Professional Documents

Culture Documents

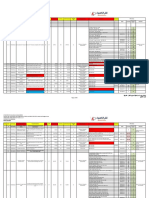

Dhofar Power Company Saog: Mott Macdonald

Uploaded by

54045114Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dhofar Power Company Saog: Mott Macdonald

Uploaded by

54045114Copyright:

Available Formats

Dhofar Power Company SAOG

Mott MacDonald

All bolt threads shall be coated with an approved grease immediately before erection. 8.4 Protective Treatment

All insulator caps, bases and pins shall either be inherently be resistant to atmospheric cOlTosion or suitably protected against corrosion, such as may occur in transit, storage and in service. All ferrous parts, which will be exposed to the atmosphere in service, except those made in the appropriate grade of stainless steel, shall be protected by hot dip galvanizing to comply with requirements of ISO 1416. All manufacturing process shall be cOlnpleted before galvanizing. The ingot zinc used for galvanizing shall comply with requirements of BS EN 1179. All galvanized material shall be stored on packing, clear off ground and away from all materials that might stain or cOlTode the galvanizing. Black steel packing or bins shall not be used. 8.5 8.5.1 Fittings Insulator and Conductor fittings

For design, construction, and quality control of insulator and conductor fittings, refer Section 9. 8.5.2 Arc Horns

Arc horns shall be provided at the line and earth end of all insulator sets. The arc horns used at substation ends shall be adjustable type, such that the horn gaps are set at the required value. Contractor shall provide design calculations showing proof for the gap length set on non-adjustable and adjustable arc horns. Arc horns shall protect the insulators, insulator assembly and conductor from damage from a power arc. Protection devices may reach a final telnperature not exceeding 400C during the short-circuit. This requirement is met considering a short circuit current density of 70 Almm2 of electrode, duration 1 second. The function of the arcing protection shall not be greatly altered by the power arc. The arcing devices shall protect the insulators against the thermal and other effects of the power arcs and assist in equalising electrical stresses around the live end of insulator strings. The arcing devices shall be designed to enclose the insulator end cap. Arcing devices shall be capable of withstanding the full fault current at any point in the component. The design of the single arc contact point (burn point) shall be such as to ensure that erosion does not significantly impair the performance of the arcing device, (ie. spherical), that the insulator is shielded and that the arc discharge is directed away from the insulator. Arcing accessories shall where appropriate be of galvanized solid steel construction of material at least 16mm in diameter. The lower component in a suspension set arrangement shall be designed to support the weight of a 90kg man standing on the fitting with adequate security. The dimensions of the arcing devices shall be appropriate to the insulator types and the thermal and dynamic stresses at the highest system voltage. Tension set arc horns shall provide for a single arc path above the upper surface of the insulator set. The design of arc horns shall be such as to prevent cascading of the arc over the line end of the insulator unit

Construction of 132kV Overhead line between Awqad GSS & SFZ GSS and Associated Works (Package-1) Volume 2 Overhead Line Specification Section 8 Long Rod Silicone Rubber Insulators

~

Rev. No. Date Page

'C~_"."''''''.''

:A : December 2010 :Page 7 of 16

...-.. ...........

~

-,~-

You might also like

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- 12 SwitchyardErectionRev07Document91 pages12 SwitchyardErectionRev07Rajesh Sirigirisetty SNo ratings yet

- 11KV TRANSMISSION LINES SpecificationDocument16 pages11KV TRANSMISSION LINES SpecificationIwan Tristiawan0% (1)

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- APTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedDocument13 pagesAPTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedAshutosh SharmaNo ratings yet

- Catalogue Long RodDocument10 pagesCatalogue Long RodTravis WoodNo ratings yet

- 11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesDocument64 pages11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesPradeepKrYadavNo ratings yet

- Insulator SpecificationDocument22 pagesInsulator SpecificationtanujaayerNo ratings yet

- Transmission Insulator SpecificationDocument0 pagesTransmission Insulator Specificationrenjithas2005No ratings yet

- Wrought Ironwork - A Manual of Instruction for Rural CraftsmenFrom EverandWrought Ironwork - A Manual of Instruction for Rural CraftsmenRating: 5 out of 5 stars5/5 (1)

- Accessories For Medium Voltage Distribution Networks LRDocument56 pagesAccessories For Medium Voltage Distribution Networks LRDamir RaljevićNo ratings yet

- 9 InsulatorDocument39 pages9 InsulatorLeo KhkNo ratings yet

- 9 InsulatorDocument39 pages9 InsulatorLeo KhkNo ratings yet

- Analysis Lightning Over Voltage 500kVDocument5 pagesAnalysis Lightning Over Voltage 500kVSteve BootmanNo ratings yet

- Commissioning Switches, Medium & High VoltageDocument53 pagesCommissioning Switches, Medium & High Voltagebookbum100% (2)

- Spec (1) .11 KV Rocking Type Tpgo IsolatorDocument7 pagesSpec (1) .11 KV Rocking Type Tpgo Isolatorarindam90No ratings yet

- Polymer Pin Insulator SpecificationDocument14 pagesPolymer Pin Insulator SpecificationdamlanNo ratings yet

- Design & Testing of ZnO Lightening ArresterDocument19 pagesDesign & Testing of ZnO Lightening ArrestersureshnfclNo ratings yet

- MV DISTRIBUTION NETWORK ACCESSORIESDocument52 pagesMV DISTRIBUTION NETWORK ACCESSORIESFedericoNo ratings yet

- 220kV GIS Tech Spec - TrackDocument42 pages220kV GIS Tech Spec - Trackaravind_k104100% (1)

- Copper Bus Duct SpecDocument135 pagesCopper Bus Duct SpecChilamkurti Siva Sankara Rao100% (2)

- 2 ++Switchyard+erection+for+400kVDocument56 pages2 ++Switchyard+erection+for+400kVracing.phreakNo ratings yet

- PellDocument49 pagesPellsohaibNo ratings yet

- 10 IsolatorDocument11 pages10 Isolatorraj_stuff006No ratings yet

- 11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesDocument61 pages11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesHemant KumarNo ratings yet

- Technical SpecificationDocument14 pagesTechnical SpecificationbinodeNo ratings yet

- ACSR Some Equal Standards-Indian StandardDocument20 pagesACSR Some Equal Standards-Indian StandardHabib EmamiNo ratings yet

- Dry Type Transformer Spec in Word FormatDocument25 pagesDry Type Transformer Spec in Word Formatarulraj1971No ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- LV Power Cable Specification - 06.11.2009Document10 pagesLV Power Cable Specification - 06.11.2009ErAkashAryanNo ratings yet

- Dhofar Power Company SAOG: 9.4 Corrosion ProtectionDocument1 pageDhofar Power Company SAOG: 9.4 Corrosion Protection54045114No ratings yet

- Ti SPC Ohe Inscom 1070Document23 pagesTi SPC Ohe Inscom 1070hardeepsingh_08No ratings yet

- WBSEDCL LT ABC Accs. SpecDocument8 pagesWBSEDCL LT ABC Accs. SpecahmedNo ratings yet

- Is 2551Document44 pagesIs 2551sankaractecheeeNo ratings yet

- RFP For LT PanelDocument13 pagesRFP For LT Panelsourendra prasad karan100% (1)

- 8.2.2 Electrical and Mechanical Characteristics: Dhofar Power Company SAOGDocument1 page8.2.2 Electrical and Mechanical Characteristics: Dhofar Power Company SAOG54045114No ratings yet

- DO Fuse UnitDocument8 pagesDO Fuse UnitImran KhanNo ratings yet

- Specification For 33 KV PTDocument7 pagesSpecification For 33 KV PTPapun Scribd100% (1)

- LT AcdbDocument44 pagesLT Acdbanu2013No ratings yet

- Technical Information PDFDocument24 pagesTechnical Information PDFsouheil boussaidNo ratings yet

- Technical Specification for Medium Voltage Cables, Street Light Poles, Fittings and Feeder Pillar DBDocument5 pagesTechnical Specification for Medium Voltage Cables, Street Light Poles, Fittings and Feeder Pillar DBAnonymous EVFw59No ratings yet

- Non-Segregated Bus Duct SpecsDocument8 pagesNon-Segregated Bus Duct SpecsGanesh KumarNo ratings yet

- Technical Specification For 11 KV AB Switch 400ADocument8 pagesTechnical Specification For 11 KV AB Switch 400AdillehNo ratings yet

- Medium Voltage Composite InsulatorsDocument14 pagesMedium Voltage Composite Insulatorsdeepthik27No ratings yet

- TST 04 Insulator Stringset OkeDocument6 pagesTST 04 Insulator Stringset Okerostyo tioNo ratings yet

- 6.8 Construction: 6.8.1 Rectifiers and ThyristorsDocument1 page6.8 Construction: 6.8.1 Rectifiers and ThyristorsSatyasrinivas PulavarthiNo ratings yet

- Section-Viii: Composite Long Rod InsulatorDocument33 pagesSection-Viii: Composite Long Rod Insulatorsaravanan jNo ratings yet

- Electrical Specification-89-102Document14 pagesElectrical Specification-89-102NUpurNo ratings yet

- Insulator: PackingDocument8 pagesInsulator: PackingZeeshan SubhaniNo ratings yet

- Insulator: PackingDocument8 pagesInsulator: PackingZeeshan SubhaniNo ratings yet

- MV and LV cable technical requirementsDocument5 pagesMV and LV cable technical requirementsFor AppsNo ratings yet

- (ERECTION PROCEDURE Insulation-Lagging) - BiddingDocument5 pages(ERECTION PROCEDURE Insulation-Lagging) - BiddingnuntaricherdchaiNo ratings yet

- T S For Power TransformerDocument11 pagesT S For Power TransformerAbhijeet Kumar SinghNo ratings yet

- 15 Sec Technical Rev 0Document13 pages15 Sec Technical Rev 0mohanksebNo ratings yet

- Technical Specs - C-EPR - RevbDocument5 pagesTechnical Specs - C-EPR - Revbgerrzen64No ratings yet

- Dhofar Power Company Saog: Matt MacdonaldDocument1 pageDhofar Power Company Saog: Matt Macdonald54045114No ratings yet

- Sec-09 Electrical Works and InstallationDocument6 pagesSec-09 Electrical Works and InstallationOmer HayatNo ratings yet

- Tower AccessoriesDocument2 pagesTower AccessoriesmulualemNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Check Aadhaar StatusDocument2 pagesCheck Aadhaar Status54045114No ratings yet

- Bill2 Jan Paschimanchal Vidyut Vitran Nigam LTDDocument1 pageBill2 Jan Paschimanchal Vidyut Vitran Nigam LTD54045114No ratings yet

- sssssss10 17 PDFDocument1 pagesssssss10 17 PDF54045114No ratings yet

- Untitled 1Document68 pagesUntitled 154045114No ratings yet

- sssssss10 17 PDFDocument1 pagesssssss10 17 PDF54045114No ratings yet

- Minnesota and Wisconsin county home sale prices 2012-2013Document80 pagesMinnesota and Wisconsin county home sale prices 2012-201354045114No ratings yet

- Construction Types: Split CoreDocument1 pageConstruction Types: Split Core54045114No ratings yet

- Insulation of A Core Pile: January 19, 2016Document1 pageInsulation of A Core Pile: January 19, 201654045114No ratings yet

- sssssss10 17Document1 pagesssssss10 1754045114No ratings yet

- Electrical maintenance tender detailsDocument1 pageElectrical maintenance tender details54045114No ratings yet

- Current Transformer Secondary Types: IEEE C57.13 IEC 60044-1Document1 pageCurrent Transformer Secondary Types: IEEE C57.13 IEC 60044-154045114No ratings yet

- sssssss10 04Document1 pagesssssss10 0454045114No ratings yet

- Questions ?: Thank YouDocument1 pageQuestions ?: Thank You54045114No ratings yet

- Equipment Exceptions List Sheet 1 of 1Document1 pageEquipment Exceptions List Sheet 1 of 154045114No ratings yet

- sssssss10 01Document1 pagesssssss10 0154045114No ratings yet

- Current Transformer Basics GuideDocument1 pageCurrent Transformer Basics Guide54045114No ratings yet

- Viewtenddoc 13Document1 pageViewtenddoc 1354045114No ratings yet

- Government of India Department of Posts (Civil Wing) : Notice Inviting TenderDocument1 pageGovernment of India Department of Posts (Civil Wing) : Notice Inviting Tender54045114No ratings yet

- Viewtenddoc 6Document1 pageViewtenddoc 654045114No ratings yet

- 23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.00Document1 page23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.0054045114No ratings yet

- Earnest Money Bank Guarantee TitleDocument1 pageEarnest Money Bank Guarantee Title54045114No ratings yet

- Oil Gas Industry GuidelinesDocument90 pagesOil Gas Industry GuidelinesAdhia Prenata Putra HuzaNo ratings yet

- Viewtenddoc 6Document1 pageViewtenddoc 654045114No ratings yet

- Government of India Department of Posts (Civil Wing) : Notice Inviting TenderDocument1 pageGovernment of India Department of Posts (Civil Wing) : Notice Inviting Tender54045114No ratings yet

- 23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.00Document1 page23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.0054045114No ratings yet

- Rated Voltage of Circuit Breaker: Current CurrentDocument2 pagesRated Voltage of Circuit Breaker: Current Current54045114No ratings yet

- Viewtenddoc 3Document1 pageViewtenddoc 354045114No ratings yet

- CTDocument1 pageCT54045114No ratings yet

- EOCR CatalogueDocument12 pagesEOCR Catalogue54045114No ratings yet

- 11 KW Tertiary Treatment Feed PumpDocument4 pages11 KW Tertiary Treatment Feed Pump54045114No ratings yet

- Detection of Corona Effect On Composite InsulatorsDocument10 pagesDetection of Corona Effect On Composite Insulatorsnamsaigon316No ratings yet

- Comp Ins PDFDocument7 pagesComp Ins PDFramsesiNo ratings yet

- ECE 765 - Module 1 - FinalDocument51 pagesECE 765 - Module 1 - FinalNamiraNo ratings yet

- C5. QCC - Young's Express - Electricity Generating Authority of ThailandDocument29 pagesC5. QCC - Young's Express - Electricity Generating Authority of ThailandRSUK Kramat Jati DiklatNo ratings yet

- Transmission Line Item BoqDocument1 pageTransmission Line Item BoqanbilselvamNo ratings yet

- Surge Arrester PresentationDocument63 pagesSurge Arrester PresentationRamiro FelicianoNo ratings yet

- Arcing Horn Gap DistanceDocument2 pagesArcing Horn Gap DistanceOktarico Pradana100% (1)

- Session 1998: 21, Rue D'artois, F-75008 Paris © CigréDocument7 pagesSession 1998: 21, Rue D'artois, F-75008 Paris © Cigrémartin mannoneNo ratings yet

- Evaluation of The Damage Caused by Bird Pecking Activity Along Composite High Voltage InsulatorsDocument4 pagesEvaluation of The Damage Caused by Bird Pecking Activity Along Composite High Voltage InsulatorsAlison BaenaNo ratings yet

- K3-Siemens 8WL6114-0 PDFDocument38 pagesK3-Siemens 8WL6114-0 PDFVictor Manuel BonettoNo ratings yet

- Substation CatalogDocument40 pagesSubstation CatalogjuliancansenNo ratings yet

- Disc Insulator PDFDocument0 pagesDisc Insulator PDFamit77999100% (1)

- Insulation - Coordination of - Arcing Horns - On - HVDC - Electrode - Lines - Protection - Perforance - Evaluation - Influence - Factors - and - Improvement - Method PDFDocument19 pagesInsulation - Coordination of - Arcing Horns - On - HVDC - Electrode - Lines - Protection - Perforance - Evaluation - Influence - Factors - and - Improvement - Method PDFLuis Angel PerezNo ratings yet

- Loop Switching PDFDocument176 pagesLoop Switching PDFshawnr7376No ratings yet

- Effect of Externally Gapped Line Arrester Placement On Insulation Coordination of A Twin-Circuit 220 KV LineDocument7 pagesEffect of Externally Gapped Line Arrester Placement On Insulation Coordination of A Twin-Circuit 220 KV LinewhitedaisyvenusNo ratings yet

- Tower Footing Resistance and Lightning TDocument9 pagesTower Footing Resistance and Lightning TiaessackjeeNo ratings yet

- Hassa MSD Format Operational Spare For 4400003961Document40 pagesHassa MSD Format Operational Spare For 4400003961Prabhakar SvNo ratings yet

- TSG SRF: Triggered Spark Gap Surge Reduction FiltersDocument8 pagesTSG SRF: Triggered Spark Gap Surge Reduction FiltersAngela TienNo ratings yet

- 7225-Ichve2010 - Jankov - HVDC System Performance With A Neutral Conductor - V1Document5 pages7225-Ichve2010 - Jankov - HVDC System Performance With A Neutral Conductor - V1Anonymous OpLDOPNo ratings yet

- 110kV 1250A isolator technical parametersDocument19 pages110kV 1250A isolator technical parametersneerajNo ratings yet

- Arcing HornDocument2 pagesArcing HornSureshraja9977100% (1)

- Frequently Asked Questions (Faqs)Document16 pagesFrequently Asked Questions (Faqs)Pamela BradleyNo ratings yet