Professional Documents

Culture Documents

ZKG 0605 005 - 9 ESPBypass - CMYK

Uploaded by

Nazeeh Abdulrhman AlbokaryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZKG 0605 005 - 9 ESPBypass - CMYK

Uploaded by

Nazeeh Abdulrhman AlbokaryCopyright:

Available Formats

AR TIFICIAL LIFT COMPLETION SYSTEMS

STANDARD & TOTAL PROTECTION BYPASS SYSTEMS

Zenith completion systems have been developed in response to industry needs for high-quality, time saving, reliable equipment, using experience gained over many years to provide the most advanced and flexible systems available in the market today.

SYSTEM FEATURES

! Patented bypass saddle assembly ! Utilises standard nipples and profiles ! Smart plug option to gain ESP operating data ! Logging plug option Top Nipple Y-Block

c/w cable clips for MLE cable

Coupling Crossover

Zenith bypass systems include unique features which address problems inherent in alternative equipment in order to:

! provide maximum protection for the ESP assembly ! simplify installation procedures with a resulting saving in rig time and improvement in safety ! maximize the efficiency and pump set run life

MAXIMISING PROTECTION

Zeniths unique system design allows the ESP assembly to longitudinally expand and contract independently of the adjacent bypass tubing as the temperature of the ESP system changes at start-up, preventing bending of the ESP and subsequent damage to motor and pump shaft bearings which may be detrimental to the continued operation of the ESP. No load is placed on the ESP and the optional logging plug prevents recirculation, affording further protection of the pump.

Teleswivel Nipple Assembly

Cable Clamps

c/w cable clip for MLE cable

SYSTEM APPLICATIONS

! Allows access to perforations (below the ESP) " add perforations " formation treatments (solvents, scale inhibitor) ! Allows logging with coiled tubing or wireline " identify water and oil zones

SIMPLIFYING INSTALLATION

Zenith completions are designed to achieve simpler installation of the system, with no space out problems or requirement for specific bypass tubing lengths. Pump

Rig time savings of 2.5 hours (20% of average competitor installation time) per installation can be achieved.

Seal

Bypass Tubing

ZENITH TOTAL PROTECTION BYPASS SYSTEM

Motor

Opt to upgrade from our standard bypass completion to the Zenith Total Protection bypass system:

In addition to the benefits of our standard bypass system (see overleaf), our Total Protection option offers operational time savings and advanced protection for your ESP.

! On running in, no wireline operations are required prior to ESP start up ! On pump shut down or following logging operations, the production tubing fluid column immediately drains through the ported nipple no back flow through the pump. ! Plug can be pulled without delay following logging operations

Saddle Assembly

Wireline Entry Guide

Zenith Bypass System

ZENITH BYPASS SYSTEM BENEFITS Problem

Risk of dropping bypass tubing downhole during installation. Danger of slippage, lost rig time and possible fishing. Temperature changes result in different expansion rates of ESP and bypass tubing leading to damaged (bent) motor and broken clamps. Reduced ESP run life. Traditional systems need to be exactly spaced out to allow components to fit together. Difficulty handling tensile or compression forces due to tailpipe or completion equipment below pump. Failed ESP monitoring system results in no data.

Solution

The Zenith Bypass Saddle prevents bypass tubing from falling.

Benefit

Eliminates risk. Quicker to run. Saves rig time. Prevents damage to the ESP equipment.

The Zenith Bypass Saddle allows for different expansion rates by allowing the bypass tubing to move unrestricted.

The Zenith Bypass Saddle allows for 8ft of tubing movement.

Eliminates complicated space out.

The Zenith Bypass Saddle passes all compression forces onto the y-block.

No load on the ESP.

The Zenith Smart Plug* replaces the standard blanking plug and measures ESP intake and discharge pressure. Unique design allows clamps to fit multiple equipment sizes.

Acquires ESP operating data on wells with failed or no sensor.

Numerous different sizes of clamps required for different ESP, cable or casing size. Lack of flexibility for change of ESP or cable.

Minimised inventory and flexibility.

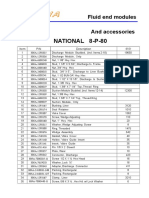

EQUIPMENT OPTIONS Item

Top Nipple Blanking Plug with Lock Saddle Assembly Smart Plug Wireline Logging Plug Coiled Tubing Logging Plug Isolation Tool

What it Does

Allows tubing to be pressure tested. Prevents blanking plug from being unseated. Simplifies installation and allows for expansion. Acquires ESP operating pressures. Allows logging below ESP using wireline. Allows logging below ESP using coiled tubing. Allows chemical treatment of formation without pumping fluid through ESP (requires top nipple)

Figures based on average installation timings

* Zenith Oilfield Technology patent pending and patent protected worldwide ZKG-0512-001 Zenith 2005

www.ZenithOilfield.com T: +44 (0) 1467 628866

AR TIFICIAL LIFT COMPLETION SYSTEMS

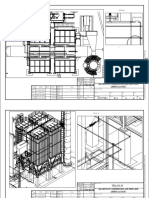

TECHNICAL SPECIFICATIONS: 9 5/8 BYPASS SYSTEM

(1) Coupling 3 /2 EUE Regular

1

(6) Bypass Tubing 2 7/8 UBT Box x Pin Max Recommended Load: 28,000 lbs Internal Drift Dia: 2.441 Lengths: 15ft, 7 1/2 ft

(1) Coupling (2) Crossover

O/Dia: 4.500 Internal Drift Dia: 2.867 Length: 5.750

(2) Crossover Pin x Pin 3 1/2 EUE x 3 1/2 - 9.2 New Vam Internal Drift Dia: 2.867 Length: 5ft

(7) Cable Support Clamp 9 5/8 Casing (53.5 lb/ft max) 2 7/8 Bypass Tubing O/Dia: 8.310

Suitable for 562 Series ESP in 47.0 lb/ft and 540 Series ESP in 53.5 lb/ft cased wells. Supplied complete with cable support clip suitable for a large range of cable sizes Cable support clamp envelopes and slides freely over 2 7/8 bypass tubing to allow ESP expansion and contraction during thermal cycling

(3) Y-Block (4a) Blanking Plug (4) Teleswivel Nipple Assembly

(3) Y-Block 3 1/2 - 9.2 New Vam Box Connections O/Dia: 8.375 Internal Drift Dia: 2.867 (production to bypass) Length: 22.250

Supplied complete with MLE cable clips suitable for a large range of cable sizes

(5) Crossover

(8) Saddle Assembly 2 7/8 UBT Box Connection 2 7/8 EUE Pin Connection O/Dia: 7.500

(6) Bypass Tubing

(4) Swivel Nipple Assembly 3 1/2 - 9.2 New Vam Pin Connection 2 /8 Universal Bypass Thread (UBT) Pin Connection

7

Internal Drift Dia: 2.441 Length: 14ft

Saddle assembly prevents back-off of parallel threaded bypass tubing, slides freely to allow ESP expansion and contraction during thermal cycling and simplifies running procedures

(7) Cable Support Clamp

Max Recommended Load: 28,000 lbs 2.750 Plain Seal Bore O/Dia: 4.075 Internal Drift Dia: 2.441 Length: 3ft (make-up)

(9) Tailpipe 2 7/8 - 6.5 EUE Box x Pin Connections Length as requiredNote load capability of UBT bypass tubing

Normally supplied by customermay be purchased from Zenith if required

(4a) Blanking Plug 2.750 Seal Dia Closed End Collet

(10) Wireline Re-entry Guide 2 7/8 EUE Box Connection

(8) Saddle Assembly

(5) Crossover 3 1/2 - 9.2 New Vam Pin 3 1/2 EUE Pin Length: 10ft

O/Dia: 5.400 Internal Drift Dia: 2.441 Length: 0.83ft

(9) Tailpipe (10) Wireline Re-entry Guide

*Zenith Oilfield Technology patent pending and patent protected worldwide ZKG-0512-001_Spec Zenith 2005

www.ZenithOilfield.com T: +44 (0) 1467 628866

AR TIFICIAL LIFT COMPLETION SYSTEMS

TECHNICAL SPECIFICATIONS: 7 BYPASS SYSTEM

(1) Coupling 3 1/2 EUE Regular O/Dia: 4.500 Internal Drift Dia: 2.867 Length: 5.750 (7) Bypass Tubing (2) Crossover 3 /2 EUE Pin

1

(6) Crossover 2 3/8 - 4.6 New Vam Pin 2 3/8 EUE Pin Length: 10ft

(1) Coupling (2) Crossover

(3) Tubing Joint (4) Y-Block (5a) Blanking Plug (5) Teleswivel Nipple Assembly

2 1/8 UBT Box x Pin Max Recommended Load: 19,000 lbs Internal Drift Dia: 1.775 Lengths: 15ft, 7 1/2 ft (7) Cable Support Clamp

2 7/8 - 6.4 New Vam Box Internal Drift Dia: 2.347 Length: 1.25ft (3) Tubing Joint Pin x Pin 2 /8 - 6.4 New Vam

7

7 Casing (32 lb/ft max) 2 1/8 Bypass Tubing O/Dia: 5.965

Suitable for 400 Series ESP in 26.0 lb/ft and 375 Series ESP in 32.0 lb/ft cased wells. Supplied complete with cable support clip suitable for a large range of cable sizes

Internal Drift Dia: 2.347 Length: 6ft (4) Y-Block 2 7/8 - 6.4 / 2 3/8 - 4.6 New Vam Box Connections O/Dia: 5.965 Internal Drift Dia: 2.347 (production to bypass) Length: 22.250

Supplied complete with MLE cable clips suitable for a large range of cable sizes

(6) Crossover

Cable support clamp envelopes and slides freely over 2 1/8 bypass tubing to allow ESP expansion and contraction during thermal cycling

(7) Bypass Tubing

(8) Saddle Assembly 2 1/8 UBT Box Connection 2 3/8 EUE Pin Connection O/Dia: 5.750 Internal Drift Dia: 1.775 Length: 14ft

Saddle assembly prevents back-off of parallel threaded bypass tubing, slides freely to allow ESP expansion and contraction during thermal cycling and simplifies running procedures

(8) Cable Support Clamp

(5) Swivel Nipple Assembly 2 /8 - 6.4 New Vam Pin Connection

7 1

2 /8 Universal Bypass Thread (UBT) Pin Connection Max Recommended Load: 19,000 lbs 1.875 Plain Seal Bore O/Dia: 3.075 Internal Drift Dia: 1.775 Length: 3ft (make-up) (5a) Blanking Plug 1.875 Seal Dia Closed End Collet

(10) Tailpipe 2 3/8 - 4.7 EUE Box x Pin Connections Length as requiredNote load capability of UBT bypass tubing

Normally supplied by customermay be purchased from Zenith if required

(9) Saddle Assembly

(11) Wireline Re-entry Guide 2 3/8 EUE Box Connection O/Dia: 5.400 Internal Drift Dia: 1.901 Length: 0.83ft

(10) Tailpipe (11) Wireline Re-entry Guide

*Zenith Oilfield Technology patent pending and patent protected worldwide ZKG-0512-001_Spec Zenith 2005

www.ZenithOilfield.com T: +44 (0) 1467 628866

You might also like

- List of Secret Codes PDFDocument1 pageList of Secret Codes PDFmudassir264083% (6)

- List of Secret Codes PDFDocument1 pageList of Secret Codes PDFmudassir264083% (6)

- Spectra™ Tubing Cutters Field Assembly and Arming: January 21, 2010Document10 pagesSpectra™ Tubing Cutters Field Assembly and Arming: January 21, 2010aliNo ratings yet

- Simha Lagna: First House Ruled by The Planet Sun (LEO) : The 1st House Known As The Ascendant orDocument3 pagesSimha Lagna: First House Ruled by The Planet Sun (LEO) : The 1st House Known As The Ascendant orRahulshah1984No ratings yet

- 722.6 Transmission Conductor Plate Replacement DIYDocument3 pages722.6 Transmission Conductor Plate Replacement DIYcamaro67427100% (1)

- SIGA Monitoring ToolDocument3 pagesSIGA Monitoring ToolMhalou Jocson EchanoNo ratings yet

- Oil & Gas Rig Roles Functions ProcessesDocument5 pagesOil & Gas Rig Roles Functions ProcessesAnant Ramdial100% (1)

- k10 GeothermalDocument1 pagek10 GeothermalshegateNo ratings yet

- Down Hole Assembly PDFDocument13 pagesDown Hole Assembly PDFOvRrj AhmedNo ratings yet

- 1140523021191Document110 pages1140523021191Irimia Matei Alex100% (3)

- Next Generation Mobile Network PosterDocument1 pageNext Generation Mobile Network PosterTarik Kazaz100% (2)

- Introduction To OCTG: API Steel Grades Handout 03Document4 pagesIntroduction To OCTG: API Steel Grades Handout 03AHMEDNo ratings yet

- AdaptersDocument69 pagesAdaptersPrakhar SarkarNo ratings yet

- Waste HeatDocument10 pagesWaste HeatRizwanKhanNo ratings yet

- Drill Stem Testing RD Sampler: SmartstarDocument1 pageDrill Stem Testing RD Sampler: SmartstarDenier RubianoNo ratings yet

- Y-Tool 7 - SLB Thailand 13% Cr-Support ClampDocument3 pagesY-Tool 7 - SLB Thailand 13% Cr-Support ClampNattakorn sangmarkNo ratings yet

- ScrapDocument22 pagesScrapranda perdanaNo ratings yet

- Lot 8 Dafora Appendix B Standards and Specifications DaforaDocument81 pagesLot 8 Dafora Appendix B Standards and Specifications DaforaZamfirMarianNo ratings yet

- CHAMP® XHP PackerDocument2 pagesCHAMP® XHP PackerservicemenruNo ratings yet

- Rupture Disk FUL-FLO Sampler: HalliburtonDocument2 pagesRupture Disk FUL-FLO Sampler: Halliburtonsaeed65No ratings yet

- DHSV TestDocument7 pagesDHSV TestRonald Lucas Silva Lefundes OliveiraNo ratings yet

- BOP Control Unit FlyerDocument2 pagesBOP Control Unit Flyeraliabd1989 alzubidiNo ratings yet

- Module 5 Greek ArchDocument22 pagesModule 5 Greek ArchKyla A. EstoestaNo ratings yet

- Hammer Unions and Swivel Joints GuideDocument16 pagesHammer Unions and Swivel Joints GuideFabricio100% (1)

- WKM Pow-R-Seal Gate Valve: Installation, Operation and Maintenance ManualDocument16 pagesWKM Pow-R-Seal Gate Valve: Installation, Operation and Maintenance ManualBureau VeritasNo ratings yet

- Husserl - Amsterdam LecturesDocument13 pagesHusserl - Amsterdam LecturesPhilip Reynor Jr.No ratings yet

- EHT Application NoteDocument3 pagesEHT Application NoteJuan SanchezNo ratings yet

- Drawing SallDocument81 pagesDrawing Sall90070878002No ratings yet

- Pumps+Valves4 MudGateValves 081129Document6 pagesPumps+Valves4 MudGateValves 081129isamelgqNo ratings yet

- Manual Panel Zenith Part B PDFDocument56 pagesManual Panel Zenith Part B PDFDiegoEstupiñanNo ratings yet

- BOP dimensions rig 231Document13 pagesBOP dimensions rig 231Heris SitompulNo ratings yet

- D&L Double Grip Pkr-Asi-Xpacker1c PDFDocument2 pagesD&L Double Grip Pkr-Asi-Xpacker1c PDFMoh Syamsul BahriNo ratings yet

- Teaching Speaking: Daily Activities Lesson PlanDocument3 pagesTeaching Speaking: Daily Activities Lesson PlanMARCELANo ratings yet

- Tubing Gauge Paraffin Cutter.Document1 pageTubing Gauge Paraffin Cutter.Cesar Jara CobosNo ratings yet

- 4 1/2Document1 page4 1/2Hassan ZakeriNo ratings yet

- Top-Co - AutoFill - BV & HF ValvesDocument4 pagesTop-Co - AutoFill - BV & HF ValvesJuan LacorteNo ratings yet

- Business Opportunity - Thru Tubing ToolsDocument24 pagesBusiness Opportunity - Thru Tubing ToolsSohaib RashidNo ratings yet

- Downhole Instrumentation Qualification RPDocument4 pagesDownhole Instrumentation Qualification RPabinadi1230% (1)

- Hydril Blowout Preventers Ram AssembliesDocument2 pagesHydril Blowout Preventers Ram AssembliesJIN WANGNo ratings yet

- D392005428-MKT-001 6012 Bop PDFDocument2 pagesD392005428-MKT-001 6012 Bop PDFMitul PatelNo ratings yet

- NV MSTP 269 Multi Shot Tubing Punch TM 235 c207 003 09 ManualDocument22 pagesNV MSTP 269 Multi Shot Tubing Punch TM 235 c207 003 09 ManualDiana Carolina Rojas TorresNo ratings yet

- Bop1006 b73s33s-3r2l3l-35h-0Document1 pageBop1006 b73s33s-3r2l3l-35h-0api-513539506No ratings yet

- Camesa Cable SpecDocument1 pageCamesa Cable SpecShashank Anand MishraNo ratings yet

- Wireline Depth CountersDocument1 pageWireline Depth CounterssitaNo ratings yet

- SUPERCHANGER Plate and FrameDocument28 pagesSUPERCHANGER Plate and Framejack-bcNo ratings yet

- SuckerRods Torque Limits V02ii PDFDocument1 pageSuckerRods Torque Limits V02ii PDFsong LiNo ratings yet

- FSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes ReliabilityDocument2 pagesFSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes Reliabilitymehmet sait öztürkNo ratings yet

- Equipment FlyerDocument7 pagesEquipment FlyerCatalin StoicescuNo ratings yet

- Dailey Hydraulic Fishing Jar 6 PDFDocument1 pageDailey Hydraulic Fishing Jar 6 PDFMuhammad ShahrukhNo ratings yet

- B+V General Catalog 2010Document32 pagesB+V General Catalog 2010Leonardo Faria Bueno100% (1)

- CS® Tubing Torque ChartDocument2 pagesCS® Tubing Torque Chartjesus infanteNo ratings yet

- Hydril Blowout Preventers Ram Seal KitsDocument1 pageHydril Blowout Preventers Ram Seal KitsJIN WANGNo ratings yet

- 8 P 80Document2 pages8 P 80lionelNo ratings yet

- ALS7501 01 Sucker Rods Brochure PDFDocument8 pagesALS7501 01 Sucker Rods Brochure PDFedinson saenzNo ratings yet

- Cameron BOP WeightDocument2 pagesCameron BOP WeightMurali SambandanNo ratings yet

- Caja de Cambio John DeereDocument52 pagesCaja de Cambio John Deerenelson.oyanadel21No ratings yet

- Introduction 15K H2S PCEDocument4 pagesIntroduction 15K H2S PCEJuanNo ratings yet

- Graco Xtreme 70 1 Airless Spray Pumps Part Numbers and Schematics Guide 206m539Document24 pagesGraco Xtreme 70 1 Airless Spray Pumps Part Numbers and Schematics Guide 206m539Maulana Mufti MuhammadNo ratings yet

- Wireline Retriever: Instruction Manual 8820Document5 pagesWireline Retriever: Instruction Manual 8820GNo ratings yet

- CamesaEMC Catalog 12-2013 7Document1 pageCamesaEMC Catalog 12-2013 7Gerardo LizardoNo ratings yet

- H00707Document2 pagesH00707AQUILES CARRERANo ratings yet

- LandRig PosterDocument1 pageLandRig PosterRaúl MárquezNo ratings yet

- Cup Type TesterDocument1 pageCup Type TesterJohnsNo ratings yet

- D391000177-MKT-001 Rev 06 WISE Catalog PDFDocument28 pagesD391000177-MKT-001 Rev 06 WISE Catalog PDFHumberto GonçalvesNo ratings yet

- Product Information Bulletin: Date: Bulletin Number: 1000059437-PIB Revision: 01Document7 pagesProduct Information Bulletin: Date: Bulletin Number: 1000059437-PIB Revision: 01carlosorizabaNo ratings yet

- VAM FJL Torque TableDocument17 pagesVAM FJL Torque TableKhaledFekairNo ratings yet

- HP Auto Clave FittingsDocument1 pageHP Auto Clave FittingsRavi Chaitanya VelamarthyNo ratings yet

- Gryphon Product OverviewDocument51 pagesGryphon Product OverviewTaras ByloNo ratings yet

- Wire LineDocument54 pagesWire LineJOUININo ratings yet

- National Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALDocument37 pagesNational Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALariel feNo ratings yet

- 2M Tek Torq Tek ZIIDocument1 page2M Tek Torq Tek ZIIamghardjillali_449230% (1)

- Completion Systems 2020Document28 pagesCompletion Systems 2020Min Thant MaungNo ratings yet

- Brochure PV-271 Low Res (A4) - tcm836-3434016Document4 pagesBrochure PV-271 Low Res (A4) - tcm836-3434016Marco BacianNo ratings yet

- 43sany Group Products ManualDocument2 pages43sany Group Products ManualNazeeh Abdulrhman AlbokaryNo ratings yet

- Isri Scrap Specifications Circular 2006 PDFDocument57 pagesIsri Scrap Specifications Circular 2006 PDFNazeeh Abdulrhman AlbokaryNo ratings yet

- Annex 3 RFQ Lot 3 Schedule 3 Bill of Quantities SR-RW-AAS-00Document10 pagesAnnex 3 RFQ Lot 3 Schedule 3 Bill of Quantities SR-RW-AAS-00Nazeeh Abdulrhman AlbokaryNo ratings yet

- Principles of Seed TechnologyDocument6 pagesPrinciples of Seed TechnologyTanvi Patel0% (2)

- Global Scrap Market Recovery - An Isri Town Hall SeriesDocument2 pagesGlobal Scrap Market Recovery - An Isri Town Hall SeriesNazeeh Abdulrhman AlbokaryNo ratings yet

- ABB March 2011Document5 pagesABB March 2011Nazeeh Abdulrhman AlbokaryNo ratings yet

- Rotary Twin Screw Compressor Packages: Specifications & DimensionsDocument4 pagesRotary Twin Screw Compressor Packages: Specifications & DimensionsNazeeh Abdulrhman AlbokaryNo ratings yet

- Starting a Business Guide - How to Legally Register Your CompanyDocument8 pagesStarting a Business Guide - How to Legally Register Your CompanyNazeeh Abdulrhman AlbokaryNo ratings yet

- Jiu Rep 2010 4 ADocument89 pagesJiu Rep 2010 4 ANazeeh Abdulrhman AlbokaryNo ratings yet

- Rotary Shaft Oil Seals For Cement and Coal Mill Pulverizers: Technical HandbookDocument6 pagesRotary Shaft Oil Seals For Cement and Coal Mill Pulverizers: Technical HandbookNazeeh Abdulrhman AlbokaryNo ratings yet

- A Study of the Scrap Metal Trade in KumasiDocument82 pagesA Study of the Scrap Metal Trade in KumasiNazeeh Abdulrhman AlbokaryNo ratings yet

- Trends in Food Science & Technology: C. LongaDocument1 pageTrends in Food Science & Technology: C. LongaNazeeh Abdulrhman AlbokaryNo ratings yet

- Ice Plant CatDocument4 pagesIce Plant CatNazeeh Abdulrhman AlbokaryNo ratings yet

- Starting a Business Guide - How to Legally Register Your CompanyDocument8 pagesStarting a Business Guide - How to Legally Register Your CompanyNazeeh Abdulrhman AlbokaryNo ratings yet

- 2016 Toyota Hilux DPL en PDFDocument48 pages2016 Toyota Hilux DPL en PDFNguyễn Kim TùngNo ratings yet

- Sheet No. 2Document3 pagesSheet No. 2Nazeeh Abdulrhman AlbokaryNo ratings yet

- 2016 Toyota Hilux DPL en PDFDocument48 pages2016 Toyota Hilux DPL en PDFNguyễn Kim TùngNo ratings yet

- 09 - Chapter IxDocument7 pages09 - Chapter IxNazeeh Abdulrhman AlbokaryNo ratings yet

- LME Zinc FactsheetDocument6 pagesLME Zinc FactsheetOscar Zuñiga SolariNo ratings yet

- Methods For Design of Hoppers, Silo's, Bins & BunkersDocument10 pagesMethods For Design of Hoppers, Silo's, Bins & BunkersJaco KotzeNo ratings yet

- Techspec QJ240 PDFDocument2 pagesTechspec QJ240 PDFNazeeh Abdulrhman AlbokaryNo ratings yet

- Dimensions and Units: SheetDocument2 pagesDimensions and Units: SheetNazeeh Abdulrhman AlbokaryNo ratings yet

- SI F09 Ch29 PDFDocument10 pagesSI F09 Ch29 PDFrenoyaboNo ratings yet

- Si F09 AddDocument3 pagesSi F09 AddJitendra Laxmikant WaniNo ratings yet

- Appendix A - Table of Time Zone CodesDocument4 pagesAppendix A - Table of Time Zone CodesSergio SemmNo ratings yet

- Nature and Scope of History as a Social ScienceDocument14 pagesNature and Scope of History as a Social SciencejustadorkyyyNo ratings yet

- ST5DB Skylake U Platform Block Diagram TitleDocument82 pagesST5DB Skylake U Platform Block Diagram TitleJOSE PAZNo ratings yet

- Schmitt Trigger FinalDocument4 pagesSchmitt Trigger Finalsidd14feb92No ratings yet

- Baghouse Compressed AirDocument17 pagesBaghouse Compressed Airmanh hung leNo ratings yet

- International Journal of Information Technology, Control and Automation (IJITCA)Document2 pagesInternational Journal of Information Technology, Control and Automation (IJITCA)ijitcajournalNo ratings yet

- Details of Nodal Officer - HD Officers of Other DepttDocument46 pagesDetails of Nodal Officer - HD Officers of Other DepttManoj KashyapNo ratings yet

- CMO Olympiad Book For Class 3Document13 pagesCMO Olympiad Book For Class 3Srividya BaiNo ratings yet

- Fireclass: FC503 & FC506Document16 pagesFireclass: FC503 & FC506Mersal AliraqiNo ratings yet

- Towards Innovative Community Building: DLSU Holds Henry Sy, Sr. Hall GroundbreakingDocument2 pagesTowards Innovative Community Building: DLSU Holds Henry Sy, Sr. Hall GroundbreakingCarl ChiangNo ratings yet

- Is BN 9789526041957Document72 pagesIs BN 9789526041957supriya rakshitNo ratings yet

- Product Item Code Model Item Description MRP Count Down PricesDocument1 pageProduct Item Code Model Item Description MRP Count Down Pricesලහිරු විතානාච්චිNo ratings yet

- Namatacan HS Report on Regional Diagnostic AssessmentDocument13 pagesNamatacan HS Report on Regional Diagnostic AssessmentDonnabelle MedinaNo ratings yet

- Dcs Ict2113 (Apr22) - LabDocument6 pagesDcs Ict2113 (Apr22) - LabMarwa NajemNo ratings yet

- Physics 8 - EnergyDocument54 pagesPhysics 8 - EnergyHakim AbbasNo ratings yet

- Quick Start Guide - QualiPoc AndroidDocument24 pagesQuick Start Guide - QualiPoc AndroidDmitekNo ratings yet

- MTPDF4 Exact and Non-Exact Differential EquationsDocument27 pagesMTPDF4 Exact and Non-Exact Differential Equationsnaughty dela cruzNo ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- Supply Chain Management 5th Edition Chopra Solutions ManualDocument3 pagesSupply Chain Management 5th Edition Chopra Solutions Manualdammar.jealousgvg6100% (18)

- Full Download Ebook Ebook PDF Oracle 12c SQL 3rd Edition by Joan Casteel PDFDocument41 pagesFull Download Ebook Ebook PDF Oracle 12c SQL 3rd Edition by Joan Casteel PDFdaniel.morones654100% (36)

- Advantages of Chain Grate Stokers: Dept of Mechanical Engg, NitrDocument3 pagesAdvantages of Chain Grate Stokers: Dept of Mechanical Engg, NitrRameshNo ratings yet

- Investigação de Um Novo Circuito de Balanceamento de Tensão para Turbinas Eólicas Baseadas em PMSG Offshore Conectadas em ParaleloDocument7 pagesInvestigação de Um Novo Circuito de Balanceamento de Tensão para Turbinas Eólicas Baseadas em PMSG Offshore Conectadas em ParaleloDaniel reisNo ratings yet

- Drone Hexacopter IjisrtDocument4 pagesDrone Hexacopter IjisrtDEPARTEMEN RUDALNo ratings yet