Professional Documents

Culture Documents

Bulldozer d10r

Uploaded by

cijosOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bulldozer d10r

Uploaded by

cijosCopyright:

Available Formats

D10R

Track-Type Tractor

Cat

3412E Diesel Engine

Gross Power 457 kW 613 HP

Flywheel Power 425 kW 570 HP

Blade Capacity to 22.0 m

3

28.7 yd

3

Featured machine may include additional equipment

applicable only for special applications. See your

Caterpillar dealer for available options.

Operator Station

The comfortable, efficient control deck

encourages top output. Controls are

low-effort and easy to reach. Cat

Contour Series Seat provides proper

support and automotive comfort. The

front, side and rear views from the seat

are exceptional.

The Caterpillar D10R Monitoring

System has easy-to-read gauges, which

constantly inform the operator of key

machine functions. pg. 8

2

D10R Track-Type Tractor

The D10R combines power and efficiency with advanced technology for outstanding

production at lower cost-per-yard.

Power Train

The rugged, easy-to-service Caterpillar

3412E engine has a 30% torque rise.

The Hydraulically actuated,

Electronically controlled, Unit Injection

(HEUI) fuel system provides reduced

sound and emission levels, with

improved fuel efficiency. An exclusive

Caterpillar designed torque divider

allows the engine to respond quickly to

varying work applications. pg. 4-5

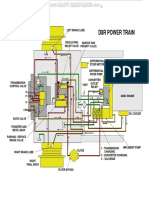

Engine Power Train Integration

The Caterpillar Data Link System

electronically combines engine,

transmission and brake information to

optimize overall tractor performance.

The Electronic Technician (ET) gives

access to stored diagnostic data,

significantly reducing downtime.

pg. 6

Cooling System

The Advanced Modular Cooling System

(AMOCS) combines higher cooling

capacity with easier servicing. AMOCS

allows the machine to be operated

efficiently in the most demanding

environments. pg. 7

Engineered for demanding work. The

D10Rs durable construction is made for

tough working conditions. It keeps material

moving with the reliability and low

operating costs you expect from Caterpillar

tractors.

3

Electronic Steering and Transmission

Controls

This Caterpillar designed and

manufactured system provides smooth,

one handed, Finger Tip Control (FTC)

for steering and transmission. Low-

effort controls can reduce cycle time for

improved production rates. pg. 9

Undercarriage

The elevated sprocket moves the final

drives above the work area, isolating

them from ground impacts. The

suspended undercarriage puts more

track on the ground for higher traction

and less slippage. It also absorbs shocks

for a smoother ride and longer machine

life. pg. 11

Structure

Mainframe is heavy, strong and durable.

Full box sections, steel castings and

continuous rolled rails provide durable

support to the suspended undercarriage,

elevated final drives and other integral

frame components. pg. 10

New feature

Work Tools

The variety of bulldozer blades, rippers

and other options allow you to adapt the

D10R to match your specific

application. pg. 12

Serviceability

Major modular components are

designed for excellent serviceability,

and allows fast in-field component

exchange. pg. 13

4

Power Train

The 3412E engine, when matched with the torque divider and field proven

power shift transmission, will provide years of dependable service.

Caterpillar

3412E engine performs at

full-rated net power of 425 kW (570 hp)

at 1900 rpm with a high torque rise of

30%. The large displacement and high

torque rise allow the D10R to doze

through tough material.

Turbocharging and aftercooling provide

high horsepower while keeping RPM

and exhaust temperatures low for long

hours of continuous operation.

1 The Hydraulically actuated

Electronically controlled Unit

Injection (HEUI) system is a unique

and proven high-pressure, direct

injection fuel system. The electronic

control module monitors operator and

sensor inputs to optimize engine

performance and fuel efficiency. The

HEUI system is truly unique in its

ability to independently control

injection pressure over the entire

engine operating speed range. These

features allow the 3412E to have

complete control over injection

timing, duration and pressure.

HEUI fuel system incorporates rate

shaping technology which modifies the

heat release characteristics of the

combustion process for significant

decreases in combustion sound and

emission levels. The engines fuel

system helps it meet current sound and

emission standards.

Exhaust smoke is significantly reduced

through precise, electronic control of

fueling limits and injection timing.

Improved reliability through reduction

of complex mechanical linkages and by

electronically protecting the engine

during:

I

Cold starts

I

Prolonged idling periods

I

High altitude operation

Easier maintenance and repair through

monitoring key functions and logging

critical indicators. Electronic diagnostic

access is possible with a single tool, the

Electronic Technician (ET).

A steel spacer between the block and

head eliminates the need for block

counterbores, extending block life.

Stellite-faced valves, through-hardened

crankshaft journals and steel-backed,

copper-bonded aluminum bearings help

assure reliable performance in the

toughest duty.

Components live longer because oil-

cooled pistons and full-length water-

cooled cylinder liners provide

maximum heat transfer. The cylinder

heads also utilize additional coolant

passages to provide maximum cooling

to the rear of the engine.

Cat dealers exchange program for

major engine components can cut repair

time and costs.

1

5

Torque Divider. A single-stage torque

converter with output torque divider

sends 75% of engine torque through the

converter, 25% through a direct drive

shaft for greater driveline efficiency and

higher torque multiplication.

The torque converter shields the

driveline from sudden torque shocks

and vibration.

Elevated final drives are isolated from

ground and equipment induced impact

loads for extended power train life.

I

Crown-shaved drive gears provide

smooth, quiet, low maintenance

operation.

I

Splash lubrication and Duo-Cone

Seals extend service life.

Planetary Power Shift Transmission has

3-speeds forward and 3-speeds reverse

and utilizes large diameter, high-

capacity, oil-cooled clutches.

I

Modulation system permits fast speed

and direction changes.

I

Modular transmission and bevel gear

slide into rear case for servicing ease,

even with ripper installed.

I

Oil-to-water cooler for maximum

cooling capacity.

I

Forced oil flow lubricates and cools

clutch packs to provide maximum

clutch life.

1 Ring gear

2 Flywheel

3 Sun gear

4 Planet gear

5 Turbine

6 Impeller

7 Stator

8 Output shaft

2

5

4

3

1

6

7

8

NOTE: Artwork represents torque divider concept only.

6

Engine/Power Train Integration

Combining the electronic engine control with the Caterpillar electronic transmission control

allows these critical power train components to work more intelligently.

By communicating, these components

work to optimize overall power train

performance, reliability and component

life for reduced power train operating

cost.

The Cat data link electronically

connects the engine and transmission

controls to provide these benefits:

I

Controlled Throttle Shifting

Regulates engine speed during

directional shifts for smoother

operation and longer component life.

1 Electronic Technician (ET)

2 Caterpillar Data Link

3 Caterpillar Monitoring System

4 Engine Control Module (ECM)

5 Demand Control Fan

6 Fan Speed Sensor

7 Odometer Sensor

8 Control Throttle Shifting

9 Finger Tip Control Module (FTC)

10 Electronic Clutch/Brake Control

Module (ECB)

11 Electric Transmission Control

12 Transmission

13 Steering, Clutch and Brakes

Improved Diagnostics/Serviceability.

The electronic engine and transmission

controls provide enhanced diagnostic

capability. The ability to store both

active and intermittent indicators will

simplify problem diagnosis and total

repair time, resulting in improved

mechanical availability and lower

operating costs.

I

Access to diagnostic data is made

easy through the use of a single

service tool ECAP or Electronic

Technician (ET) software package.

I

ET accesses data stored in the engine

and transmission controls via the Cat

data link. Information on engine

boost pressure, fuel consumption,

engine speed and transmission shift

data can be retrieved by ET.

I

ET is also a powerful diagnostic tool.

It replaces 13 mechanical tools to

perform functions like cylinder cut-

out checks, injector solenoid test, and

timing calibration.

Cat Data Link

Control Circuit

5

6

4

8

9

1

11

12

13

10

7

3

2

Hydraulic Circuit

7

Cooling System

Superior cooling in the most demanding work conditions.

Advanced Modular Cooling System

(AMOCS) utilizes an exclusive two pass

cooling system and increased cooling

surface area to provide significantly

more cooling capacity than

conventional systems.

The servicing of the AMOCS can be

performed without tilting the radiator

guard.

I

No need to remove or replace a major

component as on single-core

radiators.

I

Each core module can be replaced

individually (without removing the

entire radiator), saving considerable

cost and repair time.

Demand Control Fan

I

Engine Control Module (ECM)

regulates engine fan speed through a

multi-disc fan clutch.

I

Fan speed varies according to specific

engine cooling requirements.

I

Increases available horsepower

reducing parasitic load.

I

Fuel Efficient.

I

Reduced spectator and operator sound

levels.

Two pass cooling system circulates

coolant from the sectioned bottom tank

(1) up through one side (2) of the cooling

element and down through the other

side (3) returning it to the bottom tank.

The cooling elements are individual

core modules that are connected to a

sectioned bottom tank. There is no top

tank to remove.

I

9 steel fins per inch.

I

Brass tube construction within each

core.

1

2

3

8

Operator Station

Designed for comfort and ease of operation.

Clear panoramic view. Angled seat,

tapered hood and notched fuel tank

give the operator a clear line of sight to

the front and rear work areas.

Redesigned single shank ripper frame

improves ripper tip visibility. Large

single-pane door windows allow the

operator to see close-in to each side

without leaning.

Comfortable, non-tiring operation. An

optional isolation-mounted cab reduces

noise and vibration, maintaining an

internal sound level under 85 dB(A).

The cab is pre-wired for a 12-volt or

24-volt radio, and equipped with two

speakers, antenna and radio mount

recessed in the headliner.

1 Low effort Finger Tip Controls (FTC)

are easily accessible and provide sure,

precise maneuvering with enhanced

operator comfort. FTC module with

padded armrest is adjustable to

accommodate different size operators.

2 The Caterpillar Contour Series Seat

is fully adjustable and designed for

comfort and support. The seat cushion

reduces the pressure on the lower back

and thighs while allowing unrestricted

arm and leg movement. Retractable 75

mm (3") wide seat belt provides

positive, comfortable restraints.

3 Caterpillar D10R Monitoring System

has 3 display sections. The system

provides instant feedback on machine

systems with 3 levels of operator

alert. The system also records

performance data for assistance in

diagnosis, is easy to read, reliable and

provides fast troubleshooting.

I

Section one has analog gauges which

display engine coolant temperature,

transmission oil temperature,

hydraulic oil temperature and fuel

level.

I

Section two contains an analog

tachometer and a gear/direction

display.

I

Section three displays information

through 10 LED indicators and

through a switchable, digital display.

LED indicators provide information

on the engine oil pressure, air filter,

power train filter, battery, brake

system, parking brake, transmission

system, steering system, engine

check, and coolant flow. Switchable

digital display allows operator to

scroll through or display tachometer,

odometer, hour meter, engine oil

pressure and diagnostic codes.

4 Throttle rocker switch replaces the

throttle lever, simplifying operation.

High or low idle is delivered with the

touch of a finger.

5 Attachment control lever restraints,

when engaged, prevent inadvertent

movement of control lever. These

restraints accept standard Caterpillar

padlocks.

1

2

3

4

5

9

Finger Tip Controls (FTC) are clustered

for easy, one-handed operation to the

operators left. They control steering,

machine direction and gear selection.

1 Electronic Clutch and Brake (ECB)

steering system consists of two small

levers which send signals that control

the steering valve.

I

Levers require less than 3 pounds of

pull to actuate.

I

Steering is accomplished in much the

same way as with traditional clutch

and brake arrangements but with less

time and effort.

ECB System allows the operator to work

more precisely in close areas, around

structures, obstacles, grade stakes, other

machines or on fine grades.

Adjustable operator comfort

The system is attached to an electrical

linear actuator which allows the FTC

module to be adjusted up and down.

Fore/aft adjustment is controlled by a

manual lever on the front of the control

module.

2 Machine Direction is controlled by a

pivoting knob which can be actuated

by the thumb of the left hand.

Rotating the knob up shifts the

machine transmission to forward.

Rotating the knob down reverses the

machine. The middle setting puts the

machine transmission in neutral.

3 Gear selection is made by two

buttons to the right of the machine

direction knob. The top (up-shift)

button shifts the machine

transmission to the next higher gear

while the bottom (down-shift) button

shifts to the next lower gear.

4 Parking Brake switch electronically

locks ECB system.

Electronic Steering and Transmission Controls

Combines steering, machine direction and gear selection into a control system which can be

operated with one hand, for enhanced operator comfort and increased productivity.

2

4

3

1

Structures

Engineered to provide durability and the solid support necessary for maximum production

and service life.

10

Mainframe Strength. The D10R

mainframe is built to absorb high

impact shock loads and twisting forces.

1 Frame rails are full box section,

designed to keep components rigidly

aligned.

2 Heavy steel castings give added

strength to the main case, equalizer

bar saddle, front cross member and

tag-link trunnion.

3 The top and bottom rails are

continuous rolled sections, with no

machining or welding to provide

superior mainframe durability.

4 The main case elevates the final

drives well above the ground level

work area to protect them from

impact loads, abrasion and

contaminants.

5 A pivot shaft and pinned equalizer

bar maintain track roller frame

alignment.

Tag-link construction has fewer parts

for reduced wear and brings the blade

closer to the machine for more precise

dozing and load control.

Tag-link design provides solid lateral

stability and better cylinder positions

for constant pryout independent of

blade height.

5

5

2

2

4

3

1

11

Suspended undercarriage design

absorbs impact loads to reduce the

shock loads transferred to the

undercarriage by up to 50%.

Bogie suspension conforms more

closely to the ground to provide up to

15% more ground contact, especially in

hard, uneven terrain. Higher traction

means less slippage, better balance, and

a smoother ride.

Roller Frames are tubular, to resist

bending and twisting, with added

reinforcement where operating loads are

the highest.

I

Roller frames attach to tractor by a

pivot shaft and pinned equalizer bar.

I

Large pivot shaft bushings operate in

an oil reservoir.

I

A low friction, no maintenance

bushing is used in the saddle

connection.

I

Resilient pads restrain equalizer bar

oscillation.

I

The recoil system is sealed and

lubricated.

1

1 Sealed and Lubricated Track.

Permanently coats the track pin with

a sealed-in lubricant, minimizing

metal-to-metal contact.

I

Virtually eliminates internal pin and

bushing wear.

I

Lubricant is held in a reservoir in the

track pin.

Undercarriage

The Caterpillar elevated sprockets are designed for better machine balance and

component life.

12

1 Bulldozers. The 10SU blade, rated at

18.5 m

3

(24.2 yd

3

), and the 10U blade

at 22.0 m

3

(28.7 yd

3

) make full use of

the D10Rs power.

Dual tilt option improves load control.

Allows the operator to optimize the

blade pitch angle for each portion of the

dozing cycle.

Single lever controls all blade movements,

including the optional dual tilt.

Cutting edges are DH-2 steel. End bits

are DH-3 to provide maximum service

life in tough materials.

Rippers. Single and multi-shank rippers

are made to penetrate tough material

fast and rip thoroughly for use in a

variety of materials.

3 Multi-shank ripper tailors the tractor

to the material by using one, two or

three shanks.

Winches. Standard and slow speed

arrangements available for enhanced

line control. Single lever control and

infinite control of line speed provide

smooth response, allowing effortless

operation.

Rear counterweights provide proper

tractor balance to maximize dozing

production. Recommended if other rear

attachment not specified.

Hydraulic pitch adjustment cylinders

vary the shank angle to get the best

penetration so the material is lifted and

shattered.

2 Single Shank Ripper.

I

Operator can adjust the shank depth

from the seat using an optional single

shank pin puller.

I

Large upper frame view hole

improves ripper tip visibility.

I

Heat treated spacer bars in ripper

carriage to extend pocket life and

reduce shank notching.

I

Large one piece shank.

I

Available in deep rip configuration.

Work Tool Attachments

A variety of attachments provide the flexibility to match the machine to the job.

2

1

3

Built-in servicing ease. Less service

time means more working time. Major

components are made as modules and

most can be removed without disturbing

or removing others.

Engine oil filters are located on the

engine for easy servicing access and

minimal downtime. Further time is

saved with fast fuel and quick oil

change attachments. Equipped with a

dozer and ripper, the D10R has only 17

lube points.

Heater and air conditioner cores are

accessible without disconnecting lines.

A diagnostic connector allows the Cat

Dealer's electronic test instrument to

quickly troubleshoot the electrical

system.

Quick disconnect fittings allow for fast

diagnosis of the power train and

attachment oil systems.

Ecology drains provide an

environmentally safer method to drain

fluids. They are included on the

radiator, hydraulic tank and major

power train components.

AMOCS individual cooling elements

allow radiator servicing without major

component removal, saving

considerable time and cost.

13

Complete Customer Support

The most serviceable machines from the most committed dealers.

Dealers committed to fast, quality

customer support. Your Cat dealer's

investment in service begins with the

fastest and most complete parts

availability in the industry. The full

range of exchange components and

Caterpillar Remanufactured parts is

aimed at saving you time and money.

All carrying new-parts warranty.

Dealer service response extends to

programs such as Custom Track Service

(CTS), Scheduled Oil Sampling (S

.

O

.

S),

and guaranteed maintenance contracts

that get peak life and performance from

your machine.

Your dealer is also expert at arranging

affordable lease, rental or purchase

financing for all Caterpillar products.

Serviceability

Major modular component design allows fast in-field component exchange.

Less time spent on maintenance gives you more time on the job.

14 D10R Track-Type Tractor specifications

Engine

Four-stroke cycle, 65 V12 3412E turbocharged and aftercooled diesel engine.

*Power rating conditions

I

based on standard conditions of 25C

(77F) and 99 kPa (29.32 in Hg) dry

barometer

I

used 35C API gravity fuel having an

LHV of 42,780 kJ/kg (18,390 Btu/lb)

when used at 30C (86F) [ref. a fuel

density of 838.9 g/L (7.001 lb/

U.S. gal)]

I

net power advertised is the power

available at the flywheel when the

engine is equipped with fan, air

cleaner, muffler and alternator

I

no derating required up to 3500 m

(11,500 ft) altitude, beyond 3500 m

(11,500 ft) auto derating occurs at 3%

per 1000 ft depending on application

Features

I

high pressure injectors

I

full electronic control

I

parallel manifold porting with two

intake and two exhaust valves per

cylinder. Stellite-faced valves, hard

alloy steel seats and valve rotators

I

cam-ground and tapered, aluminum-

alloy pistons with three keystone-

designed rings, each cooled by oil

spray

I

steel-backed, copper-bonded,

aluminum bearings, through-hardened

crankshaft journals

I

pressure lubricated with full-flow

filtered and cooled oil

I

dry-type air cleaner with primary and

secondary elements

I

24-volt, direct-electric starting system,

75-amp alternator with two 12-volt,

190 amp-hour batteries

I

engine/torque divider module is

isolation mounted to the main frame

reducing machine vibration and

structure-radiated noise

I

water cooled turbocharger bearing for

longer life

Transmission

Planetary power shift with three speeds

forward and reverse.

Maximum travel speeds

Speed km/h MPH

Forward 1 4.0 2.5

2 7.1 4.4

3 12.5 7.7

Reverse 1 5.0 3.1

2 8.9 5.5

3 15.6 9.7

Features

I

controlled throttle shifting

I

special modulation system permits

fast speed and direction changes

I

432 mm (17") diameter, high torque

capacity oil clutches

I

modular transmission, bevel gear and

differential plug into rear of main

drive case

I

oil-to-water cooler mounted to the

engine

I

single stage torque converter with

output torque divider

70

80

90

100

60

50

40

30

20

10

0

200

140

160

180

120

100

80

60

40

20

0

220

lbs x

1000

kg x

1000

0 2 4 6 8 10 12 km/h

0 1 2 3 4 5 6 7 8

mph

1st Gear

2nd Gear

3rd Gear

D10R

Drawbar Pull*

vs.

Ground Speed

Speed

D

r

a

w

b

a

r

P

u

l

l

Power Shift with Steering Clutches and Brakes

Final Drives

Crown-shaved, double reduction

planetary final drive gears.

Features

I

splash lubricated and sealed with

Duo-Cone floating ring seals

I

sprockets have five bolt-on

replaceable rim segments

Net power kW HP PS

Caterpillar 425 570

ISO 1585 425 570

SAE J1349 421 564

EU 80/1269 425 570

DIN 70020 590

Dimensions

Bore 137 mm 5.4 in

Stroke 152 mm 6.0 in

Displacement 27 liters 1649 cu in

Ratings at 1900 RPM* kW HP

Gross power 457 613

Flywheel power 425 570

The following ratings apply at 1900

RPM when tested under the specified

standard conditions for the specified

standard:

15 D10R Track-Type Tractor specifications

Sealed and Lubricated

Track

Coats the track pin with a sealed-in

lubricant.

Pitch 260 mm 10.2"

Number shoes/side 44

Shoe type Extreme service

Width of shoe 610 mm 24"

Length of track

on ground 3885 mm 12'9"

Ground contact area 4.7 m

2

7326 in

2

Grouser height

(from ground

face of shoe) 93 mm 3.66"

Ground clearance 615 mm 24.2"

Gauge 2550 mm 8'4"

Features

I

lubricant reduces internal bushing

wear

I

hydraulic track adjusters, track

guiding guards and large, positive-

clamping, two-piece master link are

standard

Track Roller Frame

Lifetime Lubricated rollers and idlers

resiliently mounted to roller frame by a

series of bogies.

Features

I

tubular design resists torsional loads

I

bogies oscillate on sealed and

lubricated cartridge pin connections,

travel controlled by resilient pads

I

roller frame attaches by a pivot shaft

and fully pinned equalizer bar

I

eight rollers per side

I

large pivot bushings operate in an oil

reservoir

I

equalizer bar-roller frame ball joint

pins and high capacity bearing are

sealed and lubricated; saddle

connection is a low-friction, no-

maintenance bushing

I

recoil system is fully sealed and

lubricated

I

oscillation of 351 mm (13.8")

I

large idler caps with three bolt

mounting

Cab

Caterpillar cab is optional and Rollover

Protective Structure (ROPS) is standard.

Features

I

meets OSHA and MSHA limits for

operator and sound exposure with

doors and windows closed (according

to ANSI/SAE J1166 MAY90)

I

ROPS meets the following criteria:

SAE J394

SAE 1040 APR88

ISO 3471-1986

I

also meets the following criteria for

Falling Objects Protective Structure

(FOPS):

SAE J231 JAN81

ISO 3449-1984

NOTE:

When properly installed and maintained,

the cab offered by Caterpillar when

tested with doors and windows closed

according to ANSI/SAE J1166 MAY90,

meets OSHA and MSHA requirements

for operator sound exposure limits in

effect at time of manufacture. The oper-

ator sound pressure level is under

85 dB(A) when measured per ISO 6394

or 86/662/EU.

Service Refill Capacities

U.S.

L Gallons

Fuel tank 1109 293

Cooling system 132 34.9

Diesel engine

crankcase* 60 18

Power train 189 50

Final drives (each) 23 6

Roller frames (each) 90 23.8

Pivot shaft

compartment 30.3 8

Attachment hydraulic

system tank only 108 28.5

w/oil filters

Weight (approximate)

Shipping:

(includes lubricants, coolant, 20% fuel

and ROPS canopy) 47 174 kg (104,000 lb)

Operating:

includes lubricant, coolant, full fuel

tank, hydraulic controls and fluids,

610 mm (24") extreme service shoes,

optional equipment, (10 SU bulldozer,

single shank ripper, ROPS/FOPS cab)

and operator 65 403 kg (144,191 lb)

Steering and Brakes

Electronic Finger Tip Controls (FTC)

combine steering clutch disengagement

and braking for each track. Pull back

slightly to disengage steering clutches,

fully back to brake track.

I

low-effort, Finger Tip Controls for

steering

I

hydraulically applied multiple-disk

clutches, 392 mm (15.4") diameter

I

high capacity brakes are hydraulically

released, spring applied, with

computerized electronic brake control

for excellent brake modulation

I

single pedal simultaneously applies

brakes to tracks for fast stops

I

parking brake applied electronically

engaging parking brake

electronically locks the Finger Tip

Controls

16 D10R Track-Type Tractor specifications

Attachments - Vane-type pump geared from flywheel

Output at 1900 RPM and 6895 kPa (1000 psi)

Lift cylinder flow 408 liters/min 108 gpm

Tilt cylinder flow 121 liters/min 32 gpm

Relief valve settings

Bulldozer 18 616 kPa 2700 psi

Tilt Cylinder 19 300 kPa 2800 psi

Ripper (Lift) 18 616 kPa 2700 psi

Ripper (Pitch) 18 616 kPa 2700 psi

Hydraulic pilot valves assist operations of ripper and dozer

tilt controls. Standard hydraulic systems include two valves

for 10SU or 10U bulldozer and tilt.

Optional hydraulic control

Two additional valves for ripper function

I

hydraulic shank pitch adjustment

I

adds 102 kg (226 lb)

Hydraulic Controls

Complete system consists of pump, tank with filter, oil

cooler, valves, lines, linkage and control levers.

Weight 2265 kg 4,983 lb

Increased tractor length 284 mm 11.2"

Winch case width 1564 mm 61.6"

Flange diameter 610 mm 24.0"

Drum width 292 mm 11.5"

Drum diameter 330 mm 13.0"

Recommended Cable size 29 mm 1.13"

Optional Cable size 32 mm 1.25"

Drum Capacity

recommended cable 69 m 226'

optional cable 55 m 180'

Oil Capacity 70 L 18.5 gal

cable/ferrule size

(OD x Length) 60 mm x 70 mm 2.38" x 2.75"

Winch Specifications

Dimensions

All dimensions are approximate.

With attachments add to overall machine length:

Single Shank ripper 1892 mm 6'2.5"

Multi-shank ripper 1717 mm 5'7.6"

10 SU Dozer 2169 mm 7'1.4"

10 U Dozer 2423 mm 7'11.4"

Width over trunnions 3716 mm 12'2.0"

Drawbar height (centerline

of clevis) from ground

face of shoe 779 mm 30.7"

17 D10R Track-Type Tractor specifications

Features

I

optional single shank pin puller lets operator adjust shank depth

from seat

I

large one piece shank: 100 mm x 400 mm (4" x 15.75")

I

multi-shank ripper allows variable use of one, two or three

shanks to match job conditions

* Specifications are converted from British to metric measure and rounded.

** Operating weight includes lubricant, coolant, full fuel tank, hydraulic controls, 610 mm (24") extreme service shoe, ROPS/FOPS cab,

and operator.

+

Includes one shank. Add 524 kg (1,155 lb) for each additional shank.

Note: Single shank, deep ripping arrangement weight includes

required pin puller.

Rippers

Redesigned ripper frame for improved visibility to ripper tip.

Hydraulic tip adjustment cylinders vary shank angle to aid penetration and help lift and shatter rock.

Single Shank,

Single Deep Ripping

+

Multi-Shank

Shank Arrangement Arrangement

Overall beam width mm 2920

ft/in 9'7"

Maximum penetration force*

(shank vertical) kN 205 206 205

lb 45,980 46,135 45,980

Maximum penetration

(standard tip) mm 1370 1855 941

ft/in 4'6" 6'3" 3'1"

Pryout force

(multi-shank ripper with one tooth) kN 429 428 429

lb 96,360 96,290 96,360

Maximum clearance raised

(under tip, pinned in bottom hole) mm 1070 887 1070

in 42.1" 34.9" 42.1"

Number of shank holes 3 3 2

Weight

(without hydraulic controls) kg 6979 7240 6862

lb 15,387 15,962 15,127

Total operating weight**

(with 10 SU blade and ripper) kg 65 403 65 669 65 287

lb 144,191 144,774 143,931

18 D10R Track-Type Tractor specifications

Standard Equipment

Standard and optional equipment may vary. Consult your Caterpillar dealer for specifics.

Alarm, back-up

Alternator, 75-amp

Batteries, 12-volt(2), 190 amp-hour

Diagnostic connector

Equalizer bar, pinned

Horn, forward warning

Hydraulic control, two-valve

Lighting system, Halogen

(2 forward, 2 rear)

Pull device, front

Receptacle, starting

Vandalism protection includes;

instrument panel guard, cap locks for

fuel tank, engine oil filler, radiator

filler and dip stick, plus battery box

locks and left hand service area cover

lock

Operator Environment

Decelerator pedal

Dozer control, low-effort

Finger Tip Control (FTC) steering

Governor switch, electronic

Lever restraints, implement control

Monitoring system, Caterpillar D10R

Panel guard, instrument

Rearview mirror

ROPS/FOPS canopy (USA)

Seat, adjustable contour suspension

Seatbelt, retractable

Power train

3412E diesel engine

24-volt electric start

Air filter with precleaner

Ether starting aid, automatic

Fuel priming pump

Hydraulic Electronic Unit Injection

(HEUI)

Laminated thermoshield

Muffler with rain cap

Prescreener

Turbocharged/Aftercooled

Water separator

Advanced Modular Cooling System

Blower fan with demand drive

Controlled throttle shifting

Drains, ecology fluid

Electronic transmission control module

Engine coolant heater, 120-volt

Guards;

Bottom guards, hinged extreme service

Crankcase, hinged extreme service

Power train

Radiator and fanblast deflector, hinged

Parking brake, electronic

Power shift transmission (3 speed)

Four planet, double-reduction

planetary final drives

Torque divider

Undercarriage

610 mm (24 inch) extreme service

grouser with sealed and lubricated

track (44 section) - non PPR track links

Rollers and idlers, lifetime lubricated

Sprocket rim segments, replaceable

Suspension-type undercarriage,

Eight-roller tubular track roller frame

Track adjusters, hydraulic

Track guides

Two-piece master links

* Does not include hydraulic controls, but includes blade tilt cylinder.

** Includes hydraulic controls, blade tilt cylinder, coolant, lubricants, full fuel tank, ROPS/FOPS cab, and operator.

Features

I

dual tilt is optional for improved blade fill and dumping

I

cutting edges are DH-2 steel and end bits are DH-3 steel for maximum durability

I

dozer lift cylinders mount to top corners of radiator guard to improve mechanical

advantage

I

single lever controls all blade movements, including optional dual tilt

Bulldozers

Tag link dozer coupling brings blade closer for better balance and control.

Blade 10SU 10U 10SU ABR 10U ABR

Blade capacity (SAE J1265) m

3

18.5 22.0 18.5 22.0

yd

3

24.2 28.7 24.2 28.7

Width with blade (over end bits) mm 4862 5263 4862 5263

ft/in 15'11" 17'3" 15'11" 17'3"

Blade height mm 2119 2119 2119 2119

ft/in 6'11" 6'11" 6'11" 6'11"

Digging depth mm 674 674 674 674

in 26.5 26.5 26.5 26.5

Ground clearance mm 1497 1497 1497 1497

ft/in 4'11" 4'11" 4'11" 4'11"

Maximum tilt mm 993 1074 993 1074

ft/in 3'3" 3'6" 3'3" 3'6"

Weight* kg 10 228 10 737 11 069 12 152

lb 22,550 23,670 24,403 26,790

Total operating weight**(with blade kg 65 764 66 273 66 605 67 688

and single shank ripper) lb 144,986 146,106 146,839 149,226

19 D10R Track-Type Tractor specifications

kg lb

Air conditioner (R134a) 62 137

Air conditioner, ROPS mounted (R134A) 164 360

Armrest, adjustable right 3.6 8

Bulldozers:

Dual tilt cylinders 200 441

Rock guards (for 10U blade only) 205 453

Cab, FOPS sound suppressed, with

ROPS rollbar (includes heater,12-volt

converter, cab accessory group and mirror) 225 496

Canopy, ROPS/FOPS, includes mirror

(standard USA) 941 2,075

Counterweight:

Front mounted 2424 5,344

*Rear mounted (basic) 4213 9,288

*Rear mounted (additional weight) 1198 2,660

Drawbar, rigid 680 1,500

Engine enclosure 56 123

Fast-fill fuel system for use with:

Drawbar or counterweight 20 44

Ripper 27 59

Guard, rear power train 253 558

Heater, fuel 6 13

Hydraulic controls for dual tilt 42 93

Hydraulic controls for ripper

(two additional valves) 102 226

Lights, supplemental

2 front 10 23

2 rear 11 24

kg lb

Low temp start (includes two additional

heavy duty batteries and

additional starting motor) 173 381

Oil change system for quick service to

engine and transmission fluids 3.2 7

Operator arrangement, modified

(improves visibility and comfort

for smaller operators) 24 54

Pin puller (for single shank ripper) 74 163

Pin puller, hydraulic control 4.5 10

Prelubrication system, engine 8.2 18

Pushblock (for single shank ripper) 154 340

Radiator core protector grid 11 25

*Rippers:

Single shank Standard arrangement 7117 15,690

Single shank Deep ripping (requires

pin puller and hydraulic controls) 7253 15,990

Multi-shank (includes one shank) 6919 15,253

Ripper shank, additional

(for multi-shank ripper) 524 1,155

Roller, carrier 156 345

Screen, rear 45 100

Seat, air suspension

Sound suppression, spectator 2.3 5

Tracks, pair, Sealed and Lubricated:

711 mm (28"), Extreme Service 679 1,496

800 mm (31.5"), Extreme Service 1237 2,728

711 mm (28"), PPR Extreme Service 674 1,496

800 mm (31.5"), PPR Extreme Service 1229 2,728

Waste disposal arrangement 7707 16,990

*Winch arrangement 2015 4,442

Optional Equipment

(with approximate change in operating weight)

**

**

* A rear attachment and/or counterweight is recommended for improved performance and balance.

** Cannot be used on machines equipped with rippers.

NOTE: All specifications are converted from metric to British measure and rounded, unless otherwise specified.

D10R Track-Type Tractor

AEHQ5150-03 (5-99)

(Replaces AEHQ5150-02)

Materials and specifications are subject to change without notice.

www.CAT.com

Printed in U.S.A.

1997, 1999 Caterpillar

You might also like

- D7RDocument20 pagesD7ROmar Zelada100% (1)

- 777F PDFDocument79 pages777F PDFsergio roa100% (2)

- Symbols CATDocument11 pagesSymbols CATIsrael Ruiz100% (1)

- Cat D6T SpecsDocument24 pagesCat D6T Specsmogahed rashidNo ratings yet

- Caterpillar ADT 740B EJDocument24 pagesCaterpillar ADT 740B EJJi Uvex67% (3)

- Caterpillar ADT 740 SpecDocument20 pagesCaterpillar ADT 740 SpecLorentz MelialaNo ratings yet

- D10T (RJG) Service TrainingDocument208 pagesD10T (RJG) Service Trainingmliugong100% (36)

- Power Train d11rDocument38 pagesPower Train d11rハイメ ノボア100% (5)

- Engine Oil Pressure - Test 966H - 01Document7 pagesEngine Oil Pressure - Test 966H - 01Freddy QuispeNo ratings yet

- Cat EngineDocument94 pagesCat Enginejoshuadelapava100% (1)

- Cat 12H Motor Grader: Standard TypeDocument22 pagesCat 12H Motor Grader: Standard Typestopaferreira80% (5)

- D10R AKT Product BulletinDocument32 pagesD10R AKT Product BulletinDiego Alonso Huaraca BalerianoNo ratings yet

- 777D PDFDocument2 pages777D PDFJoshua FloresNo ratings yet

- d8r Hydraulic SystemDocument2 pagesd8r Hydraulic Systemwtn201392% (12)

- Cat 16MDocument24 pagesCat 16MLeandro Sal0% (1)

- Cat 14 M Motor GraderDocument28 pagesCat 14 M Motor GraderYudhi Salman Dwi Satya0% (2)

- Caterpillar Bulldozer D6T PDFDocument20 pagesCaterpillar Bulldozer D6T PDFMuhaimin100% (1)

- Caterpillar 980HDocument20 pagesCaterpillar 980HForomaquinas100% (8)

- 3508 Valve Setting Task SheetDocument4 pages3508 Valve Setting Task Sheetrizqi mubarak50% (2)

- Connecting Rod Bearings - Install: Table 1Document3 pagesConnecting Rod Bearings - Install: Table 1David Apaza HurtadoNo ratings yet

- Caterpillar Wheel Loader 988H Electrical SystemsDocument4 pagesCaterpillar Wheel Loader 988H Electrical Systemsgire_3pich2005100% (1)

- Componentes de Maquina de Oruga D10RDocument152 pagesComponentes de Maquina de Oruga D10RJesús Abreu100% (1)

- D10TDocument107 pagesD10Tluishvanegas100% (1)

- 797b - SISTEMASDocument196 pages797b - SISTEMASGenaro GutierrezNo ratings yet

- Material Caterpillar d8r Bulldozer Transmission Power Train Hydraulic System Components DiagramsDocument50 pagesMaterial Caterpillar d8r Bulldozer Transmission Power Train Hydraulic System Components DiagramsAhmed92% (24)

- 777D Air ComponentDocument10 pages777D Air ComponentHeppryn WidiastoNo ratings yet

- Cat Data Link PDFDocument2 pagesCat Data Link PDFjoelNo ratings yet

- D6R Error CodeDocument7 pagesD6R Error CodeRajan Mullappilly100% (4)

- D8R Ii Serv1736 SlidesDocument112 pagesD8R Ii Serv1736 SlidesArnold Quispe C100% (2)

- ACERT Technology: An In-Depth Look at Caterpillar's Emissions Reduction SystemsDocument81 pagesACERT Technology: An In-Depth Look at Caterpillar's Emissions Reduction SystemsManuel Ruiz Cayun100% (2)

- 140k Compliance FinalDocument29 pages140k Compliance FinalAGEGNEHU17No ratings yet

- Event Code 1538Document5 pagesEvent Code 1538Rajan Mullappilly100% (2)

- 988H Hydraulic System PDFDocument2 pages988H Hydraulic System PDFtom souza100% (1)

- Small Catalog OHT CAT 773E PDFDocument4 pagesSmall Catalog OHT CAT 773E PDFSupriyono Abdullah100% (1)

- 920 & 930 WHEEL LOADERS POWER TRAIN Pruebas y AjustesDocument6 pages920 & 930 WHEEL LOADERS POWER TRAIN Pruebas y AjustesKarlOs Junco Sicha100% (1)

- D10RDocument24 pagesD10RAldo Cesar Mina Sosa100% (1)

- Implement Hydraulic System WL 950h 962h 966h 972hDocument51 pagesImplement Hydraulic System WL 950h 962h 966h 972hElvis Gonzalez Huerta100% (1)

- Testing Adjusting Trans D8RDocument30 pagesTesting Adjusting Trans D8Rardan fadilah100% (1)

- 962g Trans Clutch CalibrateDocument8 pages962g Trans Clutch Calibrateluis eduardo corzo enriquez100% (1)

- NTB R9800 enGB-USDocument22 pagesNTB R9800 enGB-USEnzo Miguel Sarabia Montes100% (1)

- Data Sheets 966F-E (80e)Document20 pagesData Sheets 966F-E (80e)abdelrhmangbr86No ratings yet

- 3408E/3412E ENGINE CONTROLS: Technical PresentationDocument168 pages3408E/3412E ENGINE CONTROLS: Technical PresentationVicTor CarrAnzaa100% (6)

- d7r Solenide de ControlDocument12 pagesd7r Solenide de ControlDavid Ceron100% (6)

- 793C - ATY - Hoist Cylinder - Remove and InstallDocument7 pages793C - ATY - Hoist Cylinder - Remove and InstallCarlos LoboNo ratings yet

- Acert EnginesDocument12 pagesAcert EnginesAnonymous alQXB11EgQ100% (1)

- SERV1828Document272 pagesSERV1828Fredy Alvarez CespedesNo ratings yet

- Automatic Retarder Control (ARC)Document5 pagesAutomatic Retarder Control (ARC)lisahun100% (1)

- Differential Steering System : SMCS Code: 4005 4010Document18 pagesDifferential Steering System : SMCS Code: 4005 4010Balikpapan City75% (4)

- Engagement Pressure For The Transmission Clutch - CalibrateDocument8 pagesEngagement Pressure For The Transmission Clutch - CalibrateVictor NunezNo ratings yet

- Cat 16M Motor Grader PDFDocument28 pagesCat 16M Motor Grader PDFAzizul Kamarudin100% (1)

- Motor Cat 3176-3196Document17 pagesMotor Cat 3176-3196Fabiano Oliveira67% (3)

- 966F Wheel Loader and 966F Series II Wheel Loader Hydraulic System CaterpillarDocument4 pages966F Wheel Loader and 966F Series II Wheel Loader Hydraulic System CaterpillarHussein Sayed75% (4)

- Track-Type Tractor - d11r (Tractor Oruga)Document24 pagesTrack-Type Tractor - d11r (Tractor Oruga)Christian Kari100% (2)

- 773DDocument24 pages773DGabo GaboNo ratings yet

- Off-Highway TruckDocument28 pagesOff-Highway TruckrodizianoNo ratings yet

- Cat D11RDocument24 pagesCat D11Rluphynt_4100% (2)

- D11RDocument24 pagesD11RRicardo Contreras B100% (1)

- 777d PDFDocument24 pages777d PDFrodizianoNo ratings yet

- Designing and Tuning High-Performance Fuel Injection SystemsFrom EverandDesigning and Tuning High-Performance Fuel Injection SystemsRating: 3.5 out of 5 stars3.5/5 (7)

- Guide Bunker Quality Disputes - Part 1Document4 pagesGuide Bunker Quality Disputes - Part 1Parthiban NagarajanNo ratings yet

- Yamaha Rx100 36L1L1Document94 pagesYamaha Rx100 36L1L1paritoshNo ratings yet

- Vehicle Noise Emissions in Urban TrafficDocument5 pagesVehicle Noise Emissions in Urban TrafficSamuel Estrada RojasNo ratings yet

- Tj82pe5a en PDFDocument4 pagesTj82pe5a en PDFMin MyatNo ratings yet

- DDEC & Detroit Diesel 60 EngineDocument3 pagesDDEC & Detroit Diesel 60 EngineAriel NoyaNo ratings yet

- Naffco: Pre Testing & Commissioning Checklist of Fire Pumps, Fire Pumps Details & Field Test ReportDocument6 pagesNaffco: Pre Testing & Commissioning Checklist of Fire Pumps, Fire Pumps Details & Field Test ReportSultan Mahi ZubairNo ratings yet

- Electronic Fuel Management in I.C Engines G Nagarajan Professor Department of Mechanical Engg. Anna University Chennai 60025Document5 pagesElectronic Fuel Management in I.C Engines G Nagarajan Professor Department of Mechanical Engg. Anna University Chennai 60025alagarg137691No ratings yet

- S - Fa/Rs: Owners ManualDocument18 pagesS - Fa/Rs: Owners ManualbachstradNo ratings yet

- Data Sheet 9700 DD 4.0 Euro 6 EN 2021Document3 pagesData Sheet 9700 DD 4.0 Euro 6 EN 2021lopezNo ratings yet

- Cotizacion de Planta ElectricaDocument2 pagesCotizacion de Planta ElectricaHenry MataNo ratings yet

- Volvo Ec300eDocument28 pagesVolvo Ec300eTiago PachecoNo ratings yet

- 902900-1183 DespieceDocument448 pages902900-1183 DespieceLIBERTADNo ratings yet

- XL 10000 Air Motor: Instructions - PartsDocument27 pagesXL 10000 Air Motor: Instructions - PartsLuis LugoNo ratings yet

- Catalogue Perkins 404D 22TGDocument10 pagesCatalogue Perkins 404D 22TGDanh TrầnNo ratings yet

- Manual Serva Pump TPD600Document82 pagesManual Serva Pump TPD600Herlis Savitri88% (8)

- Operation, Maintenance and Repair Manual: For Powerkit EngineDocument108 pagesOperation, Maintenance and Repair Manual: For Powerkit EngineBen MouhandNo ratings yet

- Diesel Fuels & Diesel Fuel Systems: Application and Installation GuideDocument58 pagesDiesel Fuels & Diesel Fuel Systems: Application and Installation Guidedimaomar100% (1)

- Oikx8gqv3rz4bwq3link-Belt Htc-8660 Series II 60-Ton Hydraulic Truck Crane NetworkDocument28 pagesOikx8gqv3rz4bwq3link-Belt Htc-8660 Series II 60-Ton Hydraulic Truck Crane NetworkFabian RamirezNo ratings yet

- Research Papers On Ic EnginesDocument8 pagesResearch Papers On Ic Enginesehljrzund100% (1)

- 2005 Harley Davidson Sportster Xl883l 12Document141 pages2005 Harley Davidson Sportster Xl883l 12Marly SalasNo ratings yet

- 3kVA Diesel Vs HondaDocument1 page3kVA Diesel Vs Hondabalu9999No ratings yet

- RS6-42 RS8-42/44 RS10-44/55 RS12-42: Telescopic HandlersDocument130 pagesRS6-42 RS8-42/44 RS10-44/55 RS12-42: Telescopic Handlersjesus100% (1)

- Sullair 185 Operators ManualDocument70 pagesSullair 185 Operators ManualLouis ThevenotNo ratings yet

- Diesel Engine 8V 199 Technical SpecificationsDocument2 pagesDiesel Engine 8V 199 Technical SpecificationsOsorio Luis100% (3)

- 50T - Rt600eDocument20 pages50T - Rt600eangel lozadaNo ratings yet

- Data Sheet SDMO D400Document2 pagesData Sheet SDMO D400AhonakponNo ratings yet

- Hydraulic Mining Excavator RH120E Service Training GuideDocument20 pagesHydraulic Mining Excavator RH120E Service Training GuideOsvaldo UrbanoNo ratings yet

- Marine Diesel Engines: SeriesDocument2 pagesMarine Diesel Engines: Seriesepic sansNo ratings yet

- Control Transmisión Stacker TaylorDocument426 pagesControl Transmisión Stacker TaylorFernando Aguilar100% (8)

- Manual CAT 428-II-1990Document14 pagesManual CAT 428-II-1990Francisco BarrosNo ratings yet