Professional Documents

Culture Documents

Advanced Manufacturing Process

Uploaded by

mukesh3021Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advanced Manufacturing Process

Uploaded by

mukesh3021Copyright:

Available Formats

[4] Sample No.

Measurement per sample (hundredths of one mm) 1 2 3 4 5 6 7 8 9 10 747 748 749 749 749 749 750 751 751 751 748 749 748 749 749 750 750 750 751 752 747 750 750 750 750 751 751 750 752 752 749 748 748 750 750 749 751 750 751 753 748 749 749 751 751 750 750 752 751 751 2. 1.

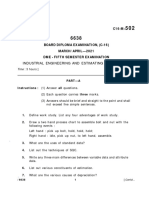

Ex/PG/ME/T/1291/100/2009

MASTER OF MECHANICAL ENGINEERING EXAMINATION, 2009

( 2nd Semester )

ADVANCED MANUFACTURING PROCESS

Time : Three hours Answer any five questions. What is Metal Matrix Composite ? Discuss their applications in industry. Draw a Schematic diagram of manufacturing Aluminum - Silicon Carbide Metal Matirx Composite through liquid metallurgy technique. 2+3+10+5=20 Full Marks : 100

a) What is ceramic material ? How ceramics are classified ? Discuss the use of ceramic materials as biomaterials. 3+3+4=10 b) Discuss two major types of oxide ceramics and nitride ceramics and their general characteristics. 10

Calculate three sigma control limits for X R charts. Show these limits on X and R charts. Plot the points and interpret the chart. 3. a) What is thermosetting and thermoset plastics ? Give some examples each of them. 4+4=8

b) What is Compression molding and Transfer molding ? How Computer Aided Drafting is used for the design of injection molding. 4. Write short notes on : a) Thermoforming b) Bonding of Thermoplastics [ Turn over 6+6=12 554=20

[2] c) Reinforced - plastic molding d) Processing of plastics. 5. a) What is meant by CIM ? Explain it. Give a structure of CIM and discuss it. b) Discuss in detail the steps involved in rapid prototyping. Also show the process chain for development of rapid prototype and explain. 6. 10+10=20 8.

[3] c) An input of 2 Sin 2t + 0.5 Sin 10t is applied to a first order instrument having a time constant of 0.3s. Find the output. If the same input is applied to an instrument of time constant 0.003s, what will be the output ? Comment on the results. 6+8+6=20 a) Sketch and explain normal curve of errors and hence explain the following : i) precision index

a) With the help of a neat sketch explain the working principle of a tool makers microscope. Mention its uses. b) What is a Tomlinson tester ? Discuss its constructional features and working. Give illustrative sketch. 10+10=20

ii) probable error iii) average daviation for the normal curve. b) 15 surface, selected at random, were found to have the following surface roughness values in m : 5.30, 5.73, 6.77, 5.26, 4.33, 5.45, 6.09, 5.64, 5.81, 5.75, 5.60, 5.58, 5.50, 5.70, 5.64. Determine any reading that can be rejected by applying Chauvenets Criterion. The ratio of maximum derivation to standard derivation should not exceed 2.13. 9. 10+10=20

7.

a) A measuring system is subjected to ramp imput of first order. Derive an expression for the out put and show its variation with time. Also determine the steady state error. b) A second - order measurement system following the differential equation given by

d Io dt 2

3dIo + 30Io = 30Ii dt

where Io and Ii are the output and input quantities respectively. Determine i) damping ratio

a) Neatly sketch an operating characteristic curve and explain it. Also discuss about consumers risk, LTPD, producers risk, AQL. 10

ii) damped natural frequency iii) static sensitivity iv) time constant.

b) Sample of 5 were taken at regular intervals from a process, 10 samples in all being taken. The results were as follows :

[ Turn over

You might also like

- Advanced Manufacturing ProcessDocument2 pagesAdvanced Manufacturing Processmukesh3021No ratings yet

- BTME 2nd Year AssignmentDocument15 pagesBTME 2nd Year AssignmentshishunalNo ratings yet

- Mech3002y 3 2011 2 PDFDocument5 pagesMech3002y 3 2011 2 PDFKeshav GopaulNo ratings yet

- Code - No: 07A6EC04Document4 pagesCode - No: 07A6EC04ideepujNo ratings yet

- PR 2303Document4 pagesPR 2303Karthik Srinivas0% (1)

- Bit2201 Bbit308 Simulation and ModelingDocument3 pagesBit2201 Bbit308 Simulation and ModelingMark Joe AburNo ratings yet

- Advanced Manufacturing ProcessDocument2 pagesAdvanced Manufacturing Processmukesh3021No ratings yet

- Mech3002y 3 2007 2 PDFDocument6 pagesMech3002y 3 2007 2 PDFKeshav GopaulNo ratings yet

- Mech3002y 3 2009 2 PDFDocument5 pagesMech3002y 3 2009 2 PDFKeshav GopaulNo ratings yet

- 2014 MFE2201 Advanced Manufacturing SystemsDocument5 pages2014 MFE2201 Advanced Manufacturing SystemsBernice JohnsonNo ratings yet

- MP Previous Qp-Me3393Document21 pagesMP Previous Qp-Me3393azhagan.mecNo ratings yet

- Metrology QPDocument3 pagesMetrology QPFaizur RahmanNo ratings yet

- May 2014Document3 pagesMay 2014Arun Prakash NatesanNo ratings yet

- 10me848qpset Design For Manufacturing and AssemblyDocument13 pages10me848qpset Design For Manufacturing and AssemblyDr. N. S. Sriram100% (1)

- Time: 3 Hours Answer All Questions Maximum: 100 MarksDocument3 pagesTime: 3 Hours Answer All Questions Maximum: 100 MarksAnonymous ZB6qyhD6No ratings yet

- 2017 Winter Question PaperDocument5 pages2017 Winter Question PaperMahesh SelokarNo ratings yet

- rr312002 Metrology and Quality ControlDocument8 pagesrr312002 Metrology and Quality ControlSRINIVASA RAO GANTANo ratings yet

- Industrial Engineering and Quality Control MSBTEDocument5 pagesIndustrial Engineering and Quality Control MSBTEJaydip Jadhav100% (2)

- WWW - Manaresults.Co - In: Set No. 1Document4 pagesWWW - Manaresults.Co - In: Set No. 1Chanumolu DushyanthNo ratings yet

- Metrology and Quality ControlDocument4 pagesMetrology and Quality ControlAsif PatelNo ratings yet

- Switchinng Theory and Logic Design July 2022Document2 pagesSwitchinng Theory and Logic Design July 2022drkhamuruddeenNo ratings yet

- Mech 204 Takehome Exam 1 of 2020Document2 pagesMech 204 Takehome Exam 1 of 2020Manuel Tikongyin WundengbaNo ratings yet

- Computational Modeling and Simulation: M.Tech - Degree Examinations, June2015 Semester - Iii & IvDocument3 pagesComputational Modeling and Simulation: M.Tech - Degree Examinations, June2015 Semester - Iii & IvMohanraj SubramaniNo ratings yet

- Mech3002y 3 2015 2Document7 pagesMech3002y 3 2015 2Keshav GopaulNo ratings yet

- M&SE Dec 2011Document4 pagesM&SE Dec 2011simalaraviNo ratings yet

- Mech3002y 3 2010 2 PDFDocument5 pagesMech3002y 3 2010 2 PDFKeshav GopaulNo ratings yet

- GGL 2205 Geo-StatisticsDocument3 pagesGGL 2205 Geo-StatisticslucyNo ratings yet

- Technology, Tbengal: Maulana Abul Kalam Azad University OFDocument7 pagesTechnology, Tbengal: Maulana Abul Kalam Azad University OFBikash ChoudhuriNo ratings yet

- Summer 2021 AMIIW Question PapersDocument32 pagesSummer 2021 AMIIW Question PapersRiyaz AhmedNo ratings yet

- Emm 315 Materials Forming Processes IDocument3 pagesEmm 315 Materials Forming Processes INehemiah LemombianNo ratings yet

- Competitive Manufacturing Systems I 002Document58 pagesCompetitive Manufacturing Systems I 002Rajueswar100% (1)

- 2019 SA Feb-19Document18 pages2019 SA Feb-19vishwas kumarNo ratings yet

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: InstructionsAmit PandeyNo ratings yet

- Metrologyand Surface EngineeringDocument4 pagesMetrologyand Surface EngineeringshivkrnNo ratings yet

- Ramaiah: Semester End Examinations - January 2020Document2 pagesRamaiah: Semester End Examinations - January 2020hari krishnaNo ratings yet

- Industrial Engineering-Estimating and Costing MAR-APRIL 2021Document4 pagesIndustrial Engineering-Estimating and Costing MAR-APRIL 2021Sai Radha KrishnaNo ratings yet

- University of Mauritius: Special Retake ExaminationsDocument6 pagesUniversity of Mauritius: Special Retake ExaminationsKeshav GopaulNo ratings yet

- University of Mauritius Faculty of Engineering: (August 2016)Document8 pagesUniversity of Mauritius Faculty of Engineering: (August 2016)Keshav GopaulNo ratings yet

- University of Mauritius: September 2015Document7 pagesUniversity of Mauritius: September 2015Keshav GopaulNo ratings yet

- ME2Document478 pagesME2आकाश संगीता प्रकाश पवारNo ratings yet

- Be Paper 1Document852 pagesBe Paper 1Vishal Gaurav100% (2)

- 01feb2016-Industrial Robotics,Design With Advanced Materials,Applied Mathematics,Optical Communication Technology,Advanced Data Structures and Algorithm Analysis,Mathematical Modeling,Analysis OfDocument15 pages01feb2016-Industrial Robotics,Design With Advanced Materials,Applied Mathematics,Optical Communication Technology,Advanced Data Structures and Algorithm Analysis,Mathematical Modeling,Analysis OfsirapuNo ratings yet

- 2023 Winter Question Paper (Msbte Study Resources)Document4 pages2023 Winter Question Paper (Msbte Study Resources)Rohan ChavanNo ratings yet

- M.E April 2016 (2008 Pat.)Document147 pagesM.E April 2016 (2008 Pat.)Apurv VaidyaNo ratings yet

- Model Question Paper - Industrial Engineering and Management - First Semester - DraftDocument24 pagesModel Question Paper - Industrial Engineering and Management - First Semester - Draftpammy313No ratings yet

- Advanced ManufacturingDocument5 pagesAdvanced Manufacturingmukesh3021No ratings yet

- ME-mit Admission FormDocument1,057 pagesME-mit Admission FormBittu50% (2)

- Highway Engineering Feb Mar 2022Document2 pagesHighway Engineering Feb Mar 2022Sobha Ranjith KumarNo ratings yet

- Assignment Booklet: BTME ProgrammeDocument20 pagesAssignment Booklet: BTME ProgrammeSarvanKumarNo ratings yet

- 22657.pdf (IEQ)Document3 pages22657.pdf (IEQ)Mc stanNo ratings yet

- Csvtu MMMDocument5 pagesCsvtu MMMManish SahuNo ratings yet

- Jntuworld: R07 Set No. 2Document7 pagesJntuworld: R07 Set No. 2zahid_polyNo ratings yet

- rr321502 Mathematical Modelling and SimulationDocument8 pagesrr321502 Mathematical Modelling and SimulationSRINIVASA RAO GANTANo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- From Microstructure Investigations to Multiscale Modeling: Bridging the GapFrom EverandFrom Microstructure Investigations to Multiscale Modeling: Bridging the GapDelphine BrancherieNo ratings yet

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsFrom EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Safety HandbookDocument17 pagesSafety HandbookRakesh JunnurNo ratings yet

- CNC Programming - PdfdsfdsDocument27 pagesCNC Programming - PdfdsfdsArie JuliantoNo ratings yet

- StabilityDocument5 pagesStabilityJenelia Jojo50% (2)

- Impact of A Jet: Experiment 4Document6 pagesImpact of A Jet: Experiment 4Eye IqbalNo ratings yet

- Laboratory Manual Physics - 1: AGH University of Science and Technology in Cracow Department of ElectronicsDocument3 pagesLaboratory Manual Physics - 1: AGH University of Science and Technology in Cracow Department of Electronicsmukesh3021No ratings yet

- Shop Safety PolicyDocument21 pagesShop Safety Policymukesh3021No ratings yet

- 00107Document9 pages00107mukesh3021No ratings yet

- Strength of MaerialsDocument45 pagesStrength of MaerialsShivakumar PatilNo ratings yet

- Convocation Adv Sept 13Document1 pageConvocation Adv Sept 13mukesh3021No ratings yet

- Experiment - 08 - Determination of Meta-Centric HeightDocument3 pagesExperiment - 08 - Determination of Meta-Centric HeightAshish YadavNo ratings yet

- LM FluidMechanicsLabDocument0 pagesLM FluidMechanicsLabmukesh3021No ratings yet

- Types of Boilers PDFDocument5 pagesTypes of Boilers PDFJosé RubioNo ratings yet

- Anleitung Ir1 eDocument16 pagesAnleitung Ir1 emukesh3021No ratings yet

- Fluid Mechanics Ans Machinery - Lab ManualDocument76 pagesFluid Mechanics Ans Machinery - Lab ManualVikram Puttenahalli Nagesh GowdaNo ratings yet

- Boilers and Thermic Fluid HeatersDocument54 pagesBoilers and Thermic Fluid HeatersParin PatelNo ratings yet

- PublicationsDocument11 pagesPublicationsmukesh3021No ratings yet

- Mechanics of Fluids Laboratory: A Manual For TheDocument52 pagesMechanics of Fluids Laboratory: A Manual For Theturnip331100% (1)

- EAS361 LabManual Fall2004 r3Document41 pagesEAS361 LabManual Fall2004 r3mukesh3021No ratings yet

- Advt ES2 03 2013EDocument1 pageAdvt ES2 03 2013Emukesh3021No ratings yet

- Fluids Lab ManualDocument67 pagesFluids Lab Manualkalyan_aubeNo ratings yet

- Fluid Mechanics Hydraulics Lab ManualDocument24 pagesFluid Mechanics Hydraulics Lab Manualsawmag123No ratings yet

- Fluids Lab Venturi Meter - 4Document5 pagesFluids Lab Venturi Meter - 4augur886No ratings yet

- Flued Mechanics & MachineryDocument4 pagesFlued Mechanics & Machinerymukesh3021No ratings yet

- Centrifugal Pump Test Rig: Fluid Mechanics and Hydraulics LabDocument6 pagesCentrifugal Pump Test Rig: Fluid Mechanics and Hydraulics Labmukesh3021No ratings yet

- Pert Time/ Cost: An Aid To Agribusiness ManagementDocument62 pagesPert Time/ Cost: An Aid To Agribusiness ManagementPangga TolentinoNo ratings yet

- 1373090220Document14 pages1373090220mukesh3021No ratings yet

- Fluid Mechanics (2003)Document6 pagesFluid Mechanics (2003)mukesh3021No ratings yet

- Laboratory ManualDocument10 pagesLaboratory Manualmukesh3021100% (1)

- CPMDocument15 pagesCPMViktor AnastasovskiNo ratings yet

- Novel High Capacitance Materials:-Batio:La and Cacu Ti ODocument10 pagesNovel High Capacitance Materials:-Batio:La and Cacu Ti ORachna SelvamaniNo ratings yet

- 09 RegulationsDocument1 page09 Regulationsسحر اکبریانNo ratings yet

- 3D Printing Method of Fabrication For Metals, Ceramics, and Multi-Materials Using A Universal Self-Curable Technique For Robocasting PDFDocument8 pages3D Printing Method of Fabrication For Metals, Ceramics, and Multi-Materials Using A Universal Self-Curable Technique For Robocasting PDFoguNo ratings yet

- Recent Progress in Graphene Based Ceramic Composites A ReviewDocument23 pagesRecent Progress in Graphene Based Ceramic Composites A ReviewAlina JumoleaNo ratings yet

- A Case Study: Ceramic Tile Production: February 2014Document26 pagesA Case Study: Ceramic Tile Production: February 2014Mito ChondriaNo ratings yet

- Bill Kremer Catalog by Eric Nisly 4.5 MB PDFDocument56 pagesBill Kremer Catalog by Eric Nisly 4.5 MB PDFspaceskipperNo ratings yet

- DSMTS-0072.5 Cr2O3Document4 pagesDSMTS-0072.5 Cr2O3Remco van den BergNo ratings yet

- Mechanical and Tribological Behavior of Particulate Reinforced Aluminum Metal Matrix Composites - A ReviewDocument33 pagesMechanical and Tribological Behavior of Particulate Reinforced Aluminum Metal Matrix Composites - A ReviewYazala PrakashNo ratings yet

- Grinding Damage Prediction For Ceramics Via CDM Model: Bi ZhangDocument8 pagesGrinding Damage Prediction For Ceramics Via CDM Model: Bi ZhangDakhlaouiNo ratings yet

- Thomas Schropfer - Material Design - 2011Document192 pagesThomas Schropfer - Material Design - 2011Lera Denisova75% (4)

- Overview of Refractory MaterialsDocument54 pagesOverview of Refractory MaterialsHenrique Alvr100% (5)

- Christy Catalytics-Product OverviewDocument2 pagesChristy Catalytics-Product OverviewWili Nur RahmanNo ratings yet

- Engineering Material II Exit ExamDocument10 pagesEngineering Material II Exit ExamwondimuNo ratings yet

- A New Classification System For All-Ceramic and Ceramic-Like Restorative Materials. 2015 - Gracis - IJPDocument11 pagesA New Classification System For All-Ceramic and Ceramic-Like Restorative Materials. 2015 - Gracis - IJPPaul AlvarezNo ratings yet

- Polishing Pad Selection GuideDocument2 pagesPolishing Pad Selection GuidegaborodcNo ratings yet

- Sintering 5Document34 pagesSintering 5Farid MuliaNo ratings yet

- Kaustubh Nerekar-Research ProjectDocument67 pagesKaustubh Nerekar-Research ProjectKaustubh NerekarNo ratings yet

- NPTEL PHASE 2 - Metallurgy and Materials Science CoursesDocument3 pagesNPTEL PHASE 2 - Metallurgy and Materials Science CoursesskbeheraNo ratings yet

- 2014 Gibbbs - Book - Review - Ceramic - Petrography - The - Inte PDFDocument2 pages2014 Gibbbs - Book - Review - Ceramic - Petrography - The - Inte PDFBokaNo ratings yet

- Product Sheet ALONDocument3 pagesProduct Sheet ALONketab_doostNo ratings yet

- Materials For Acoustic Matching in Ultrasound TransducersDocument5 pagesMaterials For Acoustic Matching in Ultrasound TransducersAnton100% (1)

- 1 s2.0 S0272884219306522 MainDocument16 pages1 s2.0 S0272884219306522 MainFábio FriolNo ratings yet

- Report For Export Ceramic ProductsDocument4 pagesReport For Export Ceramic ProductsMd. Saiful IslamNo ratings yet

- Biomaterials - An Introduction - PARK & Lakes 2007 Tec PDFDocument562 pagesBiomaterials - An Introduction - PARK & Lakes 2007 Tec PDFdambo50% (6)

- A Review On Properties of Aerospace Materials Through Additive ManufacturingDocument18 pagesA Review On Properties of Aerospace Materials Through Additive ManufacturingkrishnaNo ratings yet

- All Ceramic Crowns and Shade SelectionDocument13 pagesAll Ceramic Crowns and Shade Selectionhbusy100% (1)

- Lightweight Composite Stone PanelsDocument6 pagesLightweight Composite Stone PanelsRachel IngramNo ratings yet

- Mechanical Properties of NanomaterialsDocument9 pagesMechanical Properties of NanomaterialsFlorin AndreiNo ratings yet

- Roman Catalogs ROMAN Interior 2015 PDFDocument89 pagesRoman Catalogs ROMAN Interior 2015 PDFVidia Deasinta Kusuma ChandraNo ratings yet

- Advances in Precision Motion Control: White PaperDocument13 pagesAdvances in Precision Motion Control: White PaperGreen LemonNo ratings yet