Professional Documents

Culture Documents

JV4 20head Alignment Procedure

Uploaded by

OficinahTechniquesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JV4 20head Alignment Procedure

Uploaded by

OficinahTechniquesCopyright:

Available Formats

J V4 Head Alignment Procedure

Items Needed:

Metric Hex Wrench key 2.5 3 1/2 inches long found at Sears stores.

Philip head screw driver.

50 power Lupe with a measurement line. Buy it from us at $165 including

shipping.

Pet Gloss Paper

Note:

The adjustments should be performed with the metal plungers tip of the Mimaki

J V4 just touching the paper. If the head height is re-set higher than this position

for your material at a later date, you must recalculate Fine Bi-directional and Fine

Re. settings. You will see these settings on page 3.

Before proceeding with the functions, remove the long left side cover

of the printer with the plastic window flap. Remove the cover from the

carriage so you can get to the heads.

Steps:

1: Head Adjust / Slant Adjust

On the J V4 panel: Function / #Adjust / Head Adjust / Slant Adjust.

When viewing the dot pattern though a 50 power magnifier, you will see a

row of dots that form a line. Look at the last group of 4 passes and see if the

combination of dots have formed a thin line with the dots varying by a half a dot

on both sides of the line. This will be as good as it gets.

The procedure is as follows:

1. Run the Slant Adjust pattern first.

2. If any head is out of alignment push the left arrow key and the

carriage will jog out.

3. Loosen the 2 Metric screws on the head as seen in the

maintenance manual page 6.13. One screw is in the back of the

head and the other is in the front of the head. The angle adjustment

is shown on page 6.14. Once you make the adjustment tighten the

screws up

4. Repeat the procedure until the dots are producing a straight line.

1

2: Head Adjust R/F

# Adjust / R/F

Here is where you adjust the distance from heads 1 to 2, heads 3 to 4,

heads and 4 to 6. The goal is to have the nozzles of the front head and the

nozzles of the rear head lay down a line of dots equi distant creating an invisible

blend line. Look at the horizontal row of dots of each of the front and rear heads

where they meet. They should be the same distance apart as the row of dots

within each head.

On the J V4 panel: Function / #Adjust / Head Adjust / R/F

1. Run the R/F Test first with K.

2. If there is a gap or an overlap the front head must be adjusted.

3. Push the left arrow key and the carriage will jog out.

4. Loosen the front and rear brass screws and turn the distance

control screw as shown in illustration on page 6.15

5. Tighten the screws and perform the test over.

6. Once the heads are aligned proceed to the next set of heads 3 and

4 and then 5 and 6 and repeat the procedure.

3: Adjust X Direction

# Adjust / Prn adjust 2

On the J V4 panel: Function / #Adjust / Prn adjust 2 / X Direction

X Direction controls heads 1 to 3 and 1 to 5

1. Run the X Direction test

2. Enter in the values that most accurately describe the best

alignment.

4: Adjust / Variable 2 Y Fine

#Adjust / Prn adjust 2 Variable 2

On the J V4 panel: Function / #Adjust / Prn adjust / / Variable 2 / SY Fine

Variable 2 for Res 720 and up using variable dot.

The adjustment procedure controls each dot position to produce the finest

alignment possible. In this procedure you choose the numbers that best position

the dots in an overlapping straight line. See page 4.8 Write down your starting

point for each head. If a row of dots is off to the right, reduce the number one the

readout. If the row is off by about a half a dot start reducing the number by 1.0

point.

2

1. Run the fine adjust first for K only. This will ensure that you are

focused on producing the finest alignment between heads 1 and 2.

2. Repeat the test changing the numbers of 1 to 2 only until they line

up the best you can make it.

3. Proceed by going to End to go back to the control of color heads.

Add K and M.

4. Now that you have heads 1 and 2 well positioned you will be

adjusting only heads 1 to 3 and 1 to 4. You may want to only work

on one at a time or both.

5. When 1 to 3 and 3 and 4 are perfectly aligned forming the best

overlap possible, then proceed to 1 to 5 and 1 to 6.

5: Adjust 2 Fine Y Bi

#Adjust / Prn adjust

On the J V4 panel: Function / #Adjust / Prn adjust 2 / SY / Variable 2 /

Fine / Bi

The adjustment here is critical for bi directional usage. The test relates to

head 1 and 2.

1. Run the test for Bi

2. Choose the most accurate alignment.

6: Adjust Fine Re

On the J V4 panel: Function / #Adjust / Prn adjust 2 / SY / Variable 2 /

Fine / Re

Perform the test just like Fine Variable 2 S Y.

Once this step has been completed you have effectively controlled every

dot to its best placement.

7: High Speed / Maintenance Mode

On the J V4 panel: Function / Maintenance Mode / Print Adjust

Perform the test and set the alignment points to the best combination just

like X Adjust.

8: Head Adjust 2 Final

# Adjust / Prn Fine / Final

3

On the J V4 panel: Function / #Adjust / Prn adjust 2 / SY / Variable 2 /

Fine / Final

This step is used to check your alignment. See Page 4.9. You cannot

make adjustments here. You must go back to the area of problem.

4

You might also like

- The 2 Position Guitar Scale System: Scales and ArpeggiosFrom EverandThe 2 Position Guitar Scale System: Scales and ArpeggiosRating: 5 out of 5 stars5/5 (5)

- AR 15 Lower Receiver Step by StepDocument81 pagesAR 15 Lower Receiver Step by StepNorm96% (27)

- Paper Art - Yamaha Yzr m1 Us AssemblyDocument14 pagesPaper Art - Yamaha Yzr m1 Us AssemblyrevealedNo ratings yet

- 4E845 Machining The AR 15 Lower Reciever Forging PDFDocument62 pages4E845 Machining The AR 15 Lower Reciever Forging PDFpalaciosro100% (2)

- Rim and Face AlignmentDocument8 pagesRim and Face Alignmentnazir305No ratings yet

- Science: Quarter 4 - Module 1: Locating Places Using Coordinate SystemDocument28 pagesScience: Quarter 4 - Module 1: Locating Places Using Coordinate SystemJaken Mack100% (5)

- Procedure Setup and Calibrate ECT DefHiDocument38 pagesProcedure Setup and Calibrate ECT DefHivikramNo ratings yet

- Origami LightsDocument2 pagesOrigami LightsTatjana Valčić VuksanovićNo ratings yet

- Rim & Face Alignment MethodDocument9 pagesRim & Face Alignment Methoddg_cd7340No ratings yet

- Alignment Procedure PDocument8 pagesAlignment Procedure PvinothenergyNo ratings yet

- Blocks with Options: Quick & Easy Quilts with Color & Size VariationsFrom EverandBlocks with Options: Quick & Easy Quilts with Color & Size VariationsNo ratings yet

- Oboe Adjustment Guide by Seat OnDocument7 pagesOboe Adjustment Guide by Seat Ongl1188No ratings yet

- Oracle Process Manufacturing Master SetupsDocument42 pagesOracle Process Manufacturing Master SetupsMadhuri Uppala100% (2)

- Blend Target Bypass RingDocument5 pagesBlend Target Bypass RingPaulo MarausNo ratings yet

- Procedure Setup and Calibrate ECT BobbinDocument23 pagesProcedure Setup and Calibrate ECT BobbinJawad MunirNo ratings yet

- MD Profiler Instruction ManualDocument11 pagesMD Profiler Instruction ManualTatiana Trenogina100% (1)

- GCSE Maths Revision: Cheeky Revision ShortcutsFrom EverandGCSE Maths Revision: Cheeky Revision ShortcutsRating: 3.5 out of 5 stars3.5/5 (2)

- From Navier Stokes To Black Scholes - Numerical Methods in Computational FinanceDocument13 pagesFrom Navier Stokes To Black Scholes - Numerical Methods in Computational FinanceTrader CatNo ratings yet

- Auxiliary Switch AdjustmentsDocument3 pagesAuxiliary Switch Adjustmentsමාධව නදුන්මල්.No ratings yet

- BYHX LCD Menu & Printhead AdjustmentDocument15 pagesBYHX LCD Menu & Printhead AdjustmentErkan KabakçıNo ratings yet

- Pert PPT PresentationDocument13 pagesPert PPT PresentationDhanjay Das100% (2)

- Head Adjustment Procedure Mutoh Falcon IIDocument19 pagesHead Adjustment Procedure Mutoh Falcon IIrjcury100% (1)

- TL4100 ManualmainDocument15 pagesTL4100 ManualmainRheneir MoraNo ratings yet

- Dual-Head Machine InstallationDocument5 pagesDual-Head Machine InstallationFreddy GonzalezNo ratings yet

- Using Splines and SurfacesDocument24 pagesUsing Splines and SurfacesVICTORSJNo ratings yet

- Setting Needle Bar Depth For SWF Embroidery Machines (All Models)Document2 pagesSetting Needle Bar Depth For SWF Embroidery Machines (All Models)Jonathan Lara FandiñoNo ratings yet

- Adjustments: 5050/5100 Maintenance Manual GEK-00009A 123Document8 pagesAdjustments: 5050/5100 Maintenance Manual GEK-00009A 123dsecompNo ratings yet

- 4 Wheel Alignment - 7 Easy StepsDocument4 pages4 Wheel Alignment - 7 Easy Stepsjoko sutrisnoNo ratings yet

- Prusa Mendel Build Manual Addendum 04-08-12Document11 pagesPrusa Mendel Build Manual Addendum 04-08-12macc4071No ratings yet

- Reciprocator Compact Single and MultiheadDocument14 pagesReciprocator Compact Single and MultiheadjoecentroneNo ratings yet

- Mounting The Dial Indicator FixturesDocument10 pagesMounting The Dial Indicator Fixturesmohamed elejmiNo ratings yet

- Quick Start To Drawing A Piping Spool:See Also: More Articles Like ThisDocument12 pagesQuick Start To Drawing A Piping Spool:See Also: More Articles Like Thisnaji aliNo ratings yet

- Epson Stylus 400ch4Document11 pagesEpson Stylus 400ch4SerwisNo ratings yet

- Eb 120u英文版说明书Document66 pagesEb 120u英文版说明书محمد ابو شهابNo ratings yet

- DP60 - Registrations Settings METHODDocument4 pagesDP60 - Registrations Settings METHODZicoAjmiNo ratings yet

- 15 - Calibration of Diff PenDocument3 pages15 - Calibration of Diff PenweldsvNo ratings yet

- Chapter 07Document3 pagesChapter 07Joshua MunseyNo ratings yet

- The Big Troubleshooting GuideDocument50 pagesThe Big Troubleshooting GuidePablo PerezNo ratings yet

- Offset Turning The CamshaftDocument13 pagesOffset Turning The CamshaftNam HoangNo ratings yet

- GampaDocument21 pagesGampaALEX MPELLANo ratings yet

- Autodesk - Training - Using SplinesDocument18 pagesAutodesk - Training - Using Splinescristianalonso3259No ratings yet

- Rzcam Usrer Manual 2023Document11 pagesRzcam Usrer Manual 2023Angin MalamNo ratings yet

- 3DS Max Low-Poly Sword TutorialDocument18 pages3DS Max Low-Poly Sword TutorialshahrulkamilNo ratings yet

- Arb 5620010 Installation InstructionsDocument11 pagesArb 5620010 Installation InstructionsRafael GabrielNo ratings yet

- Mitsubishi Spindle Orient AdjustmentDocument2 pagesMitsubishi Spindle Orient AdjustmentJuan Pablo RiosNo ratings yet

- Airtronics M11 ManualDocument50 pagesAirtronics M11 Manualcns_atlargeNo ratings yet

- How To Adjust Print Head and Ink Cap PositionDocument4 pagesHow To Adjust Print Head and Ink Cap PositionAVM ECOLENo ratings yet

- MDX650 Rotary TutorialDocument17 pagesMDX650 Rotary TutorialCarlos RamirezNo ratings yet

- Begining Tutorial To Eagle PCB Schematic Editor by Azhar JaffarDocument21 pagesBegining Tutorial To Eagle PCB Schematic Editor by Azhar JaffarNazrul Ahmad KhalidNo ratings yet

- Vectrex Trouble Shooting GuideDocument18 pagesVectrex Trouble Shooting GuideMaraakate100% (1)

- Owner'S Manual: Z100 / Z300 Z500 Z700Document16 pagesOwner'S Manual: Z100 / Z300 Z500 Z700A de LegaspiNo ratings yet

- Alignment Light AdjustmentDocument11 pagesAlignment Light AdjustmentNooruddin DeroNo ratings yet

- RU Laser ProceduresDocument15 pagesRU Laser ProceduresXaviNo ratings yet

- Delmhorst J 2000Document13 pagesDelmhorst J 2000Wilson Valencia PulgarinNo ratings yet

- 4 Wheel Robot Drive TutorialDocument28 pages4 Wheel Robot Drive TutorialksaloneNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Function Flowchart: in Media Fitting Test & Cleaning KeyDocument4 pagesFunction Flowchart: in Media Fitting Test & Cleaning KeyOficinahTechniquesNo ratings yet

- JV3S Operation ManualDocument114 pagesJV3S Operation ManualOficinahTechniquesNo ratings yet

- Alignment Procedure For JV3Document3 pagesAlignment Procedure For JV3OficinahTechniques100% (1)

- Request For Daily Care: 1. Installation EnvironmentDocument8 pagesRequest For Daily Care: 1. Installation EnvironmentOficinahTechniquesNo ratings yet

- Kinetic Energy Recovery SystemDocument2 pagesKinetic Energy Recovery SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- RXM XXX ES Data GuideDocument11 pagesRXM XXX ES Data GuideAstrid PorticaNo ratings yet

- S3 3 TrigonometryDocument81 pagesS3 3 TrigonometryEugene ChoongNo ratings yet

- 50 Circular 2022Document1 page50 Circular 2022Shaurya BansalNo ratings yet

- 3g3JX InverterDocument262 pages3g3JX InverterdatdttvuNo ratings yet

- Es3Pt: User ManualDocument53 pagesEs3Pt: User ManualBITGEORGYNo ratings yet

- Atma Ram Sanatan Dharma College: PresentationDocument6 pagesAtma Ram Sanatan Dharma College: PresentationRishikeshav RaviNo ratings yet

- Compaction Factor ExperimentDocument23 pagesCompaction Factor ExperimentYI HEN ONGNo ratings yet

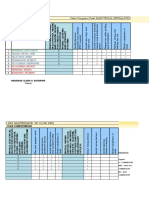

- Class Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Document2 pagesClass Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Shairrah Claire Bañares BatangueNo ratings yet

- Pso NS2Document6 pagesPso NS2sankarideviNo ratings yet

- Silvaco ATHENA Description 1 PDFDocument18 pagesSilvaco ATHENA Description 1 PDFRahul JaiswalNo ratings yet

- ElcometerDocument228 pagesElcometerMohammedMudassirNo ratings yet

- UML Class Diagram Examples of Common Scenarios - EdrawMaxDocument12 pagesUML Class Diagram Examples of Common Scenarios - EdrawMaxelizabeth enggNo ratings yet

- Shape of Water in Rotating Bucket - Physics Stack ExchangeDocument3 pagesShape of Water in Rotating Bucket - Physics Stack ExchangeHector TrianaNo ratings yet

- Effect of Salinity On Proteins in Some Wheat CultivarsDocument9 pagesEffect of Salinity On Proteins in Some Wheat Cultivarsray m deraniaNo ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) FinalDocument82 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) Finalsamarrana1234679No ratings yet

- Chapter 9 and 10Document18 pagesChapter 9 and 10billNo ratings yet

- Production of Hard Grade Bitumen For Using in High Modulus Asphalt ConcreteDocument18 pagesProduction of Hard Grade Bitumen For Using in High Modulus Asphalt ConcretePanjiNo ratings yet

- S32K14X RM Rev 4Document1,929 pagesS32K14X RM Rev 4Nguyễn Duy HùngNo ratings yet

- Visit Braindump2go and Download Full Version 350-801 Exam DumpsDocument4 pagesVisit Braindump2go and Download Full Version 350-801 Exam DumpsArsic AleksandarNo ratings yet

- Lorian Meyer-Wendt - Anton Webern - 3 Lieder Op.18Document136 pagesLorian Meyer-Wendt - Anton Webern - 3 Lieder Op.18Daniel Fuchs100% (1)

- (DT-0581) 21010-BAE-70000-IN-RL-0002 - Revb2Document8 pages(DT-0581) 21010-BAE-70000-IN-RL-0002 - Revb2karthikesan6No ratings yet

- Practical 1 PacingDocument13 pagesPractical 1 PacingFiaz Hussain0% (1)

- Degree of Kinematic IndeterminacyDocument8 pagesDegree of Kinematic IndeterminacyshahrukhNo ratings yet

- Week 4.damping ElementsDocument5 pagesWeek 4.damping ElementsTrophie NilemoaNo ratings yet

- 2-Way Doherty Amplifier With BLF888ADocument27 pages2-Way Doherty Amplifier With BLF888AerdemsecenNo ratings yet