Professional Documents

Culture Documents

Bevel Explanation

Uploaded by

Varun Vaidya0 ratings0% found this document useful (0 votes)

65 views4 pagesThis document discusses bevel gear geometry and methods for analyzing stresses in bevel gears. It defines key terms related to bevel gear geometry, such as pitch angle, cone distance, and back-cone radius. It describes the Tredgold tooth shape approximation method for determining tooth dimensions. It also summarizes the standard AGMA method for calculating maximum bending stress and simplifies it for static loading conditions. Finally, it outlines an alternative beam bending method for stress analysis that models each tooth as a beam with a trapezoidal cross-section.

Original Description:

bevel

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses bevel gear geometry and methods for analyzing stresses in bevel gears. It defines key terms related to bevel gear geometry, such as pitch angle, cone distance, and back-cone radius. It describes the Tredgold tooth shape approximation method for determining tooth dimensions. It also summarizes the standard AGMA method for calculating maximum bending stress and simplifies it for static loading conditions. Finally, it outlines an alternative beam bending method for stress analysis that models each tooth as a beam with a trapezoidal cross-section.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views4 pagesBevel Explanation

Uploaded by

Varun VaidyaThis document discusses bevel gear geometry and methods for analyzing stresses in bevel gears. It defines key terms related to bevel gear geometry, such as pitch angle, cone distance, and back-cone radius. It describes the Tredgold tooth shape approximation method for determining tooth dimensions. It also summarizes the standard AGMA method for calculating maximum bending stress and simplifies it for static loading conditions. Finally, it outlines an alternative beam bending method for stress analysis that models each tooth as a beam with a trapezoidal cross-section.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

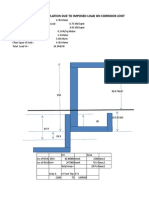

Bevel Gear Geometry Page 1 of 4

Bevel Gear Geometry

Drawings

List of symbols

N

P

Number of

teeth on Pinion

N

G

Number of

teeth on Gear

D

G

Pitch Diameter

of Gear

D

P

Pitch Diameter

of Pinion

F Face Width

(Length of one

tooth)

Pinion Pitch

Angle

(Radians)

Gear Pitch

Angle

(Radians)

A

o

Cone Distance

(Distance from

pitch circle to

intersection of

shaft axes)

r

b

Back-Cone

Radius

P Diametrical

Pitch. Teeth

per inch of

Pitch Diameter

(N/D)

p Circular Pitch.

Inches of

circumference

per tooth

(/P)

Equations

Tan = N

P

/ N

G

Tan = N

G

/ N

P

Bevel Gear Geometry Page 2 of 4

Tooth shape for bevel gears is determined by scaling spur gear tooth shapes

along the face width. The further from the intersection of the gear and pinion

axes, the bigger the tooth cross sections are. If the tooth face were to extend

all the way to the axes intersection, the teeth would approach infinitesimal size

there. The tooth cross-section at the largest part of the tooth is identical to the

tooth cross-section of a tooth from a spur gear with Pitch Diameter of 2* r

b

, or

twice the Back-Cone Radius, and with an imaginary number of teeth (N) equal

to 2* times the Back-Cone Radius (r

b

) divided by the Circular Pitch of the

bevel gear (p). This method of obtaining the dimensions and shape of the

largest tooth profile is known at the Tredgold tooth-shape approximation.

Refer to the profiles shown near the Back-cone radius dimension in the

drawing above.

AGMA Method for Determining Stresses

The standard method for determining induced bending stresses in bevel gears

comes from the American Gear Manufacturers Association and is based on

the equation below.

Symbol Name Notes / How can we simplify these terms for static

loading of normal gears

Max bending

stress in tooth

Compare to gear material strength to

determine if the gear will break

W

t

Transmitted

tangential load

Taken at large end of tooth

K

a

Application factor Accounts for probability of greater-than-design-

load occurrences. This is not something we

expect, so neglect this, and set K

a

= 1

K

v

Dynamic factor Accounts for dynamic effects and velocity of

tooth contact. For static loading, which is an

assumption we will make, since we are dealing

with relatively low speeds, neglect this term,

Bevel Gear Geometry Page 3 of 4

and set K

v

= 1

P Diametrical pitch N / D

F Face width

K

s

Size factor Accounts for unusually sized gears. Not

applicable for normal gears. Set K

s

= 1

K

m

Load-distribution

factor

Accounts for shaft misalignment and shaft

bending. Build your gearbox carefully, so you

can neglect this term and set K

m

= 1.

J Geometry factor Similar to Lewis form factor used for spur

gears. Obtain from chart based on number of

teeth on gear and pinion.

After setting those factors that do not apply to 1 (see notes above), we can

come up with a simplified AGMA equation.

This equation is highly simplified to allow for fast calculation with minimum

table look-ups. It is not for use on critical applications, high speed gears, or

gears of unusual materials.

Bevel Gear Geometry Page 4 of 4

Beam Bending Method for Determining Stresses

To do this, first we simplify the shape of the tooth. We will assume that it is a

beam with an isosceles trapezoidal cross section. If you look at a single tooth,

you will see how this is applicable. We will also assume that the forces on this

single tooth are equivalent to a resultant force applied at the pitch circle (about

halfway up the tooth), at the large end of the tooth. We get this force by

dividing the torque on the gear by the pitch radius. The length of our beam

(from base to applied force) is the dedendum of the tooth section at the large

end of the tooth face.

Knowing the applied force, the beam

length, and the cross section of the

beam (form which we can calculate the

moment of inertia of the cross section),

we can determine the maximum

stresses experienced at the base of the

beam through simple beam bending

equations.

It is important to note that in practice,

the location and direction of the force

applied to each tooth changes as the

gear rotates, and there are surface

durability considerations, as well as many other factors that govern tooth

strength that are not accounted for in this analysis. For design of production

gears or critical applications, AGMA standards should be consulted. It is

interesting to note though, that in many situations, the beam bending analysis

and the simplified AGMA standards produce very similar results.

You might also like

- Bevel GearDocument17 pagesBevel Gearparesh09No ratings yet

- 2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFDocument12 pages2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFvlad lupasteanuNo ratings yet

- MESYS Shaft CalculationDocument28 pagesMESYS Shaft CalculationZoebairNo ratings yet

- Subroutine For Cohesive ElementDocument41 pagesSubroutine For Cohesive ElementBhushanRaj100% (1)

- Deflection Calculation Due To Imposed Load On Corridor JoistDocument14 pagesDeflection Calculation Due To Imposed Load On Corridor JoistranjitNo ratings yet

- Modal Space - in Our Own Little World: by Pete AvitabileDocument2 pagesModal Space - in Our Own Little World: by Pete AvitabileVignesh SelvarajNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Bond-Slip Model For Detailed Finite-Element AnalysisDocument10 pagesBond-Slip Model For Detailed Finite-Element AnalysisSilver rayleighNo ratings yet

- Terminal Report ShredderDocument25 pagesTerminal Report ShredderEnriv YasiladNo ratings yet

- Design-II, 2016 Bevel Gear Design ProcedureDocument1 pageDesign-II, 2016 Bevel Gear Design ProcedureenggsantuNo ratings yet

- Fatigue Behavior of Materials Under Strain Cycling in Low and Intermediate Life Range PDFDocument58 pagesFatigue Behavior of Materials Under Strain Cycling in Low and Intermediate Life Range PDFLeonardo TerraNo ratings yet

- FT GT F GT D FT G D: AsteriskDocument22 pagesFT GT F GT D FT G D: Asterisk174A1 HindupriyaNo ratings yet

- Acme Thread External 29Document16 pagesAcme Thread External 29Dhanraj VasanthNo ratings yet

- Fracture Mechanics CharacterizationDocument124 pagesFracture Mechanics CharacterizationJose Luis GrajedaNo ratings yet

- Mitigation of Motion in Tall BuldingsDocument23 pagesMitigation of Motion in Tall BuldingsAkshayNo ratings yet

- CHABOCHE, J. L. - Continuum Damage Mechanics P.2 - Damage Growth, Crack InitiationDocument8 pagesCHABOCHE, J. L. - Continuum Damage Mechanics P.2 - Damage Growth, Crack InitiationhasmonteiroNo ratings yet

- PVEfea Assembly AnalysisDocument20 pagesPVEfea Assembly AnalysisAnandh PsNo ratings yet

- Major Project ShredderDocument12 pagesMajor Project Shredderaman kumarNo ratings yet

- Heat ExchangersDocument30 pagesHeat ExchangersvpjagannaathNo ratings yet

- Synechron: Customer Name Date Created byDocument1 pageSynechron: Customer Name Date Created byneelNo ratings yet

- MESYS Shaft CalculationDocument51 pagesMESYS Shaft Calculationdd hhNo ratings yet

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- This Data Was Generated Using The Function Definition: Sin (2 Pi Freq Time) Here, Time Is Defined As Integer Multiples of The Sampling FrequencyDocument44 pagesThis Data Was Generated Using The Function Definition: Sin (2 Pi Freq Time) Here, Time Is Defined As Integer Multiples of The Sampling FrequencyRaturi DeepankarNo ratings yet

- FEA Report PDFDocument24 pagesFEA Report PDFDanish JavedNo ratings yet

- (Engineersdaily Com) IBC2000E11Document21 pages(Engineersdaily Com) IBC2000E11Nazar ShafiqNo ratings yet

- 07 Axisymmetric Finite Element ModelingDocument14 pages07 Axisymmetric Finite Element ModelingSchubertDeierlein100% (1)

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83No ratings yet

- Eq Base Shear CalculationsDocument9 pagesEq Base Shear Calculationsirshad313No ratings yet

- Fracture Project PresentationDocument16 pagesFracture Project Presentationdhillon_rsdNo ratings yet

- Low Freq Simulation 2013Document33 pagesLow Freq Simulation 2013teomondoNo ratings yet

- Wind Analysis ResultsDocument8 pagesWind Analysis ResultsBrahim HammamiNo ratings yet

- Is 14812 2005Document12 pagesIs 14812 2005JayDeep KhajureNo ratings yet

- Example Problem 9.1 GivenDocument12 pagesExample Problem 9.1 GivengertjaniNo ratings yet

- Double Angle BarDocument1 pageDouble Angle BarShadin Asari ArabaniNo ratings yet

- Under, Over and Critical DampingDocument6 pagesUnder, Over and Critical Dampingxeron7126No ratings yet

- ME421-Single Degree of Freedom System (Damped) PDFDocument13 pagesME421-Single Degree of Freedom System (Damped) PDFAli Haider RizviNo ratings yet

- EQL and DesignDocument6 pagesEQL and Designsabareesan09No ratings yet

- Gantry Crane Load r2Document12 pagesGantry Crane Load r2Bang OchimNo ratings yet

- BGSCM14 C08 Ex ProbDocument85 pagesBGSCM14 C08 Ex ProbamachmouchiNo ratings yet

- Strength of LugDocument8 pagesStrength of LugnareniviNo ratings yet

- Vibration and Shock IsolationDocument3 pagesVibration and Shock IsolationSaravanan.KNo ratings yet

- LiftingLugStress Rev 1.5Document17 pagesLiftingLugStress Rev 1.5mohdshakir bahariNo ratings yet

- Downloadscrib PDFDocument2 pagesDownloadscrib PDFTuan Pham MinhNo ratings yet

- Fea Project ReportDocument58 pagesFea Project ReportAvnish DubeyNo ratings yet

- Optical Ring-Coupler Simulation Using CST MICROWAVE STUDIODocument3 pagesOptical Ring-Coupler Simulation Using CST MICROWAVE STUDIONgô Cự MạnhNo ratings yet

- Chapter 8 Two-Dimensional Problem SolutionDocument51 pagesChapter 8 Two-Dimensional Problem SolutionJoseph Daguio JrNo ratings yet

- Pages From Hyundai Welding Handbook (2006)Document1 pagePages From Hyundai Welding Handbook (2006)tuatkNo ratings yet

- Lesson AGMA Standard - Example 1 & 2Document23 pagesLesson AGMA Standard - Example 1 & 2Sphumelele SibuthaNo ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument30 pagesPV Elite Vessel Analysis Program: Input DatachampNo ratings yet

- Random Vibration 845826Document22 pagesRandom Vibration 845826yash pradhanNo ratings yet

- Ansys Lug and Pin Stress AnalysesDocument30 pagesAnsys Lug and Pin Stress AnalysesAmm WillulNo ratings yet

- Damping DynaDocument15 pagesDamping DynasbhariNo ratings yet

- Nonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceFrom EverandNonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceNo ratings yet

- Bevel Gear GeometryDocument4 pagesBevel Gear GeometryNawaz JaswalNo ratings yet

- Long Addendum Gears 1946Document15 pagesLong Addendum Gears 1946Marco ViniciusNo ratings yet

- Project PPT On Effect of Parameters On Bending and Contact Stresses Developed in GearsDocument21 pagesProject PPT On Effect of Parameters On Bending and Contact Stresses Developed in GearsHrushikesh S BharadwajNo ratings yet

- Gears: What We Need To Know About Them. 1. Type of Gears 2. Terminologies or Nomenclatures 3. Forces TransmittedDocument35 pagesGears: What We Need To Know About Them. 1. Type of Gears 2. Terminologies or Nomenclatures 3. Forces TransmittedsyampnaiduNo ratings yet

- SpurDocument57 pagesSpurDangol RupeshNo ratings yet

- japonesesCR PDFDocument7 pagesjaponesesCR PDFJavier Antonio Cardenas OliverosNo ratings yet

- Teamcenter 10.1. Installation On Windows Servers Guide. Publication Number PLM00013 JDocument398 pagesTeamcenter 10.1. Installation On Windows Servers Guide. Publication Number PLM00013 JVarun VaidyaNo ratings yet

- 4 FinsDocument28 pages4 FinsVarun VaidyaNo ratings yet

- CATIA Certification TracksDocument7 pagesCATIA Certification TracksVarun VaidyaNo ratings yet

- FJDSFJKSFJKDFKJSDNGFJSNGSKMNGKJSGJKSF Technical Specifications 146-155Document1 pageFJDSFJKSFJKDFKJSDNGFJSNGSKMNGKJSGJKSF Technical Specifications 146-155Varun VaidyaNo ratings yet

- Star Star Star StarDocument1 pageStar Star Star StarVarun VaidyaNo ratings yet

- EllipseDocument20 pagesEllipseVikas Meena100% (1)

- كورس رسم هندسيDocument223 pagesكورس رسم هندسيIbrahim MostafaNo ratings yet

- JEE Main and Advanced Combined PDF Chapter Wise Class XI PDFDocument148 pagesJEE Main and Advanced Combined PDF Chapter Wise Class XI PDFexponential spiralNo ratings yet

- AutoCAD 2014 Tutorial 3DDocument26 pagesAutoCAD 2014 Tutorial 3DseleneletoNo ratings yet

- 12th Maths EM 1 Marks Question Paper 2 English Medium PDF Download PDFDocument4 pages12th Maths EM 1 Marks Question Paper 2 English Medium PDF Download PDFSaravanan JNo ratings yet

- Circle DPPDocument2 pagesCircle DPPTaniya DattaNo ratings yet

- Stonehenge Measures With Additional Confirmatory MaterialDocument63 pagesStonehenge Measures With Additional Confirmatory MaterialHarry Sivertsen100% (1)

- Maths 11 1Document28 pagesMaths 11 1api-230427224100% (1)

- Vibrant Academy: (India) Private LimitedDocument17 pagesVibrant Academy: (India) Private LimitedVedantNo ratings yet

- Maths EMDocument7 pagesMaths EMSubramanyam K.V.RNo ratings yet

- Model 1Document6 pagesModel 1ImayaNo ratings yet

- The Orchard Hideout - 11 02 21 - Unit Problem and PortfolioDocument5 pagesThe Orchard Hideout - 11 02 21 - Unit Problem and Portfolioapi-491234402No ratings yet

- Areas Related To CirclesDocument4 pagesAreas Related To CirclesAkshita KambojNo ratings yet

- Mathematical Ideas 13th Edition Miller Solutions ManualDocument44 pagesMathematical Ideas 13th Edition Miller Solutions Manualedithclara2jb100% (26)

- EASA Part 66 Module 1 MathematicsDocument14 pagesEASA Part 66 Module 1 MathematicsHussainAhmed100% (1)

- DevelopementDocument85 pagesDevelopementGagandeep Singh MaviNo ratings yet

- Grade 10 q2 Math Las No AkDocument84 pagesGrade 10 q2 Math Las No AkZarina Roxas SantosNo ratings yet

- 19.3 - Symetry Properties of CirclesDocument3 pages19.3 - Symetry Properties of CirclesRaffaella LaxaldeNo ratings yet

- Mathematics SyllabusDocument21 pagesMathematics SyllabusAlphonsius WongNo ratings yet

- A Semi Detailed Lesson PlanDocument3 pagesA Semi Detailed Lesson PlanPascua RobelynNo ratings yet

- 2D CommandsDocument37 pages2D Commandsmsaqibraza93No ratings yet

- Catia-Training-Material Chp3 & 4Document79 pagesCatia-Training-Material Chp3 & 4Vi GaneshNo ratings yet

- Math 5-Q4-Module-1Document18 pagesMath 5-Q4-Module-1Elaine Joyce GarciaNo ratings yet

- World Wildlife Day by SlidesgoDocument17 pagesWorld Wildlife Day by SlidesgoCristy LapusNo ratings yet

- Math g7 m6 Topic D Lesson 22 TeacherDocument11 pagesMath g7 m6 Topic D Lesson 22 TeacherJeon JungkookNo ratings yet

- IGCSE Mathematics 0580 CORE QP3 2015-2019 All Vs Solutions PDFDocument529 pagesIGCSE Mathematics 0580 CORE QP3 2015-2019 All Vs Solutions PDFSherin ThomasNo ratings yet

- CH 10. Conic Section (Math +1)Document51 pagesCH 10. Conic Section (Math +1)Dinesh BabuNo ratings yet

- Class 10 Maths SA2Document10 pagesClass 10 Maths SA2Priyank GuptaNo ratings yet

- ODB - Math (Geometry)Document4 pagesODB - Math (Geometry)Jerric CristobalNo ratings yet

- Lesson Plan 3rd Quarter MathDocument4 pagesLesson Plan 3rd Quarter MathAira Joyce Nepomuceno Cuaterno76% (17)