Professional Documents

Culture Documents

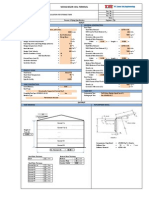

Design Calc - Cooling Tower Sizing - Rev 0

Uploaded by

Paijo TejoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Calc - Cooling Tower Sizing - Rev 0

Uploaded by

Paijo TejoCopyright:

Available Formats

S.

No 1

Description Capacity of the system STG Water Cooled condenser Lube oil cooler

Cooling tower Continuous Intermittent 1793 Cum/hr 100 Cum/hr

MCW pump

ACW pump

Remarks

1793 Cum/hr 100 Cum/hr

Generator cooler

100 Cum/hr

100 Cum/hr

Referred from HMBD Surendra project - 86.5 cum/hr. ITC STG contract document in PG annexure - 100 cum/hr. Surendra project - 75 cum/hr. ITC STG contract document in PG annexure - 100 cum/hr. Preliminary data received from Boiler team through Email dt 23/8/2011 Referred from Surendra project - 5 cum/hr for ash hoppers. As per K.Kumar telecon by Mr.Aravind, It is not required Referred from Surendra project Instrument air compressor (90DegF to 104 DegF for 80 lpm = 4.8 cum/hr) Referred from Surendra project Instrument air compressor (90DegF to 104 DegF for 80 lpm = 4.8 cum/hr) Heat balance calculation

Boiler Boiler feed water pump SWAS Coal spreader Ash Handling System Eco & APH ash hoppers

5 Cum/hr 8 Cum/hr 2 Cum/hr 0 Cum/hr

5 Cum/hr 0 Cum/hr 2 Cum/hr 0 Cum/hr

Compressor

10 Cum/hr

10 Cum/hr

Air compressor for instrument and service air

10 Cum/hr

10 Cum/hr

5 6

Condensate polishing unit - Heat Exchanger Side stream filteration (5% of Circulated water) Total No. of working Total capacity per unit Margin available Selected capacity

75 Cum/hr

75 Cum/hr 105 Cum/hr 1793 Cum/hr 1 No. 1793 Cum/hr 6% 1900 Cum/hr

2095 Cum/hr 2 Nos. 1047 Cum/hr 5% 1100 Cum/hr

407 Cum/hr 1 No. 407 Cum/hr 6% 430 Cum/hr As per contract, CT - 1100 cum/hr per cell MCWP - 1800 Cum/hr ACWP - 250 Cum/hr

1 2 3 4 5 6 7 8 9

Cooling tower make-up water requirement Cooling water inlet to cooling tower Cooling water outlet from cooling tower Cooling temperature range Cycles of concentration Evaporation loss Drift loss Blow down loss Total loss Make up water required for cooling tower

43 Deg C 35 Deg C 8 Deg C 5 1.45 % 0.05 % 0.31 % 1.8 % 37.97 Cum/hr

You might also like

- Design Calc - Cooling Tower Sizing - R1 - 15.10.2011Document1 pageDesign Calc - Cooling Tower Sizing - R1 - 15.10.2011AliAliNo ratings yet

- Cooling tower design parameters and heat balance calculationDocument47 pagesCooling tower design parameters and heat balance calculationDavid LambertNo ratings yet

- Cooling Tower FinalDocument10 pagesCooling Tower Finalmkha87100% (4)

- Cooling Tower Fan CalculationDocument6 pagesCooling Tower Fan Calculationanup_nair50% (2)

- Cooling Tower Calc Efficiency Under 40Document4 pagesCooling Tower Calc Efficiency Under 40Maman HakimNo ratings yet

- 7.steam Headers and OfftakesDocument6 pages7.steam Headers and Offtakessandeep kumarNo ratings yet

- Design of Cooling TowerDocument17 pagesDesign of Cooling TowerMohan VarkeyNo ratings yet

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemNo ratings yet

- Cooling TowerDocument27 pagesCooling Towerjogedhayal100% (1)

- Cooling Water CalculationDocument20 pagesCooling Water CalculationShahzaibUsman100% (1)

- Cooling Tower Calculation DESIGNDocument6 pagesCooling Tower Calculation DESIGNThakur Chandra Partap singh100% (1)

- UtilityDocument8 pagesUtilityAmit JainNo ratings yet

- Pressure Drop in Steam Lines CalculatorDocument7 pagesPressure Drop in Steam Lines CalculatorHiranthaNo ratings yet

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Chiller Size CalculatorDocument4 pagesChiller Size CalculatormpokeNo ratings yet

- Cooling Tower-CalculatorDocument7 pagesCooling Tower-CalculatorparykoochakNo ratings yet

- Pressure Drop Across PipelinesDocument4 pagesPressure Drop Across PipelinesDavid LambertNo ratings yet

- Pump Selection Cold WaterDocument1 pagePump Selection Cold WatersppatilNo ratings yet

- Heat Exchanger Design 1Document9 pagesHeat Exchanger Design 1Rajeev SaxenaNo ratings yet

- Boiler Steam CostingDocument10 pagesBoiler Steam CostingSomnath SinghNo ratings yet

- Effective Thermal Design of Cooling TowersDocument13 pagesEffective Thermal Design of Cooling TowersKarthick VelayuthamNo ratings yet

- Boiler FormulasDocument3 pagesBoiler FormulasCaliman SabinaNo ratings yet

- Cooling TowerDocument63 pagesCooling TowerApsara Katugaha100% (1)

- Instructions Natural Gas Boiler Calculations: AcknowledgementsDocument17 pagesInstructions Natural Gas Boiler Calculations: AcknowledgementsDavid Muñoz CastroNo ratings yet

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignAbhijeet JhaNo ratings yet

- Cooling Towers Design TrainingDocument57 pagesCooling Towers Design TrainingKagira Drawing Soltuion100% (1)

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Document4 pagesControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986No ratings yet

- Header & Piping SizingDocument9 pagesHeader & Piping Sizingmedicbest0% (1)

- Condenser Without SubcoolingDocument19 pagesCondenser Without SubcoolingtatvaNo ratings yet

- Boiler Design and Operation PDFDocument8 pagesBoiler Design and Operation PDFChungNguyenNo ratings yet

- Cooling Tower. Application - TreybalDocument81 pagesCooling Tower. Application - TreybalMarx CesarNo ratings yet

- 07/06/2019 427071582.xls Chiller - Fix CAP+Stepless: Degradation CalculationDocument7 pages07/06/2019 427071582.xls Chiller - Fix CAP+Stepless: Degradation CalculationselisenNo ratings yet

- Final Design Values of PHE C-510 CoolersDocument4 pagesFinal Design Values of PHE C-510 CoolersRamji MishraNo ratings yet

- Energy BalanceDocument11 pagesEnergy BalanceBharat VaajNo ratings yet

- 2 Design CalculationDocument22 pages2 Design CalculationLynn HuiNo ratings yet

- Cooling Towers & Desiccant Dehumidification GuideDocument23 pagesCooling Towers & Desiccant Dehumidification Guideesojsuil_tgNo ratings yet

- NFPA Pipe Sizing EXAMPLEDocument4 pagesNFPA Pipe Sizing EXAMPLEMatt AndersonNo ratings yet

- VSD Calculator for Fan Energy SavingsDocument10 pagesVSD Calculator for Fan Energy SavingsCésar Christian JankoNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingWade ColemanNo ratings yet

- Cooling Tower Efficiency CalculationsDocument5 pagesCooling Tower Efficiency Calculationsidigiti100% (1)

- Cooling Tower Workshop PETDocument2 pagesCooling Tower Workshop PETruk1921No ratings yet

- Cooling Tower-ExcelDocument14 pagesCooling Tower-ExcelpartoNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line Sizingemmanuilmoulos6339100% (1)

- 60 TPH Technical SheduleDocument32 pages60 TPH Technical SheduleSeenu HassanNo ratings yet

- 2019-250 MW Barge Technical DiaryDocument33 pages2019-250 MW Barge Technical Diarydasnulmadi61No ratings yet

- Technical Diary - FinalDocument99 pagesTechnical Diary - FinalSaurav KumarNo ratings yet

- Specification of HEFEI GAS TURBINE POWER PLANTDocument48 pagesSpecification of HEFEI GAS TURBINE POWER PLANTSalmanEjaz100% (1)

- Coal MillsDocument44 pagesCoal Millsashish364No ratings yet

- Super Critical Boiler Cycle GuideDocument32 pagesSuper Critical Boiler Cycle GuideJayaraman Kamaraj100% (1)

- Tad730ge 111797s01Document8 pagesTad730ge 111797s01roozbehxoxNo ratings yet

- V470 Compt Wise Equips From HODocument2 pagesV470 Compt Wise Equips From HOBrian FreemanNo ratings yet

- GTG 1409sc Solart60 60hzDocument21 pagesGTG 1409sc Solart60 60hzKhaldoon AlnashiNo ratings yet

- Tips On Kiln OperationDocument10 pagesTips On Kiln OperationElwathig Bakhiet100% (2)

- CGAT Catalog0303Document2 pagesCGAT Catalog0303Chinith HengNo ratings yet

- Final TL - CVL ComparativeDocument6 pagesFinal TL - CVL ComparativeRavi ChandarNo ratings yet

- Of FuelDocument11 pagesOf FuelraghbirNo ratings yet

- 616 V-Engine Characteristics and SpecificationsDocument6 pages616 V-Engine Characteristics and SpecificationssdiamanNo ratings yet

- Low Grade Flue Gas Waste Heat Utilization For Air Conditioning in Coal Based Power PlantDocument30 pagesLow Grade Flue Gas Waste Heat Utilization For Air Conditioning in Coal Based Power PlantSymron AngelNo ratings yet

- Gas Turbine Technologies for Electric GenerationDocument54 pagesGas Turbine Technologies for Electric GenerationVeerabhadra Rao Korimilli100% (1)

- Comparision Sheet-Ccoling TowersDocument16 pagesComparision Sheet-Ccoling TowersKenny RuizNo ratings yet

- Input EchoDocument42 pagesInput EchoPaijo TejoNo ratings yet

- Maw Sby Denver Apartment Exterior East ElevationDocument1 pageMaw Sby Denver Apartment Exterior East ElevationPaijo TejoNo ratings yet

- Link Brochure Dropbox.Document2 pagesLink Brochure Dropbox.Paijo TejoNo ratings yet

- Alamat APIDocument1 pageAlamat APIPaijo TejoNo ratings yet

- DD DNV Gardu PLN Alt1 ModelDocument1 pageDD DNV Gardu PLN Alt1 ModelPaijo TejoNo ratings yet

- 20409: Optimal Design of Cooling Towers Eusiel Rubio-Castro1, Medardo Serna-González1, José M. Ponce-Ortega1 and Arturo Jiménez-Gutiérrez2 1Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Michoacán, 2Instituto Tecnológico de Celaya, Celaya, Guanajuato, MéxicoDocument27 pages20409: Optimal Design of Cooling Towers Eusiel Rubio-Castro1, Medardo Serna-González1, José M. Ponce-Ortega1 and Arturo Jiménez-Gutiérrez2 1Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Michoacán, 2Instituto Tecnológico de Celaya, Celaya, Guanajuato, MéxicoRajat Yadav YaduvanshiNo ratings yet

- Tire Rolling ResistanceDocument2 pagesTire Rolling ResistancePaijo TejoNo ratings yet

- T-L R, (,li U $: LrillllDocument4 pagesT-L R, (,li U $: LrillllPaijo TejoNo ratings yet

- Outstading BQ Clarification With SgiDocument2 pagesOutstading BQ Clarification With SgiPaijo TejoNo ratings yet

- ICD EPC Volume 2 Final-ToCDocument6 pagesICD EPC Volume 2 Final-ToCPaijo TejoNo ratings yet

- Sound System (Baru)Document26 pagesSound System (Baru)Paijo TejoNo ratings yet

- Power Ups DataDocument1 pagePower Ups DataPaijo TejoNo ratings yet

- Calculate Lifecycle Costs of Equipment with 13 FactorsDocument2 pagesCalculate Lifecycle Costs of Equipment with 13 FactorsPaijo TejoNo ratings yet

- Detail GensetDocument1 pageDetail GensetPaijo TejoNo ratings yet

- Coefficient of Friction,..Document2 pagesCoefficient of Friction,..Paijo TejoNo ratings yet

- Pages From Piusi Cube 70mc EspDocument1 pagePages From Piusi Cube 70mc EspPaijo TejoNo ratings yet

- Kayu Jati - Salvador ProductionDocument3 pagesKayu Jati - Salvador ProductionPaijo TejoNo ratings yet

- Pump Data SheetDocument1 pagePump Data SheetPaijo TejoNo ratings yet

- Basic MaterialDocument1 pageBasic MaterialPaijo TejoNo ratings yet

- Valve ScheduleDocument2 pagesValve SchedulePaijo TejoNo ratings yet

- ICD EPC Volume 2 FinalDocument1 pageICD EPC Volume 2 FinalPaijo TejoNo ratings yet

- Tte033-7001-03 Pipe Support & ConfigurationDocument1 pageTte033-7001-03 Pipe Support & ConfigurationPaijo TejoNo ratings yet

- Tank design parametersDocument3 pagesTank design parametersPaijo TejoNo ratings yet

- Dust Control SystemsDocument15 pagesDust Control SystemsPaijo TejoNo ratings yet

- Tte033 7403 01 Filling Station DetailDocument1 pageTte033 7403 01 Filling Station DetailPaijo TejoNo ratings yet

- Fire PumpDocument1 pageFire PumpPaijo TejoNo ratings yet

- Rail LoadingDocument1 pageRail LoadingPaijo TejoNo ratings yet

- Tte033-7101-06 General Standard DetailDocument1 pageTte033-7101-06 General Standard DetailPaijo TejoNo ratings yet

- Diesel oil transfer pump calculationDocument1 pageDiesel oil transfer pump calculationPaijo TejoNo ratings yet

- Tte033 7403 01 Filling Station DetailDocument1 pageTte033 7403 01 Filling Station DetailPaijo TejoNo ratings yet