Professional Documents

Culture Documents

Causses of Fatal and Non-Fatal Accidents

Uploaded by

Jawad AmjadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Causses of Fatal and Non-Fatal Accidents

Uploaded by

Jawad AmjadCopyright:

Available Formats

CHAPTER 1

SAFETY

WHAT IS SAFETY?

a. Safety means prevention of accidents which can result into injury or

death to one, his fellow employee or the public, or damage to property

of public or Wapda.

b. Safety however is not just a matter of luck, nor it is a product of

uncontrollable forces like the weather.

c. It is the responsibility of every employee in the WAPA ! P"P#$ to

prevent accidents.

POLICY OF WAPDA.

%asic safety policy can be summed up as follows&

No operating on!ition" or #rgen$ o% "er&ie an e&er '#"ti%$

en!angering t(e )i%e o% an$ one*

CHARACTER OF OR+ANI,ATION.

An organi'ation is judged best by the attitude and conduct of all of it,

employees. Since WAPA is engaged in a vital public service, we have a

particular obligation to carry out this service efficiently, and with proper regard

for the safety of ourselves, our fellow workers, the public, and property. Safety

of line staff can be achieved only through intelligence, cooperation and

implementation of safety measures.

(

CHAPTER - .

CA/SES OF FATAL AND NON-FATAL ACCIDENTS

We will discuss the causes of accidents in two ways i.e. causes of

accidents in general and causes of fatal and non)fatal accidents in WAPA

distribution system.

*he general causes of accidents are divided into&)

a. DIRECT CA/SES

0. INDIRECT CA/SES

. IN- EFFICIENT S/PER1ISION

DIRECT CA/SES

irect causes can be classified into two general types.

/n"a%e At"

/n"a%e Con!ition"

Accidents do not just happen but they are the natural result of

/NSAFE CONTIONS and /NSAFE ACTS or they are the

combination of both.

In fact Statistics shows that +,- of accidents are due to the

human elements such as failure to use safety devices and observe safety

rules and procedure or we can say that the accidents are caused mainly

due to unsafe act of workers. Whereas unsafe conditions are contributing

less than (,-. *he unsafe conditions and unsafe acts are the direct causes

of accidents.

.et us have a glance over some /nsafe #onditions and unsafe acts.

0

/n"a%e Con!ition"

/nsafe conditions are substandard physical, chemical or mechanical

conditions in the work environments which can contribute to cause an accident.

Some e1amples of unsafe conditions which may cause accidents are&

(. I2proper +#ar!ing3

*his includes

a. /nshielded moving parts of machine

b. /nbarricaded floor openings and e1cavations

c. /nenclosed high voltage e2uipments

d. Insufficient warning signs

.. De%eti&e 4ateria) or E5#ip2ent

Such as

a. 3ushroomed chisels

b. Split handles

c. eteriorated poles

d. Poorly constructed or weak e2uipments

6. Ha7ar!o#" Arrange2ent"

Which includes

a. Poor house keeping at work location

b. /nsafe planning

c. Inade2uate working space

8. In"#%%iient Lig(t

Such as

a. /nsuitable location producing glare

b. $bjectionable shadows

9. I2proper 1enti)ation

Such as

a. Insufficient cross of air

b. Presence of harmful vapors, dust or gas.

4

:. /n"a%e C)ot(ing

5or e1ample

a. .ose clothing that can entangle in wires and machinery

b. 5ailure to use goggles

c. 5ailure to use proper shoes

d. 5ailure to use insulated gloves

;. /n"a%e De"ign An! Con"tr#tion

Which are due to deviations from standard design and specifications and

poor workmanships.

/NSAFE ACTS

*he endless variety of things people do or don6t do, human actions or

lack of action which can contribute to causing accidents.

Some e1amples of /nsafe acts which may cause accidents are&)

1. Operating <it(o#t A#t(orit$ or Warning

*his includes

a. #losing switches without authority

b. $perating hoist and trucks without warning

c. 5ailure to place warning signs or signal mans where

needed

d. 5ailure to block e2uipment against une1pected

movement

e. 5ailure to observe work clearance procedure

.. Operating or Wor=ing at #n"a%e "pee!

*hey are

a. riving too fast

b. *hrowing material or tools to another worker

c. 7umping from vehicles or platforms

8

d. 9unning

6. 4a=ing "a%et$ !e&ie" Inoperati&e

*his includes

a. 9emoving :uard from machines

b. /sing over si'e fuses

c. %locking safety valves

d. %locking control interlocks

e. Isolating fire protections

8. /"ing #n"a%e e5#ip2ent or /"ing E5#ip2ent I2proper)$

Such as

a. /sing dull cutting tools

b. /sing mushroom head chisels

c. /sing pipe e1tensions on wrenches not designed for that job.

d. /sing wrong tools for the job

e. /sing hands instead of hand tools

9. /n"a%e Loa!ing

Such as

a. $ver loading cranes and winches

b. #arrying too heavy loads

:. /n"a%e P)ae or 4i>ing

5or e1ample

a. .eaving objects where they are likely to fall

b. Improper packing

;

c. #ombining chemicals to form dangerous mi1ture

;. Ta=ing /n"a%e Po"ition or Po"t#re

Such as

a. Working on live conductors from above instead of below

b. Walking under suspended loads or to close to openings

c. .ifting while in awkward position

d. "ntering the areas where there are dangerous gases or fumes

e. Passing on curves of hills

f. 9iding on running boards or other unsafe places on vehicles

?. Wor=ing on E5#ip2ent <it(o#t Ta=ing proper prea#tion"

Such as

a. #leaning, oiling or adjusting moving machinery

b. Working on or near live electrical e2uipment

@. Di"tratingA tea"ing or "tart)ing

Such as

a. Practical joking

b. <orseplay

c. =uarreling or annoying

1B. Fai)#re to #"e Sa%e C)ot(ing or Proteti&e E5#ip2ent

Such as

a. 5ailure to use insulated gloves

b. 5ailure to use <ard <at

>

c. 5ailure to use :oggles

In!iret Ca#"e"

? Indirect causes may be of people oriented or procedural related. *here

are two key things to remember about indirect causes.

? 5irstly they are harder to recogni'e than direct causes. 3any times an

indirect cause is not even a part of accident scene.

? Second unless the indirect causes are found and eliminated, it is very

likely that the resulting unsafe acts and unsafe conditions will once again

begin occurring.

In-E%%iient S#per&i"ion

It is the supervisor who gambles with the safety of his people,

e2uipment and facilities. *he ineffective supervisor is not very much

concerned with the unsafe acts or unsafe conditions and most certainly

not with the indirect causes which may be behind them. $nly the

supervisor is in the position to detect indirect causes by analy'ing their

results, the unsafe acts and unsafe conditions and then working to correct

or eliminate them.

@

CHAPTER - 6

FATAL C NON FATAL ACCIDENTS

FOR THE YEAR 2005 06

COMPARISON WITH 2004 05

COMPANIES

Employees Publ! Me" A"m#ls

F#$#l No" F#$#l F#$#l No" F#$#l F#$#l

PRES PRE% PRES PRE% PRES PRE% PRES PRE% PRES PRE%

&ESCO '6 '' 20 '( ) '6 ( 0 * (

+EPCO '2 '0 '5 , 0 '5 ' 0 0 0

FESCO '( 4 2' 20 2) 24 ( 4 , 5

IESCO , '0 ' ( 0 0 0 0 0 0

MEPCO '0 * '' * , 4 ' 0 0 '

PESCO '2 '6 '' '6 '5 (0 * 6 ' '

TESCO 2 ( 0 2 0 ' 0 ' 0 0

HESCO '( '4 22 '6 (' 4( 5 '( 0 )

-ESCO ' ( 4 5 0 ' 0 0 0 0

TOTAL 88 78 105 91 91 134 20 24 17 18

FOR THE MONTH OF 06.2006

AS COMPARISON WITH 06.2005

COMPANIES

Employees Publ! Me" A"m#ls

F#$#l No" F#$#l F#$#l No" F#$#l F#$#l

PRES PRE% PRES PRE% PRES PRE% PRES PRE% PRES PRE%

&ESCO 2 ' 5 2 2 ' ' 0 ' 0

+EPCO ' 0 ' 2 0 0 0 0 0 0

FESCO 2 ' 2 4 4 4 2 ' 0 0

IESCO ( ' 0 ' 0 0 0 0 0 0

MEPCO 0 2 0 0 ' 0 0 0 0 0

PESCO ' ( 2 ( ' ( ' 0 0 0

TESCO ' 0 0 0 0 0 0 0 0 0

HESCO 4 2 ( 2 ) 6 0 0 0 0

-ESCO ' ' ' 0 0 0 0 0 0 0

TOTAL 15 11 14 14 16 14 4 1 1 0

FATAL C NON FATAL ACCIDENTS

2006/0* %s 2005/06

COMPANIES

Employees Publ! Me" A"m#ls

F#$#l No" F#$#l F#$#l No" F#$#l F#$#l

PRES PRE% PRES PRE% PRES PRE% PRES PRE% PRES PRE%

&ESCO '( '6 2) 20 2( ) 2' ( * *

+EPCO '' '2 '5 '5 4 0 0 ' ' 0

FESCO '6 '( 2( 2' () 2) '2 ( '4 ,

A

IESCO ) , * ' ' 0 0 0 0 0

MEPCO '0 '0 '6 '' '' , ' ' ' 0

PESCO , '2 ) '' '6 '5 6 * 0 '

TESCO 2 2 0 0 0 0 0 0 0 0

HESCO '' '( 20 22 45 (' 4 5 '0 0

-ESCO 5 ' 5 4 0 0 0 0 0 0

TOTAL 85 88 122 105 138 91 44 20 33 17

06.200* %s 06.2006

COMPANIES

Employees Publ! Me" A"m#ls

F#$#l No" F#$#l F#$#l No" F#$#l F#$#l

PRES PRE% PRES PRE% PRES PRE% PRES PRE% PRES PRE%

&ESCO 2 2 ' 5 0 2 0 ' 0 '

+EPCO 2 ' 0 ' 0 0 0 0 0 0

FESCO 2 2 4 2 6 4 2 2 ( 0

IESCO ' ( ' 0 0 0 0 0 0 0

MEPCO ' 0 2 0 ( ' 0 0 0 0

PESCO 2 ' ' 2 4 ' 0 ' 0 0

TESCO 0 ' 0 0 0 0 0 0 0 0

HESCO ' 4 4 ( ( ) 0 0 ' 0

-ESCO ' ' 2 ' 0 0 0 0 0 0

TOTAL 12 15 15 14 15 16 2 4 4 1

FATAL C NON FATAL ACCIDENTS

200*/0) %s 2006/0*

COMPANIES

Employees Publ! Me" A"m#ls

F#$#l No" F#$#l F#$#l No" F#$#l F#$#l

PRES PRE% PRES PRE% PRES PRE% PRES PRE% PRES PRE%

&ESCO '* '( 20 2) ' 2( 2 2' 4 *

+EPCO , '' '0 '5 2 4 0 0 0 '

FESCO '4 '5 '6 2( 2) () * '2 ( '4

IESCO * ) '' * 0 ' 0 0 0 0

MEPCO '' '0 '0 '6 '2 '' 2 ' 0 '

PESCO 2' , ) ) '5 '6 2 6 0 0

TESCO 4 2 2 0 0 0 0 0 0 0

HESCO ', '' ') 20 (* 45 5 4 0 '0

-ESCO 4 5 2 5 2 0 0 0 0 0

TOTAL 106 85 96 122 97 138 18 44 7 33

06.2006 %s 06.200*

COMPANIES Employees Publ! Me" A"m#ls

+

F#$#l No" F#$#l F#$#l No" F#$#l F#$#l

PRES PRE% PRES PRE% PRES PRE% PRES PRE% PRES PRE%

&ESCO ' 2 ( ' 0 0 0 0 2 0

+EPCO ' 2 2 0 2 0 0 0 0 0

FESCO 0 2 ' 4 ( 6 0 2 0 (

IESCO ' ' 5 ' 0 0 0 0 0 0

MEPCO ' ' 0 2 0 ( 0 0 0 0

PESCO ( 2 ' ' ( 4 0 0 0 0

TESCO 0 0 ' 0 0 0 0 0 0 0

HESCO 2 ' 4 4 2 ( 0 0 0 '

-ESCO 0 ' 0 2 0 0 0 0 0 0

TOTAL 9 12 17 15 10 16 0 2 2 4

CHAPTER - 8

SHORT CO44IN+S IN SAFETY PRACTICES

Bow returning to WAPA istribution system we can classify accidents as&)

(. Accidents due to "lectricity ! "lectrical system

0. Accidents during *ransportation

4. Accidents during handling of material, due to house keeping ha'ards and

during work in field

8. 5ailure to provide 5irst Aid to the victim

If we consider the statistics of fatal and non) fatal accidents we will

conclude that the main cause of accidents C5atal or Bon)fatalD in our

system is electricity. So we will discuss this cause in detail and the

remaining in brief.

Ai!ent" !#e to E)etriit$ C E)etria) "$"te2

(,

Accidents may be fatal or non)fatal to WAPA workers, public man,

animal or damage electrical e2uipments. *here are so many causes of accidents.

*hese causes can be divided into four major heads.

1. SOCIO-ECONO4IC ASPECTS

.. DEHA1IO/RAL ASPECTS

6. TECHNICAL ASPECTS

8. 4ANA+ERIAL ASPECTS

1. SOCIO-ECONO4IC ASPECTS

*his includes&

LACE OF ED/CATION

*he public does not know the proper use of appliances. *hey do

not adopt ordinary preventive measures to use these appliances such as

non)use of three pin shoes, rubber mat sleepers, particularly while

ironing, and non)switching off circuits before removing of plugs.

:enerally it has been observed that whenever there is a break

down on lines, people are an1ious to come to near live conductor and

even try to remove it off from the roads or try to cross it.

1IOLATION OF RI+HT OF WAY

((

It is commonly observed that people construct their houses

and balconies under or near the electric lines and as a result the less

clearance becomes a continuous ha'ard to accidents.

/N-A/THORI,ED /SEC STEALIN+ OF ENER+Y

It is usually seen that a number of accidents occur due to un)

authori'ed use or stealing of electricity. Such mishaps are fre2uent, due to

following illegal methods adopted by public.

a. Illegal illuminations at different ceremonies.

b. Stealing of electricity by use of kundi system Chook methodsD.

c. irect phase and separate earth method adopted to steal electricity

from the meter terminals

d. Illegal ! un)authori'ed energi'ation of transformers, particularly at

tube wells by crude methods, i.e. by use of roara fuses in place of )

fittings and ordinary wooden sticks in place of )operating roads.

EITE FLYIN+

It is observed that kite flying with metallic wire cause accidents,

not only to public men but also cause of damage to WAPA installation.

ALTERNATE SO/RCE OF S/PPLY +ENERATORS

uring the load shedding and faults on feeder, some consumer use

alternate source of supply from another feeder or generator due to which

supply is fed back resulting in accidents.

.. DEHA1IO/RAL ASPECTS

*his includes&

(0

ANI4ALS TIED TO STAY WIRS C POLES

People are habitual of tying their animals with stay wires or electric

poles. *he stay wires are pulled out by the animals, resulting in loosening of

poles ! jumpers, causing short circuiting of poles. .eakage current passes

through poles and animals are electrocuted.

O1ER CONFIDENCE OF LINE STAFF

3ajority of accidents to line staff occur due to over confidence,

negligence and carelessness. After their long service, they ignore the safety

instruction and start taking risks.

FAIL/RE TO /SE SAFE CLOTHIN+ OR P.P.E. FPERSONAL

PROTECTI1E EG/IP4ENTH

resses made of synthetic fiber or inflammable material, loose

shalwar kamee', and failure to use insulated gloves, safety belts etc., are the

general negligence on the part of workers which results in accidents.

TAEIN+ /N-SAFE POSITIONS OR POST/RES

Working on live conductor from above instead of below, standing

on awkaward position or on unstable platforms can also cause accidents.

PHYSICAL /N-FITNESS

(4

*he physical un)fitness due to economic reason, mental tension or

narcotics addiction adversely affects the attention of the worker and become the

cause of accidents.

/SE OF STEEL STR/CT/RE AS A LADDER

/sing of steel structure instead of ladder does not provide the stable

working position for the linemen and in)ade2uate working space causes the

accidents.

DISRACTIN+A TEASIN+ OR STARTLIN+

/n)attentive attitude of workers such as practical joking, horseplay,

2uarreling or annoying may cause an accident.

6. TECHNICAL ASPECTS

5ollowing are some technical aspects

DEFECTI1E EARTIN+ C NON-+RO/DIN+ OF DOTH SIDES

efective earthing is one of the major causes of accidents. Similarly,

many employees are electrocuted due to none earthing of the line on both side

of their working area.

CARRIER SER1ICE WIRES

Some accidents have occurred when an injured service wire came in

contact with the carrier steel wire.

(8

S/D STANDARD ELECTRICAL FITTIN+S-WIRES

*he plugs, switches etc. are usually made of substandard material. *he

2uality of these plugs, switches is very poor. *his is one of the causes of electric

shock and house fire on account of loose connections. efective, sub)standard

wiring, non utili'ation of three pin plugs, shoes is another cause of accidents.

/SE OF I4PROPER F/SE

*he use of over si'e fuse wire also becomes dangerous for not isolating

faulty section immediately and becomes a cause of fire in the circuit.

O1ER LOADIN+ OF DRANCH CIRC/IT

/sually on account of low cost peoples use sub)standard wires, which are

not in accordance to load. *hese inferior 2uality wires do not have good

insulation and can be a cause of accident.

DACE FEEDIN+

%ack feeding is mainly due to duplicate source of supply with out fool

proof change over switches. *he duplicate source of supply may be from other

feeder, transformer or house generator.

STREET LI+HT PHASE

While carrying our maintenance work, replacement of bulbs, the street

light staff energi'es the street light circuit. ue to miss understanding by

maintenance staff accident can occur.

(;

/SE OF O1ER SI,E RORA F/SES AND IN-EFFICIENT

CIRC/IT DRAEERS

Bormally in distribution field the linemen use over si'e roara fuses

instead of standard fuses. Which do not blow off in case of any short circuit and

break down occurs on the lines. Similarly, in case of abnormal plug setting of

circuit breaker at :rid Station, the earth fault as a result of are not promptly

sensed and in case of break down live the conductor lying on the ground may

cause accident.

ISOLATION OF T-OFF LINE THRO/+H DORP O/T LINES

WITHO/T WATCH AND WARD

It is usually observed that linemen start work on the section after

disconnecting )links without leaving any member of the staff behind. Any

operation of )links by complaint staff can cause accident.

/N-SAFE DESI+N AND CONSTR/CTION

ue to deviation from standard design and specification and poor

workman ship accidents can occur. Bon)maintaining of minimum

re2uired clearance of electric lines, particularly at road crossing is also a

cause of accidents.

NONDISCHAR+IN+ OF CAPACITORS

(>

It has been observed that circuits where capacitors are installed the

workers do not discharge the capacitors before the start of work causing

an accident.

CA/TION NOTICE

After getting P*W the in)charge of :rid Station and supervisors of line

staffs do not care or bother to display the caution notice on the breaker or

isolator, which has been d)energi'ed. *he operation of these breakers or isolator

by mistake can cause an accident.

8. 4ANA+ERIAL ASPECTS

4anageria) a"pet" in)#!e3

NON DRIEFIN+ OF IOD

Bormally it has been observed that supervisors do not brief the linemen

about the job. All of sudden they are boarded on the vehicle and taken to site.

*hey do not know&

What to doE

<ow to doE

And can not arrange proper *FP or material and are not mentally ready

for job. *his hapha'ard arrangement can cause an accident.

NON-COND/CTIN+ OF TJP PARADE

In order to detect the defective, un)serviceable *FP! PP" items, no

regular *FP! PP" parade as per prescribed authority schedule are conducted in

the field by the supervisors. Inspection of *FP! PP" items is not carried out

(@

before the start of the work. *his defective and unsafe *FP is a cause of an

accident.

LACE OF S/PER1ISION

It has normally been observed that supervisors do not supervise the work

personally and the workers are not informed about the un)safe areas. *he

workers are not stressed upon to adopt safety measures. /nauthori'ed un)

skilled persons are not restricted to work on live lines. Bo follow up action is

taken, by the supervisor, to check whether work has been carried out according

to standard specification an all un)necessary *FP material has been removed

form the site and all the workers have been collected. Instructions are not issued

to the linemen to keep away before energi'ation of the line, which can result in

an accident.

INS/FFICIENT CO4PLAINT CENTERS C STAFF

Staff posted at the complaint office is some time over burdened ofwork in

far flung areas. *hey work day and night due to urgency and this over

burdening may cause an accident.

ACCIDENT D/RIN+ TRANSPOTATION

*he accidents during transportation of employees generally occurr due to&

riving the vehicle too fast

Bot observing the traffic sign and signals

$verloading of vehicle

While carrying long poles not fastening of red indication on the portion of poles

out site the vehicle, for signal to other vehicles.

Sitting of workers traveling in open vehicle in improper way.

riving of vehicle by peoples having no e1perience.

(A

Parking of vehicle in improper manner.

ACCIDENT D/RIN+ HANDLIN+ OF 4ATERIALA D/E TO

POOR HO/SE EEEPIN+ AND D/RIN+ WORE IN FIELD.

While handling and storing if proper safety measures are not taken they

may cause accidents or damage to material. Similarly in office slippery floors,

in)sufficient light, in)sufficient ventilation, etc may cause accidents. Also while

working in field e1tensive sunlight may cause sun)stroke in summer. Working

in areas where wild animals e1ists without taking safety measures is also

harmful to life.

FAIL/RE TO PRO1IDE FIRST AID TO 1ICTI4

If in time first aid is not provided to victim it can result into conversion

of non)fatal accident to fatal accident. $r injured limbs may become dead for

life.

CHAPTER - 9

RE4EDIAL 4EAS/RES TO PRE1ENT ACCIDENTS

WAPA Power Safety #ode was issued long ago, but accidents could not

be controlled, and are increased at an alarming rate due to the following

unattended main reasons.

a. *he safety procedure has not been followed properly.

b. *here are some other causes still to be sorted out.

In accident Prevention, two of the most effective actions can be

taken&)

I. 5irst, become the sworn enemy of accident causes, seek them

and eliminate them out before they damage us.

(+

II. Second, become a Sherlock <olmes, when an accident occurs,

investigation and analy'e until you have answers as to how and

why it occurred.

Accident in WAPA has now become a C(roni Di"ea"eA and

when a disease becomes #hronic the octors have to make

detailed laboratory tests and investigation. Similarly, if we want

to control accidents, we will have to sort out the real and root

causes of accidents. We will have to see&)

Whether we have e2uipped our linemen with intact

*FP

Whether transport facilities are available for smooth

running of field officesE And

Whether our worker is mentally satisfied with his jobE

In addition to the above we can prevent accidents by just taking ordinary

measures. 5or e1ample, the seriousness of a shock depends on the path of the

current takes through the body and a small current passing through the heart is

much more critical than a current passing between two fingers of the same

hand. *esting for live current with one hand instead of two reduce the risk of a

dangerous shock by making current less likely to flow through the heart.

Accident Preventions have been divided into two parts&

1. +ENERAL PRE1ENTION

.. PRE1ENTI1E 4EAS/RES TO DE ADOPTED

D/RIN+ PERFOR4ANCE OF IOD

1. +ENERAL PRE1ENTIONS

5ollowing are the :eneral Preventions&)

A1AILADILITY OF TJP AND P.P.E.

0,

$ne of the main problem being faced in the sub ivision since long is the

e1treme shortage of line *FP and personal protective e2uipment for e1ample

rubber, protective gloves F insulated pliers etc. it is impossible to control

accidents unless F until we e2uip our linemen with intact *FP. All the field

officers right from .S up to #hief "1ecutive have definite responsibilities as

regards availability F inspection of *FP and these responsibilities must be

fulfilled so that ade2uate and standard *FP may be made available to the line

staff.

RE1ISION OF YARDSTICE S/PER1ISORY AS WELL AS

LINE STAFF

ue to non)creation of new sub ivisions the numbers of consumers

have increased manifold but yardstick has not been revised proportionally.

3ost of the Sub ivisions are supplying electricity to more than 0,,,,,

consumers. In some cases this figure is touching 4,,,,, but available

strength of supervisory and line staff is the same as was at the time when the

sub division was established and numbers of consumers at that time were

only ;,,,, to A,,,,.

A1AILADILITY OF TRANSPORT

It has repeatedly been mentioned in WAPA safety code that a

lineman should not climb up the structure without ladder, but there is no

facility in the complaint centers for shifting ladder to site of work. If a

lineman has to attend 0, complaints then how can we e1pect that he will

shift ladder to each site of work on his shoulders. We all admit that financial

condition of WAPA is not good, but this problem can be solved by shifting

of vehicles from less important organi'ations.

A1OID /N-NECESSARY PRESS/RE D/RIN+ E4ER+ENCIES

0(

It is common practice that when lines are de)energi'ed for

performing maintenance works or when supply is interrupted due to some

fault public makes hue F cry and starts e1erting pressure through telephone

calls and officers put pressure on field staff for early restoration of supply.

/nder these situations WAPA basic safety policy must be kept in mind that

No operating on!ition or #rgen$ o% "er&ie an

e&er '#"ti%$ en!angering t(e )i%e o% an$one.*

REHADILITATION OF DISTRID/TION NETWORE

*he deteriorated condition of distribution system needs immediate

re)habilitation. If financial constraints do not permit us to re)habilitate the

system, we can improve the situation by alternative measures.

4EETIN+S

Safety meetings may be conducted for Supervisors, employees or

other group, but in every case the purpose is to stimulate or maintain

safety interest.

*hese meetings should be held between the "1ecutives and

Supervisors to formulate policies, initiate a safety program or plan

special activities. 3eeting of all employees, sometimes including

families, or even the entire community, to serve special purposes also to

00

discuss the specific accidents or to review safety instruction. It is also

advisable to show video drama prepared by WAPA safety directorate

may be made available at sub division level for showing to staff members

and their families to educate them and arouse them to take safety measure

during the job.

SAFETY POSTERS

Posters are meant to reach large number of people on the move

with brief, simple message, designed to accomplish one or more missions to

convey information to change attitude or to change behavior. Safety posters

are one of the most visible evidence of accident prevention work.

P/RPOSE OF POSTERS

(. Posters properly used have great value in a safety program through their

influence on attitude F behavior.

0. *o remind employees of common human traits that causes accident.

4. *o impress people with the good sense of working safely.

8. *o suggest behavior patterns that help prevent accidents.

;. *o inspire a friendly interest in the company safety efforts.

>. *o foster the attitude that accidents are mistakes and safety is a mark of

skill.

@. *o remind employees of specific ha'ards.

PRE1ENTI1E 4EAS/RE TO DE ADOPTED D/RIN+

PERFOR4ANCE OF IOD

04

5ollowing preventive measure should be adopted while performing

maintenances, repair and construction work on electric line and other

installation.

IOD DRIEFIN+

"1perience has proved the importance of job briefing in prevention

of accidents. *here fore job briefing shall be made a part of every job

regardless of its si'e. All the workers should be present during briefing.

"1plain to workers.

a. What is to be doneE

b. Why it is to be doneE

c. Where it is to be doneE

d. When it is to be doneE

e. <ow it is to be doneE

f. Who is to do itE

DE-ENER+I,ATION OF LINE

%efore starting work the line should be de)energi'ed if work is to

be done on (( G.H line Ipermit to workJ should be obtain by supervisor

from authori'ed person of :rid Station. ..S should ensure that trolley of

circuit breaker has been racked out and proper caution notice has been

placed on control panels. It is matter of e1perience that ..S6s avoid taking

P*W6s. Instead they dis)connect the supply from )5uses installed on

(( G.H feeders for making sections. It must be avoided. In case lengthy

feeder if it is unavoidable then )fuse links must be removed and one person

should stay at )fuse to ensure de)energi'ation.

08

If work is to be carried out on ..* line then it should also be

de)energi'ed from sub)station and staff members be deputed at the sub

station and street light switch. So that any other employee may not energi'e

.* line or street light phase during the e1ecution of work.

EARTHIN+

It is the most important step. <.* and .* lines should be grounded

from both sides to avoid un)e1pected energi'ation. %efore starting the work

of earthing it should be ensured that line is dead. 5or this purpose high

voltage detector can be used. Authority has already issued strict instruction

on this issue and all the alternate sources of supply must be discounted with

out discrimination to avoid chances of feed back. Similarly the consumers of

big ba'aars and shopping center must be made bound to install change over

switches, if they want to use generator as alternative supply.

PHYSICAL FITNESS

%efore deputing any line man to work on line it must be seen that

he is physically and mentally fit and is not under the influence of any drug

or addiction. <is clothes are not too lose and he is free of metallic items

specially lockets and chains.

PROPER 4AN FOR PROPER IOD

Proper man should be deputed for proper job. A...3s should not

be allowed to work on line in any case.

0;

/SE OF PROPER LINE TJP

While performing the work, proper * F P should be used. .ineman

should not be allowed to climb up without ladder and safety belt should be

properly tied with structure or pole. Some linemen tie their safety belt with

cross arm, knee brace or conductor which should be avoided.

DEHA1IOR OF WOREER D/RIN+ EKEC/TION OF IOD

While performing job employee should be alter, neither he should

be over confident nor confused. Practical joking or horse play must be

prohibited. Bo employee shall distract attention of other workers form their

job. A. ..3. should not leave lineman unattended.

FOLLOW /P

It is important that fre2uent checks be made as job progress to be

sure that&)

Plans are being followed and correct work methods are

being used.

Workers are carrying out their assigned responsibilities.

All un)e1pected ha'ards have been recogni'ed and are being

proper handled.

CARE DEFORE RE-ENER+I,ATION OF LINE

After completion of job, the site should be cleared and no *F P item or

material should be left on line. %efore cancellation of P*W and re)energi'ation

0>

of line the supervisor should ensure that the crew has gathered and no one is

missing and temporary earthing has been removed.

TRAININ+ OF LINE STAFF RE+ARDIN+ FIRST AID

TECHNIG/ES

*he field staff should be trained regarding the techni2ues of first aid for

injured persons.

0@

CHAPTER :

RECO44ENDATIONS AND CONCL/SIONS

RECO44ENDATIONS

4et(o!o)og$ an! 2e(ani"2 %or t(e i2p)e2entation o%

"tan!ar! "a%et$ pratie".

Accident prevention can be made possible only through wholehearted co)

operation or all members of the crew ! organi'ation. Beither management,

supervision, nor the Safety #ode alone can prevent accidents without the help

of each employee CS"!K"B! $! S!.3!A.3D.

1. S$ should educate the line staff not to do work in hurry up condition

and not to be over confident and should ensure the non)working of un)

authori'ed A.3s on lines.

.. S$ should educate the A.3s to keep watch towards the un)safe acts of

.3 when he is working on poles ! lines and should emphasi'e the .3 to

work safely using all safety measures. At lease one spot checking report

be carried out during one week under intimation to y. 3anager CSafetyD.

6. S$ ! .S be made responsible to educate the line staff and not to do

work without ensuring the isolation of work place ! provision of

temporary earthing at both sides of work place. K"B ! S$ be made

responsible for non)use of PP"!*FP and non)observance of safety

measures by supervisory ! line staff.

8. 7ob briefing should be made mandatory before start of any work. K"B

SSF* be made responsible for any negligence ! illegal co)ordination of

:rid Station staff with $peration staff to control the situation as many

accidents have been occurred due to this very reason.

0A

9. Presence of supervisory staff on all major break downs ! e1ecutions be

made obligatory. K"B should ensure the e1ecution of work after

arrangement of P*W instead of availing benefit of .oad Shedding time.

:. K"B should ensure the holding .of daily 3orning Assembly and

PP"!*FP parade F safely lecture regularly on monthly basis by all

S$s.

;. *otal network needs to be surveyed, patrolled and all Safety <a'ards to

be identified and removed so as to ensure safe working environment for

the field staff. K"B should ensure the removal of all defects e1isting in

distribution system to avoid accidents. "specially, he should check the

replacement of 9ora fuses, deteriorated P# poles and naked joints in

service cables during his visit of S!iv. Indicators should be provided at

all feeders, both at :rid Stations and at diversion points to avoid any

mishap because of incorrect identification of feeders, some times resulted

Into occurrence of serious accidents.

?. Hery important points of Safety code be prepared in /rdu version.

@. "1emplary punishment should be given to all delin2uents held

responsible for violation of safety precautionary measures or held

responsible for .occurrence of fatal ! non)fatal accidents. All officers, ,

those who are held responsible for accidents should also be dealt strictly.

1B. esign deviation in construction of distribution system immediately be

stopped.

11. K"B!S$ be made responsible for the occurrence of accidents as it

shows their loose control and negligence.

1.. Steps to be taken for economical satisfaction of line staff.

16. All newly inducted S$s ! .Ss ! A.3s should be properly trained

regarding safety measures at 9egional *raining #enters before deputing

them for duty in field.

0+

18. Performance of Safety Inspector CSafety #o)coordinatorsD deputed for

promotion of safety culture at #ircle level have been assigned duties

other than safety. Some times y. 3anager CSafetyD is assigned

additional duties other than safety which is absolutely against the rule

hence no additional job be assigned to y. 3anager CSafetyD.

19. It has been observed that some times only lineman attends the faults

single handedly. Bo A.3 accompanies to assist the lineman. *his culture

must be stopped.

4,

CONCL/SION

1. T(e e)i2ination o% /n"a%e At" an! /n"a%e Con!ition i" t(e

on)$ "#re <a$ to 2ini2i7e ai!ent".*

.. No operating on!ition or #rgen$ o% "er&ie an e&er '#"ti%$

en!angering t(e )i%e o% an$one.*

4(

You might also like

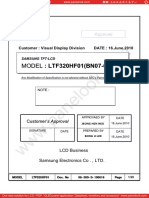

- LTF320HF01 SamsungDocument29 pagesLTF320HF01 Samsungmarius tanjalaNo ratings yet

- Note On Review/Inspection of Flagship/Other Important Centrally Sponsored Schemes in State of Punjab, 25 To 27 November, 2009Document24 pagesNote On Review/Inspection of Flagship/Other Important Centrally Sponsored Schemes in State of Punjab, 25 To 27 November, 2009Vivek KankipatiNo ratings yet

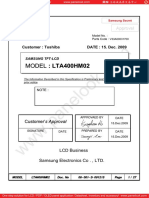

- Data Sheet Panel LTA400MH01Document27 pagesData Sheet Panel LTA400MH01kang ejaNo ratings yet

- Oop Real ProjectDocument35 pagesOop Real ProjectShivangi DeshpandeNo ratings yet

- B173RTN01 1-AuoDocument34 pagesB173RTN01 1-Auosijovow282No ratings yet

- CV of Shyamtanu SenguptaDocument3 pagesCV of Shyamtanu SenguptaArvind RoyNo ratings yet

- UA Application Form SPDocument3 pagesUA Application Form SPalistair7682No ratings yet

- Do Weak Growth and New Challenges Make Cisco A Value Trap?Document3 pagesDo Weak Growth and New Challenges Make Cisco A Value Trap?MiragleCNo ratings yet

- Project Report On CutchDocument19 pagesProject Report On CutchMeghal VadhvanaNo ratings yet

- Pm-030 Ims Transition and Contingency Plan v2Document20 pagesPm-030 Ims Transition and Contingency Plan v2Ivo HuaynatesNo ratings yet

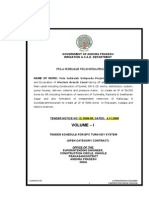

- Volume - I: Pula Subbaiah Veligonda Project: Investigation, DesignDocument347 pagesVolume - I: Pula Subbaiah Veligonda Project: Investigation, DesignThirukandiyur Sudarsana Sri RamanNo ratings yet

- InstallManual OPUS-College Environment WINDOWSDocument23 pagesInstallManual OPUS-College Environment WINDOWSAxel LanuzaNo ratings yet

- Original Instruction Manual: Parts ListDocument26 pagesOriginal Instruction Manual: Parts ListÖzten Elektrik Abdullah ÖztenNo ratings yet

- Rfi Checklist NokiaDocument6 pagesRfi Checklist NokiaBaba HimanathNo ratings yet

- Pradeep Ass TPR of CVDocument3 pagesPradeep Ass TPR of CVideepujNo ratings yet

- Project: Nokia Bac Ninh Factory) : 18 /2012 QTBD Posco Engineering Co.,LtdDocument2 pagesProject: Nokia Bac Ninh Factory) : 18 /2012 QTBD Posco Engineering Co.,LtdBùi Anh TuấnNo ratings yet

- Antamina Project 220 KV Transmission Line: Revised Approved Date 30-22-20-E - Rev ADocument9 pagesAntamina Project 220 KV Transmission Line: Revised Approved Date 30-22-20-E - Rev AOscar AlcasNo ratings yet

- David Sm13e CN 03Document15 pagesDavid Sm13e CN 03Koki MostafaNo ratings yet

- Anybodys Non AOC CAME Issue 6Document56 pagesAnybodys Non AOC CAME Issue 6Kaung MyatToe0% (1)

- PPP C 2020aDocument28 pagesPPP C 2020aGirlie SantilanNo ratings yet

- The State of Enterprise 2.0 Adoption Q4 2009: Maturity, Scale, Drivers, Ownership, SatisfactionDocument21 pagesThe State of Enterprise 2.0 Adoption Q4 2009: Maturity, Scale, Drivers, Ownership, SatisfactionSusan Scrupski100% (1)

- Accounting in Action: Summary of Questions by Study Objectives and Bloom'S TaxonomyDocument73 pagesAccounting in Action: Summary of Questions by Study Objectives and Bloom'S TaxonomyscribdpdfsNo ratings yet

- Ad No. 8 Without F.o-25!08!14Document10 pagesAd No. 8 Without F.o-25!08!14engg.satyaNo ratings yet

- Differential and Comparative Cost AnalysisDocument41 pagesDifferential and Comparative Cost AnalysisjungvoltNo ratings yet

- POF Week 6 SBDocument38 pagesPOF Week 6 SBpartyycrasherNo ratings yet

- Personal Details ObjectiveDocument3 pagesPersonal Details ObjectiveumamaheshwarraoNo ratings yet

- Asme Relevant Summarized Clouses For Pressure Vessel Fabrication (Sec Viii Div I) Sr. Remarks Code ReferenceDocument7 pagesAsme Relevant Summarized Clouses For Pressure Vessel Fabrication (Sec Viii Div I) Sr. Remarks Code ReferenceviswamanojNo ratings yet

- Procedure For Fab, Erec & Testing of Undergroud PipingDocument12 pagesProcedure For Fab, Erec & Testing of Undergroud Pipingvpsimbu86No ratings yet

- Illinois VOC and LEED 2009 LimitsDocument5 pagesIllinois VOC and LEED 2009 LimitsspecmasterNo ratings yet

- Mirza M. Raheel Baig: Application For The Post of Any Suitable JobDocument2 pagesMirza M. Raheel Baig: Application For The Post of Any Suitable JobPiyush ThukralNo ratings yet

- Tap Maths Paper 2 Set 4Document16 pagesTap Maths Paper 2 Set 4James Gikingo0% (3)

- Igs TP 010 1&2Document13 pagesIgs TP 010 1&2mahotkatNo ratings yet

- Sop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Document10 pagesSop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Iksan Adityo MulyoNo ratings yet

- Tugas JobDocument8 pagesTugas JobHenny Komala Sari SibaraniNo ratings yet

- 2 IN35 Slides 1Document61 pages2 IN35 Slides 1Matthew ThomasNo ratings yet

- Microeconomics Cue CardDocument4 pagesMicroeconomics Cue CardPaul FareseNo ratings yet

- S03 AccumulatorDocument8 pagesS03 AccumulatorAvila JorgeNo ratings yet

- Allama Iqbal Open University Course CodesDocument111 pagesAllama Iqbal Open University Course CodesBakhtawer ZainNo ratings yet

- ISM Code All Circulars MS NOTICE - 09 - 2014Document38 pagesISM Code All Circulars MS NOTICE - 09 - 2014Nilesh DalviNo ratings yet

- Train Driving Techniques PDFDocument99 pagesTrain Driving Techniques PDFआनंद कुमार विश्वकर्माNo ratings yet

- SIStec Major Project Report On GSM Based Pump Control SystemDocument81 pagesSIStec Major Project Report On GSM Based Pump Control Systemukpandey25No ratings yet

- Cellulase ProductionDocument16 pagesCellulase ProductionTanvi JainNo ratings yet

- Software Release Note.: OverviewDocument6 pagesSoftware Release Note.: Overviewmiguel062555GNo ratings yet

- Exploration and Production of Petroleum Companies in PakistanDocument15 pagesExploration and Production of Petroleum Companies in PakistanNudrat SyedNo ratings yet

- 1448 Kartika Ce1 Fstpt10 Agung RevDocument10 pages1448 Kartika Ce1 Fstpt10 Agung RevPeli L. MessiNo ratings yet

- Abhi Resume Plc1Document3 pagesAbhi Resume Plc1myscrib123No ratings yet

- weekly: Oπoioσ Eλeyθepa Σyλλoγatai Σyλλoγatai KaλaDocument33 pagesweekly: Oπoioσ Eλeyθepa Σyλλoγatai Σyλλoγatai KaλaEmpire100No ratings yet

- Project Work ForDocument27 pagesProject Work ForBonnie LimNo ratings yet

- I. II. Preface Iii. List of Figures IV. List of Tables Page No. 1 Introduction 1Document7 pagesI. II. Preface Iii. List of Figures IV. List of Tables Page No. 1 Introduction 1anon_238031053No ratings yet

- Rail Wheel Factory: SR - EDPM/MIS Centre/RWFDocument6 pagesRail Wheel Factory: SR - EDPM/MIS Centre/RWFNIlesh BhagatNo ratings yet

- Salary IDocument35 pagesSalary IParul Bhardwaj VaidyaNo ratings yet

- Science & TechnologyDocument3 pagesScience & TechnologyAmit KankarwalNo ratings yet

- Hillsborough Alabang Construction GuidelinesDocument43 pagesHillsborough Alabang Construction GuidelinesRhap CaritoNo ratings yet

- VLC Media Player DN BFS 00020 1 February 2010Document28 pagesVLC Media Player DN BFS 00020 1 February 2010scrubpriyaNo ratings yet

- Workers Children (Education) Ordinance, 1972Document3 pagesWorkers Children (Education) Ordinance, 1972Nawaz GondalNo ratings yet

- CF9001 General Service ManualDocument177 pagesCF9001 General Service ManualMarck JunoNo ratings yet

- A-$ BCC) D +!:) &$ ADocument18 pagesA-$ BCC) D +!:) &$ ATeerayut PimpakanNo ratings yet

- Sachin Patel: ObjectiveDocument4 pagesSachin Patel: Objectivemohan_krishna372No ratings yet

- Punjab - Millat Tractors LTD - RYKDocument1 pagePunjab - Millat Tractors LTD - RYKJawad AmjadNo ratings yet

- Air Guide BoxDocument2 pagesAir Guide BoxJawad AmjadNo ratings yet

- Oti Wti PDFDocument5 pagesOti Wti PDFJawad AmjadNo ratings yet

- SF6 Gas For 500kV CBDocument4 pagesSF6 Gas For 500kV CBJawad AmjadNo ratings yet

- 500 TF ManualDocument13 pages500 TF ManualJawad AmjadNo ratings yet

- Security Weapon Handing TakingDocument1 pageSecurity Weapon Handing TakingJawad AmjadNo ratings yet

- Rationalization - SummaryDocument53 pagesRationalization - SummaryJawad AmjadNo ratings yet

- Multan Region July 2014-June 2015Document110 pagesMultan Region July 2014-June 2015Jawad AmjadNo ratings yet

- Manuals A-Type StoreDocument6 pagesManuals A-Type StoreJawad AmjadNo ratings yet

- NTC Demand NoticeDocument1 pageNTC Demand NoticeJawad AmjadNo ratings yet

- Mom 04-07-2019Document7 pagesMom 04-07-2019Jawad AmjadNo ratings yet

- Handing Taking 1Document1 pageHanding Taking 1Jawad AmjadNo ratings yet

- GroE Fiam ImoedanceDocument2 pagesGroE Fiam ImoedanceJawad AmjadNo ratings yet

- Installation of 52KV Tertiary Bus Bar Along With Surge ArrestersDocument1 pageInstallation of 52KV Tertiary Bus Bar Along With Surge ArrestersJawad AmjadNo ratings yet

- Pakistan Water and Power Development Authority: Travelling Allowance BillDocument2 pagesPakistan Water and Power Development Authority: Travelling Allowance BillJawad AmjadNo ratings yet

- Rate List of Testing P&I MGHDocument2 pagesRate List of Testing P&I MGHJawad AmjadNo ratings yet

- Bookshop - Vu.edu - PK Web PrintOrderDocument1 pageBookshop - Vu.edu - PK Web PrintOrderJawad AmjadNo ratings yet

- P&I Division 500KV Grid Station NTDCL Muzaffargarh. Mob:# 0335-7401547 Fax: 066-9200167 EmailDocument1 pageP&I Division 500KV Grid Station NTDCL Muzaffargarh. Mob:# 0335-7401547 Fax: 066-9200167 EmailJawad AmjadNo ratings yet

- 2003 Wood Webefinal 2Document3 pages2003 Wood Webefinal 2Jawad AmjadNo ratings yet

- p632 Testing Procedure of Tranformer Diffrential Protection PDFDocument14 pagesp632 Testing Procedure of Tranformer Diffrential Protection PDFJawad AmjadNo ratings yet

- PT6983A SDocument4 pagesPT6983A SJawad AmjadNo ratings yet

- Shut Down Noting IsolatorsDocument1 pageShut Down Noting IsolatorsJawad AmjadNo ratings yet

- Kenwood Report FinalDocument43 pagesKenwood Report Finaltooba siddiquiNo ratings yet

- Social Connectedness and Role of HopelessnessDocument8 pagesSocial Connectedness and Role of HopelessnessEmman CabiilanNo ratings yet

- Practical Cookery 14th Edition SAMPLEDocument16 pagesPractical Cookery 14th Edition SAMPLETendaiNo ratings yet

- Roadmap Video: Answer KeyDocument4 pagesRoadmap Video: Answer KeyMaria JuneNo ratings yet

- Wago PCB Terminal Blocks and Connectors Catalog 7Document105 pagesWago PCB Terminal Blocks and Connectors Catalog 7alinupNo ratings yet

- To 33B-1-1 01jan2013Document856 pagesTo 33B-1-1 01jan2013izmitlimonNo ratings yet

- OA Standard 050505Document75 pagesOA Standard 050505fido_dagemNo ratings yet

- Arann Magazine, Issue 1-2-Online VersionDocument36 pagesArann Magazine, Issue 1-2-Online VersionmujismileNo ratings yet

- Chapter 11-15Document172 pagesChapter 11-15Mansoor AhmadNo ratings yet

- RB Boiler Product SpecsDocument4 pagesRB Boiler Product Specsachmad_silmiNo ratings yet

- Consent CertificateDocument5 pagesConsent Certificatedhanu2399No ratings yet

- Artesunat Injection 2009Document4 pagesArtesunat Injection 2009Franca ImadiyiNo ratings yet

- API 650 10th Edition ErrataDocument6 pagesAPI 650 10th Edition ErrataJosé Ramón GutierrezNo ratings yet

- RNP Rnav PDFDocument31 pagesRNP Rnav PDFhb2enbjxNo ratings yet

- Capacity Requirement PlanningDocument17 pagesCapacity Requirement PlanningvamsibuNo ratings yet

- Updated2021.KEBOS GR11-2KVA 1800W Online Rack Mount UPS DatasheetDocument2 pagesUpdated2021.KEBOS GR11-2KVA 1800W Online Rack Mount UPS DatasheetRicardo HolleroNo ratings yet

- Harmonized Household Profiling ToolDocument2 pagesHarmonized Household Profiling ToolJessa Mae89% (9)

- AQ-101 Arc Flash ProtectionDocument4 pagesAQ-101 Arc Flash ProtectionYvesNo ratings yet

- Drug AbuseDocument33 pagesDrug AbuseharshulnmimsNo ratings yet

- Latihan Soal Bahasa Inggris 2Document34 pagesLatihan Soal Bahasa Inggris 2Anita KusumastutiNo ratings yet

- Kern County Sues Governor Gavin NewsomDocument3 pagesKern County Sues Governor Gavin NewsomAnthony Wright100% (1)

- English Language Paper 1 - Answer KeyDocument5 pagesEnglish Language Paper 1 - Answer Keybangtansone1997No ratings yet

- MSU-Iligan Institute of TechnologyDocument5 pagesMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDONo ratings yet

- Recommendation On The Acquisation of VitasoyDocument8 pagesRecommendation On The Acquisation of Vitasoyapi-237162505No ratings yet

- Astm A712 PDFDocument3 pagesAstm A712 PDFCristian OtivoNo ratings yet

- Phenotype and GenotypeDocument7 pagesPhenotype and GenotypeIrish Claire Molina TragicoNo ratings yet

- Reading Assignment Nuclear ChemistryDocument2 pagesReading Assignment Nuclear Chemistryapi-249441006No ratings yet

- Ecg Quick Guide PDFDocument7 pagesEcg Quick Guide PDFansarijavedNo ratings yet

- Durock Cement Board System Guide en SA932Document12 pagesDurock Cement Board System Guide en SA932Ko PhyoNo ratings yet

- A I R P O R T S Construction Program Management 56Document56 pagesA I R P O R T S Construction Program Management 56Carl WilliamsNo ratings yet

- The United States of Beer: A Freewheeling History of the All-American DrinkFrom EverandThe United States of Beer: A Freewheeling History of the All-American DrinkRating: 4 out of 5 stars4/5 (7)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterFrom EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterRating: 3.5 out of 5 stars3.5/5 (487)

- The War Below: Lithium, Copper, and the Global Battle to Power Our LivesFrom EverandThe War Below: Lithium, Copper, and the Global Battle to Power Our LivesRating: 4.5 out of 5 stars4.5/5 (8)

- All You Need to Know About the Music Business: 11th EditionFrom EverandAll You Need to Know About the Music Business: 11th EditionNo ratings yet

- All The Beauty in the World: The Metropolitan Museum of Art and MeFrom EverandAll The Beauty in the World: The Metropolitan Museum of Art and MeRating: 4.5 out of 5 stars4.5/5 (83)

- Summary: Unreasonable Hospitality: The Remarkable Power of Giving People More than They Expect by Will Guidara: Key Takeaways, Summary & Analysis IncludedFrom EverandSummary: Unreasonable Hospitality: The Remarkable Power of Giving People More than They Expect by Will Guidara: Key Takeaways, Summary & Analysis IncludedRating: 2.5 out of 5 stars2.5/5 (5)

- Dealers of Lightning: Xerox PARC and the Dawn of the Computer AgeFrom EverandDealers of Lightning: Xerox PARC and the Dawn of the Computer AgeRating: 4 out of 5 stars4/5 (88)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- The Toyota Way (Second Edition): 14 Management Principles from the World's Greatest ManufacturerFrom EverandThe Toyota Way (Second Edition): 14 Management Principles from the World's Greatest ManufacturerRating: 4 out of 5 stars4/5 (121)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumFrom EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumRating: 3 out of 5 stars3/5 (12)

- All You Need to Know About the Music Business: Eleventh EditionFrom EverandAll You Need to Know About the Music Business: Eleventh EditionNo ratings yet

- Vulture Capitalism: Corporate Crimes, Backdoor Bailouts, and the Death of FreedomFrom EverandVulture Capitalism: Corporate Crimes, Backdoor Bailouts, and the Death of FreedomNo ratings yet

- AI Superpowers: China, Silicon Valley, and the New World OrderFrom EverandAI Superpowers: China, Silicon Valley, and the New World OrderRating: 4.5 out of 5 stars4.5/5 (399)

- Build: An Unorthodox Guide to Making Things Worth MakingFrom EverandBuild: An Unorthodox Guide to Making Things Worth MakingRating: 5 out of 5 stars5/5 (123)

- Real Life: Construction Management Guide from A-ZFrom EverandReal Life: Construction Management Guide from A-ZRating: 4.5 out of 5 stars4.5/5 (4)

- The World's Most Dangerous Geek: And More True Hacking StoriesFrom EverandThe World's Most Dangerous Geek: And More True Hacking StoriesRating: 4 out of 5 stars4/5 (49)

- What Customers Hate: Drive Fast and Scalable Growth by Eliminating the Things that Drive Away BusinessFrom EverandWhat Customers Hate: Drive Fast and Scalable Growth by Eliminating the Things that Drive Away BusinessRating: 5 out of 5 stars5/5 (1)

- The Fall: The End of Fox News and the Murdoch DynastyFrom EverandThe Fall: The End of Fox News and the Murdoch DynastyRating: 3 out of 5 stars3/5 (4)

- Pit Bull: Lessons from Wall Street's Champion TraderFrom EverandPit Bull: Lessons from Wall Street's Champion TraderRating: 4 out of 5 stars4/5 (17)

- The Formula: How Rogues, Geniuses, and Speed Freaks Reengineered F1 into the World's Fastest Growing SportFrom EverandThe Formula: How Rogues, Geniuses, and Speed Freaks Reengineered F1 into the World's Fastest Growing SportNo ratings yet

- Women's Work: The First 20,000 Years: Women, Cloth, and Society in Early TimesFrom EverandWomen's Work: The First 20,000 Years: Women, Cloth, and Society in Early TimesRating: 4.5 out of 5 stars4.5/5 (191)

- The Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewFrom EverandThe Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewRating: 4.5 out of 5 stars4.5/5 (26)