Definitions

Loose Gear - small cargo gear, such as rings, hooks, shackles, pulley blocks, links, swivels, chains,

slings and wire pennants, that is not permanently attached to a lifting appliance or the

vessel.

Main Accessory Gear - any cargo gear that is designed to be used with a lifting appliance, such as

spreaders, container frames, probes, grabs, vacuum discs, friction clamps and

heavy hooks. t does not include loose gear

!horough "#amination - in respect of cargo gear or an accommodation ladder, a detailed visual

e#amination supplemented, if necessary, by non-destructive testing,

dismantling of components, measurement of corrosion, deformation and wear,

evaluation of structural and moving parts under working conditions and other

means, in order to arrive at a reliable conclusion as to the safety of the gear or

ladder.

Load !est $e%uirements for Loose Gear and Main Accessory Gear

Loose Gear and Main Accessory Gear shall be load tested in accordance with schedule & below'

(a) before the gear is used for the first time* and

(b) after the gear is modified or repaired and before it is used again.

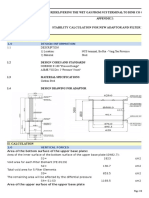

+,-"D.L" &

(Subsection 305(1))

!"+!/G 01 L00+" A/D MA/ A,,"++0$2 G"A$

,olumn 3 ,olumn 4

tem Gear Load

3. ,hains, hooks, links, rings, shackles, slings, sockets, swages,

swivels and similar loose gear

4 5 +6L

4. +ingle-sheave pulley blocks without a becket 7 5 +6L

8. +ingle-sheave pulley blocks with a becket 9 5 +6L

7. Multiple-sheave pulley blocks with an +6L of

(a) not more than 4: tonnes (a) 4 5 +6L

(b) more than 4: tonnes but not more than 7: tonnes (b) +6L ; 4: tonnes

(c) more than 7: tonnes (c) 3.& 5 +6L

&. Main accessory gear with an +6L of

(a) not more than 3: tonnes (a) 4 5 +6L

(b) more than 3: tonnes but not more than 39: tonnes (b) (3.:7 5 +6L) ; <.9 tonnes

(c) more than 39: tonnes (c) 3.3 5 +6L

9. 1riction, electro-magnetic and vacuum connectors (& Minutes) 4 5 +6L

Main Accessory Gear cannot be load tested until the inspector receives one of the following first

A =revious certificate of a thorough e#amination

!he manufacturer>s design information including the +6L

A letter from the manufacturer or an engineer stating the +6L

!horough "#amination

Loose Gear and Main Accessory Gear is to be thoroughly e#amined'

After a Load !est is conducted as above

At least annually

,ertificate of Load !est or of !horough "#amination

f loose gear or main accessory gear passes a Load !est or a !horough "#amination, the competent

person shall sign and issue a certificate that certifies that it passed the test or e#amination and sets out'

(a) the location and a description of the gear*

(b) any identifying marks on the gear*

(c) in the case of loose gear,

(i) the name of its manufacturer or supplier, and

(ii) if a test was conducted, the date of the test and the number of similar pieces of gear tested

on that date*

(d) if a test was conducted, the load applied and the safe working load*

(e) in the case of a test of a friction, an electro-magnetic or a vacuum connector, the type of material

tested*

(f) their name and

(i) if they are an employee, the name and address of their employer, or

(ii) if they are not an employee, their address* and

(g) the position, %ualifications, certification or e#perience that %ualifies them as a competent person.

,ondition of .se

Loose Gear or wire rope may not be used unless it has a current certificate of a !horough "#amination

(within the past year) and an e#pert person inspected it within the preceding three months and

determined that it is safe to use.

Registers

3. !he master of a vessel shall keep on board the vessel a register that lists the cargo gear that

forms part of the e%uipment of the vessel.

4. A register that lists cargo gear that does not form part of the e%uipment of a vessel and is tested

or thoroughly e#amined under any of sections 303 to 306 shall be kept at the premises of the

gear?s owner.

8. A competent person who tests or thoroughly e#amines a lifting appliance, loose gear or main

accessory gear shall enter the following in the register in a space ad@acent to the listing for the

appliance or gear and shall sign the register'

(a) the date of the test or e#amination*

(b) the particulars and results of the test or e#amination*

(c) their name and

(i) if they are an employee, the name and address of their employer, or

(ii) if they are not an employee, their address* and

(d) the position, %ualifications, certification or e#perience that %ualifies them as a competent

person.

Main Accessory Gear

847. Main accessory gear shall have its safe working load clearly marked on it.

Pulley Blocks

84&. "very pulley block shall have its safe working load permanently engraved or stamped on it.

Slings

849. !he safe working load of slings in a straight vertical lift configuration shall be indicated as

follows'

(a) in the case of chain slings, by marking them in figures or letters on the sling or on a tablet or ring of

durable material attached securely to the sling*

(b) in the case of wire-rope slings and reusable natural- or synthetic-fibre rope or webbing slings, as

specified in paragraph (a) or by stating the safe working loads for the various siAes of slings used on a

notice and e#hibiting it so that it can be easily read by persons using the slings*

(c) in the case of disposable webbing slings, by marking the slings with a B.C or the word

BD+=0+ADL"C or BE"!ADL"C* and

(d) in the case of disposable stranded rope slings, by using marker yarns or other means that identify

the slings with their certificates issued under subsection 312(4).

Wire Ropes

8:F. Defore being used, wire rope shall be tested by a competent person causing a sample section to be

pulled to destruction.

8:G. (3) 6ire rope shall be thoroughly e#amined by a competent person at least once every year after it

is tested or, if the rope passes over a drum or sheave, at least once every si# months after it is tested.

(4) 6ire rope passes the e#amination if

(a) there is no sign of internal corrosion*

(b) there is no sign of a tendency towards separation of the strands or wires*

(c) there are no flats on individual wires*

(d) the number of broken wires in any length e%ual to eight diameters does not e#ceed

(i) 3:H of the total number of wires in the length, or

(ii) any lesser number of broken wires that is re%uired by section 34 of Wear Standards for Cargo Gear,

!= <8<9, published by the Department of !ransport* and

(e) its diameter is not reduced by more than

(i) FH when elongation of the lay has occurred or a strand is becoming buried, or

(ii) 3:H when the lay is uniform.

/o wire rope in which any wire is broken shall be used unless an e#pert person inspects it on the day of

its intended use and determines that it is safe to use.

Metal Fittings Attached to Wire Ropes

8:<. (3) Defore being used, a metal fitting attached to a wire rope by swaging or socketing shall be

tested by a competent person with a load e%ual to 4::H of the rope?s safe working load.

(4) A fitting passes the test if it does not break and no defects or signs of permanent deformation are

detected.

(8) Despite subsections (3) and (4), fittings attached by swaging by the same machine to wire rope that

is the same type and siAe and is less than 4& mm in diameter may be type tested if

(a) at least 3:H of the fittings are proof tested by a person referred to in paragraph 300(4)(b) with a

load e%ual to 4::H of the rope?s safe working load and the fittings tested do not break and no defects

or signs of permanent deformation are detected*

(b) one fitting in every one thousand or fewer is pulled to destruction and the fitting does not break or

fail at less than the breaking strength of the rope*

(c) the person who performs the proof testing signs a certificate that certifies that the fitting passed the

test and sets out

(i) a description of the fittings and the rope,

(ii) any identifying marks on the fittings,

(iii) the name of the manufacturer of the fittings,

(iv) the date of the test, the number of fittings tested and the total number of fittings being certified,

(v) the load applied and the safe working load,

(vi) their name and

(A) if they are an employee, the name and address of their employer, or

(D) if they are not an employee, their address, and

(vii) their technical %ualifications*

(d) the fittings are marked to identify them to the test certificate* and

(e) the certificate is kept on board the vessel or at the rope owner?s premises, as the case may be.