Professional Documents

Culture Documents

Verify Correct Version Before Use.: PRC-5002 Rev. E

Uploaded by

konazoiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Verify Correct Version Before Use.: PRC-5002 Rev. E

Uploaded by

konazoiCopyright:

Available Formats

PRC-5002 Rev.

Verify correct version before use. Page 1 of 9

PRC-5002 Rev. E

Verify correct version before use. Page 2 of 9

PRC-5002 Rev. E

1.0

SCOPE

This process specification establishes technical require ents for the passivation of corrosion-resistant steel in the anufacture of !"C flight har#$are. %n a##ition& it covers speciali'e# pic(ling treat ents for the re oval of foreign particles fro nic(el-copper allo)s. *ote+ ,ll references in this #ocu ent to passivation refer to corrosion-resistant steel an# all references in this #ocu ent to pic(ling refer to speciali'e# pic(ling for the re oval of foreign etal fro the surface of nic(el-copper allo)s. 2.0 APPLICABILITY

This process specification covers passivation treat ents for use on austenitic& ferritic& artensitic& an# precipitation-har#ening corrosion-resistant steels. %n a##ition& it covers speciali'e# pic(ling treat ents for the re oval of foreign particles fro nic(el-copper allo)s. 3.0 SA!E

This process specification shall be calle# out on the engineering #ra$ing b) using a #ra$ing note that i#entifies the process specification an# the t)pe of passivation or pic(ling treat ent to be use#. -or e.a ple+ PASSIVATE PE" #ASA$%SC P"C&'002( TYPE VI. %f the specific passivation process is not critical to a particular #esign& the process t)pe a) be left off the #ra$ing callout. -or e.a ple+ PASSIVATE PE" #ASA$%SC P"C&'002. The #ecision to allo$ this shop option shoul# be coor#inate# in a#vance $ith the responsible aterials engineer. The four t)pes of passivation processes are as follo$s+ T)pe %% T)pe 0% T)pe 0%% T)pe 0%%% /e#iu -te perature nitric aci# solution $ith so#iu a##itive 1o$-te perature nitric aci# solution /e#iu -te perature nitric aci# solution /e#iu -te perature& high-concentration nitric aci# solution Verify correct version before use. Page 2 of 9 #ichro ate

PRC-5002 Rev. E

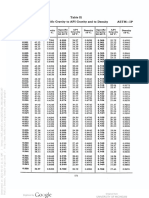

"election of the passivation t)pe shall be T)pe %% T)pe 0% /P159 /P25* %*314 ,245 12-4/o6 15-5P76 15-3/o6 13-8P76 13-3P76 Custo 8556 Custo 8556 21-5-9 ,%"% 201 ,%"% 202 ,%"% 201 ,%"% 202

a#e accor#ing to the follo$ing table+ T)pe 0%% T)pe 0%%%

,245 12-4/o 15-5P7 15-3/o 13-8P7 13-3P7 Custo 855 Custo 855 21-5-9

,245 12-4/o 15-5P7 15-3/o 13-8P7 13-3P7 Custo 855 ,%"% 201 ,%"% 202 ,%"% 201 ,%"% 202 ,%"% 202 ,%"% 202"e

,%"% 202 ,%"% 202"e ,%"% 208 ,%"% 208 ,%"% 2081 ,%"% 2081 ,%"% 2087 9/-3 9/-3 ,%"% 208* ,%"% 208* ,%"% 205 ,%"% 205 ,%"% 204 ,%"% 204 ,%"% 209 ,%"% 209 ,%"% 209" ,%"% 209" ,%"% 209Cb ,%"% 209Cb ,%"% 210 ,%"% 210 ,%"% 210" ,%"% 210" ,%"% 211 ,%"% 211 ,%"% 218 ,%"% 218 ,%"% 215 ,%"% 215 ,%"% 215 ,%"% 215 ,%"% 2151 ,%"% 2151 ,%"% 2157 ,%"% 221 ,%"% 221 ,%"% 2217 ,%"% 229 ,%"% 229 ,%"% 283 ,%"% 283 ,%"% 2837 Verify correct version before use. Page 8 of 9

,%"% 2087

,%"% 2157 ,%"% 2217 ,%"% 2837

PRC-5002 Rev. E

,%"% 283" ,%"% 283"e ,/250 ,/255 ,l ar 252 ,%"% 802 ,%"% 805 ,%"% 809 ,%"% 810 ,%"% 818 ,%"% 815 ,%"% 815"e ,%"% 820 ,%"% 829 ,%"% 820,%"% 820-"e ,%"% 821 ,%"% 828 ,%"% 825 ,%"% 880, ,%"% 880: ,%"% 880C ,%"% 880,%"% 880-"e ,%"% 882 9/-23

,%"% 829 ,%"% 820

,%"% 283" ,%"% 283"e ,/250 ,/255 ,l ar 252 ,%"% 802 ,%"% 805 ,%"% 809 ,%"% 810 ,%"% 818 ,%"% 815 ,%"% 815"e ,%"% 820 ,%"% 829

,%"% 821 ,%"% 828 ,%"% 825 ,%"% 880, ,%"% 880: ,%"% 880C ,%"% 880,%"% 880-"e ,%"% 882 ,%"% 885 9/-23

T)pe 0% is the preferre# process $hen per itte# b) the table above. %t is the inhouse process at !"C. %t utili'es no ha'ar#ous he.avalent chro iu an# is available in ore etal finishing facilities. ;l#er #ra$ings shoul# be change# so this process can be utili'e# $henever possible to save ti e an# re#uce costs. ,llo)s not liste# on the table above a) be passivate# to this specification& provi#e# there is /<P approval for a specific passivation t)pe on the engineering #ra$ing or other process #ocu entation. *ote that stainless steel parts that have har#ene# surfaces fro nitri#ing& fro carbonitri#ing& or fro other si ilar #iffusion treat ents shoul# not be passivate#. "evere corrosion an#=or severe pitting of the har#ene# surfaces coul# rea#il) occur. %n a##ition& stainless steels that are carburi'e# shoul# not be passivate#& since the chro iu co bines $ith the carbon to for chro iu carbi#es along the surface& $hich #o not benefit fro passivation.

Verify correct version before use. Page 5 of 9

PRC-5002 Rev. E

>nless other$ise specifie#& the cleaning pre-treat ent for passivation shall consist of an al(aline cleaning process accor#ing to the require ents of *,",=!"C PRC-5001. 7o$ever& no reference to PRC-5001 nee#s to be a#e on the #ra$ing. -or pic(ling treat ents of nic(el-copper allo)s& the stan#ar# engineering #ra$ing callout shall be si ilar to the follo$ing e.a ple+ PIC)LE PE" #ASA$%SC P"C&'002( TYPE L. T)pe 1 refers to a solution of h)#rochloric aci# an# ferric chlori#e ?-or ula 1 fro p. 81 in 7untington ,llo) %,%-21 ?"econ# E#ition& 1943@. *.0 "E+E"E#CES Passivation Treat ents for Corrosion-Resistant "teel "tan#ar# Practice for ;perating "alt "pra) ?-og@ ,pparatus Fabricating& %nco ,llo)s %nternational& %nc.& "econ# E#ition& 1943. -e#eral "pecification& Passivation Treat ents for CorrosionResistant "teel Corrosion-Resistant "teel Parts+ "a pling& %nspection an# Testing for "urface Passivation

,/"-AA-P-25 ,"T/ :113 %nco Publication %,%-21 AA-P-25C /%1-"TB-352C

'.0 *one ..0 ..1

,ATE"IALS "E- I"E,E#TS

P"OCESS "E- I"E,E#TS /O") I#ST" CTIO#S

,ll $or( shall be perfor e# to $ritten proce#ures. The $or( instructions shall contain sufficient #etail to ensure that the anufacturing process pro#uces consistent& repeatable pro#ucts that co pl) $ith this specification. -or $or( perfor e# at !"C facilities& these $or( proce#ures consist of Betaile# Process %nstructions ?BP%Cs@.

Verify correct version before use. Page 5 of 9

PRC-5002 Rev. E

-or contracte# $or(& the contractor shall be responsible for preparing an# aintaining& an# certif)ing $ritten $or( proce#ures that eet the require ents of this specification. ..1 !E#E"AL "E- I"E,E#TS

,ll passivation of corrosion-resistant steel shall be con#ucte# accor#ing to the require ents of ,/"-AA-P-25& $ith the o#ifications inclu#e# in this process specification. Dhen no passivation t)pe is specifie#& the etal finishing facilit) has the option of using an) t)pe process allo$e# for the allo) in the table above. ,ll pic(ling treat ents shall be con#ucte# $ithin the gui#elines of 7untington ,llo) :oo(let %,%-21 ?"econ# E#ition& 1943@. ..2 SPECI+IC "E- I"E,E#TS +O" PASSIVATIO#

The etal finishing facilit) shall aintain a recor# of the control proce#ures use# for a given passivation treat ent. The passivation solution shall be anal)'e# $ee(l) to verif) that the concentration of nitric aci# ?an# so#iu #ichro ate if applicable@ eet the specifie# ranges in ,/"-AA-P-25. The bath te perature of the passivation tan( shall be verifie# before each use. %f a etal finishing facilit) uses the T)pe 0% process for allo)s in the table ar(e# $ith an asteris( ?6@& the process bath shall be teste# onthl) to verif) that the chlori#e concentration is less than 1000 pp . Testing of bath for chlori#e before parts are processe# is also acceptable. "hops that #o not perfor onthl) chlori#e testing a) not use the T)pe 0% process for these allo)s. ..3 SPECI+IC "E- I"E,E#TS +O" PIC)LI#!

-or pic(ling operations& the aci#ic solution shall be controlle# such that copper flash $ill not occur. Eeneral gui#elines on the prevention an# re oval of copper flash are provi#e# on p. 25 in 7untington ,llo) %,%-21 ?"econ# E#ition& 1943@. The aci#it) levels shall be perio#icall) onitore# to ensure that the bath is at the proper initial strength. -resh solution shoul# be a#e up $hen salts begin to cr)stalli'e on the si#es of the tan(. ,lso& anal)sis of the pic(ling solution shall be #one perio#icall) to verif) that the etallic content is belo$ 150 gra s per liter ?g=1@. The solution ust be #iscar#e# if the 150 g=1 level is e.cee#e#.

0.0

P"OCESS - ALI+ICATIO#

*one require# Verify correct version before use. Page 3 of 9

PRC-5002 Rev. E

1.0

P"OCESS VE"I+ICATIO#

The surface?s@ being passivate# or pic(le# shall be inspecte# for cleanliness prior to che ical treat ent. The post-treat ent verification is #etaile# belo$ in section 4.1 or 4.2. The etho# use# an# result shall be inclu#e# in the facilit) or ven#or certificate of confor ance of this process. 1.1 VE"I+ICATIO# O+ PASSIVATIO# P"OCESS

,fter the passivation process has been co plete#& the passivate# co ponents ust e.hibit che icall) clean surfaces that sho$ no etching& pitting& or frosting. , slight #iscoloration $ill be allo$e# if the subFect surface passes the $ater brea( free test. Each lot of parts shall be teste# to verif) that e be##e# iron has been re ove# using one of the follo$ing 8 test etho#s that are #etaile# in ,/"-AA-P-25+ ?1@ ?2@ ?2@ ?8@ 1.2 Test /etho# 100 of /%1-"TB-352C ?$ater i ersion test@.

7igh hu i#it) test per section 8.8.1.2 of ,/"-AA-P-25. "alt spra) testing for 2 hours accor#ing to the proce#ures of ,"T/ :113. Test /etho# 102 of /%1-"TB-352C ?copper sulfate test@. VE"I+ICATIO# O+ PIC)LI#! P"OCESS etal shall

0erification that the pic(le# surface is free of e be##e# iron or other be acco plishe# using one or ore of the follo$ing test etho#s+ ?1@

"canning electron icroscop) $ith bac(scatter o#e #etection an# $in#o$less energ) #ispersive spectroscop) can be utili'e#. This is a ver) e.pensive technique an# shoul# be li ite# to s all ite s of a li ite# quantit). Test /etho# 102 of /%1-"TB-352C ?Potassiu -erric)ani#e-*itric ,ci# "olution@ is an ultra-sensitive technique for s all batches that can be use# if inspectors have proper training in its use.

?2@

?2@ , salt spra) test utili'ing a solution of 1G so#iu chlori#e for 12-28 hours can be use# for large scale testing. ,n) free iron on the surface $ill appear as rust spots. Verify correct version before use. Page 4 of 9

PRC-5002 Rev. E

2.0

T"AI#I#! A#3 CE"TI+ICATIO# O+ PE"SO##EL

Personnel perfor ing passivation an# pic(ling treat ents of etallic aterials shall be certifie# to con#uct this process b) their supervisor. This certification shall be $ritten. %f these processes are to be perfor e# b) an outsi#e ven#or& the #evelop ent of an appropriate training progra shall be the responsibilit) of the ven#or. 10.0 3E+I#ITIO#S The che ical treat ent of a stainless steel allo) or iron base# superallo) $ith a il# o.i#i'er& such as nitric aci#& to re ove free iron or other conta inants e be##e# in the surface& for e.a ple tool steel fro achining. Passivation treat ent also pro#uces an o.i#e fil $ith superior corrosion resistance to the o.i#e fil that occurs naturall). Passivation is not generall) effective in re oving o.i#e scale or heat tint. The che ical treat ent of etallic aterials $ith an aqueous aci# solution that results in the re oval of surface o.i#es or scale for e# #uring heating. This etho# also re oves other foreign etals an# other substances. , test to #eter ine if a surface is che icall) clean b) the use of a #istille# $ater rinse. %f the surface is clean& the $ater $ill brea( an# sprea# across the surface in a sheet-li(e anner. , conta inate# surface $ill cause the $ater to for #roplets an# Hbea#I. ,n allo)e# steel that contains chro iu 10.5 $t-G. in e.cess of

Passivation

Pic(ling

Dater :rea( -ree Test

Corrosion-resistant "teel

Verify correct version before use. Page 9 of 9

You might also like

- Pipeline Hydrotest PlanDocument16 pagesPipeline Hydrotest PlanSunday Paul0% (1)

- Piping Stress SpecificationDocument23 pagesPiping Stress Specificationpourang1361No ratings yet

- HUP & LUP CCS C64A HDB Housekeeping & Safety Audit Report 13.01.2011Document9 pagesHUP & LUP CCS C64A HDB Housekeeping & Safety Audit Report 13.01.2011Shahid AliNo ratings yet

- 230529Document8 pages230529thanh_79No ratings yet

- C Topic 1 1 en 199903Document7 pagesC Topic 1 1 en 199903Uğur AydemirNo ratings yet

- SECTION 22 15 00 General Service Compressed-Air SystemsDocument8 pagesSECTION 22 15 00 General Service Compressed-Air Systemsm2110No ratings yet

- API 510 Data Sheet - AnswersDocument6 pagesAPI 510 Data Sheet - Answersjithinjose86No ratings yet

- Post Tensioning ManualDocument11 pagesPost Tensioning ManualSatish KumarNo ratings yet

- 9 Cswip 3.1 Welding Notes Unsolved Question With Given Answers Table Most Important Question Answers Solved Past Papers Cswip 3.1Document34 pages9 Cswip 3.1 Welding Notes Unsolved Question With Given Answers Table Most Important Question Answers Solved Past Papers Cswip 3.1patvin3100% (4)

- Distribution Transformers G210-12-1Document14 pagesDistribution Transformers G210-12-1boopelectraNo ratings yet

- PVC 300DataSheetDocument3 pagesPVC 300DataSheetarnella_hNo ratings yet

- High Density Polyethylene (HDPE) Pipe and FittingsDocument8 pagesHigh Density Polyethylene (HDPE) Pipe and FittingsJhe InibamNo ratings yet

- Verification of Lifting EquipmentDocument14 pagesVerification of Lifting EquipmentsurnaikNo ratings yet

- (Pipes & Fittings)Document8 pages(Pipes & Fittings)Santhu MeprathuNo ratings yet

- Inspection Test Plan On Welding Quality ControlDocument12 pagesInspection Test Plan On Welding Quality Controlnike_y2kNo ratings yet

- Document No PCPL-0532-4-407-04-08-1 MV Switchgear Data Sheet Section - 4 PAGE: 1 of 12Document12 pagesDocument No PCPL-0532-4-407-04-08-1 MV Switchgear Data Sheet Section - 4 PAGE: 1 of 12tceterexNo ratings yet

- Pip Elssg11 PDFDocument21 pagesPip Elssg11 PDFAna TorresNo ratings yet

- The 50 Major Engineering FailuresDocument22 pagesThe 50 Major Engineering FailuresMarius Bodea100% (1)

- 2.5 C - SMUH Electrical Systems - Key Materials & ProductsDocument6 pages2.5 C - SMUH Electrical Systems - Key Materials & ProductsmangjuhaiNo ratings yet

- MIG Gas Mix Developed by EdDocument7 pagesMIG Gas Mix Developed by Edc_e_z_a_rNo ratings yet

- UG Syllabus 2010 11 NITtDocument33 pagesUG Syllabus 2010 11 NITtNitin VarmanNo ratings yet

- IC TDA-11115, TDA-11145 Service Manual enDocument24 pagesIC TDA-11115, TDA-11145 Service Manual enJeank Rivadeneyra50% (2)

- ABB Substation Condition Monitoring ScheduleDocument16 pagesABB Substation Condition Monitoring Schedulelbk50No ratings yet

- Asme Boiler and Pressure Vessel Code, Section I Design GuideDocument11 pagesAsme Boiler and Pressure Vessel Code, Section I Design Guidepeach5No ratings yet

- NL Master Specification Guide For Public Funded Buildings: Re-Issued 2009/10/01Document4 pagesNL Master Specification Guide For Public Funded Buildings: Re-Issued 2009/10/01Sharat ChandraNo ratings yet

- Format For Weekly ReportsDocument2 pagesFormat For Weekly ReportsRejoice Chikutye ChakawaNo ratings yet

- CSWIP NotesDocument32 pagesCSWIP NotesWaqar Dar100% (1)

- Aramco Specific Evaluations For WeldingDocument6 pagesAramco Specific Evaluations For WeldingSiddiqui Abdul Khaliq89% (9)

- API 510 Data Sheet - AnswersDocument11 pagesAPI 510 Data Sheet - Answersnikafiq100% (1)

- Galvanizing Procedure PDFDocument7 pagesGalvanizing Procedure PDFkhuzafa50% (4)

- Code General Design GuideDocument12 pagesCode General Design Guidec_nghiaNo ratings yet

- Dokumen - Tips Boq HousingDocument198 pagesDokumen - Tips Boq HousingRaja SekaranNo ratings yet

- API 570 Bench Mark Quiz (1-55)Document56 pagesAPI 570 Bench Mark Quiz (1-55)Christopher Randolph100% (5)

- Iec 62271 202 StandardsenpptxDocument27 pagesIec 62271 202 StandardsenpptxtammamshNo ratings yet

- Wet Wall Panel System July 2010 FDocument8 pagesWet Wall Panel System July 2010 FaggibudimanNo ratings yet

- SECTION 03 37 13 ShotcreteDocument7 pagesSECTION 03 37 13 Shotcretejajun-IchromNo ratings yet

- Process Specification For The Resistance Spot Welding of Battery and Electronic AssembliesDocument19 pagesProcess Specification For The Resistance Spot Welding of Battery and Electronic AssembliesjesycubanNo ratings yet

- O&M Manual For FCUDocument30 pagesO&M Manual For FCUBeatrice Li50% (2)

- Hgu Job List For Sept '08Document3 pagesHgu Job List For Sept '08Alex LeeNo ratings yet

- Dokumen - Tips Cswip 31 Exam AnsDocument32 pagesDokumen - Tips Cswip 31 Exam Anszuheb100% (1)

- M E (Water Resource Engg)Document35 pagesM E (Water Resource Engg)Chandrashekhar KulkarniNo ratings yet

- Rajalakshmi Engineering College, Chennai: EE1402 - High Voltage Engineering PART-A (2 Marks)Document3 pagesRajalakshmi Engineering College, Chennai: EE1402 - High Voltage Engineering PART-A (2 Marks)sasikalasivakumarNo ratings yet

- Kimo Kigaz 200 Combustion Gas Analyzer DatasheetDocument4 pagesKimo Kigaz 200 Combustion Gas Analyzer DatasheetayannathompsoneqsNo ratings yet

- Energy Conversion Lab Manual NewDocument50 pagesEnergy Conversion Lab Manual NewRavi TejNo ratings yet

- Introducing The GEK Gasifier Systems - Rev3Document18 pagesIntroducing The GEK Gasifier Systems - Rev3ettypasewangNo ratings yet

- Project Report: On Analyze Submerged Arc Welding (SAW) With Respect To MIG Welding (GMAW)Document32 pagesProject Report: On Analyze Submerged Arc Welding (SAW) With Respect To MIG Welding (GMAW)Rama Krishna Reddy DonthireddyNo ratings yet

- U-00034-PR-CRT-0001 - Rev.ADocument46 pagesU-00034-PR-CRT-0001 - Rev.AthinhviproNo ratings yet

- Procedure For Fab, Erec & Testing of Abovegroud PipingDocument16 pagesProcedure For Fab, Erec & Testing of Abovegroud Pipingvpsimbu86No ratings yet

- Candidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Document4 pagesCandidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)nike_y2k85% (13)

- Testing of Circuit BreakersDocument19 pagesTesting of Circuit BreakersPradeep Singh100% (2)

- Bechtel France S.A.S.: Reliance Petroleum Limited Jamnagar Export Refinery ProjectDocument22 pagesBechtel France S.A.S.: Reliance Petroleum Limited Jamnagar Export Refinery Projectravi00098No ratings yet

- Advances in Structural Concrete: Association of Engineers, Gaza Governorates, PalestineDocument33 pagesAdvances in Structural Concrete: Association of Engineers, Gaza Governorates, Palestinehanan-3000-1999No ratings yet

- Project RPRTDocument80 pagesProject RPRTVaibhav JainNo ratings yet

- Qap Comments On LV (Dry), LV (Oil) & MVDocument1 pageQap Comments On LV (Dry), LV (Oil) & MVpulasta109No ratings yet

- Final DR Dharmasa HamdonDocument6 pagesFinal DR Dharmasa HamdonSanthosh RMNo ratings yet

- Method Statement For Plumbing Piping Works Rev 01Document46 pagesMethod Statement For Plumbing Piping Works Rev 01sakhrs2000No ratings yet

- Epitaxial Silicon TechnologyFrom EverandEpitaxial Silicon TechnologyB BaligaNo ratings yet

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesFrom EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNo ratings yet

- SPLM Laptop Rev3 PDFDocument13 pagesSPLM Laptop Rev3 PDFkonazoiNo ratings yet

- NDE-6407 Rev0Document116 pagesNDE-6407 Rev0konazoiNo ratings yet

- New Text Document - TXT CGDFDocument1 pageNew Text Document - TXT CGDFkonazoiNo ratings yet

- Inside TT44 Manual p4Document27 pagesInside TT44 Manual p4konazoiNo ratings yet

- Sites Default Files Documentos Gnli 2Document32 pagesSites Default Files Documentos Gnli 2konazoiNo ratings yet

- Emmer2 2012 PDFDocument20 pagesEmmer2 2012 PDFkonazoiNo ratings yet

- file:///C/Users/i.doukas/Desktop/qq - TXT (23/8/2018 11:22:47 AM)Document1 pagefile:///C/Users/i.doukas/Desktop/qq - TXT (23/8/2018 11:22:47 AM)konazoiNo ratings yet

- Emmer2 2012 PDFDocument20 pagesEmmer2 2012 PDFkonazoiNo ratings yet

- Afaqfqa: file:///C/Users/i.doukas/Desktop/qq - TXT (18/4/2018 1:49:04 PM)Document1 pageAfaqfqa: file:///C/Users/i.doukas/Desktop/qq - TXT (18/4/2018 1:49:04 PM)konazoiNo ratings yet

- DfasfDocument1 pageDfasfkonazoiNo ratings yet

- Mpojl VCGCGCGCG GCFM: file:///C/Users/douk/Desktop/a.txt (25/05/2017 7:32:32 PM)Document1 pageMpojl VCGCGCGCG GCFM: file:///C/Users/douk/Desktop/a.txt (25/05/2017 7:32:32 PM)konazoiNo ratings yet

- Sfasffdgsgbsfb: SF - TXT (08/03/2017 3:16:53 PM)Document1 pageSfasffdgsgbsfb: SF - TXT (08/03/2017 3:16:53 PM)konazoiNo ratings yet

- Farafa: 1.txt (19/06/2017 11:39:00 AM)Document1 pageFarafa: 1.txt (19/06/2017 11:39:00 AM)konazoiNo ratings yet

- FRFGTGTGDDocument1 pageFRFGTGTGDkonazoiNo ratings yet

- Adsqfqav ghmjncfm890vcb V FGJH: Aa - TXT (21/03/2017 1:24:33 PM)Document1 pageAdsqfqav ghmjncfm890vcb V FGJH: Aa - TXT (21/03/2017 1:24:33 PM)konazoiNo ratings yet

- Cartolina AGV - Pista GP R Anniversario - 2017 - EU-EnDocument2 pagesCartolina AGV - Pista GP R Anniversario - 2017 - EU-EnkonazoiNo ratings yet

- s1.txt AaaDocument1 pages1.txt AaakonazoiNo ratings yet

- Lav TeamDocument1 pageLav TeamkonazoiNo ratings yet

- t1.txt DDDDDocument1 paget1.txt DDDDkonazoiNo ratings yet

- Rts 1Document1 pageRts 1konazoiNo ratings yet

- Sdgsgsgsgs fdhd36hb: Fa - TXT (17/03/2017 2:21:19 PM)Document1 pageSdgsgsgsgs fdhd36hb: Fa - TXT (17/03/2017 2:21:19 PM)konazoiNo ratings yet

- ANew Text DocumentDocument1 pageANew Text DocumentkonazoiNo ratings yet

- rs1 PDFDocument1 pagers1 PDFkonazoiNo ratings yet

- Dsasdawds: Raq - TXT (18/10/2016 11:57:00)Document1 pageDsasdawds: Raq - TXT (18/10/2016 11:57:00)konazoiNo ratings yet

- Heat ExchangersDocument16 pagesHeat ExchangersNaveen SinghNo ratings yet

- D 103585 X 012Document12 pagesD 103585 X 012konazoiNo ratings yet

- l1.txt AaaaaaaaaaDocument1 pagel1.txt AaaaaaaaaakonazoiNo ratings yet

- Y1.txt AaaaaaaaDocument1 pageY1.txt AaaaaaaakonazoiNo ratings yet

- Vjhbgvujh: CCC - TXT (08/04/2016 10:28:50 AM)Document1 pageVjhbgvujh: CCC - TXT (08/04/2016 10:28:50 AM)konazoiNo ratings yet

- 1cd1269a FWF 8230 SP 0000 0003 - 00RDocument310 pages1cd1269a FWF 8230 SP 0000 0003 - 00RkonazoiNo ratings yet

- ScP031 States LADocument2 pagesScP031 States LAORBeducation100% (4)

- Study: Cbse X Mathematic Pair of Li.. NCERT Question SolutionDocument1 pageStudy: Cbse X Mathematic Pair of Li.. NCERT Question SolutionParth GoyalNo ratings yet

- Zacharaki - A Digital SubtractionDocument14 pagesZacharaki - A Digital Subtractiondorasani99No ratings yet

- Spidi 2017 CatalogueDocument210 pagesSpidi 2017 CatalogueRoman GetmanNo ratings yet

- Lubricant Application: Grease Volumes and FrequenciesDocument7 pagesLubricant Application: Grease Volumes and FrequenciesAmjedNo ratings yet

- Belt Drives CalculationDocument15 pagesBelt Drives CalculationmalharNo ratings yet

- Introduction - Spectro-Chrome MetryDocument4 pagesIntroduction - Spectro-Chrome MetryitounosNo ratings yet

- Topic 6 Plumbing & Sanitary (2012) Stud-1Document30 pagesTopic 6 Plumbing & Sanitary (2012) Stud-1LuisLoNo ratings yet

- Cv218 4 Get The Part BuilderDocument24 pagesCv218 4 Get The Part BuilderMiles MathesonNo ratings yet

- Electromagnetic EngineDocument2 pagesElectromagnetic EngineGiri Wip NxNo ratings yet

- Chemical Engineering Graduate Transport - HW 3Document3 pagesChemical Engineering Graduate Transport - HW 3Luthfir RahmanNo ratings yet

- Handbook of Lubrication and TribologyDocument1,139 pagesHandbook of Lubrication and Tribologydouglas100% (5)

- Specification For Polymer Pin InsulatorDocument9 pagesSpecification For Polymer Pin InsulatorBinay PaudyalNo ratings yet

- Corrosion Control MethodsDocument4 pagesCorrosion Control MethodsYousuf MemonNo ratings yet

- Bivariate Data ProjectDocument5 pagesBivariate Data ProjectTrang VuNo ratings yet

- Kalkulasi Steam Trap MFO Rev 00Document20 pagesKalkulasi Steam Trap MFO Rev 00Rifka AisyahNo ratings yet

- API Astm IP: Specific Gravity Gravity Density API APIDocument1 pageAPI Astm IP: Specific Gravity Gravity Density API APIمحمد مNo ratings yet

- Guide To Better GuardingDocument20 pagesGuide To Better GuardingLew MingNo ratings yet

- BU FCAI BS111 P&S Lec08Document66 pagesBU FCAI BS111 P&S Lec08صلاح متوليNo ratings yet

- NR 320103 Irrigation EngineeringDocument8 pagesNR 320103 Irrigation EngineeringSrinivasa Rao GNo ratings yet

- Activation Sequence Ror Smoke Exnuast Tans Smoke Exhaust Fan Status of Fan SZ-B1-01Document19 pagesActivation Sequence Ror Smoke Exnuast Tans Smoke Exhaust Fan Status of Fan SZ-B1-01kkmsNo ratings yet

- Eriez Sl08 Lifting Magnets BrochureDocument24 pagesEriez Sl08 Lifting Magnets Brochuredante224No ratings yet

- Rittal SK - 3302100 PDFDocument49 pagesRittal SK - 3302100 PDFSisminto Hardjo100% (3)

- L Inverted Siphon 3rd CDocument6 pagesL Inverted Siphon 3rd CPreston VargheseNo ratings yet

- All Physics Formula and Glossary - GCE Study Buddy - The Best O Level Revision ResourceDocument13 pagesAll Physics Formula and Glossary - GCE Study Buddy - The Best O Level Revision ResourceVei Adoptante100% (2)

- TDS Gabion Galvanized PDFDocument2 pagesTDS Gabion Galvanized PDFdinah musyawarohNo ratings yet

- Soil Engineering & Geotechnics: Analysis of Potential ProblemsDocument1 pageSoil Engineering & Geotechnics: Analysis of Potential ProblemsdzingoNo ratings yet

- Primary Checkpoint - Science (0846) October 2016 Paper 1 PDFDocument20 pagesPrimary Checkpoint - Science (0846) October 2016 Paper 1 PDFdinakarc88% (8)

- Mechanical Properties of Metals - IIDocument33 pagesMechanical Properties of Metals - IIarulmuruguNo ratings yet

- RLX Precision Range-8pDocument8 pagesRLX Precision Range-8pAngela MarkovskaNo ratings yet