Professional Documents

Culture Documents

US20130131400 Etil Asetat

Uploaded by

Debby Theresia Silaban0 ratings0% found this document useful (0 votes)

11 views43 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views43 pagesUS20130131400 Etil Asetat

Uploaded by

Debby Theresia SilabanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 43

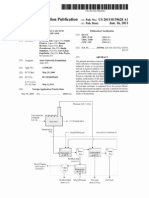

US 20130131400A1

( 19 ) United Sta tes

( 12) Pa tent Applica tion Publica tion ( 10) Pub. N 0. 2 US 2013/0131400 A1

D uf f et a l. ( 43) Pub. D a te: Ma y 23, 2013

( 5 4) HYD ROGEN ATIN G ACETIC ACID TO Rela ted US. Applica tion D a ta

PROD UCE ETHYLACETATE AN D . . . .

RED UCIN G ETHYLACETATE T0 ETHAN OL ( 6 0) 5 303131101118 1 a pplica tlon N o. 6 1/5 6 2, 8 5 9 , ? led on N ov .

( 7 1) Applica nt: Cela nes e Inter na tiona l Cor por a tion, publica tion Cla s s i? ca tion

Ir v ing , TX ( US)

_ ( 5 1) Int. Cl.

( 7 2) Inv entor s : Em ily D uf f , Lea g ue City, TX ( US) ; Iv a C07 C 29 /149 ( 2006 01)

F r a nj k ic, Lea g ue City, TX ( US) ; V ictor ( 5 2) us CL

J - 1011m m Hous ton TX ( Us ) ; D a v id CPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C07 C 29 /149 ( 2013. 01)

Lee Sea br ook , TX ( Us ) ; R- J a y USPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 6 8 /8 8 5 ; 5 6 8 /8 8 4

W a r ner , Hous ton, TX ( US) ; Heik o

W einer , Pa s a dena , TX ( US) ; Ra dm ila ( 5 7 ) ABSTRACT

W ollr a b, Pa s a dena TX ( Us ) ; Zhenhua D is clos ed her ein a r e pr oces s es f or a lcohol pr oduction by

Z110 , Hous ton TX ( Us ) r educing a n ethyl a ceta te pr oduced by hydr og ena ting a cetic

a cid in the pr es ence of a s uita ble ca ta lys t. The ethyl a ceta te is

( 7 3) As s ig nee: CELAN ESE IN TERN ATION AL r educed W ith hydr og en in the pr es ence of a ca ta lys t to obta in

CORPORATION , Ir v ing , TX ( Us ) a cr ude r ea ction m ix tur e com pr is ing the a lcohol, in pa r ticula r

etha nol, W hich m a y be s epa r a ted f r om the cr ude r ea ction

m ix tur e. Thus , etha nol m a y be pr oduced f r om a cetic a cid

thr oug h a n ethyl a ceta te inter m edia te W ithout a n es ter i? ca

tion s tep. This m a y r educe the r ecycle of etha nol in the hydr o

( 22) F iled: N ov . 20, 2012 g enolys is pr oces s a nd im pr ov e etha nol pr oductiv ity.

( 21) Appl. N o. : 13/6 8 1, 8 8 4

m 15 1

19 3 112 J

18 9 147

18 5 123

H2 19 2 _ 146

104 3/ , _

18 7 6 15 0

\ /

1 19 1 19 4 144

HOAc 8 8 19 148 \

T

8 7 Q? 124

\

113 / 132 15 2

102

% 101

~~131

133

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 1 0f 13 US 2013/0131400 A1

m : . 6 5

6 5 5 m

2%2 2m

E25 2

8 5 % coem o

6 5 5 m

228 , Em

g 2 0. 6 2

22%

8 5 0m 5 28

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 2 0f 13 US 2013/0131400 A1

113

19 4

19 0 19 1

F IG. 2A

18 8

HOAc

T

18 7

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 3 0f 13 US 2013/0131400 A1

15 2

EtOH

143 /_ 7 < 140

3146 2 _ 15 ( )

145

1

02

141

; 14

144

1

19 3

19 4

19 1

G

* 18 5

9 0

101% F IG. 2B

18 9 \

HOAc 18 in

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 4 0f 13 US 2013/0131400 A1

15 1

/

EIOH

H2 141

_ /

128

125 1

\125

i f

132

K 1 31

133

113

F IG. 3

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 5 0f 13 US 2013/0131400 A1

15 2

131

133

113

101

F IG. 4

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 6 0f 13 US 2013/0131400 A1

( 1

18 % N

i6 8 5

19 0

101%

F IG. 5

H2

T

18 6 HOAc

T

18 7

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 7 0f 13 US 2013/0131400 A1

15 1 K

15 2

A140

146

H} 14

EtOH

19 4

1s 9 \ \'

Ag es

18 8 19 0

101;

F IG. 6

| " 2

T

18 6 HOAc

T

18 7

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 8 0f 13 US 2013/0131400 Al

< 140

120

(

12

[ 121

113

19 0

10

F IG. 7 A

HOAc

T

18 7

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 9 0f 13 US 2013/0131400 A1

9 5

/ L E

| \

LC)

_

//

EN 9 E

/- 15 0

15 2

l 18 1

18 2

19 3 112

19 2

19 4

113

19 1

* 1 8 5 9 0

101%

F IG. 7 B

H2

T

18 6 HOAc

T

18 7

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 10 0f 13 US 2013/0131400 A1

I

Q Q

J /

l\ 8

LD " - o

/ K

5 00

L0

T N 5 9

\ 5 9

G $

3 , ? /

- < 2

i g

" - O)

; @F IM: % E 2

" " - l

( N \ \

I

E

a v ? T

- r

K ' - Q

' _ \i

|

|

| - \ 0' ) q

: E o

. /

2

_ , _ m

N I

or ) O3

5 3

35

g E

9 0

18 9 \ Q

{

18 8 1

18 6 HOAc

T

18 7

F IG. 8 A

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 11 0f 13 US 2013/0131400 A1

16 4

141 143

\

; 14

144

\131

133

121

120

12

113

F IG. 8 B

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 12 0f 13 US 2013/0131400 A1

3

E!

z :

/\ J G

o2l\ / 5

m m : K

A E

x w e

M ( 9 : \

\g :

11 F l\

8 T\

a : m i N 3 m 2

Q: M V ,

f

\ \ Mk

E E c: m :

\i

E

ON F

m 3

< 0 . 9 5

m :

m :

m 2

2: o2 m m ? _

m 2

U

Pa tent Applica tion Publica tion Ma y 23, 2013 Sheet 13 0f 13 US 2013/0131400 A1

15 7

15 6 b

1/6

\

e0

K 7 < 140

113

19 4

19 1

19 0

F IG. 9 B

18 8

HOAc

T

18 7

US 2013/0131400 A1

HYD ROGEN ATIN G ACETIC ACID TO

PROD UCE ETHYLACETATE AN D

RED UCIN G ETHYLACETATE TO ETHAN OL

CROSS REF EREN CE TO RELATED

APPLICATION S

[ 0001] This a pplica tion cla im s pr ior ity to US. Pr ov is iona l

App. N o. 6 1/5 6 2, 8 5 9 , ? led N ov . 22, 2011, the entir ety of

W hich is incor por a ted her ein by r ef er ence.

F IELD OF THE IN V EN TION

[ 0002] The pr es ent inv ention r ela tes g ener a lly to a lcohol

pr oduction f r om a n a cetic a cid hydr og ena tion to f or m ethyl

a ceta te, a nd in pa r ticula r to pr oducing etha nol by r educing

ethyl a ceta te.

BACK GROUN D OF THE IN V EN TION

[ 0003] Etha nol f or indus tr ia l us e is conv entiona lly pr o

duced f r om petr ochem ica l f eed s tock s , s uch a s oil, na tur a l

g a s , or coa l, f r om f eed s tock inter m edia tes , s uch a s s yng a s , or

f r om s ta r chy m a ter ia ls or cellulos e m a ter ia ls , s uch a s cor n or

s ug a r ca ne. Conv entiona l m ethods f or pr oducing etha nol

f r om petr ochem ica l f eed s tock s , a s W ell a s f r om cellulos e

m a ter ia ls , include the a cid- ca ta lyZed hydr a tion of ethylene,

m etha nol hom olog a tion, dir ect a lcohol s ynthes is , a nd F is

cher - Tr ops ch s ynthes is . Ins ta bility in petr ochem ica l f eed

s tock pr ices contr ibutes to ? uctua tions in the cos t of conv en

tiona lly pr oduced etha nol, m a k ing the need f or a lter na tiv e

s our ces of etha nol pr oduction a ll the g r ea ter W hen f eed s tock

pr ices r is e. Sta r chy m a ter ia ls , a s W ell a s cellulos e m a ter ia l,

a r e conv er ted to etha nol by f er m enta tion. HoW ev er , f er m en

ta tion is typica lly us ed f or cons um er pr oduction of etha nol,

W hich is s uita ble f or f uels or hum a n cons um ption. In a ddi

tion, f er m enta tion of s ta r chy or cellulos e m a ter ia ls com petes

W ith f ood s our ces a nd pla ces r es tr a ints on the a m ount of

etha nol tha t ca n be pr oduced f or indus tr ia l us e.

[ 0004] Etha nol pr oduction v ia the r eduction of a lk a noic

a cids a nd/or other ca r bonyl g r oup- conta ining com pounds ,

including es ter s , ha s been W idely s tudied, a nd a v a r iety of

com bina tions of ca ta lys ts , s uppor ts , a nd oper a ting conditions

ha v e been m entioned in the liter a tur e.

[ 0005 ] Mor e r ecently, ev en thoug h it m a y not s till be com

m er cia lly v ia ble it ha s been r epor ted tha t etha nol ca n be

pr oduced f r om hydr og ena ting a cetic a cid us ing a coba lt ca ta

lys t a t s uper a tm os pher ic pr es s ur es s uch a s a bout 40 to 120

ba r , a s des cr ibed in US. Pa t. N o. 4, 5 17 , 39 1.

[ 0006 ] On the other ha nd, US. Pa t. N o. 5 , 149 , 6 8 0

des cr ibes a pr oces s f or the ca ta lytic hydr og ena tion of ca r

box ylic a cids a nd their a nhydr ides to a lcohols a nd/or es ter s

utiliZing a pla tinum g r oup m eta l a lloy ca ta lys t. The ca ta lys t is

com pr is ed of a n a lloy of a t lea s t one noble m eta l of Gr oup

V III of the Per iodic Ta ble a nd a t lea s t one m eta l ca pa ble of

a lloying W ith the Gr oup V III noble m eta l, a dm ix ed W ith a

com ponent com pr is ing a t lea s t one of the m eta ls r henium ,

tung s ten or m olybdenum . Althoug h it ha s been cla im ed

ther ein tha t im pr ov ed s electiv ity to a m ix tur e of a lcohol a nd

its es ter W ith the unr ea cted ca r box ylic a cid is a chiev ed ov er

the pr ior a r t r ef er ences it W a s s till r epor ted tha t 3 to 9 per cent

of a lk a nes , s uch a s m etha ne a nd etha ne a r e f or m ed a s by

pr oducts dur ing the hydr og ena tion of a cetic a cid to etha nol

under their optim a l ca ta lys t conditions .

Ma y 23, 2013

[ 0007 ] US. Pa t. N o. 7 , 8 6 3, 48 9 des cr ibes the dir ect a nd

s electiv e pr oduction of etha nol f r om a cetic a cid us ing a pla ti

num /tin ca ta lys t.

[ 0008 ] US. Pa t. N o. 7 , 8 20, 8 5 2 des cr ibes the dir ect a nd

s electiv e pr oduction of ethyl a ceta te f r om a cetic a cid utiliZing

a bim eta l s uppor ted ca ta lys t.

[ 0009 ] US. Pub. N o. 2010/019 7 9 5 9 des cr ibes pr oces s es

f or m a k ing ethyl a ceta te f r om a cetic a cid. Acetic a cid is

hydr og ena ted in the pr es ence of a ca ta lys t under conditions

ef f ectiv e to f or m ethyl a ceta te, W her ein the ca ta lys t com pr is es

a ? r s t m eta l, a s econd m eta l a nd a s uppor t. The ? r s t m eta l is

s elected f r om the g r oup cons is ting of nick el, pa lla dium , a nd

pla tinum a nd is pr es ent in a n a m ount g r ea ter tha n 1 W t. %,

ba s ed on the tota l W eig ht of the ca ta lys t.

[ 0010] US. Pub. N o. 2010/019 7 48 6 des cr ibes ca ta lys ts f or

m a k ing ethyl a ceta te f r om a cetic a cid. The ca ta lys t com pr is es

a ? r s t m eta l, a s econd m eta l, a nd a s uppor t. The ? r s t m eta l is

s elected f r om the g r oup cons is ting of nick el, pa lla dium a nd

pla tinum , a nd is pr es ent in a n a m ount g r ea ter tha n 1 W t. %,

ba s ed on the tota l W eig ht of the ca ta lys t. The s econd m eta l

m a y be s elected f r om the g r oup cons is ting of m olybdenum ,

r henium , Zir conium , copper , coba lt, tin a nd Zinc, a nd W her ein

the ca ta lys t ha s a s electiv ity to ethyl a ceta te of g r ea ter tha n

40%.

[ 0011] US. Pub. N o 2011/009 8 5 01 des cr ibes pr oces s es f or

m a k ing etha nol or ethyl a ceta te f r om a cetic a cid us ing bim e

ta llic ca ta lys ts . The ca ta lys t com pr is es pla tinum , tin, a nd a t

lea s t one s uppor t, W her ein the m ola r r a tio of pla tinum to tin is

f r om 0. 4106 to 06 10. 4.

[ 0012] US. Pub. N o. 2010/0121 1 14 des cr ibes tuna ble ca ta

lys t g a s pha s e hydr og ena tion of ca r box ylic a cids a nd a ls o

des cr ibes etha nol pr oduction pr oces s es by r eduction of a cetic

a cid. The ca ta lys t com pr is es pla tinum a nd tin. A g a s eous

s tr ea m com pr is ing hydr og en a nd a cetic a cid in the v a por

pha s e, W ith a m ola r r a tion of a t lea s t 4: 1 hydr og en to a cetic

a cid, a t a tem per a tur e betW een 225 a nd 3000 C. is pa s s ed ov er

a hydr og ena tion ca ta lys t com pr is ing pla tinum a nd tin dis

per s ed on a s ilica ceous s uppor t. The a m ounts a nd ox ida tion

s ta tes of the pla tinum a nd tin, a s W ell a s the r a tio of pla tinum

to tin, a nd the s ilica ceous s uppor t a r e s elected, com pos ed a nd

contr olled s uch tha t a t lea s t 8 0% of the a cetic a cid is con

v er ted to etha nol, les s tha n 4% of the a cetic a cid is conv er ted

to com pounds other tha n com pounds s elected f r om the g r oup

cons is ting of etha nol, a ceta ldehyde, ethyl a ceta te, ethylene

a nd m ix tur es ther eof , a nd the a ctiv ity of the ca ta lys t declines

by les s tha n 10% W hen ex pos ed to a v a por ous m ix tur e of

a cetic a cid a nd hydr og en a t a m ola r r a tio of 10: 1 a t a pr es s ur e

of 2 a tm , a tem per a tur e of 27 5 0 C. a nd a GHSV of 25 00 hr - l

f or a per iod of 16 8 hour s .

[ 0013] A s lig htly m odi? ed pr oces s f or the pr epa r a tion of

ethyl a ceta te by hydr og ena ting a cetic a cid ha s been r epor ted

in EP037 28 47 . In this pr oces s , a ca r box ylic a cid es ter , s uch a s

f or ex a m ple, ethyl a ceta te is pr oduced a t a s electiv ity of

g r ea ter tha n 5 0% W hile pr oducing the cor r es ponding a lcohol

a t a s electiv ity les s tha n 10% f r om a ca r box ylic a cid or a nhy

dr ide ther eof by r ea cting the a cid or a nhydr ide W ith hydr og en

a t elev a ted tem per a tur e in the pr es ence of a ca ta lys t com po

s ition com pr is ing a s a ? r s t com ponent a t lea s t one of Gr oup

V III noble m eta l a nd a s econd com ponent com pr is ing a t lea s t

one of m olybdenum , tung s ten a nd r henium a nd a thir d com

ponent com pr is ing a n ox ide of a Gr oup IV B elem ent. HoW

ev er , ev en the optim a l conditions r epor ted ther ein r es ult in

s ig ni? ca nt a m ounts of by- pr oducts including m etha ne,

etha ne, a ceta ldehyde a nd a cetone in a ddition to etha nol. In

US 2013/0131400 A1

a ddition, the conv er s ion of a cetic a cid is g ener a lly loW a nd is

in the r a ng e of a bout 5 to 40% ex cept f or a f eW ca s es in W hich

the conv er s ion r ea ched a s hig h a s 8 0%.

[ 0014] Copper - ir on ca ta lys ts f or hydr og enolyZing es ter s to

a lcohols a r e des cr ibed in US. Pa t. N o. 5 , 19 8 , 5 9 2. A hydr o

g enolys is ca ta lys t com pr is ing nick el, tin, g er m a nium a nd/or

lea d is des cr ibed in US. Pa t. N o. 4, 6 28 , 130. A r hodium

hydr og enolys is ca ta lys t tha t a ls o conta ins tin, g er m a nium

a nd/or lea d is des cr ibed in US. Pa t. N o. 4, 45 6 , 7 7 5 .

[ 0015 ] Sev er a l pr oces s es tha t pr oduce etha nol f r om

a ceta tes , including m ethyl a ceta te a nd ethyl a ceta te, a r e

k noW n in the liter a tur e.

[ 0016 ] W O8 303409 des cr ibes pr oducing etha nol by ca r bo

nyla tion of m etha nol by r ea ction W ith ca r bon m onox ide in the

pr es ence of a ca r bonyla tion ca ta lys t to f or m a cetic a cid W hich

is then conv er ted to a n a ceta te es ter f olloW ed by hydr o g enoly

s is of the a ceta te es ter f or m ed to g iv e etha nol or a m ix tur e of

etha nol a nd a nother a lcohol W hich ca n be s epa r a ted by dis

tilla tion. Pr ef er a bly the other a lcohol or pa r t of the etha nol

r ecov er ed f r om the hydr o g enolys is s tep is r ecycled f or f ur ther

es ter i? ca tion. Ca r bonyla tion ca n be ef f ected us ing a CO/H2

m ix tur e a nd hydr og enolys is ca n s im ila r ly be conducted in the

pr es ence of ca r bon m onox ide, lea ding to the pos s ibility of

cir cula ting g a s betW een the ca r bonyla tion a nd hydr og enoly

s is Zones W ith s ynthes is g a s , pr ef er a bly a 2: 1 H2: CO m ola r

m ix tur e being us ed a s m a k eup g a s .

[ 0017 ] W O2009 06 317 4 des cr ibes a continuous pr oces s f or

the pr oduction of etha nol f r om a ca r bona ceous f eeds tock . The

ca r bona ceous f eeds tock is ? r s t conv er ted to s ynthes is g a s

W hich is then conv er ted to etha noic a cid, W hich is then es ter i

? ed a nd W hich is then hydr og ena ted to pr oduce etha nol.

[ 0018 ] W O2009 009 320 des cr ibes a n indir ect r oute f or pr o

ducing etha nol. Ca r bohydr a tes a r e f er m ented under hom oa ci

dog enic conditions to f or m a cetic a cid. The a cetic a cid is

es ter i? ed W ith a pr im a r y a lcohol ha v ing a t lea s t 4 ca r bon

a tom s a nd hydr og ena ting the es ter to f or m etha nol.

[ 0019 ] US Pub. N o. 20110046 421 des cr ibes a pr oces s f or

pr oducing etha nol com pr is ing conv er ting ca r bona ceous f eed

s tock to s yng a s a nd conv er ting the s yng a s to m etha nol.

Metha nol is ca r bonyla ted to etha noic a cid, W hich is then

s ubj ected to a tW o s ta g e hydr og ena tion pr oces s . F ir s t the

etha noic a cid is conv er ted to ethyl etha noa te f olloW ed by a

s econda r y hydr og ena tion to etha nol.

[ 0020] US Pub. N o. 2010027 3229 des cr ibes a pr oces s f or

pr oducing a cetic a cid inter m edia te f r om ca r bohydr a tes , s uch

a s cor n, us ing enz ym a tic m illing a nd f er m enta tion s teps . The

a cetic a cid inter m edia te is a cidi? ed W ith ca lcium ca r bona te

a nd the a cetic a cid is es ter i? ed to pr oduce es ter s . Etha nol is

pr oduced by a hydr og enolys is r ea ction of the es ter .

[ 0021] US. Pa t. N o. 5 , 414, 16 1 des cr ibes a pr oces s f or pr o

ducing etha nol by a g a s pha s e ca r bonyla tion of m etha nol W ith

ca r bon m onox ide f olloW ed by a hydr og ena tion. The ca r bo

nyla tion pr oduces a cetic a cid a nd m ethyl a ceta te, W hich a r e

s epa r a ted a nd the m ethyl a ceta te is hydr og ena ted to pr oduce

etha nol in the pr es ence of a copper - conta ining ca ta lys t.

[ 0022] US. Pa t. N o. 4, 49 7 , 9 6 7 des cr ibes a pr oces s f or pr o

ducing etha nol f r om m etha nol by ? r s t es ter if ying the m etha

nol W ith a cetic a cid. The m ethyl a ceta te is ca r bonyla ted to

pr oduce a cetic a nhydr ide W hich is then r ea cted W ith one or

m or e a lipha tic a lcohols to pr oduce a ceta tes . The a ceta tes a r e

hydr og ena ted to pr oduce etha nol. The one or m or e a lipha tic

a lcohols f or m ed dur ing hydr og ena tion a r e r etur ned to the

a cetic a nhydr ide es ter i? ca tion r ea ction.

Ma y 23, 2013

[ 0023] US. Pa t. N o. 4, 45 4, 35 8 des cr ibes a pr oces s f or pr o

ducing etha nol f r om m etha nol. Metha nol is ca r bonyla ted to

pr oduce m ethyl a ceta te a nd a cetic a cid. The m ethyl a ceta te is

r ecov er ed a nd hydr og ena ted to pr oduce m etha nol a nd etha

nol. Etha nol is r ecov er ed by s epa r a ting the m etha nol/ etha nol

m ix tur e. The s epa r a ted m etha nol is r etur ned to the ca r bony

la tion pr oces s .

[ 0024] The need r em a ins f or im pr ov ed pr oces s es f or e? i

cient etha nol pr oduction by r educing es ter s on a com m er

cia lly f ea s ible s ca le.

SUMMARY OF THE IN V EN TION

[ 0025 ] In a ? r s t em bodim ent, the pr es ent inv ention is

dir ected to a m ethod of pr oducing etha nol com pr is ing hydr o

g ena ting a cetic a cid in a ? r s t r ea ctor in the pr es ence of a ? r s t

ca ta lys t to f or m a hydr og ena tion pr oduct com pr is ing ethyl

a ceta te, W a ter , a nd a cetic a cid; r ecov er ing a n es ter f eed s tr ea m

f r om the hydr og ena tion pr oduct; a nd r educing the es ter f eed

s tr ea m in a s econd r ea ctor in the pr es ence of a s econd ca ta lys t

to f or m etha nol. The ? r s t ca ta lys t ha s a s electiv ity tha t f a v or s

ethyl a ceta te ov er etha nol. Thus , the es ter f eed s tr ea m m a y be

r ecov er ed in the a bs ence of a n es ter i? ca tion pr oces s . In a ddi

tion, none of the etha nol f or m ed by r educing the es ter f eed

s tr ea m is r ecycled to the ? r s t r ea ctor . The hydr og ena tion

pr oduct m a y com pr is e f r om 20 to 9 5 W t. % ethyl a ceta te, f r om

5 to 40 W t. % W a ter , a nd f r om 0. 01 to 9 0 W t. % a cetic a cid. The

hydr og ena tion pr oduct m a y f ur ther com pr is e f r om 0. 1 to 30

W t. % etha nol. The hydr og ena tion pr oduct m a y be f ed to a

dis tilla tion colum n to yield a dis tilla te com pr is ing ethyl

a ceta te, etha nol, a nd W a ter , W her ein the es ter f eed s tr ea m

com pr is es the dis tilla te; a nd a r es idue com pr is ing a cetic a cid,

a nd W her ein the r es idue is r etur ned to the ? r s t r ea ctor . The

dis tilla te m a y be f ur ther condens ed a nd bipha s ica lly s epa

r a ted into a n or g a nic pha s e a nd a n a queous pha s e, W her ein the

or g a nic pha s e is the es ter f eed s tr ea m f ed to the s econd r ea c

tor . In s om e em bodim ents , the dis tilla te m a y be f ur ther s epa

r a ted in a n ex tr a ctiv e colum n us ing a t lea s t one ex tr a ctiv e

a g ent, a nd obta ining a n ethyl a ceta te r ich ex tr a cta nt s tr ea m

f r om the ex tr a ctiv e colum n, W her ein the or g a nic pha s e is the

es ter f eed s tr ea m f ed to the s econd r ea ctor . The es ter f eed

s tr ea m m a y com pr is e les s tha n 5 W t. % etha nol a nd les s tha n

5 W t. % W a ter . The s econd ca ta lys t m a y com pr is e a copper

ba s ed ca ta lys t or a Gr oup V III- ba s ed ca ta lys t. The m ola r r a tio

of hydr og en to ethyl a ceta te f ed to the s econd r ea ctor m a y be

f r om 2: 1 to 100: 1. The s econd r ea ctor m a y be oper a ted a t a

tem per a tur e f r om 125 to 35 00 C. a nd a pr es s ur e of 7 00 to

8 , 5 00 k Pa . The ? r s t ca ta lys t m a y ha v e a s electiv ity to ethyl

a ceta te tha t is g r ea ter tha n 5 0%. The ? r s t r ea ctor m a y be

oper a ted a t a tem per a tur e of f r om 125 0 C. to 35 00 C. , a

pr es s ur e of 10 k Pa to 5 000 k Pa , a nd a hydr og en to a cetic a cid

m ole r a tio of g r ea ter tha n 4: 1. In s om e em bodim ents , the

m ethod f ur ther com pr is es conv er ting a ca r bon s our ce into

m etha nol a nd conv er ting the m etha nol into the a cetic a cid,

W her ein the ca r bon s our ce is s elected f r om the g r oup cons is t

ing of na tur a l g a s , petr oleum , biom a s s a nd coa l. In a nother

em bodim ent, the m ethod f ur ther com pr is es conv er ting a ca r

bon s our ce into s yng a s , conv er ting a t lea s t a por tion of the

s yng a s into m etha nol, a nd conv er ting the m etha nol into the

a cetic a cid, W her ein the ca r bon s our ce is s elected f r om the

g r oup cons is ting of na tur a l g a s , petr oleum , biom a s s a nd coa l.

In a nother em bodim ent, the m ethod m a y f ur ther com pr is e

conv er ting a ca r bon s our ce into s yng a s , s epa r a ting a t lea s t a

por tion of the s yng a s into a hydr og en s tr ea m a nd a ca r bon

m onox ide s tr ea m , a nd r ea cting a t lea s t a por tion of the ca r bon

US 2013/0131400 A1

m onox ide s tr ea m W ith m etha nol to f or m a cetic a cid, W her ein

the ca r bon s our ce is s elected f r om the g r oup cons is ting of

na tur a l g a s , petr oleum , biom a s s , a nd coa l. In a nother em bodi

m ent, the m ethod f ur ther com pr is es conv er ting a ca r bon

s our ce into s yng a s , s epa r a ting a t lea s t a por tion of the s yng a s

into a hydr og en s tr ea m a nd a ca r bon m onox ide s tr ea m , con

v er ting a t lea s t s om e of the s yng a s into m etha nol, a nd r ea cting

a por tion of the ca r bon m onox ide s tr ea m W ith a por tion of the

m etha nol to f or m the a cetic a cid, W her ein a t lea s t a por tion of

the es ter f eed s tr ea m is r educed W ith a t lea s t a por tion of the

hydr og en s tr ea m .

[ 0026 ] In one em bodim ent, the ? r s t ca ta lys t com pr is es a t

lea s t one m eta l s elected f r om the g r oup cons is ting of nick el,

pla tinum a nd pa lla dium a nd a t lea s t one m eta l s elected f r om

copper a nd coba lt s uppor ted on a ca ta lys t s uppor t s elected

f r om the g r oup cons is ting of H- ZSM- 5 , s ilica , a lum ina ,

s ilica - a lum ina , ca lcium s ilica te, ca r bon, a nd m ix tur es .

[ 0027 ] In a nother em bodim ent, the ? r s t ca ta lys t com pr is es

0. 5 W t. % to 1 w t. % of pla tinum or pa lla dium a nd 2. 5 W t. %

to 5 W t. % of copper or coba lt on a ca ta lys t s uppor t s elected

f r om the g r oup cons is ting of H- ZSM- 5 , s ilica , a lum ina ,

s ilica - a lum ina , ca lcium s ilica te, ca r bon, a nd m ix tur es

ther eof .

[ 0028 ] In yet a nother em bodim ent, the ? r s t ca ta lys t com

pr is es pla tinum a nd tin on a s uppor t s elected f r om the g r oup

cons is ting of H- ZSM- 5 , s ilica , a lum ina , s ilica - a lum ina , ca l

cium s ilica te, ca r bon, a nd m ix tur es ther eof .

[ 0029 ] In yet a nother em bodim ent, the ? r s t ca ta lys t com

pr is es m eta llic com bina tion of nick el/m olybdenum ( N i/ Mo) ,

pa lla dium /m olybdenum ( Pd/Mo) or pla tinum /m olybdenum

( Pt/Mo) s uppor ted on H- ZSM- 5 .

[ 0030] In yet a nother em bodim ent, the ? r s t ca ta lys t com

pr is es a ? r s t m eta l, a s econd m eta l a nd a s uppor t, W her ein the

? r s t m eta l is s elected f r om the g r oup cons is ting of nick el,

pa lla dium a nd pla tinum a nd is pr es ent in a n a m ount g r ea ter

tha n 1 W t %, ba s ed on the tota l W eig ht of the ca ta lys t, a nd

W her ein the s econd m eta l is s elected f r om the g r oup cons is t

ing of Zir conium , copper , coba lt, tin, a nd Zinc a nd W her ein the

ca ta lys t ha s a s electiv ity to ethyl a ceta te of g r ea ter tha n 40%.

[ 0031] In yet a nother em bodim ent, the ? r s t ca ta lys t com

pr is es a ? r s t m eta l, a s econd m eta l a nd a s ilica /a lum ina s up

por t, W her ein the ? r s t m eta l is s elected f r om the g r oup con

s is ting of nick el, pa lla dium a nd pla tinum , the s econd m eta l is

s elected f r om the g r oup cons is ting of Zir conium , copper ,

coba lt, tin, a nd Zinc, a nd W her ein the s ilica /a lum ina s uppor t

com pr is es a lum inum in a n a m ount g r ea ter tha n 1 W t. %, ba s ed

on the tota l W eig ht of the hig h s ur f a ce a r ea s ilica /a lum ina

s uppor t a nd ha s a s ur f a ce a r ea of a t lea s t 15 0 m 2/ g a nd

W her ein the ca ta lys t ha s a s electiv ity to ethyl a ceta te of

g r ea ter tha n 40%.

[ 0032] In yet a nother em bodim ent, the ? r s t ca ta lys t com

pr is es a ? r s t m eta l, a s econd m eta l a nd a s uppor t, W her ein the

? r s t m eta l is s elected f r om g r oup cons is ting of nick el a nd

pa lla dium , a nd W her ein the s econd m eta l is s elected f r om the

g r oup cons is ting of tin a nd Zinc, W her ein the ca ta lys t ha s a

s electiv ity to ethyl a ceta te of g r ea ter tha n 40%.

[ 0033] In yet a nother em bodim ent, the ? r s t ca ta lys t com

pr is es a ? r s t m eta l s elected f r om the g r oup cons is ting of

copper , ir on, coba lt, nick el, r uthenium , r hodium , pa lla dium ,

os m ium , ir idium , pla tinum , tita nium , Zinc, chr om ium , a s ec

ond m eta l s elected f r om the g r oup cons is ting of copper , tin,

chr om ium , ir on, coba lt, v a na dium , pa lla dium , pla tinum , la n

tha num , cer ium , m a ng a nes e, r uthenium , g old, a nd nick el,

W her ein the s econd m eta l is dif f er ent tha n the ? r s t m eta l, a

Ma y 23, 2013

s uppor t, a nd a t lea s t one s uppor t m odi? er s elected f r om the

g r oup of ox ides of Gr oup IV B m eta ls , ox ides of Gr oup V B

m eta ls , ox ides of Gr oup V IB m eta ls , ir on ox ides , a lum inum

ox ides a nd m ix tur es ther eof . The a t lea s t one s uppor t m odi? er

m a y be s elected f r om the g r oup cons is ting of W 03, M003,

F e2O3, Cr 2O3, TiO2, Zr O2, N b2O5 , Ta 2O5 , a nd A1203.

[ 0034] In a s econd em bodim ent, the pr es ent inv ention is

dir ected to a m ethod of pr oducing etha nol com pr is ing hydr o

g ena ting a cetic a cid in a ? r s t r ea ctor in the pr es ence of a ? r s t

ca ta lys t to f or m a hydr og ena tion pr oduct com pr is ing ethyl

a ceta te, W a ter , a nd a cetic a cid; s epa r a ting a t lea s t a por tion of

the hydr og ena tion pr oduct in a ? r s t colum n to yield a ? r s t

dis tilla te com pr is ing ethyl a ceta te, etha nol, a nd W a ter , a nd a

? r s t r es idue com pr is ing a cetic a cid; bipha s ica lly s epa r a ting a t

lea s t a por tion of the ? r s t dis tilla te in a deca nter into a n

or g a nic pha s e com pr is ing ethyl a ceta te a nd a n a queous pha s e

com pr is ing etha nol a nd W a ter ; a nd r ea cting a t lea s t a por tion

of the or g a nic pha s e W ith hydr og en in a s econd r ea ctor to

pr oduce etha nol.

[ 0035 ] In a thir d em bodim ent, the pr es ent inv ention is

dir ected to a m ethod of pr oducing etha nol com pr is ing : hydr o

g ena ting a cetic a cid in a ? r s t r ea ctor in the pr es ence of a ? r s t

ca ta lys t to f or m a hydr og ena tion pr oduct com pr is ing ethyl

a ceta te, W a ter , a nd a cetic a cid; s epa r a ting a t lea s t a por tion of

the hydr og ena tion pr oduct in a ? r s t colum n to yield a ? r s t

dis tilla te com pr is ing ethyl a ceta te, etha nol, a nd W a ter , a nd a

? r s t r es idue com pr is ing a cetic a cid; bipha s ica lly s epa r a ting a t

lea s t a por tion of the ? r s t dis tilla te in a deca nter into a n

or g a nic pha s e com pr is ing ethyl a ceta te a nd a n a queous pha s e

com pr is ing etha nol a nd W a ter ; com pr is ing s epa r a ting a t lea s t

a por tion of the a queous pha s e in a s econd dis tilla tion colum n

to yield a s econd dis tilla te com pr is ing etha nol a nd ethyl

a ceta te, a nd a s econd r es idue com pr is ing W a ter ; a nd r ea cting

a t lea s t a por tion of the or g a nic pha s e a nd a t lea s t por tion of

the s econd dis tilla te W ith hydr og en in a s econd r ea ctor to

pr oduce etha nol.

[ 0036 ] In a f our th em bodim ent, the pr es ent inv ention is

dir ected to a m ethod of pr oducing etha nol com pr is ing : hydr o

g ena ting a cetic a cid in a ? r s t r ea ctor in the pr es ence of a ? r s t

ca ta lys t to f or m a hydr og ena tion pr oduct com pr is ing ethyl

a ceta te, W a ter , a nd a cetic a cid; s epa r a ting a t lea s t a por tion of

the hydr og ena tion pr oduct in a ? r s t colum n to yield a ? r s t

dis tilla te com pr is ing ethyl a ceta te, etha nol, a nd W a ter , a nd a

? r s t r es idue com pr is ing a cetic a cid; bipha s ica lly s epa r a ting a t

lea s t a por tion of the ? r s t dis tilla te in a deca nter into a n

or g a nic pha s e com pr is ing ethyl a ceta te a nd a n a queous pha s e

com pr is ing etha nol a nd W a ter ; s epa r a ting a t lea s t of por tion of

the or g a nic pha s e into a n es ter - enr iched s tr ea m a nd a n etha

nol- W a ter s tr ea m , W her ein the es ter - enr iched s tr ea m ha s a

tem per a tur e tha t is a t lea s t 7 0 C. ; a nd r ea cting a t lea s t a

por tion of the es ter - enr iched s tr ea m W ith hydr og en in a s ec

ond r ea ctor to pr oduce etha nol.

[ 0037 ] In a ? f th em bodim ent, the pr es ent inv ention is

dir ected to a m ethod of pr oducing etha nol com pr is ing : hydr o

g ena ting a cetic a cid in a ? r s t r ea ctor in the pr es ence of a ? r s t

ca ta lys t to f or m a hydr og ena tion pr oduct com pr is ing ethyl

a ceta te, W a ter , a nd a cetic a cid; s epa r a ting a t lea s t a por tion of

the hydr og ena tion pr oduct in a ? r s t colum n to yield a ? r s t

dis tilla te com pr is ing ethyl a ceta te, etha nol, a nd W a ter , a nd a

? r s t r es idue com pr is ing a cetic a cid; bipha s ica lly s epa r a ting a t

lea s t a por tion of the ? r s t dis tilla te in a deca nter into a n

or g a nic pha s e com pr is ing ethyl a ceta te a nd a n a queous pha s e

com pr is ing etha nol a nd W a ter ; pa s s ing the or g a nic pha s e

thr oug h a t lea s t one m em br a ne to yield a r etenta te com pr is ing

US 2013/0131400 A1

a dr y or g a nic pha s e a nd a per m ea te com pr is ing W a ter ,

W her ein the r etenta te is f ed to the s econd r ea ctor ; a nd r ea cting

a t lea s t a por tion of the dr y or g a nic pha s e W ith hydr og en in a

s econd r ea ctor to pr oduce etha nol.

[ 0038 ] In a s ix th em bodim ent, the pr es ent inv ention is

dir ected to a m ethod of pr oducing etha nol com pr is ing : hydr o

g ena ting a cetic a cid in a ? r s t r ea ctor in the pr es ence of a ? r s t

ca ta lys t to f or m a hydr og ena tion pr oduct com pr is ing ethyl

a ceta te, W a ter , a nd a cetic a cid; s epa r a ting a t lea s t a por tion of

the hydr og ena tion pr oduct in a n ex tr a ctiv e colum n us ing a t

lea s t one ex tr a ctiv e a g ent to yield a n ex tr a cta nt com pr is ing

ethyl a ceta te, a nd a r a ? ina te com pr is ing etha nol a nd W a ter ;

a nd r ea cting a t lea s t a por tion of the ex tr a cta nt W ith hydr og en

in a s econd r ea ctor to pr oduce etha nol.

[ 0039 ] In a s ev enth em bodim ent, the pr es ent inv ention is

dir ected to a m ethod of pr oducing etha nol com pr is ing hydr o

g ena ting a cetic a cid in a ? r s t r ea ctor in the pr es ence of a ? r s t

ca ta lys t to pr oduce a n es ter f eed s tr ea m ; r ea cting a t lea s t a

por tion of the es ter f eed s tr ea m W ith hydr og en in a s econd

r ea ctor to pr oduce a cr ude r ea ction m ix tur e com pr is ing ethyl

a ceta te, etha nol, a nd a t lea s t one a lcohol ha v ing a t lea s t 4

ca r bon a tom s ; s epa r a ting a t lea s t a por tion of the cr ude r ea c

tion m ix tur e in a ? r s t dis tilla tion colum n to yield a ? r s t dis

tilla te com pr is ing ethyl a ceta te a nd a ? r s t r es idue com pr is ing

etha nol; a nd s epa r a ting a t lea s t a por tion of the ? r s t r es idue in

a s econd dis tilla tion colum n to yield a n etha nol s ides tr ea m

a nd a s econd r es idue com pr is ing the a t lea s t one a lcohol

ha v ing a t lea s t 4 ca r bon a tom s . The es ter f eed s tr ea m m a y

com pr is e les s tha n 6 W t. % etha nol a nd les s tha n 5 W t. %

W a ter . The a t lea s t one a lcohol ha v ing a t lea s t 4 ca r bon a tom s

m a y be s elected f r om the g r oup cons is ting of n- buta nol a nd

2- buta nol. The cr ude r ea ction m ix tur e m a y com pr is e f r om

0. 01 to 2 W t. % 2- buta nol. Conv er s ion of ethyl a ceta te to

etha nol in the s econd r ea ctor m a y be f r om 5 0 to 9 5 or f r om 7 0

to 8 5 %.

[ 0040] In a n eig hth em bodim ent, the pr es ent inv ention is

dir ected to a m ethod of pr oducing etha nol com pr is ing hydr o

g ena ting a cetic a cid in a ? r s t r ea ctor in the pr es ence of a ? r s t

ca ta lys t to pr oduce a n es ter f eed s tr ea m ; r ea cting a t lea s t a

por tion of the es ter f eed s tr ea m W ith hydr og en in a s econd

r ea ction Zone to pr oduce a cr ude r ea ction m ix tur e com pr is ing

etha nol, diethyl a ceta l, a nd a t lea s t one a lcohol ha v ing a t lea s t

4 ca r bon a tom s ; a nd s epa r a ting a t lea s t a por tion of the cr ude

r ea ction m ix tur e in one or m or e dis tilla tion colum ns to yield

a n etha nol pr oduct, W her ein the etha nol pr oduct, ba s ed on the

cr ude r ea ction m ix tur e, ha s a r educed a m ount of diethyl

a ceta l a nd a r educed a m ount of the a t lea s t one a lcohol ha v ing

a t lea s t 4 ca r bon a tom s .

BRIEF D ESCRIPTION OF D RAW IN GS

[ 0041] The inv ention is des cr ibed in deta il beloW W ith r ef

er ence to the a ppended dr a W ing s , W her ein lik e num er a ls des

ig na te s im ila r pa r ts .

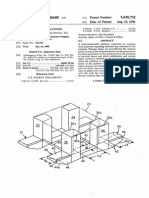

[ 0042] F IGS. 1A a nd 1B a r e g ener a l ? oW s chem es f or pr o

ducing etha nol f r om a ca r bon s our ce in a ccor da nce W ith one

em bodim ent of the pr es ent inv ention.

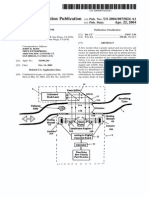

[ 0043] F IG. 2A is a s chem a tic dia g r a m of etha nol pr oduc

tion pr oces s tha t dir ectly f eeds a n or g a nic pha s e of the pr od

uct f r om a cetic a cid hydr og ena tion to the hydr og enolys is

Zone in a ccor da nce W ith one em bodim ent of the pr es ent

inv ention.

[ 0044] F IG. 2B is a s chem a tic dia g r a m of etha nol pr oduc

tion pr oces s ha v ing a hydr og en r ecycle f r om the hydr o

g enolys is r ea ctor to hydr og ena tion r ea ctor in a ccor da nce W ith

one em bodim ent of the pr es ent inv ention.

Ma y 23, 2013

[ 0045 ] F IG. 3 is a s chem a tic dia g r a m of etha nol pr oduction

pr oces s tha t us es a pur i? ca tion colum n to r em ov e W a ter a nd/

or etha nol f r om the or g a nic pha s e in a ccor da nce W ith one

em bodim ent of the pr es ent inv ention.

[ 0046 ] F IG. 4 is a s chem a tic dia g r a m of etha nol pr oduction

pr oces s tha t us es a m em br a ne unit to r em ov e W a ter f r om the

or g a nic pha s e in a ccor da nce W ith one em bodim ent of the

pr es ent inv ention.

[ 0047 ] F IG. 5 is a s chem a tic dia g r a m of etha nol pr oduction

pr oces s tha t us es a n ex tr a ctiv e colum n to pr epa r e a n es ter f eed

s tr ea m f or the hydr og enolys is unit in a ccor da nce W ith one

em bodim ent of the pr es ent inv ention.

[ 0048 ] F IG. 6 is a s chem a tic dia g r a m of etha nol pr oduction

pr oces s W her e the dis tilla te of the lig ht ends colum n in the

hydr og enolys is unit is f ed to the a Zeotr ope colum n in a ccor

da nce W ith one em bodim ent of the pr es ent inv ention.

[ 0049 ] F IG. 7 A is a s chem a tic dia g r a m of etha nol pr oduc

tion pr oces s ha v ing a ? nis hing colum n in the hydr og enolys is

Zone in a ccor da nce W ith one em bodim ent of the pr es ent

inv ention.

[ 005 0] F IG. 7 B is a s chem a tic dia g r a m s hoW ing m ultiple

? a s her s in the hydr og enolys is Zone in a ccor da nce W ith one

em bodim ent of the pr es ent inv ention.

[ 005 1] F IG. 8 A is a s chem a tic dia g r a m of etha nol pr oduc

tion pr oces s ha v ing a W a ter s epa r a tor f or the etha nol pr oduct

in the hydr og enolys is Zone in a ccor da nce W ith one em bodi

m ent of the pr es ent inv ention.

[ 005 2] F IG. 8 B is a s chem a tic dia g r a m s hoW ing a W a ter

s epa r a tor f or a n etha nol r etur n s tr ea m in a ccor da nce W ith one

em bodim ent of the pr es ent inv ention.

[ 005 3] F IG. 9 A is a s chem a tic dia g r a m s hoW ing a W a ter

s epa r a tor f or pr oducing a nhydr ous etha nol in a ccor da nce

W ith one em bodim ent of the pr es ent inv ention.

[ 005 4] F IG. 9 B is a s chem a tic dia g r a m of etha nol pr oduc

tion ha v ing s epa r a te liquid etha nol r etur n s tr ea m a nd W a ter

s epa r a tor f or the etha nol pr oduct in the hydr o g enolys is Zone

in a ccor da nce W ith one em bodim ent of the pr es ent inv ention.

D ETAILED D ESCRIPTION OF THE IN V EN TION

Intr oduction

[ 005 5 ] The pr es ent inv ention r ela tes to pr oces s es f or pr o

ducing etha nol f r om a cetic a cid thr oug h a n a ceta te inter m e

dia te. In one em bodim ent, a cetic a cid is hydr og ena ted to ethyl

a ceta te a nd the ethyl a ceta te is r educed to etha nol. Adv a nta

g eous ly, no s epa r a te es ter i? ca tion s tep is r equir ed to pr oduce

the ethyl a ceta te. Als o, a s epa r a te s our ce of etha nol is not

r equir ed to es ter if y W ith the a cetic a cid. In a ddition, it m a y not

be neces s a r y to r ecycle a por tion of the pr oduced etha nol.

[ 005 6 ] The pr oces s inv olv es a t lea s t tW o dif f er ent r ea ctions

tha t m a y f or m m inor a m ounts of im pur ities , na m ely hydr o

g ena tion of a cetic a cid a nd hydr og enolys is of ethyl a ceta te.

The pr es ent inv ention pr ov ides a n a dv a nta g eous m ethod of

pr oducing a n es ter f eed f r om a hydr og ena tion pr oduct s o tha t

the es ter f eed is s uita ble f or hydr og enolys is . Pur e ethyl

a ceta te m a y be les s cos t ef f ectiv e in pr oducing etha nol tha n

a cetic a cid, a nd to pr ov ide a cos t ef f ectiv e es ter f eed em bodi

m ents of the pr es ent inv ention s im plif y the a cetic a cid hydr o

g ena tion s ys tem a nd us e m inim a l ethyl a ceta te s epa r a tion. In

a ddition, the pr es ent inv ention pr ov ides e? icient s epa r a tion

pr oces s es f or r ecov er ing etha nol a f ter the hydr og enolys is of

ethyl a ceta te. The pr oces s es of the pr es ent inv ention a dv a n

ta g eous ly pr ov ide a com m er cia lly f ea s ible s ca le f or pr oduc

ing etha nol.

US 2013/0131400 A1

[ 005 7 ] The pr es ent inv ention com pr is es pr oducing etha nol

f r om a cetic a cid by hydr og ena ting the a cetic a cid to f or m a n

es ter a nd r educing the es ter . The em bodim ents of the pr es ent

inv ention m a y a ls o be integ r a ted W ith m ethods f or pr oducing

a cetic a cid a s s hoW n in F IGS. 1A a nd 1B. F or ex a m ple, a cetic

a cid m a y be pr oduced f r om m etha nol, a nd thus etha nol pr o

duction a ccor ding to em bodim ents of the pr es ent inv ention

m a y be pr oduced f r om m etha nol. In one em bodim ent, the

pr es ent inv ention com pr is es pr oducing etha nol f r om m etha

nol by ca r bonyla ting the m etha nol to f or m a cetic a cid, hydr o

g ena ting the a cetic a cid to f or m a n es ter , a nd r educing the

es ter to f or m etha nol. In yet a nother em bodim ent, the pr es ent

inv ention com pr is es pr oducing m etha nol f r om s yng a s , ca r

bonyla ting the m etha nol to f or m a cetic a cid, hydr og ena ting

the a cetic a cid to f or m a n es ter , a nd r educing the es ter to a n

a lcohol, na m ely etha nol. In s till a nother em bodim ent, the

pr es ent inv ention com pr is es pr oducing etha nol f r om a ca r bon

s our ce, s uch a s coa l, biom a s s , petr oleum , or na tur a l g a s , by

conv er ting the ca r bon s our ce to s yng a s , f olloW ed by conv er t

ing the s yng a s to m etha nol, ca r bonyla ting the m etha nol to

f or m a cetic a cid, hydr og ena ting the a cetic a cid to f or m a n

es ter , a nd r educing the es ter to a n a lcohol. In s till a nother

em bodim ent, the pr es ent inv ention com pr is es pr oducing

etha nol f r om a ca r bon s our ce, s uch a s coa l, biom a s s , petr o

leum , or na tur a l g a s , by conv er ting the ca r bon s our ce to

s yng a s , s epa r a ting the s yng a s into a hydr og en s tr ea m a nd a

ca r bon m onox ide s tr ea m , ca r bonyla ting a m etha nol W ith the

ca r bon m onox ide s tr ea m to f or m a cetic a cid, hydr og ena ting

the a cetic a cid to f or m a n es ter , a nd r educing the es ter to a n

a lcohol. In a ddition, the es ter m a y be r educed W ith the hydr o

g en s tr ea m . Als o, m etha nol m a y be pr oduced f r om the s yn

g a s .

[ 005 8 ] In pa r ticula r , the pr es ent inv ention is dir ected to a

pr oces s f or im pr ov ing the pr oduction of the es ter f eed to

e? iciently pr oduce etha nol f r om the hydr og enolys is pr oces s .

One obs ta cle to pr oducing etha nol f r om ethyl a ceta te is the

thoug ht tha t pur e ethyl a ceta te needs to be pr oduced a s the

f eed to pr oduce etha nol. Pur e ethyl a ceta te incr ea s es pr oduc

tion cos ts a nd m a y not a chiev e des ir ed im pr ov em ents in the

hydr og enolys is pr oces s . The pr es ent inv ention pr ov ides e? i

cient hydr og ena tion pr oduction cos ts to r es ult in im pr ov e

m ents to the ov er a ll etha nol pr oduction. Contr olling the

hydr og ena tion r ea ctions a nd s epa r a tion pr ov ide f or a n e? i

cient pr oduction of es ter f eed s tr ea m tha t ha s a com pos ition

s uita ble to being r educed to etha nol.

[ 005 9 ] In g ener a l, a s uita ble es ter f eed s tr ea m m a y be

enr iched in ethyl a ceta te, conta ins les s tha n 5 W t. % etha nol

a nd/ or W a ter , a nd is s ubs ta ntia lly f r ee of a cetic a cid. Beca us e

no es ter i? ca tion is us ed, ther e m a y be v er y little etha nol

pr es ent W hen r ecov er ing the ethyl a ceta te. F or ex a m ple,

r educing the W a ter content in the es ter f eed s tr ea m m a y

im pr ov e the r ecov er y of etha nol, a nd in pa r ticula r a nhydr ous

etha nol, f r om the hydr og enolys is r ea ction. This m a y r educe

the num ber of dis tilla tion colum ns a nd s epa r a tion ca pita l

r equir ed f or the etha nol r ecov er y. HoW ev er , loW ? nite W a ter

concentr a tions , e. g . , les s tha n 5 W t. %, in the es ter f eed s tr ea m

m a y incr ea s e etha nol s electiv ity a nd/ or etha nol pr oductiv ity

in the hydr og enolys is r ea ction W hile inhibiting the a ldol con

dens a tion to hig her a lcohols , s uch a s pr opa nol a nd buta nol.

N ot only does W a ter f unction a s a diluent in the hydr og enoly

s is r ea ction, but W a ter m a y ef f ectiv ely s loW doW n the r ea ction

a s W a ter com petitiv ely binds to the ca ta lys t a ctiv e s ites . Oper

a ting the hydr og ena tion pr oces s in a m a nner tha t a lloW s f or

loW ? nite W a ter concentr a tions r educes the cos ts f or s epa r a t

ing in the hydr og ena tion pr oduct W hile pr ov iding a n

im pr ov ed bene? t in hydr o g enolys is to etha nol.

Ma y 23, 2013

I. Hydr og ena tion

[ 006 0] The hydr og ena tion r ea cta nts , a cetic a cid a nd hydr o

g en, us ed in connection W ith the pr oces s of this inv ention m a y

be der iv ed f r om a ny s uita ble s our ce including ca r bon s our ce

s uch a s na tur a l g a s , petr oleum , coa l, biom a s s , a nd s o f or th.

Acetic a cid m a y be pr oduced by s ev er a l m ethods , including

but not lim ited to, m etha nol ca r bonyla tion, a ceta ldehyde ox i

da tion, ethylene ox ida tion, ox ida tiv e f er m enta tion, a nd

a na er obic f er m enta tion.

[ 006 1] A. Acetic Acid Sour ces

[ 006 2] 1. Ca r bonyla tion

[ 006 3] In one em bodim ent, the pr oduction of etha nol m a y

be integ r a ted W ith s uch m etha nol ca r bonyla tion pr oces s es .

Metha nol ca r bonyla tion pr oces s es s uita ble f or pr oduction of

a cetic a cid a r e des cr ibed in Us . Pa t. N os . 7 , 208 , 6 24; 7 , 115 ,

7 7 2; 7 , 005 , 5 41; 6 , 6 5 7 , 07 8 ; 6 , 6 27 , 7 7 0; 6 , 143, 9 30; 5 , 5 9 9 , 9 7 6 ;

5 , 144, 06 8 ; 5 , 026 , 9 08 ; 5 , 001, 25 9 ; a nd 4, 9 9 4, 6 08 , the entir e

dis clos ur es of W hich a r e incor por a ted her ein by r ef er ence. A

ca r bonyla tion s ys tem pr ef er a bly com pr is es a r ea ction Zone,

W hich includes a r ea ctor , a ? a s her a nd optiona lly a r ea ctor

r ecov er y unit. In one em bodim ent, ca r bon m onox ide is

r ea cted W ith m etha nol in a s uita ble r ea ctor , e. g . , a continuous

s tir r ed ta nk r ea ctor ( CSTR) or a bubble colum n r ea ctor .

Pr ef er a bly, the ca r bonyla tion pr oces s is a loW W a ter , ca ta

lyZed, e. g . , r hodium - ca ta lyz ed, ca r bonyla tion of m etha nol to

a cetic a cid, a s ex em pli? ed in Us . Pa t. N o. 5 , 001, 25 9 , W hich

is her eby incor por a ted by r ef er ence.

[ 006 4] The ca r bonyla tion r ea ction m a y be conducted in a

hom og eneous ca ta lytic r ea ction s ys tem com pr is ing a r ea ction

s olv ent, m etha nol a nd/ or r ea ctiv e der iv a tiv es ther eof , a Gr oup

V III ca ta lys t, a t lea s t a ? nite concentr a tion of W a ter , a nd

optiona lly a n iodide s a lt.

[ 006 5 ] Suita ble ca ta lys ts include Gr oup V III ca ta lys ts , e. g . ,

r hodium a nd/or ir idium ca ta lys ts . W hen a r hodium ca ta lys t is

utiliZed, the r hodium ca ta lys t m a y be a dded in a ny s uita ble

f or m s uch tha t the a ctiv e r hodium ca ta lys t is a ca r bonyl iodide

com plex . Ex em pla r y r hodium ca ta lys ts a r e des cr ibed in

Micha el Ga u[ 3, et a l. , Applied Hom og eneous Ca ta lys is w ith

Or g a nom ela llic Com pounds ' A Com pr ehens iv e Ha ndbook in

Tw o V olum es , Cha pter 2. 1, p. 27 - 200, ( 1 ed. , 19 9 6 ) . Iodide

s a lts optiona lly m a inta ined in the r ea ction m ix tur es of the

pr oces s es des cr ibed her ein m a y be in the f or m of a s oluble s a lt

of a n a lk a li m eta l or a lk a line ea r th m eta l or a qua ter na r y

a m m onium or phos phonium s a lt. In cer ta in em bodim ents , a

ca ta lys t co- pr om oter com pr is ing lithium iodide, lithium

a ceta te, or m ix tur es ther eof m a y be em ployed. The s a lt co

pr om oter m a y be a dded a s a non- iodide s a lt tha t W ill g ener a te

a n iodide s a lt. The iodide ca ta lys t s ta biliZer m a y be intr o

duced dir ectly into the r ea ction s ys tem . Alter na tiv ely, the

iodide s a lt m a y be g ener a ted in- s itu s ince under the oper a ting

conditions of the r ea ction s ys tem , a W ide r a ng e of non- iodide

s a lt pr ecur s or s W ill r ea ct W ith m ethyl iodide or hydr oiodic

a cid in the r ea ction m edium to g ener a te the cor r es ponding

co- pr om oter iodide s a lt s ta biliZer . F or a dditiona l deta il

r eg a r ding r hodium ca ta lys is a nd iodide s a lt g ener a tion, s ee

U. S. Pa t. N os . 5 , 001, 25 9 ; 5 , 026 , 9 08 ; a nd 5 , 144, 06 8 , W hich

a r e her eby incor por a ted by r ef er ence.

[ 006 6 ] W hen a n ir idium ca ta lys t is utiliZed, the ir idium

ca ta lys t m a y com pr is e a ny ir idium - conta ining com pound

W hich is s oluble in the liquid r ea ction com pos ition. The ir i

dium ca ta lys t m a y be a dded to the liquid r ea ction com pos i

tion f or the ca r bonyla tion r ea ction in a ny s uita ble f or m W hich

dis s olv es in the liquid r ea ction com pos ition or is conv er tible

to a s oluble f or m . Ex a m ples of s uita ble ir idium - conta ining

US 2013/0131400 A1

com pounds W hich m a y be a dded to the liquid r ea ction com

pos ition include: Ir Cl3, Ir I3, Ir Br 3, [ Ir ( CO) 2I] 2, [ Ir ( CO) 2Cl] 2,

[ Ir ( CO) 2Br ] 2, [ Ir ( CO) 2I2] _ H+ , [ Ir ( CO) 2Br 2] _ H+ , [ Ir ( CO)

214TH" , [ Ir ( CH3) I3( CO2) ] _ H+ , Ir 4( CO) 12, Ir Cl3. 3H2O, Ir Br 3.

3H2O, ir idium m eta l, Ir 2O3, Ir ( a ca c) ( CO) 2, Ir ( a ca c) 3, ir idium

a ceta te, [ Ir 3O( OAc) 6 ( H2O) 3] [ OAc] , a nd hex a chlor oir idic

a cid [ H2Ir Cl6 ] . Chlor ide- f r ee com plex es of ir idium s uch a s

a ceta tes , ox a la tes a nd a cetoa ceta tes a r e us ua lly em ployed a s

s ta r ting m a ter ia ls . The ir idium ca ta lys t concentr a tion in the

liquid r ea ction com pos ition m a y be in the r a ng e of 100 to

6 000 W ppm . The ca r bonyla tion of m etha nol utiliz ing ir idium

ca ta lys t is W ell k noW n a nd is g ener a lly des cr ibed in Us . Pa t.

N os . 5 , 9 42, 46 0; 5 , 9 32, 7 6 4; 5 , 8 8 3, 29 5 ; 5 , 8 7 7 , 348 ; 5 , 8 7 7 , 347

a nd 5 , 6 9 6 , 28 4, the entir eties of W hich a r e her eby incor po

r a ted by r ef er ence.

[ 006 7 ] A ha log en co- ca ta lys t/pr om oter is g ener a lly us ed in

com bina tion W ith the Gr oup V III m eta l ca ta lys t com ponent.

Methyl iodide is a pr ef er r ed ha log en pr om oter . Pr ef er a bly, the

concentr a tion of the ha log en pr om oter in the r ea ction

m edium r a ng es f r om 1 W t. % to 5 0 W t. %, a nd m or e pr ef er a bly

f r om 2 W t. % to 30 W t. %.

[ 006 8 ] The ha log en pr om oter m a y be com bined W ith the

s a lt s ta biliZer /co- pr om oter com pound. Pa r ticula r ly pr ef er r ed

a r e iodide or a ceta te s a lts , e. g . , lithium iodide or lithium

a ceta te.

[ 006 9 ] Other pr om oter s a nd co- pr om oter s m a y be us ed a s

pa r t of the ca ta lytic s ys tem of the pr es ent inv ention a s

des cr ibed in Us . Pa t. N o. 5 , 8 7 7 , 348 , W hich is her eby incor

por a ted by r ef er ence. Suita ble pr om oter s a r e s elected f r om

r uthenium , os m ium , tung s ten, r henium , Zinc, ca dm ium ,

indium , g a llium , m er cur y, nick el, pla tinum , v a na dium , tita

nium , copper , a lum inum , tin, a ntim ony, a nd a r e m or e pr ef er

a bly s elected f r om r uthenium a nd os m ium . Speci? c co- pr o

m oter s a r e des cr ibed in Us . Pa t. N o. 6 , 6 27 , 7 7 0, W hich is

incor por a ted her ein by r ef er ence.

[ 007 0] A pr om oter m a y be pr es ent in a n ef f ectiv e a m ount

up to the lim it of its s olubility in the liquid r ea ction com po

s ition a nd/or a ny liquid pr oces s s tr ea m s r ecycled to the ca r

bonyla tion r ea ctor f r om the a cetic a cid r ecov er y s ta g e. W hen

us ed, the pr om oter is s uita bly pr es ent in the liquid r ea ction

com pos ition a t a m ola r r a tio of pr om oter to m eta l ca ta lys t of

0. 5 : 1 to 15 : 1, pr ef er a bly 2: 1 to 10: 1, m or e pr ef er a bly 2: 1 to

7 . 5 : 1. A s uita ble pr om oter concentr a tion is 400 to 5 000

W ppm .

[ 007 1] In one em bodim ent, the tem per a tur e of the ca r bo

nyla tion r ea ction in the r ea ctor is pr ef er a bly f r om 15 00 C. to

25 0 C. , e. g . , f r om 15 0 C. to 225 C. , or f r om 15 0 C. to 200

C. The pr es s ur e of the ca r bonyla tion r ea ction is pr ef er a bly

f r om 1 to 20 MPa , pr ef er a bly 1 to 10 MPa , m os t pr ef er a bly 1. 5

to 5 MPa . Acetic a cid is typica lly m a nuf a ctur ed in a liquid

pha s e r ea ction a t a tem per a tur e f r om a bout 15 0 C. to a bout

200 C. a nd a tota l pr es s ur e f r om a bout 2 to a bout 5 MPa .

[ 007 2] In one em bodim ent, r ea ction m ix tur e com pr is es a

r ea ction s olv ent or m ix tur e of s olv ents . The s olv ent is pr ef

er a bly com pa tible W ith the ca ta lys t s ys tem a nd m a y include

pur e a lcohols , m ix tur es of a n a lcohol f eeds tock , a nd/or the

des ir ed ca r box ylic a cid a nd/or es ter s of thes e tW o com

pounds . In one em bodim ent, the s olv ent a nd liquid r ea ction

m edium f or the ( loW W a ter ) ca r bonyla tion pr oces s is pr ef er

a bly a cetic a cid.

[ 007 3] W a ter m a y be f or m ed in s itu in the r ea ction m edium ,

f or ex a m ple, by the es ter i? ca tion r ea ction betW een m etha nol

r ea cta nt a nd a cetic a cidpr oduct. In s om e em bodim ents , W a ter

is intr oduced to the r ea ctor tog ether W ith or s epa r a tely f r om

Ma y 23, 2013

the other com ponents of the r ea ction m edium . W a ter m a y be

s epa r a ted f r om the other com ponents of the r ea ction pr oduct

W ithdr a W n f r om r ea ctor a nd m a y be r ecycled in contr olled

a m ounts to m a inta in the r equir ed concentr a tion of W a ter in

the r ea ction m edium . Pr ef er a bly, the concentr a tion of W a ter

m a inta ined in the r ea ction m edium r a ng es f r om 0. 1 W t. % to

16 W t. %, e. g . , f r om 1 W t. % to 14 W t. %, or f r om 1 W t. % to

3 W t. % of the tota l W eig ht of the r ea ction pr oduct.

[ 007 4] The des ir ed r ea ction r a tes a r e obta ined ev en a t loW

W a ter concentr a tions by m a inta ining in the r ea ction m edium

a n es ter of the des ir ed ca r box ylic a cid a nd a n a lcohol, des ir

a bly the a lcohol us ed in the ca r bonyla tion, a nd a n a dditiona l

iodide ion tha t is ov er a nd a bov e the iodide ion tha t is pr es ent

a s hydr og en iodide. An ex a m ple of a pr ef er r ed es ter is m ethyl

a ceta te. The a dditiona l iodide ion is des ir a bly a n iodide s a lt,

W ith lithium iodide ( LiI) being pr ef er r ed. It ha s been f ound, a s

des cr ibed in Us . Pa t. N o. 5 , 001, 25 9 , tha t under loW W a ter

concentr a tions , m ethyl a ceta te a nd lithium iodide a ct a s r a te

pr om oter s only W hen r ela tiv ely hig h concentr a tions of ea ch

of thes e com ponents a r e pr es ent a nd tha t the pr om otion is

hig her W hen both of thes e com ponents a r e pr es ent tog ether .

The a bs olute concentr a tion of iodide ion is not a lim ita tion on

the us ef ulnes s of the pr es ent inv ention.

[ 007 5 ] In loW W a ter ca r bonyla tion, the a dditiona l iodide

ov er a nd a bov e the or g a nic iodide pr om oter m a y be pr es ent in

the ca ta lys t s olution in a m ounts r a ng ing f r om 2 W t. % to 20

W t. %, e. g . , f r om 2 W t. % to 15 W t. %, or f r om 3 W t. % to 10

W t. %; the m ethyl a ceta te m a y be pr es ent in a m ounts r a ng ing

f r om 0. 5 W t. % to 30 W t. %, e. g . , f r om 1 W t. % to 25 W t. %, or

f r om 2 W t. % to 20 W t. %; a nd the lithium iodide m a y be

pr es ent in a m ounts r a ng ing f r om 5 W t. % to 20 W t. %, e. g . ,

f r om 5 W t. % to 15 W t. %, or f r om 5 W t. % to 10 W t. %. The

ca ta lys t m a y be pr es ent in the ca ta lys t s olution in a m ounts

r a ng ing f r om 200 W ppm to 2000 W ppm , e. g . , f r om 200 W ppm

to 15 00 W ppm , or f r om 5 00 W ppm to 15 00 W ppm .

[ 007 6 ] Alter na tiv ely, a cetic a cid in v a por f or m m a y be

ta k en dir ectly a s cr ude pr oduct f r om the ? a s h v es s el of a

m etha nol ca r bonyla tion unit of the cla s s des cr ibed in Us .

Pa t. N o. 6 , 6 5 7 , 07 8 , the entir ety of W hich is incor por a ted

her ein by r ef er ence. The cr ude v a por pr oduct, f or ex a m ple,

m a y be f ed dir ectly to the hydr og ena tion r ea ction Zone of the

pr es ent inv ention W ithout the need f or condens ing the a cetic

a cid a nd lig ht ends or r em ov ing W a ter , s a v ing ov er a ll pr oces s

ing cos ts .

[ 007 7 ]

[ 007 8 ] As petr oleum a nd na tur a l g a s pr ices ? uctua te

becom ing either m or e or les s ex pens iv e, m ethods f or pr oduc

ing a cetic a cid a nd inter m edia tes s uch a s m etha nol a nd ca r

bon m onox ide f r om a lter na te ca r bon s our ces ha v e dr a W n

incr ea s ing inter es t. In pa r ticula r , W hen petr oleum is r ela tiv ely

ex pens iv e, it m a y becom e a dv a nta g eous to pr oduce a cetic

a cid f r om s ynthes is g a s ( s yng a s ) tha t is der iv ed f r om m or e

a v a ila ble ca r bon s our ces . U. S. Pa t. N o. 6 , 232, 35 2, the

entir ety of W hich is incor por a ted her ein by r ef er ence, f or

ex a m ple, tea ches a m ethod of r etr o? tting a m etha nol pla nt f or

the m a nuf a ctur e of a cetic a cid. By r etr o? tting a m etha nol

pla nt, the la r g e ca pita l cos ts a s s ocia ted W ith CO g ener a tion

f or a neW a cetic a cid pla nt a r e s ig ni? ca ntly r educed or la r g ely

elim ina ted. All or pa r t of the s yng a s is div er ted f r om the

m etha nol s ynthes is loop a nd s upplied to a s epa r a tor unit to

r ecov er CO, W hich is then us ed to pr oduce a cetic a cid. In a

s im ila r m a nner , hydr og en f or the hydr og enolys is s tep m a y be

s upplied f r om s yng a s .

2. D ir ect f r om Syng a s

You might also like

- Raise ClimberDocument14 pagesRaise ClimberAngeline WolfNo ratings yet

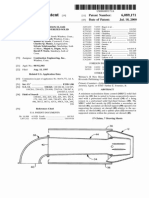

- US Patent 2011/0024635 CSLILN HALIDE SCINTILLATORDocument17 pagesUS Patent 2011/0024635 CSLILN HALIDE SCINTILLATORBill HigginsNo ratings yet

- US20130261330 Vynil AsetatDocument11 pagesUS20130261330 Vynil AsetatDebby Theresia SilabanNo ratings yet

- Us 20110139628Document9 pagesUs 20110139628Rahma Ama NuryantyNo ratings yet

- United States Patent (19) (11) Patent Number: 6,018,225: Garces (45) Date of Patent: Jan. 25, 2000Document15 pagesUnited States Patent (19) (11) Patent Number: 6,018,225: Garces (45) Date of Patent: Jan. 25, 2000kfaliNo ratings yet

- Patent - Paul BabcockDocument25 pagesPatent - Paul BabcockHappyJoeNo ratings yet

- Aegis Patent US20140162965Document45 pagesAegis Patent US20140162965maneshdixit4312No ratings yet

- Us 20130079618Document30 pagesUs 20130079618Fercalo AndreiNo ratings yet

- (12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1Document13 pages(12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1danceNo ratings yet

- Us 20130266664 PatentDocument40 pagesUs 20130266664 PatentV Phanindra BoguNo ratings yet

- Bioprinting Three-Dimensional Structure Onto Microscale Tissue Analog DevicesDocument20 pagesBioprinting Three-Dimensional Structure Onto Microscale Tissue Analog DeviceswerfqwetfgNo ratings yet

- Umted States Patent (10) Patent N0.2 US 8,415,942 B2: Fletcher (45) Date of Patent: Apr. 9, 2013Document19 pagesUmted States Patent (10) Patent N0.2 US 8,415,942 B2: Fletcher (45) Date of Patent: Apr. 9, 2013bonesisaliveNo ratings yet

- Us 4962706Document8 pagesUs 4962706drivinerNo ratings yet

- 106 Yms @eiei: (19) United StatesDocument15 pages106 Yms @eiei: (19) United Statesacela3248No ratings yet

- Gel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2Document9 pagesGel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2b4rfNo ratings yet

- Us 20140060005Document44 pagesUs 20140060005Victor Von DoomNo ratings yet

- United States Patent (191 (11) Patent Number: 4,508,572: Sakuta Et A1. (45) Date of Patent: Apr. 2, 1985Document6 pagesUnited States Patent (191 (11) Patent Number: 4,508,572: Sakuta Et A1. (45) Date of Patent: Apr. 2, 1985atnmmm100No ratings yet

- Web 1T: (12) United States PatentDocument18 pagesWeb 1T: (12) United States PatentadeindrawijayaNo ratings yet

- Us 20120097550Document11 pagesUs 20120097550ddsfathNo ratings yet

- United States Patent (10) Patent No.: US 8,301,867 B1Document12 pagesUnited States Patent (10) Patent No.: US 8,301,867 B1Ghouse MohammedNo ratings yet

- US6863865Document7 pagesUS6863865trscribdforworkNo ratings yet

- United States Patent 1191 1111 4,030,523: Cram Et A1. (45) 7 June 21, 1977Document5 pagesUnited States Patent 1191 1111 4,030,523: Cram Et A1. (45) 7 June 21, 1977Brunno VasquesNo ratings yet

- Combustion Engineering-2000-Minimum Recirculation Flame Control (MRFC) Pulverized Solid Fuel Nozzle Tip PDFDocument22 pagesCombustion Engineering-2000-Minimum Recirculation Flame Control (MRFC) Pulverized Solid Fuel Nozzle Tip PDFKrozeNo ratings yet

- 13cv21177 - 8-1 - Obj. To Magistrate's R & R Attachments - Apr 26, 2013Document60 pages13cv21177 - 8-1 - Obj. To Magistrate's R & R Attachments - Apr 26, 2013Ralph IrwinNo ratings yet

- Serdox AppsDocument13 pagesSerdox AppsCesar MartinezNo ratings yet

- Us 20040075824Document18 pagesUs 20040075824presuraNo ratings yet

- US Patent No. 8499869Document11 pagesUS Patent No. 8499869mlpraterNo ratings yet

- L1 - GSM Alcatel IntroductionDocument104 pagesL1 - GSM Alcatel Introductionsoyuz90No ratings yet

- United States Patent (10) Patent No.: US 8,014,526 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,014,526 B2sat258No ratings yet

- Falha de Mola Por ContatoDocument5 pagesFalha de Mola Por ContatoFelipe UngaroNo ratings yet

- Us 6362718 (US Patent For Free Energy Device)Document15 pagesUs 6362718 (US Patent For Free Energy Device)jajahahaNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,362,408 B2Document11 pagesUlllted States Patent (10) Patent N0.: US 8,362,408 B2werwer44345No ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,971,999 B2Document17 pagesUnited States Patent: (12) (10) Patent N0.: US 6,971,999 B2ghftr456No ratings yet

- Generator: United States Patent (191Document11 pagesGenerator: United States Patent (191Niki MikiNo ratings yet

- 9366 CMSDocument7 pages9366 CMSRecordTrac - City of OaklandNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,273,739 B2Document6 pagesUlllted States Patent (10) Patent N0.: US 8,273,739 B2Sam SonNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0145519 A1Document17 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0145519 A1Catalin AlexandruNo ratings yet

- United States Patent (10) Patent N0.: US 6,827,075 B1Document7 pagesUnited States Patent (10) Patent N0.: US 6,827,075 B1Cristhian GraefNo ratings yet

- Hydrocyclones: D-Sa N Der D-SilterDocument10 pagesHydrocyclones: D-Sa N Der D-Siltersaa6383No ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,523,785 B1Document11 pagesUnited States Patent: (12) (10) Patent N0.: US 6,523,785 B1HRNo ratings yet

- 2011 Donors Trust 990Document111 pages2011 Donors Trust 990airlifter2No ratings yet

- Trivich 1982 TR FinalDocument118 pagesTrivich 1982 TR FinalAlberto Mittiga0% (1)

- United States Patent (10) Patent N0.: US 8,091,836 B2Document8 pagesUnited States Patent (10) Patent N0.: US 8,091,836 B2werwer44345No ratings yet

- United States Patent (191 4,774,373: Hundeck Et Al. (11) Patent Number: (45) Date of PatentDocument4 pagesUnited States Patent (191 4,774,373: Hundeck Et Al. (11) Patent Number: (45) Date of PatentChrisna Al HafizNo ratings yet

- Umted States Patent (191 (11) Patent Number: 5 038 702: Bowes (45) Date of Patent: Aug. 13, 1991Document15 pagesUmted States Patent (191 (11) Patent Number: 5 038 702: Bowes (45) Date of Patent: Aug. 13, 1991Phan Trọng NghĩaNo ratings yet

- United States Patent (191: Bieniosek (45) Date of Patent: May 23, 1989Document4 pagesUnited States Patent (191: Bieniosek (45) Date of Patent: May 23, 1989harishkumarsinghNo ratings yet

- Research 2Document45 pagesResearch 2anaqiaisyahNo ratings yet

- United States Patent: Harlander Et A) - (10) Patent N0.: (45) Date of PatentDocument24 pagesUnited States Patent: Harlander Et A) - (10) Patent N0.: (45) Date of PatentFaizan KhanNo ratings yet

- United States Patent: (10) Patent N0.: (45) Date of PatentDocument6 pagesUnited States Patent: (10) Patent N0.: (45) Date of Patent89gt89gtNo ratings yet

- Alt-O. : Indlvlduelly /@Document7 pagesAlt-O. : Indlvlduelly /@drivinerNo ratings yet

- United States Patent (10) Patent N0.2 US 6,276,459 B1Document6 pagesUnited States Patent (10) Patent N0.2 US 6,276,459 B1Jessica CehNo ratings yet

- United States Patent (191 4,927,800: Nishiki Et AlDocument7 pagesUnited States Patent (191 4,927,800: Nishiki Et AlchecolonoskiNo ratings yet

- Us 3995792Document5 pagesUs 3995792werwer44345No ratings yet

- Olo + I: Effect OF Hydrostatic Extrusion ON Properties OF Trip SteelsDocument4 pagesOlo + I: Effect OF Hydrostatic Extrusion ON Properties OF Trip SteelspabusaoNo ratings yet

- United States Patent (19) (11) Patent Number: 4,859,054: Harrison (45) Date of Patent: Aug. 22, 1989Document9 pagesUnited States Patent (19) (11) Patent Number: 4,859,054: Harrison (45) Date of Patent: Aug. 22, 1989drivinerNo ratings yet

- United States PatentDocument20 pagesUnited States PatentpamururamuNo ratings yet

- United States Patent: GrimesDocument61 pagesUnited States Patent: GrimesMladen MuskinjaNo ratings yet

- Surfactant Analysis by TLC PDFDocument12 pagesSurfactant Analysis by TLC PDFKristopher Glenn AltonNo ratings yet

- United States Patent (191: (11) Patent Number: (45) Date of PatentDocument5 pagesUnited States Patent (191: (11) Patent Number: (45) Date of PatentSalmanPashaNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0101312 A1Document10 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0101312 A1Debby Theresia SilabanNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0184498 A1Document10 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0184498 A1Debby Theresia SilabanNo ratings yet

- Cannot Create Restore Point On Windows 7 64Document3 pagesCannot Create Restore Point On Windows 7 64Debby Theresia SilabanNo ratings yet

- Kode Komoditas Ekspor Impor DuniaDocument322 pagesKode Komoditas Ekspor Impor DuniaadimaulNo ratings yet

- US20130131400 Etil AsetatDocument43 pagesUS20130131400 Etil AsetatDebby Theresia SilabanNo ratings yet

- EngineeringDocument7 pagesEngineeringDebby Theresia SilabanNo ratings yet

- FairishDocument1 pageFairishDebby Theresia Silaban100% (1)