 28 - 01 - 2014shuvo134No ratings yet

- Format Income StatementDocument1 pageFormat Income StatementAdenrele SalakoNo ratings yet

- By 19 - DDR - 2014 01 28Document5 pagesBy 19 - DDR - 2014 01 28shuvo134No ratings yet

- Invitation For Tender: Bangladesh Petroleum Exploration & Production Company Limited (Bapex)Document2 pagesInvitation For Tender: Bangladesh Petroleum Exploration & Production Company Limited (Bapex)shuvo134No ratings yet

- 39 DMLR - By-21 - 19 - 11 - 2013Document2 pages39 DMLR - By-21 - 19 - 11 - 2013shuvo134No ratings yet

- 1QWHe9RVuATender - 668Document2 pages1QWHe9RVuATender - 668shuvo134No ratings yet

- Fold Res HistoryDocument1 pageFold Res Historyshuvo134No ratings yet

- Invitation For Tender: Bangladesh Petroleum Exploration & Production Company Limited (Bapex)Document2 pagesInvitation For Tender: Bangladesh Petroleum Exploration & Production Company Limited (Bapex)shuvo134No ratings yet

- Dt6ETayxrwTender - 670Document2 pagesDt6ETayxrwTender - 670shuvo134No ratings yet

- 1rmeuj3iyminvitation For Bids - Drilling Works - Adb Edit - 03102013Document3 pages1rmeuj3iyminvitation For Bids - Drilling Works - Adb Edit - 03102013shuvo134No ratings yet

- By 19 - DDR - 2013 11 10Document5 pagesBy 19 - DDR - 2013 11 10shuvo134No ratings yet

- Invitation For Tender: Bangladesh Petroleum Exploration & Production Company Limited (Bapex)Document2 pagesInvitation For Tender: Bangladesh Petroleum Exploration & Production Company Limited (Bapex)shuvo134No ratings yet

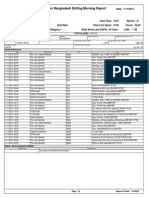

- Chevron Bangladesh Drilling Morning Report: Date: 11/12/2013Document4 pagesChevron Bangladesh Drilling Morning Report: Date: 11/12/2013shuvo134No ratings yet

- By 19 - DDR - 2013 11 10Document5 pagesBy 19 - DDR - 2013 11 10shuvo134No ratings yet

- By 19 - DDR - 2013 11 07Document5 pagesBy 19 - DDR - 2013 11 07shuvo134No ratings yet

- By 19 - DDR - 2013 11 08Document6 pagesBy 19 - DDR - 2013 11 08shuvo134No ratings yet

- By 19 - DDR - 2013 11 09Document5 pagesBy 19 - DDR - 2013 11 09shuvo134No ratings yet

- By 19 - DDR - 2013 11 06Document4 pagesBy 19 - DDR - 2013 11 06shuvo134No ratings yet

- 2017 Reviving Tribal Tattoo TraditionsDocument3 pages2017 Reviving Tribal Tattoo Traditions高權梁No ratings yet

- PP in Ii 001Document15 pagesPP in Ii 001Dav EipNo ratings yet

- Communicative English Lab Manual 1643268175Document24 pagesCommunicative English Lab Manual 1643268175Dimple BhatiNo ratings yet

- THE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFDocument3 pagesTHE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFUjjwalNo ratings yet

- 9A02505 Electrical Machines-IIIDocument4 pages9A02505 Electrical Machines-IIIsivabharathamurthyNo ratings yet

- Occupational Therapy Examination Review Guide 4th Edition Ebook PDFDocument57 pagesOccupational Therapy Examination Review Guide 4th Edition Ebook PDFrobert.campbell485No ratings yet

- Fire Alarm SymbolsDocument6 pagesFire Alarm Symbolscarlos vasquezNo ratings yet

- Motorola Talkabout T82 PDFDocument184 pagesMotorola Talkabout T82 PDFAlex TamayoNo ratings yet

- Pepperl KFD2 STC4 EX1.20 DatasheetDocument2 pagesPepperl KFD2 STC4 EX1.20 DatasheetAhmed HusseinNo ratings yet

- AIMMS Modeling Guide - Linear Programming TricksDocument16 pagesAIMMS Modeling Guide - Linear Programming TricksgjorhugullNo ratings yet

- 1991 - Defect Chemistry of BaTiO3Document20 pages1991 - Defect Chemistry of BaTiO3Beh NaatNo ratings yet

- Basic Electrical Safety Module 1Document39 pagesBasic Electrical Safety Module 1malawi200No ratings yet

- VSR Trans. PPT3Document16 pagesVSR Trans. PPT3VSR TRANSNo ratings yet

- Wakit, Nico P.Document5 pagesWakit, Nico P.yeng botzNo ratings yet

- One Plan Student 1Document7 pagesOne Plan Student 1api-465826207No ratings yet

- Chapter4 RetainingwallDocument55 pagesChapter4 RetainingwallNur HazwaniNo ratings yet

- Introduction To Rhetorical Analysis: Week 1Document16 pagesIntroduction To Rhetorical Analysis: Week 1Will KurlinkusNo ratings yet

- Jimma UniversityDocument99 pagesJimma UniversityBekan NegesaNo ratings yet

- Statistical MethodsDocument77 pagesStatistical MethodsGuruKPO100% (1)

- Prof Ed 9-A - Module 6 - Tumacder, DHMLDocument6 pagesProf Ed 9-A - Module 6 - Tumacder, DHMLDanica Hannah Mae TumacderNo ratings yet

- Law of DemandDocument16 pagesLaw of DemandARUN KUMARNo ratings yet

- Silenat Berhanu SimaDocument6 pagesSilenat Berhanu SimaSilenat BerhanuNo ratings yet

- Studi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoDocument9 pagesStudi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoAri WibowoNo ratings yet

- Rule Based ClassificationsDocument14 pagesRule Based ClassificationsAmrusha NaallaNo ratings yet

- Catalogo Perylsa CompletoDocument221 pagesCatalogo Perylsa CompletoAlvaro Diaz0% (1)

- UnitPlan (P.E) Grade 6Document13 pagesUnitPlan (P.E) Grade 6Lou At CamellaNo ratings yet

- Re 150821Document2 pagesRe 150821francis puthuserilNo ratings yet

- Ut 621024Document14 pagesUt 621024DarleiDuarteNo ratings yet

- One Wavelength To Loop SkywireDocument2 pagesOne Wavelength To Loop SkywireRobert TurnerNo ratings yet

- Lithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileDocument29 pagesLithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileAbdiel MuñozNo ratings yet