Professional Documents

Culture Documents

An Engineering Method To Mitigate The Impact of Regulatory Focus On Relief System Installations by Prioritizing Risk

Uploaded by

kirandevi1981Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Engineering Method To Mitigate The Impact of Regulatory Focus On Relief System Installations by Prioritizing Risk

Uploaded by

kirandevi1981Copyright:

Available Formats

GCPS 2013 __________________________________________________________________________

An Engineering Method to Mitigate the Impact of Regulatory Focus on Relief System Installations by Prioritizing Risk Dustin Smith Smith & Burgess 5700 NW Central Dr. Ste 301 Houston, TX 77092 dustin.smith@smithburgess.com

Smith & Burgess LLC grants AIChE permission for itself and its designated agents to reproduce, sell, or distribute your paper. Copyright to this paper is retained by Smith & Burgess LLC, from whom permission to reproduce must be obtained by any other party. All information deemed reliable but may not be applicable to any given installation. Any risk assessment or safety analysis should be independently verified by a qualified engineer.

Prepared for Presentation at American Institute of Chemical Engineers 2013 Spring Meeting 9th Global Congress on Process Safety San Antonio, Texas April 28 May 1, 2013 UNPUBLISHED

AIChE shall not be responsible for statements or opinions contained in papers or printed in its publications

GCPS 2013 ____________________________________________________________________

An Engineering Method to Mitigate the Impact of Regulatory Focus on Relief System Installations by Prioritizing Risk

Dustin Smith Smith & Burgess 5700 NW Central Dr. Ste 301 Houston, TX 77092 dustin.smith@smithburgess.com Keywords: Pressure Relief Valve Installation, API 3% Rule, Chatter, Relief Device Stability Abstract Since around 2005, regulators in the United States have put greater emphasis on relief device installations meeting the 3% rule. Spending large amounts of money to "fix" relief device installations that pose no safety risk decreases the plant's overall safety. To date, more incidents have occurred during facility construction / modifications than due to relief device chatter. This paper presents a method to assist engineers in determining if relief devices are susceptible to chatter. The methodology in this paper provides an engineering study to determine if existing installations are safe, which are allowed in the relevant engineering standards (API STD 520), and shows the research data by which it was validated. The model is used as a screening method that places the relief devices into two categories: (1) those installations that may chatter and (2) those installations that need no further review. The goal of any experimental comparison is that the model will error on the side of predicting chatter, but will be reliable enough to screen valves. In addition to presenting the model, this paper will compare instances of known chatter to research conducted by API and work done by the Electric Power Research Institute in the 1980s. Thus far, based on research and acquired information, the method predicted all instances of chatter known to the authors. By providing a screening methodology that is supported by experimental data, plants can focus their spending on fixing real safety issues by identifying which relief installations are not expected to chatter. The paper will close by giving a brief explanation of the on-going research in relief valve stability.

GCPS 2013 ____________________________________________________________________

1. Introduction

In November 2011, Hydrocarbon Processing published a paper that documented a method to determine if relief devices were susceptible to chatter. Other methods are being developed to determine the chances of chatter for a specific installation; however, the model discussed in the published paper is the only screening method that places the relief devices into two categories: (1) those installations that may chatter and (2) those installations that need no further review. The goal of any experimental comparison is that it will error on the side of predicting chatter, but will be reliable enough to screen valves. Since the publication of that article, the Oil & Gas industry has continued to struggle with the issue of relief device stability, so much so that API delayed issuance of API STD 520 Part II Sizing, Selection, and Installation of Pressure-Relieving Devices in Refineries-Part II, Installation. This paper compares instances of known chatter to research conducted by API, and uses this comparison to evaluate the model. Thus far, based on research and all acquired information, the method predicted all instances of chatter known to the authors. This paper summarizes the analysis methods and validation for vapor service valves. The November 2011, Hydrocarbon Processing paper documents analysis methods for twophase and liquid services. The focus on vapor / gas service valves is based on the validation data for these services analyzed herein.

2. Summary of the Stability Screening Method

The following is a summary of items used to confirm if chattering is likely to occur. Refer to the published paper for an extensive discussion of the methodology: 1. Confirm that the inlet line length is within the criteria to ensure that the pressure wave decay is not high enough to cause valve instability. The following equation (from Frommann & Friedel, Source 4) is used for this criteria:

Li < 45,390

d i2 w%O

PS PRC P S

(PS PB ) t o

Equation 1

2. Confirm that the systems frictional and acoustic losses are less than the difference between the operating pressure and the valves closing pressure. The formula for estimating the acoustical losses (from Singh, Source 5) is presented below:

PAcoustic

LwPSV 1 = + 2 12.6d i tO 10.5

wPSV L cd t i O

Equation 2

GCPS 2013 ____________________________________________________________________

3. Ensure that stability will not be compromised due to vortex shedding in the inlet line (this phenomenon occurs during normal operation and is generally not associated with relief conditions).

Li < di c 2 .4 U

Equation 3

4. Ensure that the relief rate or system size is at sufficient capacity to confirm that chattering will not occur from being oversized. For vapor service relief devices, this is assumed to not occur if the open-close cycle time for the system is greater than 1 second. This cycle is broken into two components: the time it takes for the system pressure to increase from the relief devices blowdown/closing pressure to the set pressure and the time it takes for the system to depressure through the relief valve from the set pressure to the blowdown/closing pressure. This is represented by the following equation.

1 > tcycle = t PRC PS + t PS PRC

Equation 4

5. Ensure that the relief device is installed per the manufacturers and/or general installation guidelines. These guidelines are shown in the catalogs, ASME B&PVC Section VIII, API STD 520, etc. 6. Review the valves operational history to ensure that there is no known history of chatter. For a complete discussion on the methodology of this analysis, the reader is referred to the work published by Smith Et. al, as the discussion is not further expanded in this paper.1 Note that equation 17 does not follow the verbiage, and the less than sign should be replaced with a greater than sign.

3. Acceptance Criteria

This model is the only screening method to place the relief devices into two categories: (1) those installations that may chatter and (2) those installations that need no further review. The goal of any experimental comparison is that it will error on the side of predicting chatter, but will be reliable enough to screen valves. The author considers this model to be reliable as an engineering screening tool if the following criteria are met:

High Correlation to Experimental Data If the method predicts that valves will chatter and valves wont chatter most of the time, then it is a viable screening tool given the low cost of performing the analysis compared to making piping modifications.

GCPS 2013 ____________________________________________________________________

No False Negatives The screening tool will be considered valid so long as it does not predict any installations as safe (no chatter) when in fact chatter was experimentally found. Limited False Positives Given that the method is a conservative screening tool, some level of false positives are to be expected. This includes instances when the model would indicate the possibility of chatter when experimental results show valve stability. Screens Valves as Acceptable The model will only be of value if the results of the model result in existing installations not requiring further modification. Based on the results presented in the referenced paper, 50% of the installations with inlet pressure losses greater than 3% were deemed acceptable as is.

The model, therefore, will be deemed conservative and reliable if the previous four criteria are met.

4. Comparisons / Validations

To confirm the validity of the procedure, the procedure has been reviewed against all cases of chatter known to the authors. The cases are divided into three different categories: 1. Known Installations These installations are those that are known by the authors to have failed with a loss of containment and those installations that have sufficient information to perform the analysis. The information for some of the installations is not available in the public domain, as the confidentiality of these installations has been preserved. 2. ASME Studies In the 80s, Zahorsky performed a set of research for the nuclear industry in which they experimentally set the blowdown as the minimum percentage needed for stable operation2. In order to meet the acceptance criteria, therefore, this method should determine that these installations are unstable. The results were re-checked with an increased blowdown of 2% above what the author listed to see what would happen. 3. API PERF Studies In 2011 the results of the API PERF study were presented at the API 520 Committee meeting. In this work, the API subgroup tested 18 different valves with three different inlet line lengths to determine when chatter would occur. The results of the 54 trials were introduced in their presentation (some combinations were not tested).

GCPS 2013 ____________________________________________________________________

5. Results

The following are the results of the comparisons: Table 1 lists the results of the model comparison with the valves that have had a loss of containment where inlet line chatter was the cause or a contributor to the incident. The model predicted the potential for chatter for each of these installations.

Table 1: Summary of known installations that have chattered Installation Service Chatter Data Source Predicted Refinery, North Liquid Yes Internal company incident America investigation Gas Plant, Middle Vapor Yes Internal company incident East investigation Refinery, North Liquid Yes Internal company incident America investigation Refinery, North Liquid Yes API Published Document 3 America

Table 2 lists the blowdown at which the relief devices do not chatter as experimentally determined by Zahorsky. The table also lists the blowdown at which the model would predict stability. The difference between the two values can be taken as an estimate to which the model is conservative. Since the blowdown was experimentally set as the minimum percentage, the model is accurate, as it predicts false positives for these devices.

Table 2: Comparison of minimum predicted blowdown to the results experimentally derived by Zahorsky Run Experimentally Predicted Acceptable ( Blowdown) Case Determined Blowdown Blowdown Predicted Expermintal) 1 3.9% 4% 0.1% 2 3.9% 5.6% 1.7% 3 5.6% 9.7% 4.1% 4 8.4% 16.7% 8.3% 5 8.3% 12.6% 4.3% 6 4.3 5.3 1.0%

Table 3 lists the comparison of the model results to the experimental PERF results. The model had agreement ~72% of the time if the cases that were not tested were excluded. If one assumes that the results for the untested cases would have chattered, the agreement is ~76%. Of the cases that the model did not agree with the experimental results, the model always predicted chatter on stable valves; thus, the model is accurately screening and is slightly conservative.

GCPS 2013 ____________________________________________________________________

Table 3: Comparison of the model to the API PERF Study Results Model PERF Results Model No. Of Correlation Prediction Cases Agreement Chatter Chatter 9 Agreement Stable Stable 25 False Negative Chatter Stable 0 False Positive Stable Chatter 15 Agreement Not Tested Chatter 7 Note 1: There are a number of cases that were not tested, but were assumed to chatter as the reason for not being tested was not included.

6. Conclusion

The model results always predicted when valves may chatter (need modifications). There are no instances of valves that have chattered where the model predicted stability.

High Correlation to Experimental Data There is a 70% to 75% agreement with the API PERF Studies and all industry installations with known chatter where identified with the model. This model predicted if a valve would chatter accurately 75% of the time (see the next item on false negatives). No False Negatives No cases of chatter were found when the model predicted stable operation. Limited False Positives 25% of the PERF study valves that were stable indicated that chatter was possible. Also, the work by Zahorsky indicated that the model predicts stable operation with an inlet blowdown generally 2% to 4% greater than needed.

The model, therefore, is a reliable method to screen relief devices based on the comparison to 60+ experimental and industrial data points.

7. Notation

The equations presented in this paper are dimensional and the following listing explains the variables and unit set. c = speed of sound (ft/s) d = diameter (in) L = length (ft) P = pressure (psig) t = time (s) U = process fluid velocity as it passes the PSV nozzle (ft/s) w = mass flow rate (lb/s) Greek Letters = fluid density (lb/ft)

GCPS 2013 ____________________________________________________________________

Subscripts B = backpressure on relief device i = inlet o = opening PSV = process safety valve RC = valve reclosing pressure S = relief device set pressure %O = flow rate at the valves percent open

8. References

[1] [2] [3] [4] Smith, Dustin P.E., John Burgess P.E., and Craig Powers PhD. "Relief Device Inlet Piping: Beyond the 3% Rule." Hydrocarbon Processing. 2011. Zahorsky, J.R. Testing and Analysis of Safety/Relief Valve Performance. The ASME Winter Annual Meeting. November 15-19, 1982. Atlanta, GA Myers, DF, Conoco. "Denver Refinery Fire." API. 1986. Frommann, O. and Friedel, L. Analysis of safety relief valve chatter induced by pressure waves in gas flow. Journal of Loss Prevention in the Process Industries. 1998. Singh, A. On the Stability of a Coupled Safety Valve-Piping System. The ASME Winter Annual Meeting. November 15-19, 1982. Atlanta, GA.

[5]

You might also like

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Reliability Prediction from Burn-In Data Fit to Reliability ModelsFrom EverandReliability Prediction from Burn-In Data Fit to Reliability ModelsRating: 3 out of 5 stars3/5 (2)

- Maintenance Ass Q1Document6 pagesMaintenance Ass Q1Samatha Farai ZviuyaNo ratings yet

- Pipeline Leak Detection Study - OTH94Document58 pagesPipeline Leak Detection Study - OTH94ElcioDiasJrNo ratings yet

- Procedure Natural Gas Piping Purging HazardsDocument4 pagesProcedure Natural Gas Piping Purging HazardsEko KurniawanNo ratings yet

- A Cost Effective Simulation Algorithm FoDocument40 pagesA Cost Effective Simulation Algorithm FoSimon van BentenNo ratings yet

- Simplified Calibration Interval AnalysisDocument8 pagesSimplified Calibration Interval AnalysisCarlos RoqueNo ratings yet

- PERD Predicting Relief Valve ReliabilityDocument6 pagesPERD Predicting Relief Valve ReliabilityMOhamad YarmohamadiNo ratings yet

- Proof Testing of Safety Instrumented Systems in The Onshore ChemicalDocument13 pagesProof Testing of Safety Instrumented Systems in The Onshore ChemicalmuathudongNo ratings yet

- EXIDA: Estimating The Beta Factor 1Document7 pagesEXIDA: Estimating The Beta Factor 1Kareem RasmyNo ratings yet

- Strategies of Succesful Distillation Equipment Revamps PDFDocument6 pagesStrategies of Succesful Distillation Equipment Revamps PDFJose DavalilloNo ratings yet

- Fad Api 579 PDFDocument11 pagesFad Api 579 PDFMalik BetaNo ratings yet

- Boiler OH Intervals-EPRIDocument93 pagesBoiler OH Intervals-EPRIBhargav Chaudhari100% (1)

- Some Fiber Optic Measurement ProceduresDocument6 pagesSome Fiber Optic Measurement ProceduresAmir SalahNo ratings yet

- Robustness Valdiation Step by StepDocument36 pagesRobustness Valdiation Step by StepGreenheart OussamaNo ratings yet

- Balancing Mechanical and Instrumented Protections in Brownfield ProjectsDocument11 pagesBalancing Mechanical and Instrumented Protections in Brownfield Projectskirandevi1981No ratings yet

- Simplified Calibration Interval AnalysisDocument8 pagesSimplified Calibration Interval AnalysisRoy HowardNo ratings yet

- 4.SIL Studies ExternalDocument12 pages4.SIL Studies ExternalHarivanan ShanmugamNo ratings yet

- A Strategy For The Risk-Based Inspection of Pressure Safety Valves (2009) PDFDocument9 pagesA Strategy For The Risk-Based Inspection of Pressure Safety Valves (2009) PDFHabibie RahmanNo ratings yet

- Agilent Calibration FrequencyDocument6 pagesAgilent Calibration Frequencyzilangamba_s4535No ratings yet

- Setting and Adjusting Instrument Calibration Intervals: Application NoteDocument6 pagesSetting and Adjusting Instrument Calibration Intervals: Application NoteJennifer McdanielNo ratings yet

- Valve OnLine TestDocument7 pagesValve OnLine TestnisiagorethNo ratings yet

- The Use of Portable Hardness Testing in FieldDocument120 pagesThe Use of Portable Hardness Testing in Fieldantant3052No ratings yet

- Selecting Particle Count Points For A Continuous FMS System - Manufacturing & Packaging - NG Pharmaceutical Europe - GDS PublishingDocument3 pagesSelecting Particle Count Points For A Continuous FMS System - Manufacturing & Packaging - NG Pharmaceutical Europe - GDS PublishingDavide GrioniNo ratings yet

- Understanding The Results of An Intelligent Pig InspectionDocument18 pagesUnderstanding The Results of An Intelligent Pig InspectionLeonardo VazNo ratings yet

- Inspection Quality Depends On People, Procedures, and PoliciesDocument10 pagesInspection Quality Depends On People, Procedures, and PoliciesRaja ANo ratings yet

- Condition Based MaintenanceDocument18 pagesCondition Based Maintenancedshalev8694No ratings yet

- Assessment of The Licensing of ThorCon Reactors in IndonesiaDocument9 pagesAssessment of The Licensing of ThorCon Reactors in IndonesiaBobSoelaimanEffendiNo ratings yet

- Gage Repeatability and Reproducibility PDFDocument4 pagesGage Repeatability and Reproducibility PDFsebastiantobon85No ratings yet

- Flaw Detection and Characterization in Welded Samples Used For Ultrasonic System QualificationDocument6 pagesFlaw Detection and Characterization in Welded Samples Used For Ultrasonic System Qualificationcal2_uniNo ratings yet

- Uncertainity Measurement Requirements of ISO IEC 17025 2005Document28 pagesUncertainity Measurement Requirements of ISO IEC 17025 2005ahkiaenaaaaNo ratings yet

- TechniquesDocument29 pagesTechniquessankaran_muthukumarNo ratings yet

- Structural Coverage MetricsDocument19 pagesStructural Coverage MetricsRamu BanothNo ratings yet

- Model Based Diagnosis For The Air Intake System of The SI-EngineDocument12 pagesModel Based Diagnosis For The Air Intake System of The SI-EngineecasayangNo ratings yet

- The ISO 13381-1 Standard's Failure Prognostics Process Through An ExampleDocument12 pagesThe ISO 13381-1 Standard's Failure Prognostics Process Through An ExampleJom BonhayagNo ratings yet

- MIL-STD-781C and Confidence Intervals On MTBF PDFDocument49 pagesMIL-STD-781C and Confidence Intervals On MTBF PDFrab__bitNo ratings yet

- Mil STD 105eDocument76 pagesMil STD 105eAli HassanNo ratings yet

- Failure Rate Data Analysis For High Technology ComponentsDocument9 pagesFailure Rate Data Analysis For High Technology ComponentsganeshdhageNo ratings yet

- 1.0 Introduction On Reliability: Figure 1.0 Bathtub Curve, Failure Rate vs. TimeDocument9 pages1.0 Introduction On Reliability: Figure 1.0 Bathtub Curve, Failure Rate vs. TimeShukri ShabriNo ratings yet

- Leak Detection A4 2013Document17 pagesLeak Detection A4 2013Sharon LambertNo ratings yet

- Understanding The Results of An Intelligent Pig Inspection PenspenDocument19 pagesUnderstanding The Results of An Intelligent Pig Inspection Penspenmobpas100% (1)

- F 065 Liu F PDFDocument4 pagesF 065 Liu F PDFFari PratomosiwiNo ratings yet

- Burst Testing - Common ProblemsDocument3 pagesBurst Testing - Common ProblemsAmit SharmaNo ratings yet

- Ut Defect AssessementDocument48 pagesUt Defect AssessementKarthikeyan Shanmugavel0% (1)

- Partial Stroke TestDocument10 pagesPartial Stroke TestOmar RiganeNo ratings yet

- PSV MisconceptionDocument11 pagesPSV Misconceptiontetiospam100% (1)

- Modern Safety DiagnosticDocument6 pagesModern Safety DiagnosticpzanasiNo ratings yet

- Understanding ISO 6789 - Calibration Laboratories - BlogDocument3 pagesUnderstanding ISO 6789 - Calibration Laboratories - BlogAntmavrNo ratings yet

- Ada 347357sadDocument10 pagesAda 347357sadSyahrial RamadhanNo ratings yet

- White - Paper - Commissioning - and - QA - Experiances - With - Halcyon Rev 2.0 - MARC0595 ApprovedDocument25 pagesWhite - Paper - Commissioning - and - QA - Experiances - With - Halcyon Rev 2.0 - MARC0595 ApprovedMukhlishin bin muhammadNo ratings yet

- On-Line Vibration Technology Development: Feasibility of Commercialization of TechnologyDocument50 pagesOn-Line Vibration Technology Development: Feasibility of Commercialization of TechnologyDante Filho100% (1)

- RBI Basis JustificationDocument17 pagesRBI Basis JustificationTommy100% (1)

- Determining The Reliability and Plant Availability of A Production SyztemDocument53 pagesDetermining The Reliability and Plant Availability of A Production SyztemGeorgina SuleNo ratings yet

- Reliability Centered Maintenance of Substation EquipmentDocument5 pagesReliability Centered Maintenance of Substation Equipmenttunghtd100% (1)

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceFrom EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceRating: 5 out of 5 stars5/5 (2)

- Fault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesFrom EverandFault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesRating: 4 out of 5 stars4/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Aircraft System Safety: Assessments for Initial Airworthiness CertificationFrom EverandAircraft System Safety: Assessments for Initial Airworthiness CertificationNo ratings yet

- Measurement and Control Basics, 4th EditionFrom EverandMeasurement and Control Basics, 4th EditionRating: 4 out of 5 stars4/5 (11)

- Gap Analysis of Kandla Site With Respect To Fire Protection and Control Document Number 0101Document13 pagesGap Analysis of Kandla Site With Respect To Fire Protection and Control Document Number 0101kirandevi1981No ratings yet

- GST Licence PDFDocument3 pagesGST Licence PDFkirandevi1981No ratings yet

- OISD. PESO Gap AnalysisDocument18 pagesOISD. PESO Gap Analysiskirandevi1981100% (1)

- 2014 Self Assessment ToolDocument28 pages2014 Self Assessment Toolkirandevi1981No ratings yet

- Preamble: Description of GuidelinesDocument2 pagesPreamble: Description of Guidelineskirandevi1981No ratings yet

- Part PR Requirements For Boilers Fabricated by RivetingDocument1 pagePart PR Requirements For Boilers Fabricated by Rivetingkirandevi1981No ratings yet

- Storage Tanks Inspection ReportDocument15 pagesStorage Tanks Inspection ReportAreo Tolulope A80% (5)

- Riggers ChecklistDocument8 pagesRiggers Checklistkirandevi1981No ratings yet

- Asme1pfh PDFDocument1 pageAsme1pfh PDFkirandevi1981No ratings yet

- Guideline On The Approval of New Materials Under The Asme Boiler and Pressure Vessel CodeDocument2 pagesGuideline On The Approval of New Materials Under The Asme Boiler and Pressure Vessel Codekirandevi1981No ratings yet

- OSHA's Definition: Confined Space Entry: Permit RequiredDocument1 pageOSHA's Definition: Confined Space Entry: Permit Requiredkirandevi1981No ratings yet

- OSHA Definition of First AidDocument1 pageOSHA Definition of First Aidmedodedo2010No ratings yet

- Sr. No. Date Company Assignment Time To Reach at Company Assignment Co-OrdinatorDocument3 pagesSr. No. Date Company Assignment Time To Reach at Company Assignment Co-Ordinatorkirandevi1981No ratings yet

- Appendix 3 Incident Zoning Diagram: Hot ZoneDocument1 pageAppendix 3 Incident Zoning Diagram: Hot Zonekirandevi1981No ratings yet

- Appendix B: Quantitative Risk Assessment: Cif Scheme No 26 Segregated M5 Crossing Full Business CaseDocument4 pagesAppendix B: Quantitative Risk Assessment: Cif Scheme No 26 Segregated M5 Crossing Full Business Casekirandevi1981No ratings yet

- Guide Lines For Progressive Discipline For HSE: 1-IntroductionDocument4 pagesGuide Lines For Progressive Discipline For HSE: 1-Introductionkirandevi1981No ratings yet

- Safety - Index - KPP OCTDocument114 pagesSafety - Index - KPP OCTkirandevi1981No ratings yet

- Datsasheet of LM347 IcDocument24 pagesDatsasheet of LM347 IcShubhamMittalNo ratings yet

- Percy JacksonDocument13 pagesPercy JacksonDawn Marco0% (2)

- Supply Chain Analytics For DummiesDocument69 pagesSupply Chain Analytics For DummiesUday Kiran100% (7)

- Role LibrariesDocument57 pagesRole LibrariesGiovanni AnggastaNo ratings yet

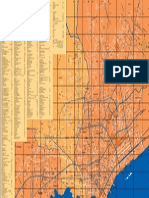

- Map Index: RD - To CE MP AR KDocument1 pageMap Index: RD - To CE MP AR KswaggerboxNo ratings yet

- Functions of Ecgc and Exim BankDocument12 pagesFunctions of Ecgc and Exim BankbhumishahNo ratings yet

- Effect of Employee Loyalty On Customer S PDFDocument37 pagesEffect of Employee Loyalty On Customer S PDFShailendra DasariNo ratings yet

- Biology Chapter 23.1Document2 pagesBiology Chapter 23.1Carlos Enrique Altamar BorjaNo ratings yet

- HSE Matrix PlanDocument5 pagesHSE Matrix Planवात्सल्य कृतार्थ100% (1)

- The Distracted Mind - ExcerptDocument15 pagesThe Distracted Mind - Excerptwamu885No ratings yet

- 1654557191.969365 - Signed Contract Application 212143Document11 pages1654557191.969365 - Signed Contract Application 212143ella may sapilanNo ratings yet

- Calculation For Service Platform & Pump Shelter StructureDocument36 pagesCalculation For Service Platform & Pump Shelter Structuretrian33100% (1)

- Simple Linear Regression Analysis: Mcgraw-Hill/IrwinDocument16 pagesSimple Linear Regression Analysis: Mcgraw-Hill/IrwinNaeem AyazNo ratings yet

- 2 Beginner 2nd GradeDocument12 pages2 Beginner 2nd GradesebNo ratings yet

- Masterlist of Private Elem. Schools S.Y. 2016 2017 Cavite ProvinceDocument17 pagesMasterlist of Private Elem. Schools S.Y. 2016 2017 Cavite ProvinceacinehhjNo ratings yet

- Eurokids Parent Manual (ECity) - PDF-EJ and ESDocument18 pagesEurokids Parent Manual (ECity) - PDF-EJ and ESsabarin_72100% (2)

- Simple Linear Equations A Through HDocument20 pagesSimple Linear Equations A Through HFresgNo ratings yet

- NAT FOR GRADE 12 (MOCK TEST) Language and CommunicationDocument6 pagesNAT FOR GRADE 12 (MOCK TEST) Language and CommunicationMonica CastroNo ratings yet

- SWOT ANALYSIS - TitleDocument9 pagesSWOT ANALYSIS - TitleAlexis John Altona BetitaNo ratings yet

- Exam3 Buscom T F MC Problems FinalDocument23 pagesExam3 Buscom T F MC Problems FinalErico PaderesNo ratings yet

- Statistical TestsDocument47 pagesStatistical TestsUche Nwa ElijahNo ratings yet

- Theology and Pipe Smoking - 7pDocument7 pagesTheology and Pipe Smoking - 7pNeimar HahmeierNo ratings yet

- Chapter 2-EER and Relational Database SchemaDocument146 pagesChapter 2-EER and Relational Database Schemagirmay tadeseNo ratings yet

- Art of Insight PDFDocument409 pagesArt of Insight PDF31482No ratings yet

- Sosa Ernest - Causation PDFDocument259 pagesSosa Ernest - Causation PDFtri korne penal100% (1)

- Present Tenses ReviewDocument6 pagesPresent Tenses ReviewRamona DinuNo ratings yet

- ( (LEAD - FIRSTNAME) ) 'S Spouse Visa PackageDocument14 pages( (LEAD - FIRSTNAME) ) 'S Spouse Visa PackageDamon Culbert0% (1)

- Philippines My Beloved (Rough Translation by Lara)Document4 pagesPhilippines My Beloved (Rough Translation by Lara)ARLENE FERNANDEZNo ratings yet

- Long Range Plans ReligionDocument3 pagesLong Range Plans Religionapi-266403303No ratings yet

- BD9897FS Ic DetailsDocument5 pagesBD9897FS Ic DetailsSundaram LakshmananNo ratings yet