Professional Documents

Culture Documents

Buhar Separatörü - PN 25

Uploaded by

jf2003Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buhar Separatörü - PN 25

Uploaded by

jf2003Copyright:

Available Formats

SPR 25

BUHAR SEPARATR - PN 25 STEAM SEPARATOR - PN 25

zellikler / Main Features: AYVAZ SPR 25 Separatrler, yksek randmanl, deiken buhar hzlar ve maksimum 25 bara kadar alan hatlarda separasyon verimini korumak iin zel olarak tasarlanmlardr. Bu rn proses sistemleri iin paslanmaz elikten zel olarak retilebilir. Avantajlar:

retkenlii ve retim kalitesini arttrr Bakm maliyeti ve duru zamann azaltr Buhar ve hava sistemlerindeki tesis ve kontrol vanalarnn

mrn uzatr.

Ko darbesi hasarn ve bunun sebebiyet verecei

bakm masraflarn ortadan kaldrr.

Basit, salam tasarm bakm gerektirmez. Geni malzeme ve balant seimi. Buhar, hava veya gazn net llmesini salar.

ALIMA ARTLARI / OPERATING CONDITIONS

DN

15 - 80 100 - 150 15 - 150

(Ak sayalarn korumak iin kullanldnda)

Max. alma Basnc Max. Working Pressure (bar)

25 (Buhar / Steam ) 21 (Buhar / Steam ) 17 ( Hava / Air)

Max. alma Scakl Max. Working Temp. (C)

228 217 50

Application: Suitable for air, gas and steam applications were the entrained liquid load does not exeed 40% (by weight) of the separators maximum gas flow capacity. This is a traditional looking separator and many engineers simply prefer this configuration because they are accustomed to it. Performance: The Wright-Austin Type T entrainment separator, when properly sized, installad and drained, will remove 99% of all liquid droplet and solid particle entrainment where the droplet and/or particle size equals or exeeds 10 microns. Operation: Moisture-laden gas enters the inlet of the separator where it is deflected in a centrifugal downward motion. The entrained moisture is thrown to the outer wall and separated by a reduction in velocity. The separated liquid falls below the Vortex Containment Plate (VCP) where it cannot be re-entrained. Dry, clean exit gas is drawn from the vessel center and it flows upward through the outlet of the separator. ASME Code Construction: These type T separators are of welded steel construction in accordance with section 8. Division 1 of the ASME Code for unfired pressure vessels. Inlet and outlet connections can be rotated radially upon request.

DN

15 - 20 - 25 32 - 40 - 50 65 - 80 - 100 125 - 150 - 200

Balant Connection

Flanl Flanged PN 25 (DIN 2567)

Malzeme Material

Karbon elik Paslanmaz elik Carbon steel Stainless steel

SPR 25

BUHAR SEPARATR / STEAM SEPARATOR - PN 25

Buhar separatr seim diyagram Steam separator selection diagram

DN 150

Buhar iin diyagramn kullanlmas:

1 - 10 bar buhar basnc ve 1000 kg/h debi alarak A - D izgisini izelim. 2 - A - B yatay izgisini uzatalm. 3 - Mavi alan iinde A - B izgisiyle kesilen herhangi bir separatr erisi yaklak %100 randmanla alacaktr. (DN 50) 4 - Ak hz B - C dikey izgisi ile tayin edilir. (19 m/s) 5 - Basn d A - B ve C - D izgileri kesitirilerek bulunur. (0.03 bar) 6 - Separatr; hat ap, hz ve basn d arasndaki uzla zerine seilmelidir.

Buhar debisi / Steam mass flow (kg/h)

10.000 5.000

DN 125 DN 100 DN 80 DN 65 DN 50 DN 40

2.000

1.000

Separatr ap Separator diameter

DN 32 DN 25 DN 20 DN 15

500 20 0

10 0

How to use the diagram

1 - 10 bar steam pressure and 1000 kg/h mass flow form A- D line. 2 - Extend A- B line horizontally. 3 - Any separator are intersecting with the A- B line in the blue are will be working 100% efficiently (DN 50). 4 - Flow rate is determined by B - C vertical line (19 m/s). 5 - Pressure loss is established by intersecting A-B line to C- D line (0.03 bar). 6 - Separatr; should be chosen by determining the flow rate line diameter and pressure loss.

50

1 2 3 4 5 6 7 8 9 10 11 12 14

16

18

20

22 24 25 5

10

15

20

25

30

35

40

Buhar basnc / Steam pressure (bar)

0. 0 03

Ak hz / Flow rate (m/s)

0.

01

0.0

D

0.0

5

0.1

0.2

Basn kayb / Pressure loss (bar)

SPR 25

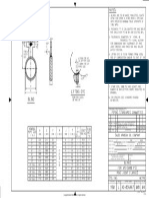

BOYUTLAR / DIMENSIONS DN A

180 230 230 250 300 300 400 450 500 600 600 700 850 950 1000

B C

A1

120 150 160 200 220 220

B

324 389 384 426 467 493 616 683 782 937 1037 1210 1750 1900 2000

C

242 298 306 315 346 384 481 520 589 725 817 968 1350 1450 1500

D

R 1/2 R 1 X 1/2 R 1 X 1/2 R 1 X 1/2 R 1 X 1/2 R 1 X 1/2 R 1 1/2 X 3/4 R 1 1/2 X 3/4 R 2 X 1 R 2 X 1 R 2 X 1 R 2 X 1 R 2 R 2 R 2

15 20 25 32 40 D R 1/4 50 65 80 100 125 150 200

SPR 25

A1

250 300 350

Atatrk Sanayi Blgesi, stasyon Mah. Mustafa nan Cad. No: 36 34860 Hadmky - STANBUL - TRKYE Tel : 90(212) 771 01 45 (pbx) Fax: 90(212) 771 47 27 - 90(212) 771 25 60, e-mail : info @ ayvaz.com.tr

www.ayvaz.com

HACI AYVAZ ENDSTRYEL MAMLLER SANAY VE TCARET A..

DISTRIBUTOR

You might also like

- Pump Protection Valve DatasheetDocument9 pagesPump Protection Valve DatasheetmishraenggNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Water Meter Flanged PN16Document6 pagesWater Meter Flanged PN16sunilNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Bus Bar k0186 MC 10 Busbar Systems 2013 IinfoDocument47 pagesBus Bar k0186 MC 10 Busbar Systems 2013 IinfoManish ThakurNo ratings yet

- Flow SwitchDocument2 pagesFlow SwitchSachin DarneNo ratings yet

- Series 826YD Specification SheetDocument2 pagesSeries 826YD Specification SheetFEBCONo ratings yet

- Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDDocument11 pagesInline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDAllan ArraisNo ratings yet

- Pressure Reducing Valves Part 3Document12 pagesPressure Reducing Valves Part 3SAKDA MAPRADITKULNo ratings yet

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- Pump Protection Valve OverviewDocument9 pagesPump Protection Valve OverviewReyNo ratings yet

- Flowmeter For Compressed-Air Systems: Description SpecificationsDocument2 pagesFlowmeter For Compressed-Air Systems: Description Specificationsherysyam1980No ratings yet

- FSM4000 Medidor de Vazão Magnético PDFDocument40 pagesFSM4000 Medidor de Vazão Magnético PDFthiagofilipiniNo ratings yet

- FPZ Membrane BlowersDocument16 pagesFPZ Membrane BlowersadifoteaNo ratings yet

- Mc. Daniel - Pressure GaugeDocument6 pagesMc. Daniel - Pressure GaugeMuhammad FuadyNo ratings yet

- Select the Right Gas and Air Filter for Your ApplicationDocument8 pagesSelect the Right Gas and Air Filter for Your ApplicationJulio OrtegaNo ratings yet

- 3-Way Valve - ThreadedDocument4 pages3-Way Valve - ThreadedAhrian BenaNo ratings yet

- Lifting Eye Blind: NotesDocument1 pageLifting Eye Blind: Notesnarutothunderjet216No ratings yet

- SBC 782 Slam Shut Valves GuideDocument8 pagesSBC 782 Slam Shut Valves Guideluis_d_mNo ratings yet

- Pressure Control Valve VRCDDocument4 pagesPressure Control Valve VRCDFlavius Oros100% (1)

- Airhandling UnitsDocument62 pagesAirhandling UnitsMiroslav Aleksic100% (1)

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter Specificationsjimbo2032No ratings yet

- BPE Technical DataDocument5 pagesBPE Technical Datasmtamaskar2277No ratings yet

- Accuracy:: US Patent 6,802,217Document2 pagesAccuracy:: US Patent 6,802,217Logist ChinaNo ratings yet

- Desuperheater That Combines Proven Technologies For Better Operational EconomyDocument4 pagesDesuperheater That Combines Proven Technologies For Better Operational Economyhappale2002No ratings yet

- Piping Design Quick Reference CardDocument3 pagesPiping Design Quick Reference CardPiping_SpecialistNo ratings yet

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter SpecificationsMechanicalMarwanNo ratings yet

- Venta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)Document5 pagesVenta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)isombardNo ratings yet

- TescomDocument16 pagesTescomrafaareNo ratings yet

- Features of Orifice MetersDocument2 pagesFeatures of Orifice MetersAkshat KejriwalNo ratings yet

- Using Flange Joint in Duct SiystemDocument23 pagesUsing Flange Joint in Duct Siystematamete100% (1)

- Series MR Flowmeters: FeaturesDocument2 pagesSeries MR Flowmeters: FeaturesccnbtNo ratings yet

- Dss020 Standard Us enDocument13 pagesDss020 Standard Us enMilenko TulencicNo ratings yet

- 0497 4 Flow Straightener Catalog Sheet 05 14Document2 pages0497 4 Flow Straightener Catalog Sheet 05 14mkfe2006No ratings yet

- Manual Threaded Balancing Valves: Product Data SheetDocument20 pagesManual Threaded Balancing Valves: Product Data SheethalackNo ratings yet

- Condensate Management: OWS Series CS SeriesDocument4 pagesCondensate Management: OWS Series CS SeriesEthan HuntNo ratings yet

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123No ratings yet

- Directional Control Valves GuideDocument193 pagesDirectional Control Valves GuidephaindikaNo ratings yet

- Catalogue Pressure GaugesDocument50 pagesCatalogue Pressure GaugesIra MartianiNo ratings yet

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- Pipe Sizing and Pressure Drop CalculationDocument7 pagesPipe Sizing and Pressure Drop Calculationvino2winNo ratings yet

- Series 825YD Specification SheetDocument2 pagesSeries 825YD Specification SheetFEBCONo ratings yet

- 12AT/50AT Series: Spin-On FiltersDocument8 pages12AT/50AT Series: Spin-On FiltersPartsGopher.comNo ratings yet

- Piping Components & Their Uses: PipeDocument3 pagesPiping Components & Their Uses: PipeParameswararao BillaNo ratings yet

- Bermad - Filtro en y 70fDocument2 pagesBermad - Filtro en y 70fYadir BojacaNo ratings yet

- Donaldson Visokotlačni FilteriDocument86 pagesDonaldson Visokotlačni FilteriViktor -stNo ratings yet

- Reliable flow measuring system for steam, air and waterDocument4 pagesReliable flow measuring system for steam, air and waterEdgarParedesNo ratings yet

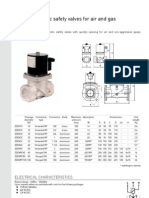

- ZDEV Electromagnetic Safety ValvesDocument2 pagesZDEV Electromagnetic Safety ValvesŠime RončevićNo ratings yet

- Visual Flow Indicator Guide from Flow-MonDocument12 pagesVisual Flow Indicator Guide from Flow-Mondhanu_aquaNo ratings yet

- Abrasive CycloneDocument4 pagesAbrasive Cycloneoverlord5555No ratings yet

- p405 01Document8 pagesp405 01Utku KepcenNo ratings yet

- Plastic Industrial Fans for Optimizing ProcessesDocument6 pagesPlastic Industrial Fans for Optimizing ProcessesNicole FelicianoNo ratings yet

- Pump STDRDocument7 pagesPump STDRsopian320No ratings yet

- V SeguridadDocument8 pagesV SeguridadARJONA_JGNo ratings yet

- Stream Sensus 620 - LD - 1621 - Int - 620-620m - 0002Document4 pagesStream Sensus 620 - LD - 1621 - Int - 620-620m - 0002csudhaNo ratings yet

- Filteri Za Gas - Fini Sa Izmenjivim Ulo (CimaDocument6 pagesFilteri Za Gas - Fini Sa Izmenjivim Ulo (Cimamicaziv4786No ratings yet

- 2040 2e6Document6 pages2040 2e6Jaikishan KumaraswamyNo ratings yet

- Groth Calaouge 31-05-15Document6 pagesGroth Calaouge 31-05-15Alberto CorticelliNo ratings yet

- IR60W6 10-20 DataSheet en 07 05 02Document2 pagesIR60W6 10-20 DataSheet en 07 05 02jf2003No ratings yet

- IOPW6 11-21 DataSheet en 07 12 2Document2 pagesIOPW6 11-21 DataSheet en 07 12 2jf2003No ratings yet

- Siemens Sintony 60Document8 pagesSiemens Sintony 60jf2003No ratings yet

- IC60 DataSheet en 08 01 28Document8 pagesIC60 DataSheet en 08 01 28jf2003No ratings yet

- IMKW6 10-20 DataSheet en 08 01 25Document2 pagesIMKW6 10-20 DataSheet en 08 01 25jf2003No ratings yet

- BellowsDocument2 pagesBellowsjf2003No ratings yet

- IGBW6 10-20 DataSheet en 07 12 21Document2 pagesIGBW6 10-20 DataSheet en 07 12 21jf2003No ratings yet

- BR Sintony-60 A2405-A333-B217 EN PDFDocument10 pagesBR Sintony-60 A2405-A333-B217 EN PDFjf2003No ratings yet

- Catálogo H InglêsDocument28 pagesCatálogo H Inglêsjf2003No ratings yet

- Catálogo M-DA InglêsDocument20 pagesCatálogo M-DA Inglêsjf2003No ratings yet

- Catálogo DX-DXS InglêsDocument16 pagesCatálogo DX-DXS Inglêsjf2003No ratings yet

- Catálogo H InglêsDocument28 pagesCatálogo H Inglêsjf2003No ratings yet

- Catálogo DP InglêsDocument20 pagesCatálogo DP Inglêsjf2003No ratings yet

- BROCHURE ODE Bassa - Valv para Maq CaféDocument7 pagesBROCHURE ODE Bassa - Valv para Maq Caféjf2003No ratings yet

- Preventing and Mitigating COVID-19 at Work: Policy Brief 19 May 2021Document21 pagesPreventing and Mitigating COVID-19 at Work: Policy Brief 19 May 2021Desy Fitriani SarahNo ratings yet

- If V2 would/wouldn't V1Document2 pagesIf V2 would/wouldn't V1Honey ThinNo ratings yet

- "Behind The Times: A Look at America's Favorite Crossword," by Helene HovanecDocument5 pages"Behind The Times: A Look at America's Favorite Crossword," by Helene HovanecpspuzzlesNo ratings yet

- Book Networks An Introduction by Mark NewmanDocument394 pagesBook Networks An Introduction by Mark NewmanKhondokar Al MominNo ratings yet

- 08 Sepam - Understand Sepam Control LogicDocument20 pages08 Sepam - Understand Sepam Control LogicThức Võ100% (1)

- Attributes and DialogsDocument29 pagesAttributes and DialogsErdenegombo MunkhbaatarNo ratings yet

- Survey Course OverviewDocument3 pagesSurvey Course OverviewAnil MarsaniNo ratings yet

- Passenger E-Ticket: Booking DetailsDocument1 pagePassenger E-Ticket: Booking Detailsvarun.agarwalNo ratings yet

- DECA IMP GuidelinesDocument6 pagesDECA IMP GuidelinesVuNguyen313No ratings yet

- India: Kerala Sustainable Urban Development Project (KSUDP)Document28 pagesIndia: Kerala Sustainable Urban Development Project (KSUDP)ADBGADNo ratings yet

- Origins and Rise of the Elite Janissary CorpsDocument11 pagesOrigins and Rise of the Elite Janissary CorpsScottie GreenNo ratings yet

- Sewage Pumping StationDocument35 pagesSewage Pumping StationOrchie DavidNo ratings yet

- Chennai Metro Rail BoQ for Tunnel WorksDocument6 pagesChennai Metro Rail BoQ for Tunnel WorksDEBASIS BARMANNo ratings yet

- Quality Management in Digital ImagingDocument71 pagesQuality Management in Digital ImagingKampus Atro Bali0% (1)

- Unit 1 TQM NotesDocument26 pagesUnit 1 TQM NotesHarishNo ratings yet

- 17BCE0552 Java DA1 PDFDocument10 pages17BCE0552 Java DA1 PDFABHIMAYU JENANo ratings yet

- Trading As A BusinessDocument169 pagesTrading As A Businesspetefader100% (1)

- Postgraduate Notes in OrthodonticsDocument257 pagesPostgraduate Notes in OrthodonticsSabrina Nitulescu100% (4)

- FranklinDocument4 pagesFranklinapi-291282463No ratings yet

- 10 1 1 124 9636 PDFDocument11 pages10 1 1 124 9636 PDFBrian FreemanNo ratings yet

- Sarvali On DigbalaDocument14 pagesSarvali On DigbalapiyushNo ratings yet

- Tension field beams: Aircraft wing spar analysisDocument19 pagesTension field beams: Aircraft wing spar analysisPrajeesh RajNo ratings yet

- Difference Between Mark Up and MarginDocument2 pagesDifference Between Mark Up and MarginIan VinoyaNo ratings yet

- India Today 11-02-2019 PDFDocument85 pagesIndia Today 11-02-2019 PDFGNo ratings yet

- Chem 102 Week 5Document65 pagesChem 102 Week 5CAILA CACHERONo ratings yet

- Udaan: Under The Guidance of Prof - Viswanathan Venkateswaran Submitted By, Benila PaulDocument22 pagesUdaan: Under The Guidance of Prof - Viswanathan Venkateswaran Submitted By, Benila PaulBenila Paul100% (2)

- Radio Frequency Transmitter Type 1: System OperationDocument2 pagesRadio Frequency Transmitter Type 1: System OperationAnonymous qjoKrp0oNo ratings yet

- Cushman Wakefield - PDS India Capability Profile.Document37 pagesCushman Wakefield - PDS India Capability Profile.nafis haiderNo ratings yet

- Fernandez ArmestoDocument10 pagesFernandez Armestosrodriguezlorenzo3288No ratings yet

- Jfif 1.02Document9 pagesJfif 1.02Berry Hoekstra100% (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)