Professional Documents

Culture Documents

Standard Installation: Combination Fire/Smoke Damper Fire Damper

Uploaded by

Woei Tding ChongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Installation: Combination Fire/Smoke Damper Fire Damper

Uploaded by

Woei Tding ChongCopyright:

Available Formats

August 2006

AIR BALANCE INSTALLATION INSTRUCTION

II-FS(SS)-06.08

Page 1 of 6

Standard Installation

Combination Fire/Smoke Damper Models: Fire Damper Models: MD19(SS)

APPLICATION

These dynamically rated fire/smoke and fire dampers are intended to restrict the passage of flame. The dynamically rated fire/smoke dampers are also intended to restrict the passage of smoke. When the damper is intended to be used as a fire rated damper, the standard installation requires that the damper is positioned so that the closed plane of the blades is within the fire rated masonry/concrete or metal or wood framed gypsum wallboard barrier. When the damper is to be used as a leakage rated damper only, the damper is to be installed within 24" of the smoke barrier and upstream of any duct outlets. This damper may be mounted in the vertical or horizontal position with the damper blades running horizontally. Airflow can be from either direction. When mounted in the vertical position, the damper may be mounted right side up or upside down and can be mounted in a fire barrier constructed of masonry/concrete or metal or wood (32"W x 32"H maximum in wood framing) framed gypsum wallboard materials. When mounted in the horizontal position, the damper must be mounted with the actuator on the top side of the floor and can only be mounted in a fire barrier constructed of masonry/concrete materials.

_________________________________________________________________________________________________________________________________________________________________________________

FS1(SS), FS2(SS)

_________________________________________________________________________________________________________________________________________________________________________________

MULTIPLE PANEL SIZE LIMITATIONS

Actuation Orientation Assembly Horizontal Max Panel 250 Max Panel 350 24"Wx24"H 24"Wx24"H not available 24"Wx24"H Max Assy not available not available

Electric

Vertical Max Panel 250 Max Panel 350 Max Assy 250 36"Wx32"H 36"Wx32"H not available 36"Wx32"H 108"Wx32"H 108"Wx32"H Max Assy 350 not available 108"Wx32"H

Model

FS1(SS) FS2(SS)

Actuation Orientation Assembly Horizontal Max Panel 250 Max Panel 350 24"Wx24"H 24"Wx24"H not available 24"Wx24"H Max Assy not available not available

Pneumatic

Vertical Max Panel 250 Max Panel 350 Max Assy 250 36"Wx32"H 36"Wx32"H not available 36"Wx32"H 108"Wx32"H 108"Wx32"H Max Assy 350 not available 108"Wx32"H

Model

FS1(SS) FS2(SS)

Actuation Orientation Assembly Horizontal Max Panel 165 Max Panel 212 24"Wx24"H 24"Wx24"H Max Assy not available

Non-Motorized

Vertical Max Panel 165 Max Panel 212 Max Assy 165 36"Wx32"H 36"Wx32"H 108"Wx32"H Max Assy 212 108"Wx32"H

Model

MD19(SS)

_______________________________________________________________________________

SUPPLEMENTAL INSTALLATION INSTRUCTIONS / SUBMITTAL DATA

Sleeve Extension Integral Duct Access Door Electric or Pneumatic Heat Response Device (SD-EHRD or SD-PHRD) Integral Dual Position Indication (SD-IDPI) Electric or Pneumatic Sensotherm (SD-ESOT or SD-PSOT) Flow-Rated Smoke Detector (SM-501) No-Flow Smoke Detector (2151) Transitions (SD-TRFS) Sleeves (SD-SLVFS)

Division of Mestek Member of AMCA

August 2006

AIR BALANCE INSTALLATION INSTRUCTION

INSTALLATION

II-FS(SS)-06.08

Page 2 of 6

1.

General: The installation of the damper and all duct connections to the damper sleeve shall conform to NFPA-90A and the SMACNA Fire, Smoke and Radiation Damper Installation Guide. All duct connections shall also conform to UL555 when the damper is intended to be used as a fire damper. Actuators: Dampers must be supplied with factory mounted actuators (except Model MD19(SS)) and are intended to close automatically when sensing heat or upon loss of electrical power or release of air pressure. When this damper is used as a leakage rated damper only, it shall be arranged to operate automatically and is to be controlled by a smoke detector. See additional instructions, which detail damper actuator sequence of operations. Multiple Panel / Multiple Section Assembly: Refer to page 4 for details. Sleeves: Sleeves are required for the proper installation of fire rated dampers, but need not be factory mounted. Dampers with factory mounted external actuators can be supplied without sleeves, but require sideplates. Dampers with factory mounted internal actuators can be supplied without sleeves or sideplates. Sleeves shall be the same gauge or heavier as the duct to which it is attached. Gauges shall conform to SMACNA or ASHRAE duct standards. A field supplied sleeve is attached to the damper frame with 3/16" diameter stainless steel rivets, 1/4" diameter stainless steel bolts, #10 stainless steel sheet metal screws, or " long welds. Fasteners shall be staggered on each side of the damper frame on 6" maximum centers and 3-" maximum from each corner. For Class I Fire/Smoke dampers, approved caulking (reference note 7) shall be applied along the perimeter between the sleeve and the damper on both sides. For Class II Fire/Smoke dampers, approved caulked (reference note 7) shall be applied along the perimeter between the sleeve and the damper on only one side. Expansion Clearance: The opening in the wall for the fire rated damper shall be sized to provide expansion clearance between the sleeve and the opening. The minimum expansion clearance shall be the greater of 1/4" or 1/8" per foot of overall damper/sleeve width and height. The maximum expansion clearance shall not exceed 1/8" per foot of overall damper/sleeve width and height plus 1". Retaining Angle Attachment: Perimeter retaining angles shall increase in size, proportionately, so there will be a minimum of 1" overlap on the wall, including at the corners. The angles shall be flush against the barrier. The leg attached to the damper can turn away from or into the opening. In metal frame construction, the angles can be mounted under or over the gypsum board. In wood frame construction, the angles must be mounted over the gypsum board. The perimeter mounting angles shall be fastened on all four sides and on both faces of the damper to the sleeve only, with 3/16" diameter stainless steel nuts and bolts or by tack welding with beads 1/2" 1/4" in length or with #10 stainless steel sheet metal screws or 3/16" stainless steel pop rivets. All connections shall be spaced on 6" maximum centers and 3" maximum from each corner (a minimum of 2 fasteners are required per side). Perimeter retaining angles shall be a minimum of 1-1/2" x 7/8" x 16 gauge steel. Corners of angles are not welded together for dampers with width or height dimensions exceeding 24". For dampers 24"W x 24"H or smaller, the corners of the perimeter mounting angles can be welded. Some local codes may not allow welded corners. Attachment of these angles must not restrict operation of the damper. Perimeter retaining angles and their mounting fasteners are not typically supplied with the damper. Caulking: Caulk shall be one of the following: Dow Corning RTV732, Silco Sil-Bond RTV 4500, General Electric IS808, or Novagard RTV300. Caulking is allowed between the retaining angles and the damper sleeve, and between the retaining angles and the face of the floor or wall construction. Caulking is not allowed between the damper sleeve and the wall or floor inside the opening. Duct Connections: All connecting ducts shall not be continuous, but shall terminate at the fire damper sleeve. Duct connections not listed as breakaways shall be considered rigid. For rigid type duct connections, the sleeve shall be a minimum of 16-GA on dampers not exceeding 36" wide or 24" high or 24" diameter and 14-GA on larger units. Maximum sleeve thickness shall not exceed 10-GA galvanized steel. Dampers supplied with thinner sleeves require a breakaway connection. The following breakaway duct-to-sleeve connections may be used: Plain S Slip, Double S Slip, Inside Slip, Hemmed S Slip, Standing S Slip, Standing S Slip (Bar Reinforced), Standing S Slip (Angle Reinforced), and Standing S Slip (Alternate Bar). Breakaway joints shall have no more than two No. 10 sheet metal screws on each side and on the bottom. The screws shall penetrate both sides of the slip pocket. When a breakaway joint is used along the top and bottom duct connection, a flat drive slip no longer than 20 inches is permitted on the two sides. The damper is normally supplied with a factory attached sleeve (see Note 4 when field supplied sleeve). The standard factory supplied sleeve is 20-GA stainless steel (18-GA on dampers wider or higher than 84") and assumes that a breakaway type duct connection will be employed. Maintenance: Dampers shall be maintained at intervals as stated in NFPA 90A and 92A. Local codes or building conditions may require more frequent inspections and maintenance. A duct access door is to be located on the jackshaft side of each damper for periodic inspection and maintenance.

2.

3. 4.

5.

6.

7.

8.

9.

Division of Mestek Member of AMCA

August 2006

AIR BALANCE INSTALLATION INSTRUCTION

STANDARD MOUNTING DETAILS

II-FS(SS)-06.08

Page 3 of 6

Vertical, 2-Side Retaining, Masonry (108"W x 32"H Maximum)

Retaining Angle Overlap (See Note 6) Expansion Clearance (See Note 5)

Horizontal, 2-Side Retaining, Masonry (24"W x 24"H Maximum)

Retaining Angle Overlap (See Note 6) 16" Maximum Actuator Side Perimeter Retaining Angle (See Note 6)

Duct Connector (See Note 8)

Perimeter Retaining Angle (See Note 6)

Airflow

16" Maximum Actuator Side

6" Maximum Non-Actuator Side

Airflow 6" Maximum Non-Actuator Side Duct Connector (See Note 8) Expansion Clearance (See Note 5)

Vertical, 2-Side Retaining, Metal Stud (108"W x 32"H Maximum)

Retaining Angle Overlap (See Note 6) Expansion Clearance (See Note 5)

Vertical, 2-Side Retaining, Wood Stud (32"W x 32"H Maximum)

Retaining Angle Overlap (See Note 6) Expansion Clearance (See Note 5)

Duct Connector (See Note 8)

Duct Connector (See Note 8)

Perimeter Retaining Angle (See Note 6)

Airflow

Perimeter Retaining Angle (See Note 6)

Airflow

16" Maximum Actuator Side

6" Maximum Non-Actuator Side

16" Maximum Actuator Side

6" Maximum Non-Actuator Side

*See multiple panel size limitations on page 1 for further restrictions.

Division of Mestek Member of AMCA

August 2006

AIR BALANCE INSTALLATION INSTRUCTION

MULTIPLE PANEL / MULTIPLE SECTION INSTALLATION DETAILS

II-FS(SS)-06.08

Page 4 of 6

Fire/Smoke Dampers (Models FS1(SS), FS2(SS)) 1. 2. 3. Damper assemblies ordered without factory mounted sleeves are limited in size, so that the entire assembly ships as a single section. Multiple panel wide damper assemblies are mechanically and electrically linked. Damper assembly sections that are mechanically and electrically linked share a single heat response device and a single supply connection point. Multiple actuators within a linked section are factory wired together.

Fire Dampers (MD19(SS)) 1. 2. 3. 4. Damper assemblies ordered without factory mounted sleeves are limited in size, so that the entire assembly ships as a single section. Multiple panel wide damper assemblies are not mechanically linked between panels. Damper assembly sections that are not mechanically linked each have their own heat response device, such that they operate independently. Damper assemblies that ship in multiple sections shall be fastened together using 1/4" diameter stainless steel bolts, lockwashers, and nuts. Fasteners shall be on 6" maximum centers on both faces of the frame.

ELECTRIC WIRING SCHEMATICS

Notes 1. All wiring to be in accordance with N.E.C. (NFPA 70). 2. Refer to actuator label for appropriate voltage. 3. Connect incoming ground to the actuator assembly. 4. If the actuator remains electrically energized, yet the damper remains in the closed position, check to ensure that the reset button on the heat response device is depressed. Electric Heat Response Device (EHRD)

Temp. Disc

Integral Dual Position Indication (IDPI)

Yellow

Blue

Motor

Motor

Red or White

Black

Customer Wiring

Smoke Detector NC

Integral Dual Position Indication (IDPI) Wiring Chart actuator mounting location external left external right damper full open damper full close closed circuit red / blue yellow / gray yellow / gray red / blue yellow / gray red / blue red / blue yellow / gray none none none none damper mid-stroke

See Actuator for Appropriate Voltage L1 Customer Wiring L2

internal left internal right

* This wiring is opposite if the actuator is rotated 90 .

Gray

Red

Division of Mestek Member of AMCA

August 2006

AIR BALANCE INSTALLATION INSTRUCTION

ELECTRIC WIRING SCHEMATICS (CONT.)

Electric/Pneumatic Sensotherm (ESOT/PSOT) with included Integral Dual Position Indication (IDPI)

II-FS(SS)-06.08

Page 5 of 6

Low Temp. Disc

High Temp. Disc

Yellow Blue Gray Red

Motor or E.P. Valve

Red or White

Motor or E.P. Valve

Orange

Black

Customer Wiring

Smoke Detector NC Damper Re-open SPDT Center See Actuator for Appropriate Voltage L1 Customer Wiring L2

Integral Dual Position Indication (IDPI) Wiring Chart actuator mounting location external left external right internal left internal right damper full open damper full close closed circuit red / blue yellow / gray yellow / gray red / blue yellow / gray red / blue red / blue yellow / gray none none none none damper mid-stroke

Damper Close

* This wiring is opposite if the actuator is rotated 90.

ESOT/PSOT Wiring, Test, and Operating Instructions Damper is supplied with one low temperature thermal disc and one high temperature thermal disc. All dampers require a master control switch (supplied by others) for re-openable operation. CUSTOMER WIRING 1. Connect input power lead L1 from the normal closed position lead of the (MCS) switch to damper lead L1. Note: If a smoke detector or other sensing device is to be employed, its NC contact set should be wired in series between the (MCS) position switch normal wire and lead L1. 2. Connect incoming lead L2 to damper lead L2. 3. Connect the reopen switch lead from (MCS) to orange damper lead. 4. Connect the incoming ground lead to the wiring enclosure. 5. Install IDPI (if used) per the schematic. 6. Replace enclosure cover. CIRCUIT TEST 1. Place (MCS) switch in damper close position. 2. Apply power. Result: The closed indicator light (if used) should be on and the damper blades closed. 3. Transfer (MCS) switch to damper re-open position. Result: The damper blades should open; the closed indicator light (if used) should go off and the open indicator light (if used) should go on. 4. Transfer (MCS) switch to the normal position. Result: The damper blades should remain open and the open indicator light (if used) should remain on. 5. Transfer the (MCS) switch to the closed position. Result: The damper blades should close; the open indicator light (if used) should go off and the closed indicator light (if used) should go on. EMERGENCY OPERATION (SMOKE MANAGEMENT) 1. MCS closed position: Damper will close regardless of whether the thermal switch device has activated or not and regardless of the command from the smoke system. 2. MCS re-open position: If the damper has not been exposed to an elevated temperature higher than its rating, the damper will open. Also, the damper will open regardless of whether the low temperature thermal disc (165F or 212F) has activated or not and regardless of a command from additional sensing devices, such as a smoke detector. NOTE: If the master control switch (MCS) is in the re-open position and the high temperature thermal disc has not been tripped, the damper will remain open regardless of whether the low temperature thermal disc and/or other sensing devices have tripped or not. If the damper has been exposed to an elevated temperature higher than its temperature degradation rating, or if the electrical or pneumatic supply has been disconnected, the damper will close and remain closed regardless of any (MCS) position.

Division of Mestek Member of AMCA

August 2006

AIR BALANCE INSTALLATION INSTRUCTION

FRAMING DETALS (METAL OR WOOD 1 HOUR AND 2 HOUR RATED BARRIERS)

II-FS(SS)-06.08

Page 6 of 6

Ceiling Runner 24" O.C. Max 16" O.C. Max B B Runner 90 Bend Local Codes May Require Double Header A A

12"

Section A-A

Min. 2-1/2" Runner

2 Fasteners

2"

Min. 2-1/2" Stud Panhead Screws (Metal Studs) Nails (Wooden Studs) 4 Per 90 Bend

2 Fasteners

2"

Floor Runner

NOTES:

1. These illustrated partition designs have successfully been tested in conjunction with 1-1/2 hour classified fire dampers, for additional designs, reference Underwriters Laboratories, Inc. Fire Resistance Directory. Specific framing requirements of openings may vary with the Local Authority that has jurisdiction. Specific framing requirements should be provided in the architectural and structural drawings. Reference the damper's installation instructions regarding the approved method of attaching the damper to the sleeve, attaching the retaining angles to the sleeve, required expansion clearances, sleeve gauge, etc. Type of framing does not affect the stated required expansion clearance. Gypsum panels surrounding the opening are to be fastened to all stud and runner flanges, 12" o.c. maximum. When wooden studs are used, filler pieces must be installed around the entire opening. Filler pieces are optional when metal studs are used (consult local codes to determine if filler pieces are required). Filler pieces are to be double screwed (or nailed to wooden studs) on 12" max. centers to the web of runners and studs. Double jamb studding shown and required when opening width or length exceeds 36". Single jamb studding acceptable for openings 36"W x 36"H and smaller.

Section B-B (1 Hour Rated Fire Barrier)

Min. 2-1/2" Stud or Runner Min. 1/2" Thick Gypsum Wallboard Drywall Screws (Metal Studs) Dw Screws or Nails (Wood Studs) Retaining Angle (May Be Reversed Providing Adequate Clearance is Maintained

Min. 1" Overlap

2. (See Note 2) Min. 1/2" Thick Filler Piece (See Note 4) Fire Damper Sleeve

Section B-B (2 Hour Rated Fire Barrier)

Min. 2-1/2" Stud or Runner

3.

Min. 1/2" Thick 4. Gypsum Wallboard Drywall Screws (Metal Studs) Dw Screws or Nails (Wood Studs) Retaining Angle (May Be Reversed Providing Adequate Clearance is Maintained 5. (See Note 2)

Min. 1" Overlap

Min. 1/2" Thick Filler Piece (See Note 4)

Fire Damper Sleeve

In the interest of product develpoment, Air Balance reserves the right to make changes without notice.

Division of Mestek Member of AMCA

You might also like

- M400 Advanced Framing Construction GuideDocument24 pagesM400 Advanced Framing Construction GuideAndyPalmer100% (1)

- Metal Stud Framing - DrywallDocument1 pageMetal Stud Framing - DrywallMuhammadIqbalMughalNo ratings yet

- JisDocument706 pagesJisHenry Poudel48% (25)

- Indoor Air QualityDocument16 pagesIndoor Air QualityMichael Grant WhiteNo ratings yet

- Construction of Post Tension Slab System.: MaterialsDocument13 pagesConstruction of Post Tension Slab System.: Materialsdindo lauron100% (1)

- Fire Damper Installation 2Document9 pagesFire Damper Installation 2Mirza Mohammed Yousuf BaigNo ratings yet

- VARIO GT 24 Standard PanelsDocument57 pagesVARIO GT 24 Standard PanelsdonnyervinNo ratings yet

- Shaftwall7.0 001Document9 pagesShaftwall7.0 001Wissam AlameddineNo ratings yet

- Schwab Product Catalogue 2015 (53 - 0112 - 14) PDFDocument100 pagesSchwab Product Catalogue 2015 (53 - 0112 - 14) PDFRobert Nito100% (1)

- Thesoundbook PDFDocument124 pagesThesoundbook PDFPedro PereiraNo ratings yet

- D502Document5 pagesD502Gustavo Adolfo Quintero RuizNo ratings yet

- Modern Methods of Construction Full PDFDocument81 pagesModern Methods of Construction Full PDFKenneth PunlaNo ratings yet

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansNo ratings yet

- Redflex BrochureDocument24 pagesRedflex BrochuremecarrascogNo ratings yet

- Installation ManualDocument20 pagesInstallation ManualHasan GüleryüzNo ratings yet

- Firestop HILTIDocument44 pagesFirestop HILTIronaldo aguirreNo ratings yet

- Mastering BOMBA QuestionDocument56 pagesMastering BOMBA QuestionWoei Tding ChongNo ratings yet

- Astm C11Document6 pagesAstm C11Ramiro VasquezNo ratings yet

- Standard Installation: Fire DamperDocument8 pagesStandard Installation: Fire DamperMedhat ElhagrasiNo ratings yet

- "Out of Wall/Partition": Fire Damper and Combination Fire/Smoke DamperDocument4 pages"Out of Wall/Partition": Fire Damper and Combination Fire/Smoke DamperMariIacomiNo ratings yet

- Fire Dampers Installation Instructions: (Static and Dynamic)Document4 pagesFire Dampers Installation Instructions: (Static and Dynamic)sbalu12674No ratings yet

- FD-1600 1.5 Hour Dynamic Rated Multi-Blade Fire DamperDocument6 pagesFD-1600 1.5 Hour Dynamic Rated Multi-Blade Fire DampernuqNo ratings yet

- FC-2000 1.5 Hour Curtain Fire DampersDocument6 pagesFC-2000 1.5 Hour Curtain Fire DampersnuqNo ratings yet

- Graphite Slide PlateDocument1 pageGraphite Slide PlateSuthan SelvarajNo ratings yet

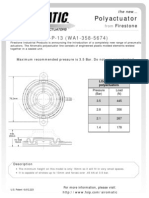

- Wa1 358 5674Document30 pagesWa1 358 5674MROstop.comNo ratings yet

- Rola Star CatalogueDocument8 pagesRola Star CataloguemaximghNo ratings yet

- Diffuser ConnectionDocument4 pagesDiffuser Connectionbsh1978No ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- BXUV.P204 Fire Resistance Ratings - ANSI/UL 263Document5 pagesBXUV.P204 Fire Resistance Ratings - ANSI/UL 263AlexNo ratings yet

- Style 38 Bolted Couplings For Steel PipeDocument3 pagesStyle 38 Bolted Couplings For Steel PipeAndrres UlloaNo ratings yet

- Bondstrand Fiberglass Flanges Assembly Instructions - AmeronDocument8 pagesBondstrand Fiberglass Flanges Assembly Instructions - AmeronFabio SilvaNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- P.08 Installation Maintenance Manual SD 125Document4 pagesP.08 Installation Maintenance Manual SD 125Christian DaganzoNo ratings yet

- FD Installation StandardsDocument4 pagesFD Installation Standardsanwer_quadriNo ratings yet

- W01 358 7561Document29 pagesW01 358 7561MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- The Solarsheat 1500G/1500Gs/1501Gs - Flush Roof Mount Installation ManualDocument11 pagesThe Solarsheat 1500G/1500Gs/1501Gs - Flush Roof Mount Installation ManualOrganic MechanicNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 6910Document29 pagesW01 358 6910MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 6900 Firestone Double Convoluted Air SpringDocument29 pagesW01 358 6900 Firestone Double Convoluted Air SpringMROstop.comNo ratings yet

- "Out of Wall/Partition": Fire Damper and Combination Fire/Smoke DamperDocument4 pages"Out of Wall/Partition": Fire Damper and Combination Fire/Smoke DamperCTHNo ratings yet

- W01 358 7902Document30 pagesW01 358 7902MROstop.com100% (1)

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Gs-Flange SystemDocument188 pagesGs-Flange SystemMarcin MarcinkiewiczNo ratings yet

- UPE Universal Couplings and Flange AdaptorsDocument8 pagesUPE Universal Couplings and Flange AdaptorsnoormohammedahNo ratings yet

- W02 358 4001Document30 pagesW02 358 4001MROstop.comNo ratings yet

- Support Distance For FRP PipeDocument1 pageSupport Distance For FRP PipePhyu Mar Thein KyawNo ratings yet

- Manometre Fise Tehnice 2000.i PDFDocument2 pagesManometre Fise Tehnice 2000.i PDFGaina IOnutNo ratings yet

- AC Design Brief ReportDocument8 pagesAC Design Brief ReportARUL SANKARANNo ratings yet

- W01 358 9603Document29 pagesW01 358 9603MROstop.comNo ratings yet

- Disc ValvesDocument8 pagesDisc ValvesMahesh KumarNo ratings yet

- Steel Repair SleevesDocument7 pagesSteel Repair SleevesErickNo ratings yet

- Assembly Instructions For Bondstrand Fiberglass FlangesDocument8 pagesAssembly Instructions For Bondstrand Fiberglass FlangesHoang CongNo ratings yet

- W01 358 7751Document29 pagesW01 358 7751MROstop.comNo ratings yet

- Design No. I504Document1 pageDesign No. I504KaylaNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7830Document29 pagesW01 358 7830MROstop.comNo ratings yet

- Checklist QualityDocument14 pagesChecklist QualityCheeragNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- 11apr - Propolis and It's Effects On Fungus or CandidaDocument5 pages11apr - Propolis and It's Effects On Fungus or CandidaWoei Tding ChongNo ratings yet

- 05JanWillner - Butterbur Herbal Extract Shown To Prevent Migraine HeadachesDocument2 pages05JanWillner - Butterbur Herbal Extract Shown To Prevent Migraine HeadachesWoei Tding ChongNo ratings yet

- 10JulUS - Garlic and Onion May Boost Mineral AbsorptionDocument2 pages10JulUS - Garlic and Onion May Boost Mineral AbsorptionWoei Tding ChongNo ratings yet

- PAYGB Quotation Sample 2019Document53 pagesPAYGB Quotation Sample 2019Jamiu LateefNo ratings yet

- Muslin Cloth Fiber Reinforced Gypsum: Polytechnic University of The PhilippinesDocument80 pagesMuslin Cloth Fiber Reinforced Gypsum: Polytechnic University of The PhilippinesJerome PalicteNo ratings yet

- C 1002 - 00 QzewmditmdaDocument4 pagesC 1002 - 00 QzewmditmdaHumberto GutierrezNo ratings yet

- 9C306 59Document28 pages9C306 59SHIRISHA YADAVNo ratings yet

- Dimension Online Training GuideDocument36 pagesDimension Online Training Guidecharles_kiokoNo ratings yet

- ModuSec-Secure Modular Construction SystemDocument49 pagesModuSec-Secure Modular Construction SystemBrendan LynchNo ratings yet

- Ikoustic - Materiais para Tratamento AcusticoDocument12 pagesIkoustic - Materiais para Tratamento AcusticodiracmoutinhoNo ratings yet

- Critical ReportDocument66 pagesCritical ReportbmpitcherNo ratings yet

- Manual PDFDocument932 pagesManual PDFSyed Baqir Hussain0% (1)

- On Brick Construction: Technical NotesDocument11 pagesOn Brick Construction: Technical NotesniroNo ratings yet

- Designer Interiors Lincoln Price ListDocument19 pagesDesigner Interiors Lincoln Price Listwilburn1No ratings yet

- W111 EngDocument2 pagesW111 EngStefan PalaghiaNo ratings yet

- White Book C02 Technical PerformanceDocument60 pagesWhite Book C02 Technical PerformancePavaloaie Marian ConstantinNo ratings yet

- GC Cram Trade - Complete SetDocument143 pagesGC Cram Trade - Complete SetJose TorresNo ratings yet

- BoqDocument202 pagesBoqAmit SinghNo ratings yet

- Heradesign InstallationDocument12 pagesHeradesign InstallationshanNo ratings yet

- LBGD PDFDocument145 pagesLBGD PDFsiva ramakrishnanNo ratings yet

- Drywall Solutions: Everest Industries LimitedDocument34 pagesDrywall Solutions: Everest Industries LimitedVengatesh HariNo ratings yet

- Greater London Council - 1961 - Code of Practice For Means of Escape in The.. Roof EscapeDocument12 pagesGreater London Council - 1961 - Code of Practice For Means of Escape in The.. Roof EscapeJitesh NichaniNo ratings yet

- Mechanical Properties and Physical PropertiesDocument3 pagesMechanical Properties and Physical Propertiesimran shakirNo ratings yet

- Standard Data For Gyp Board False CeilingDocument1 pageStandard Data For Gyp Board False CeilingAlisa SerranoNo ratings yet

- 7 - SDS-Gypsum-1Document1 page7 - SDS-Gypsum-1Bashar Al AliNo ratings yet