Professional Documents

Culture Documents

Efficient Charcoal (EC) Final

Uploaded by

Lauren Shaw0 ratings0% found this document useful (0 votes)

57 views4 pagesPeople every day use 2. Lb of wood to cook their food in developing countries around the world. Our solution is focus on making charcoal out of local resources we find in rural communities for example the corn plant after harvesting or any grass from three feet tall. Since people started using charcoal from grass or any other local resource, it will reduce the deforestation.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPeople every day use 2. Lb of wood to cook their food in developing countries around the world. Our solution is focus on making charcoal out of local resources we find in rural communities for example the corn plant after harvesting or any grass from three feet tall. Since people started using charcoal from grass or any other local resource, it will reduce the deforestation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

57 views4 pagesEfficient Charcoal (EC) Final

Uploaded by

Lauren ShawPeople every day use 2. Lb of wood to cook their food in developing countries around the world. Our solution is focus on making charcoal out of local resources we find in rural communities for example the corn plant after harvesting or any grass from three feet tall. Since people started using charcoal from grass or any other local resource, it will reduce the deforestation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

Efficient Charcoal (EC) Project

Mt. Hood Community College

Sustainable Engineering Class

Presented by:

Yenori Vasquez

Moises Maqueda

Hovard Guerrier

Ariel Rodriguez

June 5th 2014

Efficient Charcoal

(EC) Report

Efficient Charcoal (EC) Project

Introduction

People every day use 2.5 lb of wood to cook their food in developing countries around the world.

According with studies made every time you burn 1.3 lbs of wood, leave, grass or any woody

debris you are putting in the atmosphere 300 g of CO which later will become CO2. Since

Electrical power is hard to get in very rural areas in Haiti, Honduras, Nicaragua and in The State

of Guerrero in Mexico, and the cost of electric stoves or the payment of natural gas or methane is

just not at peoples reach our team has focus to work on a sustainable solution which supplies

peoples need of cooking, but also protect the local forest through not cutting trees. People are

already creating alternatives for reducing the reforestation caused by the needs of fuel, among

them efficient stoves, solar stoves, briquettes out of sawdust, news paper, leaves. Our solution is

focus on making charcoal out of local resources we find in rural communities for example the

corn plant after harvesting or any grass from three feet tall. Indeed research shows that the

charcoal from grass specifically corn works supplanting the charcoal made out of wood.

Problem Statement

Deforestation has increased over last decades, since it has become the main fuel for many

families to cook and make their own income. In most cases, in Mexico, C.A people in the rural

area burn wood and the intention of this project is to replace that wood by making charcoal from

local resources in communities for example corn stick or cones in case of Oregon. Since people

started to use charcoal from grass or any other local resource, it will reduce the deforestation.

Objectives

Reduce levels of deforestation in rural communities in C.A, Mexico and the Caribbean, by

making charcoal in an efficient way, which means elaboration of briquettes without wood.

Increase income for families in the community by selling the briquettes.

Methodology

Project materials and tools list:

Material Units Size

Almidon 1lb

Metal tube 1 12 inches

Metal blade 2 10*10 inches

Metal bucket 1 small

Wood 1 6*6 inches

Matches 1 box

Efficient Charcoal (EC) Project

In order to have ready all the equipment to start to do the project on Tuesday 15th was necessary

to buy some of the materials to build the charcoal machine. For this sustainable project is not

necessary a lot of equipment so, the expenses were minimum. Tuesday April 22th was the cones

collection and after that the amount of collected cones was approximately 15 pounds. The

collection of the cones was successfully because that day was perfect to collect them dry. The

group had meeting the same day and come up with ideas for the project.

After the meeting and all the process discussed was necessary to collect some data such as at

what temperature do the cones burn, what chemical can it produce etc. The researching wasnt

successful because it wasnt possible to find. On Tuesdays 6th, the group started to burn the

cones. The first try was in a kiln approximately 4 pounds in a container. The cones started to

burn at 430 degrees in 10 minutes, after that the result wasnt effectible because just the cones

that were at the top of the container get fire and the others not.

After that was necessary to burn the cones in a different container. The second try was to burn on

a thing that has holes and can have more air between the cones. This time the cones get so much

fire so the cones started to turn ash. After seen the results it was necessary to find another

solution so the solution was to burn the cones in an open space to get the right temperature and

the cones get the enough air.

This process was outside of the ceramic art facilities. With this method was possible to get the

right temperature to burn the cones. After 2 hours and 30 minutes was necessary to start grind

the cones to get them ready to mix with the others materials in order to start the charcoal. The

majority of this preprocess was at the burning place at Mt. Hood Community College. Some of

the results after do all this process is that in order to burn the cones it is necessary to do that in an

open place because in this process was necessary to use file and it is not the best way to do that.

After all of this process it was necessary to bring the material to a close space, in order to keep it

save and ready to mix it the text week with others materials. A brief meting after finishing with

the burning was necessary to discuses some of the result of this project, and also talk about how

can the project be improve in order to have better results next time.

Efficient Charcoal (EC) Project

Result

First, this project focused on the efficient charcoal by using corn or other waste instead of cutting

down trees. In fact, after all of the process followed the result of product was acceptable in

reason to see how efficient it is.

For the first experiment, taken two of briquettes and put it in a barbecue stove. During that time,

with two pound lasted about one hour and thirty-five minutes. However, this experiment of this

project was a success, and that time the name value of the project and result found work to make

in better, and in a bigger scale. The more efficient it is the more people will be interested to make

it an open their own business to feed and support families.

Conclusion

This sustainable project can be applicable in different parts in the world especially in our rural

communities where we come from. By using local materials, we came up with this idea thinking

in the different benefits that it can produce for the community and the environment. Adopting

this sustainable project, we are reducing the deforestation in our communities and the possibility

for income for them. Lung-function declines by the smoke from wood or grass burning, and the

project could affect humans health, but in comparison with the amount of wood people burn

every day, the effect of the charcoal will be in a small scale. There will be an educational

component since we will teach everyone on how to make the efficient charcoal.

Some material will need to bayed, and the corn grass will obtain after the harvest time in the

community plantations. The machine to make the charcoal can last for more than 20 years; it

does not require maintenance every month. How urgent is this project (does this challenge affect

peoples health)? Well deforestation is a very critical issue, because it contributes to global

warming, after that temperatures change around the world, and in our communities is becoming

hot, making rivers to get dry, and increasing health risks. This project is also a long-term solution

to the challenge because people can keep doing that as many times as they decide to. This project

we try to involve the whole community and make them work together to have better

communication and interaction with each other.

You might also like

- Good Stoves Facilitation: How to Innovate and Change the WorldFrom EverandGood Stoves Facilitation: How to Innovate and Change the WorldNo ratings yet

- Template BODY TEXT of The SIP PaperDocument5 pagesTemplate BODY TEXT of The SIP PaperReign Imee NortezNo ratings yet

- Paper Coal SIPDocument5 pagesPaper Coal SIPNicole LopezNo ratings yet

- Biogas Generator PDFDocument5 pagesBiogas Generator PDFamerican_guy10No ratings yet

- Planuri Cuptor Pe LemneDocument15 pagesPlanuri Cuptor Pe Lemnea_steri_x2000No ratings yet

- Comparing Biomass Briquettes to Traditional FuelsDocument5 pagesComparing Biomass Briquettes to Traditional FuelsJasperOndap100% (1)

- Eco-Friendly Biomass StoveDocument7 pagesEco-Friendly Biomass Stoveadrianpaul villenaNo ratings yet

- Group2 Sip-1Document16 pagesGroup2 Sip-1Vincent VernalNo ratings yet

- Capstone Research ProjectDocument11 pagesCapstone Research Project구독봉이No ratings yet

- Group 2Document17 pagesGroup 2Maribel Tan-Losloso Nayad100% (1)

- AN ALTERNATIVE FOR CHARCOAL: BIOBRIQUETTE FROM DRIED BANANA LEAVES/PEELSDocument7 pagesAN ALTERNATIVE FOR CHARCOAL: BIOBRIQUETTE FROM DRIED BANANA LEAVES/PEELSTriszha DeinlaNo ratings yet

- sOLAR_OVEN (1)Document8 pagessOLAR_OVEN (1)abeer.rashidalikhanNo ratings yet

- Clean Cooking Stoves: How to Innovate and Change the WorldFrom EverandClean Cooking Stoves: How to Innovate and Change the WorldRating: 5 out of 5 stars5/5 (1)

- ELS Research Paper Complete (Chap. 1-3)Document14 pagesELS Research Paper Complete (Chap. 1-3)MicaelaNo ratings yet

- Project Proposal For PhysicsDocument4 pagesProject Proposal For PhysicsDustinehlae ValdboyashikzNo ratings yet

- The Utilization of Banana Peels To Produce BriquettesDocument7 pagesThe Utilization of Banana Peels To Produce BriquettesEarl Joy EJ DalaganNo ratings yet

- Sip Group 1 1Document29 pagesSip Group 1 1Kurt SantocildesNo ratings yet

- Jathroper Charcoal As Alternative Heat Source. Clyde2Document29 pagesJathroper Charcoal As Alternative Heat Source. Clyde2Charles Jebb Belonio JuanitasNo ratings yet

- Fire BlocksDocument6 pagesFire BlocksnixoneNo ratings yet

- GAFIRE FinalDocument45 pagesGAFIRE FinalJanna Jean EdiosNo ratings yet

- 2 Bisu, DY SOS Cnference ArticleDocument12 pages2 Bisu, DY SOS Cnference ArticleDanladi Yusuf BisuNo ratings yet

- 4 Ijsrpas 04242Document4 pages4 Ijsrpas 04242Irvin Mark BagsitNo ratings yet

- Solar Oven Research PaperDocument5 pagesSolar Oven Research Papergz8qs4dn100% (1)

- CharcoalDocument14 pagesCharcoalEl-j GaraldeNo ratings yet

- Trifold fINAL_082847Document7 pagesTrifold fINAL_082847kohikat5019No ratings yet

- Folio Cooking NatureDocument9 pagesFolio Cooking NatureMariAm NabiLah NaSrudinNo ratings yet

- Charcoal Briquet Ting Technology in The Province of Aurora, PhilippinesDocument18 pagesCharcoal Briquet Ting Technology in The Province of Aurora, PhilippinesEutiquio Rotaquio100% (8)

- Presentation2 Power Point/ Improve Cooking StoveDocument67 pagesPresentation2 Power Point/ Improve Cooking StoveRamon Chua Jr.No ratings yet

- Utilization of Goose Grass (Eleusine Indica) and Sawdust As Biomass BriquettesDocument5 pagesUtilization of Goose Grass (Eleusine Indica) and Sawdust As Biomass BriquettesKris BelkaNo ratings yet

- BiogasDocument6 pagesBiogasTitush Sohahau HiaNo ratings yet

- Leila Abdikadir (1) 444Document17 pagesLeila Abdikadir (1) 444Snev EvansNo ratings yet

- Chapter 1 3editedDocument17 pagesChapter 1 3editedAlnor Latabat AlontoNo ratings yet

- Title Presentattion 1Document2 pagesTitle Presentattion 1Adriel PerezNo ratings yet

- Acknowledgment Abstract Objective Introduction Problem Statement Hypothesis Material/Apparatus Procuder ResultDocument14 pagesAcknowledgment Abstract Objective Introduction Problem Statement Hypothesis Material/Apparatus Procuder Resultms ijati100% (2)

- G8 I Likha ProposalDocument8 pagesG8 I Likha ProposalKARIZZA ABOLENCIANo ratings yet

- Carbon Sequestration Lab ReportDocument5 pagesCarbon Sequestration Lab Reportapi-329950402No ratings yet

- Lang ProposalDocument3 pagesLang ProposalYan Hao NamNo ratings yet

- Science Invetigatory Project For Print 1 2Document9 pagesScience Invetigatory Project For Print 1 2florendoandreijoaqueNo ratings yet

- Global Warming Essay Discusses Causes and SolutionsDocument5 pagesGlobal Warming Essay Discusses Causes and SolutionsadeNo ratings yet

- EST micro project newww subjectDocument13 pagesEST micro project newww subjectPratik GavaleNo ratings yet

- Benefits, Drawbacks and Environmental Impacts of GreenhousesDocument9 pagesBenefits, Drawbacks and Environmental Impacts of GreenhousesKevontae ArthurtonNo ratings yet

- Earth SciDocument2 pagesEarth SciCharmaine Krystel Ramos IINo ratings yet

- Class Task 2Document2 pagesClass Task 2Mateo Trujillo JimenezNo ratings yet

- 2012ASEE PeanutShell Paper r1Document9 pages2012ASEE PeanutShell Paper r1Missia H. SabtalNo ratings yet

- Final 12 Pager EssayDocument13 pagesFinal 12 Pager Essayapi-509659360No ratings yet

- Papaya and Mango Peelings For Fuel Briquette (05-03-12)Document39 pagesPapaya and Mango Peelings For Fuel Briquette (05-03-12)Joshua PicartNo ratings yet

- Physics Homework RubricDocument4 pagesPhysics Homework RubricTrisha TulipatNo ratings yet

- Proyecto General 2023Document24 pagesProyecto General 2023DANNA XIMENA ARRIAGA PEREZNo ratings yet

- Climate Change Lesson PlanDocument7 pagesClimate Change Lesson PlanNita TatianaNo ratings yet

- Creativity & Innovation Project ReportDocument5 pagesCreativity & Innovation Project ReportMayLeong100% (1)

- Energy Sources ResearchDocument38 pagesEnergy Sources Researchapi-237313810No ratings yet

- Go green to reduce pollutionDocument3 pagesGo green to reduce pollutionManisha RuikarNo ratings yet

- Grated Coconut-Oil-As Alternative Energy Solution (Gracoals) For Consumersin Donsol, SorsogonDocument27 pagesGrated Coconut-Oil-As Alternative Energy Solution (Gracoals) For Consumersin Donsol, SorsogonJohn Earl CaramancionNo ratings yet

- CHAPTER 1 3isDocument13 pagesCHAPTER 1 3isRhein David CamaNo ratings yet

- Nonfiction Reading Test Garbage: Directions: Read The Following Passage and Answer The Questions That Follow. Refer ToDocument4 pagesNonfiction Reading Test Garbage: Directions: Read The Following Passage and Answer The Questions That Follow. Refer ToMusab AlbarbariNo ratings yet

- Lester Chapter1Document4 pagesLester Chapter1Fernando AgbulosNo ratings yet

- Garbage: The Text To Check Your Answers When AppropriateDocument4 pagesGarbage: The Text To Check Your Answers When AppropriateSORN CHHANNYNo ratings yet

- Sustainable PackagingDocument11 pagesSustainable Packagingneha.menon.2005No ratings yet

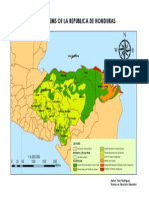

- Honduras DRM Management3Document18 pagesHonduras DRM Management3Lauren ShawNo ratings yet

- Environmental Threats in My Home Biome at CholutecaDocument1 pageEnvironmental Threats in My Home Biome at CholutecaLauren ShawNo ratings yet

- Two Ways of How My Country and Local Government Can Address Environmental Threats As Deforestation of Mangroves and Different Species of TreesDocument1 pageTwo Ways of How My Country and Local Government Can Address Environmental Threats As Deforestation of Mangroves and Different Species of TreesLauren ShawNo ratings yet

- Environmental Threats in My Home Biome at CholutecaDocument1 pageEnvironmental Threats in My Home Biome at CholutecaLauren ShawNo ratings yet

- Ecosystems Management2Document79 pagesEcosystems Management2Lauren ShawNo ratings yet

- Environmental Threats in My Home Biome at CholutecaDocument1 pageEnvironmental Threats in My Home Biome at CholutecaLauren ShawNo ratings yet

- Deforestation PopularDocument4 pagesDeforestation PopularLauren ShawNo ratings yet

- Northern Honduras Mangroves PopularDocument4 pagesNorthern Honduras Mangroves PopularLauren ShawNo ratings yet

- Ecosystem ManagementDocument5 pagesEcosystem ManagementLauren ShawNo ratings yet

- The Condor Nov 2005 107, 4 Proquest Biology JournalsDocument2 pagesThe Condor Nov 2005 107, 4 Proquest Biology JournalsLauren ShawNo ratings yet

- Coral Reefs PopularDocument2 pagesCoral Reefs PopularLauren ShawNo ratings yet

- Scienticic Article TDocument9 pagesScienticic Article TLauren ShawNo ratings yet

- Adaptation and Natural SelectionDocument5 pagesAdaptation and Natural SelectionLauren ShawNo ratings yet

- Threatened and Endangered Species in HondurasDocument11 pagesThreatened and Endangered Species in HondurasLauren ShawNo ratings yet

- CholutecaDocument1 pageCholutecaLauren ShawNo ratings yet

- Lab #5 Germination and ProductivityDocument6 pagesLab #5 Germination and ProductivityLauren ShawNo ratings yet

- Dwarf GeckoDocument6 pagesDwarf GeckoLauren ShawNo ratings yet

- Honduras EcosystemsDocument1 pageHonduras EcosystemsLauren ShawNo ratings yet

- Lab #5 Germination and ProductivityDocument4 pagesLab #5 Germination and ProductivityLauren ShawNo ratings yet

- Excited To Learn From Tropical Ecology: Name: Ariel Rodriguez Osorto To: Shadia DueriDocument1 pageExcited To Learn From Tropical Ecology: Name: Ariel Rodriguez Osorto To: Shadia DueriLauren ShawNo ratings yet

- Lab #4Document2 pagesLab #4Lauren ShawNo ratings yet

- Biology Lab 2Document2 pagesBiology Lab 2Lauren ShawNo ratings yet

- Tropical Ecology: Tiny Gecko Is 'World's Smallest'Document1 pageTropical Ecology: Tiny Gecko Is 'World's Smallest'Lauren ShawNo ratings yet

- Dwarf GueckoDocument1 pageDwarf GueckoLauren ShawNo ratings yet

- NRLM Skills PresentationDocument23 pagesNRLM Skills PresentationVinod Kumar NooluNo ratings yet

- (Type The Document Title) : School English Language Competition Primary SchoolsDocument15 pages(Type The Document Title) : School English Language Competition Primary SchoolsHodžić NisvetaNo ratings yet

- A Practical Guide To Healthcare DataDocument20 pagesA Practical Guide To Healthcare DataGeorge Tanaruno100% (1)

- lm2841 Transistor RegulatorDocument27 pageslm2841 Transistor RegulatorAbbas MaghazehiNo ratings yet

- Commercial Construction ScheduleDocument2 pagesCommercial Construction Schedulefinus marcalNo ratings yet

- Infobroture - 201Document25 pagesInfobroture - 201TauseefNo ratings yet

- Visualforce Cheat SheetDocument2 pagesVisualforce Cheat SheetMahendraKumarNo ratings yet

- TerminologyDocument77 pagesTerminologyBianca Emanuela LazarNo ratings yet

- Tablita-Comandos 2.3Document2 pagesTablita-Comandos 2.3hernan_27No ratings yet

- Specification FOR Approval: 10.1" HD TFT LCD TitleDocument27 pagesSpecification FOR Approval: 10.1" HD TFT LCD TitlenicusorceldurNo ratings yet

- CinemaDocument38 pagesCinemabrooklynsnowNo ratings yet

- Mechanical Engineer Resume CAD Skills 12 Years ExperienceDocument3 pagesMechanical Engineer Resume CAD Skills 12 Years ExperienceNilay GandhiNo ratings yet

- HTTPS://FR - Scribd.com/doc/294639869/method Statement For Cable Pulling and ConnectionsDocument22 pagesHTTPS://FR - Scribd.com/doc/294639869/method Statement For Cable Pulling and ConnectionsCripoNo ratings yet

- XDM-100 V9.1 Imm - 2019123166Document308 pagesXDM-100 V9.1 Imm - 2019123166Anh Ba LâmNo ratings yet

- ComNav Vector G2 & G2B CompassDocument2 pagesComNav Vector G2 & G2B CompasstariktunadNo ratings yet

- MCT0000230072Document2 pagesMCT0000230072Anonymous 51rRHZeeYNo ratings yet

- Codificare VWDocument2 pagesCodificare VWnicolicescu_claudiu5152No ratings yet

- ACX5 Brochure enDocument44 pagesACX5 Brochure enrnkmip100% (3)

- Chapter 5 Concrete StructuresDocument432 pagesChapter 5 Concrete StructuresrizwanNo ratings yet

- Apple ProjectDocument94 pagesApple ProjectUdit BhargavaNo ratings yet

- Shell Scripting PreparationDocument23 pagesShell Scripting Preparationnjoy986No ratings yet

- PT 100 Za TemperaturaDocument21 pagesPT 100 Za Temperaturawarmaster81No ratings yet

- Grade 10 Math Textbook Principles of MathematicsDocument4 pagesGrade 10 Math Textbook Principles of MathematicsDebi0% (2)

- The Physics of The Trumpet (Bostjan Berkopec)Document12 pagesThe Physics of The Trumpet (Bostjan Berkopec)carmechanicNo ratings yet

- Fourier OpticsDocument9 pagesFourier Opticssal.paradise.1No ratings yet

- 172R Wiring Diagram ManualDocument488 pages172R Wiring Diagram ManualmidunNo ratings yet

- Integration of MEP Virtual Design in BIM For The New Age Construction - eLogicTech BlogDocument7 pagesIntegration of MEP Virtual Design in BIM For The New Age Construction - eLogicTech BlogeLogicTechNo ratings yet

- Eaton Fuller Rtlo 16713a t2Document36 pagesEaton Fuller Rtlo 16713a t2Joselee Ramos TitoNo ratings yet

- Abap Dynamic TableDocument8 pagesAbap Dynamic TablevenkatNo ratings yet

- Business Objects Enterprise XI 2 SP 2 - Installation Guide For Windows and UNIXDocument50 pagesBusiness Objects Enterprise XI 2 SP 2 - Installation Guide For Windows and UNIXFrenzy BenzyNo ratings yet