Professional Documents

Culture Documents

Proceedings of The Institution of Mechanical Engineers, Part F - Journal of Rail and Rapid Transit-2010-Kwok-45-52

Uploaded by

Trihandoyo Budi CahyantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proceedings of The Institution of Mechanical Engineers, Part F - Journal of Rail and Rapid Transit-2010-Kwok-45-52

Uploaded by

Trihandoyo Budi CahyantoCopyright:

Available Formats

Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit http://pif.sagepub.

com/

Value engineering for railway construction projects: Cost driver analysis

E C S Kwok, P M Anderson and S H S Ng Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit 2010 224: 45 DOI: 10.1243/09544097JRRT291 The online version of this article can be found at: http://pif.sagepub.com/content/224/1/45

Published by:

http://www.sagepublications.com

On behalf of:

Institution of Mechanical Engineers

Additional services and information for Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit can be found at: Email Alerts: http://pif.sagepub.com/cgi/alerts Subscriptions: http://pif.sagepub.com/subscriptions Reprints: http://www.sagepub.com/journalsReprints.nav Permissions: http://www.sagepub.com/journalsPermissions.nav Citations: http://pif.sagepub.com/content/224/1/45.refs.html

>> Version of Record - Jan 1, 2010 What is This?

Downloaded from pif.sagepub.com at University of Birmingham on February 25, 2013

CASE STUDY

45

Value engineering for railway construction projects: cost driver analysis

E C S Kwok1 , P M Anderson2 , and S H S Ng3 1 MTR Corporation, Hong Kong, Peoples Republic of China 2 Vision Skills Consulting Limited, Hong Kong, Peoples Republic of China 3 Atkins China Limited, Hong Kong, Peoples Republic of China The manuscript was received on 5 May 2009 and was accepted after revision for publication on 11 August 2009. DOI: 10.1243/09544097JRRT291

Abstract: Railway construction projects involve major capital investments, and a slight variance in design could lead to a signicant change in the total project cost. To achieve value for money, it is necessary to optimize the design as far as possible. However, in reducing costs, it is important that key project objectives such as system capacity and operational exibility are not sacriced. In this article, a value engineering methodology, with particular emphasis on maintaining project objectives and requirements, is introduced. It involves identifying major cost drivers, devising explicit knowledge representations for these cost drivers, and analysing how they could be optimized without compromising key requirements such as the passenger-carrying capacity. The methodology is illustrated using real-world examples taken from the West Rail project in Hong Kong, which was originally conceived to be a twelve-car railway and subsequently optimized to become a seven-car system initially, with provisions to grow into an eight-car and then a nine-car conguration, without compromising the planned carrying capacity. The savings achieved were in the order of billions of Hong Kong dollars. One novel aspect of the proposed methodology is the development of a structured representation for a cost driver, through which non-obvious but signicant savings could be derived. Keywords: value engineering, infrastructure projects, cost drivers, railway construction

INTRODUCTION

Railway construction projects, or large infrastructure projects in general, involve the design of complex engineering artefacts by a large number of designers from a wide range of disciplines civil, mechanical, electrical, electronic, and computer engineering. The design could take months to complete, and the designers are often located in different ofces. In the case of a new railway extension, the design process can take 1 2 years, depending on the complexity of the project. The rate of progress is generally fast, with each design team (working on, e.g. stations, tunnels, viaduct, signalling system, etc.) trying to complete its allotted

Corresponding author: Projects Division, MTR Corporation, 5/F, Fo

tasks to the agreed schedule. The level of coordination is often reduced as design progresses, which if not managed carefully could lead to mismatch at interface boundaries and conict among contractors during the construction stage. Effective management of this process is essential to control the ultimate cost of the project and to avoid unnecessary contractual claims. To ensure that the project as a whole is taking a holistic view in coming up with a cost-effective design, some form of value engineering is necessary.

2 VALUE ENGINEERING FOR MAJOR CAPITAL WORKS The origin of value engineering can be traced back to the period after the Second World War, partly driven by the need to increase productivity with limited raw material. For consumer products, a small saving attributed to an enhanced design or manufacturing

Proc. IMechE Vol. 224 Part F: J. Rail and Rapid Transit

Tan Railway House, Sha Tin, N.T., Hong Kong, Peoples Republic of China. email: ecskwok@mtr.com.hk

JRRT291

Downloaded from pif.sagepub.com at University of Birmingham on February 25, 2013

46

E C S Kwok, P M Anderson, and S H S Ng

step could make a substantial difference overall due to the large number of units involved. A general account of value engineering applications can be found in Webb [1]. In the infrastructure sector, Wilson [2] surveys value engineering applications in highway projects in North America. Omigbodun [3] focuses on building projects, covering cost items arising from specic sub-systems as well as the building as a whole. Stoy and Schalcher [4] show that the identication of a representative cost driver is useful for preliminary cost estimation for the project as a whole. In this article, the focus is on the big cost drivers, with a view to reduce capital investments, as well as recurrent operation and maintenance costs. Each cost driver can be analysed in turn to identify potential

savings. The process is illustrated in Fig. 1, using ow chart conventions.

COST-DISTRIBUTION ANALYSIS

Capital projects in different sectors, e.g. aerospace, energy, etc., have different cost drivers. The major components of work are known within the industry, and their costs in past projects could be systematically collected. For railways, the major work items include stations, tunnels, trains, and electrical and mechanical systems. A recent railway project theWest Rail project in Hong Kong is used as an example to illustrate a typical cost distribution for these items.

Select a Cost Driver C

Devise a VE Representation for C

Step 1 Design a suitable VE Representation for the Cost Driver Identify logical relationships of the Representation

Take a systems approach to develop proposals for reducing C

Step 2 Conduct brainstorming sessions & fine-tune the VE representation Take a holistic view & ask probing questions

Select a "promising" proposal P for reducing C

Step 3 Select a proposal to work on

Conduct feasibility study on P

Step 4 Analyse constraints Assess design / construction programme Assess impact on contractual implications if any Conduct Cost Benefit Analysis

no Is P feasible?

Step 5 Analyse feasibility of the proposal with respect to project objectives and constraints for the Cost Driver

yes Conduct detailed analysis & implementation plan for P

Step 6 Develop an implementation plan

Implement P

Fig. 1

Proc. IMechE Vol. 224 Part F: J. Rail and Rapid Transit

Cost driver analysis

JRRT291

Downloaded from pif.sagepub.com at University of Birmingham on February 25, 2013

Value engineering for railway construction projects

47

West Rail is a 30.5 km domestic railway with nine stations, an operation control centre and a depot, and commenced revenue operation in 2003 as scheduled. The railway is essentially underground for 16.6 km from the Nam Cheong terminus to the depot, at grade for 2.3 km through the depot site, and elevated on viaduct for the remaining 13.4 km from Kam Sheung Road to Tuen Mun stations. The maximum train speed is 130 km/h. An end-to-end journey between Nam Cheong and Tuen Mun takes about 30 min. The system was planned to be a twelve-car system, with a budget of HK$64 billion. It was subsequently optimized to become a seven-car system for initial operation, with civil provisions for expansion to become an eight-car and then a nine-car system. This notion of varying the train length, as well as the service level, to accommodate long-term changes in demand pattern helped to maintain the projects viability when the local economy was undergoing a signicant downturn in 1998. The nal project cost was HK$46 billion, about 70 per cent of which was on civil works, including stations, tunnels, viaducts, depot, and operation control centre. The rest was for rolling stock, electrical and mechanical systems, and permanent way. The cost of each individual piece of work as a percentage of the total cost is shown below.

driver and how such information relate to each other. The exact form of the representation would vary, and can be a table, a cause-and-effect diagram, a schematic showing the relevant design parameters, etc. To identify the inter-dependencies among different disciplines or components, the use of mathematical logic [5] or other formalisms for knowledge representation [6] would be fruitful. Examples will be given in the next section to demonstrate how this can lead to multi-discipline solutions or aha insight. The typical issues involved in devising a VE representation are illustrated below, using tunnel size as an example. The cost of a tunnel depends primarily on its size and the method of excavation. For tunnels built using tunnel boring machines (TBM), a small reduction of say 100 mm in the tunnel diameter can result in a cost reduction of 1 per cent or more (the actual percentage could vary, the savings in absolute terms would be substantial). For railway tunnels, the tunnel diameter would be dictated by the kinematic envelop, catenary system, track-form, walkways, and trackside services, as elaborated below. 1. Kinematic envelop (KE) the KE of a train is largely dependent on its cross-sectional area, the contact wire height, and the maximum travelling speed. These dimensions would be xed as a result of rolling stock design and alignment characteristics. 2. Catenary system the system height of the overhead line is governed by the dynamic performance between the contact wire and the pantograph. Other vertical spatial requirements include electrical clearance, overlap, system tolerance, and soft clearance. 3. Trackform and slab the dimensions of the trackform and slab would vary with the design. Floating slab tracks and low vibration tracks have different trackform depths. Thus the spatial requirements are tight and potential savings limited. 4. Walkways evacuation walkways may have to be provided for side detrainment in case of emergency. They have to be at a suitable height above the top of rail so that the step difference between the walkways surface and the trains oor level would not be too big to cause a tripping hazard. Furthermore, a minimum electrical clearance between the surface of the walkway and a live part, as stipulated in the European Standard EN50122 [7], must be maintained. 5. Trackside services trackside equipment installed on each side of the tunnel could have an impact on the horizontal dimension. A useful way of capturing all these parameters is to have a VE representation based on a cross-section

Proc. IMechE Vol. 224 Part F: J. Rail and Rapid Transit

Percentage of total cost (%) Civil works: stations/depot/control centre Tunnels Viaducts Other civil infrastructure Railway systems: Rolling stock E&M systems (E&M systems include signalling and train control systems, radio and communication systems, automatic fare collection systems, traction power, catenary systems, tunnel ventilation systems, etc.) Permanent way 43 15 7 3 11 7

The cost distributions of other railway projects would vary with the passenger-carrying capacity, level of service, number of stations, and other factors, but by and large, the major cost drivers are stations, civil structures between stations, and rolling stock 4 REPRESENTATION OF COST DRIVER

The key to our methodology is an explicit value engineering (VE) representation of a cost driver. This is to be derived and presented in a form that is suitable for identifying cost-saving proposals, and should include all the known information about the cost

JRRT291

Downloaded from pif.sagepub.com at University of Birmingham on February 25, 2013

48

E C S Kwok, P M Anderson, and S H S Ng

Catenary System

Contact Wire Height

Electrical Clearance

Walkway Height Trackform Drainage Trackside Services Evacuation Walkway KE Trackside Services Maintenance Walkway

Fig. 2

A VE representation for tunnel size

schematic showing all the items that would need to be accommodated, as shown in Fig. 2. Notice that both the vertical and horizontal dimensions can be optimized. For the vertical dimension, consideration should be give to train size, travelling speed, which affects the train/pantograph dynamic performance, system voltage that affects the electrical clearance, and inter-station distance that affects the drainage system design. For the horizontal dimension, train size, travelling speed, cant, evacuation strategy, and maintenance requirements are relevant. To determine whether one should start with the vertical or horizontal dimension rst, the above parameters would be instantiated with actual gures (for a typical 25 kV a.c. system, one would end up with a tunnel diameter ranging from say 6.3 m to more than 7 m). If for example the critical dimension is the vertical one, then one optimization would be to investigate the use of rigid conductor rail to reduce the contact wire height. If on the other hand the critical dimension is the horizontal one, then the width of the evacuation walkway or even detrainment strategy could be critically reviewed. For railways with low travelling speed, e.g. up to 80 km/h, low system voltage, e.g. 1500 V d.c., and short inter-station distance, the adoption of a detrainment strategy through either ends of a train onto the tracks becomes feasible, thereby rendering an evacuation

Proc. IMechE Vol. 224 Part F: J. Rail and Rapid Transit

walkway not necessary. This would lead to substantial reduction in both the vertical and horizontal dimension of the tunnel. This end detrainment strategy is typical of mass transit metro systems, like the MTR urban lines in Hong Kong. It is beyond the scope of this article to compare side detrainment and end detrainment, but clearly the re safety strategy, compatibility with connected lines, and human factors will all have to be taken into account. The example above shows that explicit representation of all the data and knowledge related to a cost driver would allow one to critically review not just specic technology issues but also strategic operational issues.

ILLUSTRATIONS OF THE VE METHODOLOGY

In this section, applications of the proposed value engineering methodology to railway construction projects are given.

5.1

Station sizing

As shown in the previous section, a high proportion of the total project cost would come from the construction of stations (around 40 per cent for West Rail).

JRRT291

Downloaded from pif.sagepub.com at University of Birmingham on February 25, 2013

Value engineering for railway construction projects

49

Step 1 develop VE representation for station size. A larger station leads to a higher construction cost, not just due to more material and labour costs, but also due to a higher likelihood of having to overcome site constraints arising from a larger footprint. For instance, it may be necessary to divert utilities or underpin existing structures within the vicinity. With station size identied as a cost driver, a VE representation based on the spatial relationship of a station can be devised, as shown in Fig. 3. As discussed in the last section, it is fruitful to identify the inter-dependencies among different elements in this representation. One clear logical relationship here is that the size of the building services plant, residing in non-public areas, is dependent on the heating, ventilation, and air conditioning requirements for all the areas to be served, including in particular the public areas. Similarly, the amount of space required for operation control functions is proportional to the size of the concourse and platforms. Hence it can be derived that the size of the public areas partly determines the size of the non-public areas. Referring to this representation, a value engineering exercise could focus on different levels. At level 4, the focus is on individual rooms, challenging whether a particular room is larger than necessary. At level 3, some synergy could be achieved by looking at groups of rooms, e.g. whether some systems can share a common plant room. The saving here is not just on the rooms themselves but also on the need for separate access to them, leading to more opportunities to optimize the layout of the station. This kind of plant room amalgamation has been done in some recent railway projects, such as the Tseung Kwan O Extension in Hong Kong. Without an explicit representation of station size, there is a tendency to stop the spatial optimization process at this level. Step 2 ask probing questions on station size. With an explicit top-down representation, however, it is possible to make a quantum leap in space-saving ideas. In this example, going up to level 2 would lead to

non-obvious questions, e.g. how can public areas like platforms be reduced without affecting service objectives? A not so obvious idea is to operate shorter trains at shorter intervals to maintain the same passenger-carrying capacity. This would be particularly fruitful because shorter platforms should lead to less non-public areas as explained earlier. Steps 3 and 4 identify issues and constraints. To establish the feasibility of a shorter train scheme, a detailed analysis on the following would need to be undertaken: (a) evaluation of headway simulation results from the signalling suppliers; (b) revision of the alignment to suit shorter trains; (c) investigation of the capacity of the tunnel ventilation system; (d) revision of overhead line equipment locations; (e) revision of safety and reliability targets; (f ) revision of station design, depot layout, and tunnel layout. Step 5 conrm feasibility of the VE proposal. To ascertain that a sufciently high line capacity could be achieved, a funnelling process for the procurement of the signalling system was adopted in phase 1 suppliers were paid to conduct detailed simulations to conrm the best headway that can be achieved with nine-car trains, in phase 2 only suppliers who can demonstrate the ability to achieve a line capacity of 33 trains per hour per direction were invited to submit a tender for the signalling system (details of this funnelling process are given in Patel [8]). Based on the assurance that all the tenderers for the signalling contract could achieve the required line capacity, the railway was changed from a twelve-car scheme to an incremental seveneightnine car scheme, while meeting the required passenger-carrying capacity. Step 6 develop an implementation plan. Having conrmed the feasibility of the seveneightnine car scheme, the design group, in particular the station

Level 1

Station Size

Partly Determines Level 2 Size of Public Areas Size of Non-public Areas

Level 3 Concourse

Platforms

Miscellaneous Operation Control Areas Miscellaneous

Plant Rooms

Level 4

Station Control Room Platform Booth

Fig. 3

JRRT291

A VE representation for station size

Proc. IMechE Vol. 224 Part F: J. Rail and Rapid Transit

Downloaded from pif.sagepub.com at University of Birmingham on February 25, 2013

50

E C S Kwok, P M Anderson, and S H S Ng

Fig. 4

Comparison of platform and station sizes

designers, revised the design accordingly. Figure 4 contrasts the footprints for a twelve-car platform and a nine-car platform, extracted from engineering drawings drawn on the same scale for comparison (it is not intended to show detailed layout here, it would sufce to note that the shortened platforms are not only shorter but also narrower). The optimized scheme improved the alignment at some locations, the reduced stations were shifted slightly so that they are no longer on curves. It facilitated civil construction work by avoiding a large culvert in one of the station sites. Recurrent costs on energy consumption and maintenance of stations are reduced. To passengers, waiting time is reduced by virtue of more frequent services, and walking distance within a station is also reduced. 5.1.1 Summary of the VE exercise on station sizing

and environmental implications, yet operating a low service level could have a detrimental effect of reducing demand further. With the incremental train length approach, judicious combination of different train lengths and different service levels could be adopted to match the demand. As an illustration, West Rails planned capacity was based on forecasts made at the early planning stages of the project, when the population of the catchments areas was estimated to have a 70 per cent increase in 5 years. The actual population growth turned out to be much slower due to economic and other unforeseen factors, and as a result, West Rails rider-ship is much lower than expected. Ironically, it is then the benets of incremental train length are fully realized a reasonably frequent service can be maintained without incurring higher operating costs associated with longer trains.

The use of shorter trains reduced station construction costs signicantly based on the cost distribution presented earlier, the overall saving was in the order of HK$6 billion. More specically, the number of piles needed for the whole railway was reduced from 8000 to 5000, with an estimated saving of over HK$2 billion. The feasibility of this VE exercise on station sizing hinges on the ability to deliver the required passengercarrying capacity. For a mass transit railway, the number of passengers that can be carried is characterized by the carrying capacity of a train and the maximum number of trains that can be operated per hour. Traditionally, the capacity of each train is xed by virtue of having a xed train length, while the frequency of services would be varied to match demand. The problem here is that should demand be low, maintaining a service level higher than necessary would have cost

Proc. IMechE Vol. 224 Part F: J. Rail and Rapid Transit

5.2 Viaduct design a system approach to noise control One major cost driver in infrastructure projects is bridges and viaducts. Hennessey and Bexten [9] present the results of a value engineering effort for the replacement of the Arbor Rail Line Bridge in Nebraska, where the adoption of a precast concrete design over the original proposal of steel superstructure had led to major cost and programme benets. Viaduct structures for railways can be value engineered through investigations on the thermal interaction forces from continuous welded rail, see for example Fryba [10]. The design of the West Rail viaducts can be found in Cooper and Harrison [11]. The focus below is on noise control measures as a cost driver.

JRRT291

Downloaded from pif.sagepub.com at University of Birmingham on February 25, 2013

Value engineering for railway construction projects

51

The West Rail viaducts are in close proximity to residential areas at some locations. In Hong Kong, there is a stringent requirement on an average noise level of 5560 db(A) between 11 pm and 7 am. Now a railway operating at say 6080 km/h could generate a trackside noise of over 80 db(A), to comply with statutory requirements, full noise enclosures or other effective measures would have to be implemented. Step 1 develop VE representation for noise control on viaduct. A VE representation for noise levels is shown in Fig. 5. Step 2 ask probing questions on noise control on viaduct. A fully enclosed structure incurs high civil cost, plus additional electrical and mechanical provisions to full more demanding statutory requirements like re services installations. Eliminating it would lead to substantial savings in capital cost as well as recurrent operation and maintenance cost. How could this be achieved? With an explicit representation of the air-borne and structure-borne noise levels, the project team asked if the noise could be effectively suppressed as close to the source as possible through the use of specic plenums to attenuate the noise. This led to the proposal of a multi-plenum noise control system. Steps 3 and 4 identify issues and constraints. The multi-plenum noise control system involves the following major elements: (a) rolling stock train skirt, under-car sound absorbing material;

(b) track oating slab track, resilient baseplates, rubber bearings; (c) viaduct noise attenuation plenum, noiseabsorbing lining. Step 5 conrm feasibility of the VE proposal. To conrm the feasibility of this integrated design of rolling stock, track, and viaduct, detailed simulation and analysis were conducted; details can be found in Crockett and Pyke [12]. It was concluded that the multi-plenum design could indeed comply with the requirements of the noise control ordinance. The completed design is shown in Fig. 6. Step 6 develop an implementation plan. Having demonstrated the feasibility of the multi-plenum concept, appropriate requirements were incorporated into the rolling stock, permanent way, and viaduct contracts of West Rail. The noise performance of these systems was monitored during the construction phase and ne-tuning implemented to ensure that the noise control system as a whole functioned effectively as intended.

5.2.1

Summary of the VE exercise on viaduct design

Today West Rail is recognized by passengers and the public at large as one of the quietest railways around. The cost of installing full enclosures for 13.4 km of viaduct would have been prohibitively large, to the extent that the viability of the project could be at risk.

Fig. 5

JRRT291

A VE representation for noise levels

Proc. IMechE Vol. 224 Part F: J. Rail and Rapid Transit

Downloaded from pif.sagepub.com at University of Birmingham on February 25, 2013

52

E C S Kwok, P M Anderson, and S H S Ng

authors are grateful to all those who had contributed to various value engineering initiatives for West Rail, which triggered the attempt to formalize the approach based on the identication and analysis of cost drivers. The feasibility of changing the railway from a twelve-car system to an incremental seveneightnine scheme was identied by Paul Anderson, and implemented by a team led by James Blake, Ian Thoms, Paul Anderson, Wilfred Lau, and Jaya Jesudason. The development and renement of the multi-plenum noise control system was a joint effort involving many specialists from ERM, Itochu Kinki Sharyo Kawasaki Consortium, KCRC, Maeda Chun Wo Joint Venture, Ove Arup & Partners, Robert Benaim and Associates, and WIA and Rupert Taylor Ltd; Vic McNally led the effort of the employer KCRC. The authors would like to thank the referees for their constructive comments on previous versions of the article. Authors 2010 REFERENCES

Fig. 6 Multi-plenum noise control system

1 Webb, A. Value engineering, part I. Eng. Manage. J., 1993, 3(4), 171175. 2 Wilson, D. C. Value engineering applications in transportation. NCHRP synthesis of highway practice, issue 352, Transportation Research Board of the National Academies, Washington, DC, 2005. 3 Omigbodun, A. Value engineering and optimal building projects. J. Archit. Eng., 2001, 7(2), 4043. 4 Stoy, C. and Schalcher, H.-R. Residential building projects: building cost indicators and drivers. J. Constr. Eng. Manage., 2007, 133(2), 139145. 5 Kowalski, R. A. Logic for problem solving, 1979 (Elsevier North Holland, New York). 6 Sowa, J. E. Knowledge representation: logical, philosophical, and computational foundations, 2000 (Brooks/Cole, Pacic Grove, CA). 7 EN50122-1 Railway Applications Fixed Installations. Part 1: protective provisions relating to electrical safety and earthing, European Committee for Electrotechnical Standardization, 1997. 8 Patel, S. D. Procurement strategy for train control and signalling the west rail paradigm. In Proceedings of the IRSE Aspect 99, London, 1999. 9 Hennessey, S. A. and Bexten, K. A. Value engineering results in successful precast railroad bridge solution. PCI J., 2002, 47(4), 7277. 10 Fryba, D. L. Thermal interaction of long welded rails with railway bridges. Rail Int., 1985, 16(3), 524. 11 Cooper, J. H. and Harrison, M. F. Development of an alternative design for the west rail viaducts. Proc. Inst. Civ. Eng. Transp., 2002, 153(2), 8795. 12 Crockett, A. R. and Pyke, J. R. Viaduct design for minimization of direct and structure-radiated train noise. J. Sound Vibr., 2000, 231(3), 883897.

CONCLUSIONS

A value engineering methodology for railway construction projects has been presented. The methodology involves identifying major cost drivers, deriving explicit representations for them, taking a holistic view to come up with effective solutions, assessing feasibility by analysing constraints, and developing an implementation plan. The examples given are railway related, but it should be clear that the methodology can be readily applied to other infrastructure projects. Various value engineering methods and techniques are being practised in the engineering and construction industries. What is new about our methodology is the development of a structured representation for a cost driver, through which non-obvious but signicant savings could be derived. In the case of West Rail, the original twelve-car system was changed to one that is capable of supporting trains of seven, eight, or nine cars in length, the initial operation being seven car. The savings arising from this value engineering exercise alone were estimated to be in the order of several billion Hong Kong dollars. ACKNOWLEDGEMENTS This work was done while the authors were with the Kowloon-Canton Railway Corporation (KCRC). The

Proc. IMechE Vol. 224 Part F: J. Rail and Rapid Transit

Downloaded from pif.sagepub.com at University of Birmingham on February 25, 2013

JRRT291

You might also like

- ResumeDocument4 pagesResumeapi-19608934No ratings yet

- Rail Feasibility Study Appendix FDocument4 pagesRail Feasibility Study Appendix FKushal DagliNo ratings yet

- GHD Annual Review 2013Document20 pagesGHD Annual Review 2013mikiarroyoNo ratings yet

- Final Manual For Specification StandardsDocument192 pagesFinal Manual For Specification Standardsbhargavraparti100% (1)

- Managed Lanes Corridor Project Feasibility StudyDocument28 pagesManaged Lanes Corridor Project Feasibility StudyDistrict Department of TransportationNo ratings yet

- 5.a Cons RFP Icb Section 6 - TorDocument68 pages5.a Cons RFP Icb Section 6 - TorFNo ratings yet

- Comparative Study of Bridge Concepts Master's Thesis2013 55Document191 pagesComparative Study of Bridge Concepts Master's Thesis2013 55NicholasOmodingNo ratings yet

- Am Tris Resume Update-1Document6 pagesAm Tris Resume Update-1AMTRISNo ratings yet

- McDonald Case StudyDocument9 pagesMcDonald Case StudyAnuranjanSinhaNo ratings yet

- Highway Research Record No. 33 (2005-06)Document199 pagesHighway Research Record No. 33 (2005-06)shanil3001100% (1)

- MBO ProfileDocument50 pagesMBO ProfileimansaripkNo ratings yet

- IISE Paper Integral Frames For Mumbai Monorail Guideway PDFDocument9 pagesIISE Paper Integral Frames For Mumbai Monorail Guideway PDFTran Tien DungNo ratings yet

- Engineering Services Business GroupDocument10 pagesEngineering Services Business GroupSujan SinghNo ratings yet

- Digital Quality Management in ConstructionDocument275 pagesDigital Quality Management in ConstructionChrisNo ratings yet

- DC2RVA SEHSR Final Basis of Design 02-24-2015 PDFDocument105 pagesDC2RVA SEHSR Final Basis of Design 02-24-2015 PDFdiablopapanatasNo ratings yet

- Proposed Methodology For Upgrading Bridge BarriersDocument13 pagesProposed Methodology For Upgrading Bridge Barriersyyanan1118No ratings yet

- Relative Displacement Method For Track Structure Interaction-397515Document8 pagesRelative Displacement Method For Track Structure Interaction-397515JEETENDRA PRAKASHNo ratings yet

- DPR - Volume II - Main Report - Part B (Version 2.1)Document607 pagesDPR - Volume II - Main Report - Part B (Version 2.1)Jobins JamesNo ratings yet

- Design Criteria of Guideway - BMR-51-LD-00 Rev01Document26 pagesDesign Criteria of Guideway - BMR-51-LD-00 Rev01Basyaruddin BasyarNo ratings yet

- Implementation of SFCL in Dfig Based Wind Energy System and Its ApplicationDocument40 pagesImplementation of SFCL in Dfig Based Wind Energy System and Its ApplicationSK RIYAZ ALI Research Scholar, Electrical Engineering, IIT(BHU)No ratings yet

- Proposal For Light Rail On The Lower Montauk BranchDocument19 pagesProposal For Light Rail On The Lower Montauk BranchcrainsnewyorkNo ratings yet

- Progress Report of Nepal Electricity Authority 2013Document120 pagesProgress Report of Nepal Electricity Authority 2013Vijay TamrakarNo ratings yet

- Tram Cost-Benefit DataDocument2 pagesTram Cost-Benefit Datarooseveltislander100% (2)

- Introduction To CRECDocument36 pagesIntroduction To CRECNayef FtouniNo ratings yet

- FR - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDDocument184 pagesFR - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDwalaywanNo ratings yet

- RFP Nippon Copy UpdatedDocument162 pagesRFP Nippon Copy Updatedkmmanoj1968100% (1)

- Fib Various Types of Structures For Namma MetroDocument34 pagesFib Various Types of Structures For Namma MetroRohitNo ratings yet

- DPR - Volume II - Main Report PartD (Version 2.1)Document259 pagesDPR - Volume II - Main Report PartD (Version 2.1)Jobins JamesNo ratings yet

- 243 Rupprecht PDFDocument6 pages243 Rupprecht PDFdonnypsNo ratings yet

- Module 1-G High Speed Rail Design - RuppertDocument124 pagesModule 1-G High Speed Rail Design - RuppertAshok KumarNo ratings yet

- EIA - 1215 SGR Realingment Within NNP Kenya Railways Corporation Report PDFDocument79 pagesEIA - 1215 SGR Realingment Within NNP Kenya Railways Corporation Report PDFPGKahumbu50% (2)

- Georgetown-Rosslyn Gondola Feasibility StudyDocument74 pagesGeorgetown-Rosslyn Gondola Feasibility StudyRachel SadonNo ratings yet

- De Beers 'Project Plus' Management SystemDocument36 pagesDe Beers 'Project Plus' Management Systemkhonzaphi dubeNo ratings yet

- Monorail Reconfiguration Evaluation ReportDocument43 pagesMonorail Reconfiguration Evaluation ReportThe Urbanist100% (1)

- Edmonton's New Walterdale BridgeDocument5 pagesEdmonton's New Walterdale BridgeTeo Peng KeatNo ratings yet

- How Can Tram Systems Solve Congestion in Growing Cities - Alstom WPDocument23 pagesHow Can Tram Systems Solve Congestion in Growing Cities - Alstom WPNathathonNo ratings yet

- Project Report: Employee Claim Reimbursement (Ecrs) Engineers India Limited (EIL)Document132 pagesProject Report: Employee Claim Reimbursement (Ecrs) Engineers India Limited (EIL)Ramesh Chandra Mishra0% (1)

- Camber For Construction StageDocument18 pagesCamber For Construction StageOanh PhanNo ratings yet

- Hydro Feasibility Studies GuideDocument2 pagesHydro Feasibility Studies GuideconlesterNo ratings yet

- TOC Feasibility Study Lowres V2 0Document269 pagesTOC Feasibility Study Lowres V2 0shahjada687013No ratings yet

- FinalreportDocument44 pagesFinalreportRiya soniNo ratings yet

- Mumbai Monorail ProjectDocument61 pagesMumbai Monorail ProjectAmit GargNo ratings yet

- 021 1700 023e 11e - MarineDocument56 pages021 1700 023e 11e - Marine김남균No ratings yet

- MAHSR Project & PMC Civil ScopeDocument5 pagesMAHSR Project & PMC Civil Scopenikesh dubeyNo ratings yet

- SEP WAD CO MS 0009 Method Statement For Piling Work Rev.00Document28 pagesSEP WAD CO MS 0009 Method Statement For Piling Work Rev.00Mohammad BayisNo ratings yet

- Preparatory Survey FOR The Chao Phraya River Crossing Bridge at Nonthaburi 1 Road Construction ProjectDocument308 pagesPreparatory Survey FOR The Chao Phraya River Crossing Bridge at Nonthaburi 1 Road Construction ProjectSony JsdNo ratings yet

- 0.CT ITD DWG 0103 R2 - LG Assembly P978 P979 (Combined)Document26 pages0.CT ITD DWG 0103 R2 - LG Assembly P978 P979 (Combined)Mark Carlo TullaoNo ratings yet

- Investigation of Fallen Precast BeamsDocument28 pagesInvestigation of Fallen Precast BeamsDeepak KrishnanNo ratings yet

- Gas-Insulated Switchgear From 72.5 To 550 KV: Excellent Systems That Create Lasting ValueDocument16 pagesGas-Insulated Switchgear From 72.5 To 550 KV: Excellent Systems That Create Lasting ValueMartin HroudnýNo ratings yet

- Pre-Bid Conference - NSCR CP01 - 02 PDFDocument38 pagesPre-Bid Conference - NSCR CP01 - 02 PDFAhmed Mobashshir SamaniNo ratings yet

- 도로설계편람 도로포장 편 2012 PDFDocument251 pages도로설계편람 도로포장 편 2012 PDFjinwook75No ratings yet

- Laamu Gan-Fonadhoo Feasibility Study & Technical Requirements Final 090315Document160 pagesLaamu Gan-Fonadhoo Feasibility Study & Technical Requirements Final 090315yamin4142No ratings yet

- Design-Build Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesDocument31 pagesDesign-Build Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesSakhawat HossainNo ratings yet

- Assessment 2 - Case StudyDocument5 pagesAssessment 2 - Case StudykhadijjatariqNo ratings yet

- Design BidDocument57 pagesDesign BidpraveenNo ratings yet

- Aster Brochure T&D PowerDocument8 pagesAster Brochure T&D PoweritsmevamsiNo ratings yet

- Delcan - Ottawa Rail System StudyDocument48 pagesDelcan - Ottawa Rail System StudyJohn NganNo ratings yet

- Preliminary Cost Estimate Model For Culverts: SciencedirectDocument9 pagesPreliminary Cost Estimate Model For Culverts: SciencedirectSUDEESH KUMAR GAUTAMNo ratings yet

- Opentrack - A Tool For Simulation of Railway NetworksDocument9 pagesOpentrack - A Tool For Simulation of Railway NetworksDwi HartantoNo ratings yet

- HCMC MRT Strategic Financial Model UpdateDocument20 pagesHCMC MRT Strategic Financial Model UpdateHermi VillaNo ratings yet

- Frederick W. Taylor - S Scientific Management PrinciplesDocument19 pagesFrederick W. Taylor - S Scientific Management PrinciplesTrihandoyo Budi Cahyanto100% (1)

- 05917859Document4 pages05917859Trihandoyo Budi CahyantoNo ratings yet

- Book Review: Leadership For 21st Century Learn-Ing: Global Perspectives From Educational Inno - VatorsDocument4 pagesBook Review: Leadership For 21st Century Learn-Ing: Global Perspectives From Educational Inno - VatorsTrihandoyo Budi CahyantoNo ratings yet

- Books Reviews 2008Document17 pagesBooks Reviews 2008Trihandoyo Budi CahyantoNo ratings yet

- 05688707Document4 pages05688707Trihandoyo Budi CahyantoNo ratings yet

- Porter 5 ForcesDocument4 pagesPorter 5 ForcesTrihandoyo Budi CahyantoNo ratings yet

- 05448519Document4 pages05448519Trihandoyo Budi CahyantoNo ratings yet

- 1 s2.0 S1877705812046607 MainDocument10 pages1 s2.0 S1877705812046607 MainTrihandoyo Budi CahyantoNo ratings yet

- The Elements of Organizational Engineering: Assumptions of Oe A N ODocument13 pagesThe Elements of Organizational Engineering: Assumptions of Oe A N OTrihandoyo Budi CahyantoNo ratings yet

- Tactical Patterns: Key PointsDocument14 pagesTactical Patterns: Key PointsTrihandoyo Budi CahyantoNo ratings yet

- Strategic Alliances - Fiat - Chrysler Alliance - Pranav SharmaDocument94 pagesStrategic Alliances - Fiat - Chrysler Alliance - Pranav SharmaTrihandoyo Budi Cahyanto100% (1)

- Challenge No. 6: Teambuilding: CompatibilityDocument10 pagesChallenge No. 6: Teambuilding: CompatibilityTrihandoyo Budi CahyantoNo ratings yet

- 1 s2.0 S0263786304000808 MainDocument8 pages1 s2.0 S0263786304000808 MainTrihandoyo Budi CahyantoNo ratings yet

- Management Strategies Management StrategiesDocument39 pagesManagement Strategies Management StrategiesTrihandoyo Budi CahyantoNo ratings yet

- Panama Canal - Compliance Check-ListDocument5 pagesPanama Canal - Compliance Check-ListDragan JerčićNo ratings yet

- Income Tax Jurisdictions Chart - New Revised On 2015Document6 pagesIncome Tax Jurisdictions Chart - New Revised On 2015Ca T.SANKARAMURTHYNo ratings yet

- HD325-7R Shop ManualDocument1,315 pagesHD325-7R Shop ManualSON100% (1)

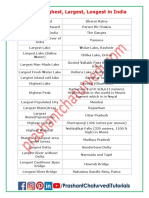

- Biggest Highest Largest Longest in IndiaDocument4 pagesBiggest Highest Largest Longest in IndiaSaikumarNo ratings yet

- Lifting PlanDocument30 pagesLifting PlanYusuf Jappie33% (3)

- 3 Brendan Finn Bus Based Transit Bus Based Tranist SeminarDocument130 pages3 Brendan Finn Bus Based Transit Bus Based Tranist SeminarRohit VermaNo ratings yet

- Panchkula Zone Residential19102020Document3 pagesPanchkula Zone Residential19102020AJAYNo ratings yet

- b3 Ultimate Railroads RulebookDocument48 pagesb3 Ultimate Railroads RulebookAngel RadnessNo ratings yet

- Ferry TimetableDocument3 pagesFerry TimetableAiden HayesNo ratings yet

- Scope of Work BRTS JaipurDocument27 pagesScope of Work BRTS JaipurGaurav Meena100% (1)

- SPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Document24 pagesSPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Eduardo OchaitaNo ratings yet

- High-Speed Rail Technology As Revealed by The Shinkansen: Hiromasa TANAKA Central Japan Railway Company, Tokyo, JapanDocument7 pagesHigh-Speed Rail Technology As Revealed by The Shinkansen: Hiromasa TANAKA Central Japan Railway Company, Tokyo, JapanIndra MauLanaNo ratings yet

- TCRP Report 57 - Track Design Handbook For Light Rail TransitDocument344 pagesTCRP Report 57 - Track Design Handbook For Light Rail TransitbcleeNo ratings yet

- ZRXZR 01 PDocument6 pagesZRXZR 01 Pasdqwe123dsaNo ratings yet

- UCJ Architecture PlanningDocument53 pagesUCJ Architecture PlanningNagpal ChetanNo ratings yet

- DDA Output SpecificationDocument72 pagesDDA Output SpecificationMichael BatleyNo ratings yet

- CKP WTT 21 22Document170 pagesCKP WTT 21 22SantanuPradhanNo ratings yet

- Great Northern and Thameslink Route MapDocument1 pageGreat Northern and Thameslink Route MapMangeshNo ratings yet

- Guia Carro Casa Miluska P-37Document76 pagesGuia Carro Casa Miluska P-37Adan Arribasplata SeguinNo ratings yet

- Standardi Dati Tenderskom DokumentacijomDocument4 pagesStandardi Dati Tenderskom DokumentacijomArfan NezirićNo ratings yet

- Metro Line 4 (Wadala To Kasarvadavali)Document462 pagesMetro Line 4 (Wadala To Kasarvadavali)Anonymous wrHR1JlNo ratings yet

- Halfin ProductDocument92 pagesHalfin ProductmfkanjetaNo ratings yet

- CEA Safety Regulations 2010Document87 pagesCEA Safety Regulations 2010Abin MeetuNo ratings yet

- Redfern Station Upgrade - New Southern Concourse: Consultation ReportDocument14 pagesRedfern Station Upgrade - New Southern Concourse: Consultation ReporthjfashjasNo ratings yet

- Chapter 10Document36 pagesChapter 10api-261956145No ratings yet

- Guideline From EC For Action On BridgesDocument256 pagesGuideline From EC For Action On BridgesMUHAMMAD UMAR RIAZNo ratings yet

- Trainz 2004 DRAFT Content Creation ProceduresDocument101 pagesTrainz 2004 DRAFT Content Creation ProceduresAndrei Chirilescu100% (1)

- Coimbatore Railway: Kanishka.TDocument6 pagesCoimbatore Railway: Kanishka.TAravindhanNo ratings yet

- Telemecanique Mini Control Relays TechnicalDocument12 pagesTelemecanique Mini Control Relays Technicalfelipeintegra100% (1)