Professional Documents

Culture Documents

Diopside Based White Porcelain Tiles

Uploaded by

Kerem Alev ZenginoğluOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diopside Based White Porcelain Tiles

Uploaded by

Kerem Alev ZenginoğluCopyright:

Available Formats

(SPAIi\) iB QUALI

DIOPSIDE BASED WHITE PORCELAIN TILES

F. Ka ra and M. Ca va e

Tubi tak Cera mic Resea rch Ce ntre

Anadolu University, Iki Eyl ul Karnpusu, Eskise hir / Tu rke y

INTRODUCTI ON

In th is study, a porcel ain tile bod y containing a substantial amount of alkal ine ea rth

elements was for mulated to form di opside cryst al s (and / or wollastonite crysta ls if

required ) d u ring firi ng. It is thought that less pure raw materials, es pecially clays

containing iron oxide can be used with out substantia lly degrading the whi teness of the

tile since di opside can d issol ve iron in its latti ce by substit uti ng for magnes iu m.

EXPERIMENTAL

The porcelain body wa s fo rmulated by using a frit , Ukrainian clay, quart z, albite,

calcite and a lte red magnesite. The compositional range of the body is given in Tabl e I. The

tri t was ad ded in order to facili tate easy sintering d uring fast firi ng. Although any type

of frit ca n be used, a d iopside formi ng fri t was d evel oped in order to obtain maximum

d iopside formation d uring firing . The frit containe d 5iO" Ca O, and Kp . Industrial

melting of the fri t was carri ed out in a rota ry furnace at I-tOO"C.

65- 75

AhO,

7- 12

CaO

16- 12

M O

4- 10

Na,O

1-3

K,O

1-3

Fc, O, TiO.!

0.30-0.35

The crys ta lline phases that developed during firi ng of the bod y were characterised

by X-ra y d iiiracti on (XRD) and sh rinkage behaviour was followed by a di latometer. The

microstr uct u re of the sintcrcd porcel ain ti le was investigated usi ng ZI scanning electron

microscope. For ind ustrial production trial s, 30 tons o f s pray d ried granules we re

I' o- - ItII

ill QUAU 2002

prepared and 330x330 mm and 300x600 mm size tiles were pressed at 40 MPa . These tiles

were sintered at a peak temperature of 121O"C in an industri al roller kiln for 55 min and

65 min for 330x330 mm and 300x600 mm size tiles, respective ly.

RESULTS

The XRD spectrum of the frit after crys tallisation at 11 30"C in a fast firing furnace

and that of the porcelain tile after sinter ing at 121O"C are given in Fig. 1. Frit crys tallises

mainl y to diopside but some amount of cristobalite also occu rs (Fig. l a). The porcelain tile

bod y contains di opside and quartz as main phases but a trace of cris tobalite is also present

(Fig. Ib).

' bl

.,

I'

__.._;J

r(lco

eCC<I

' 000

t

;;

, 1\

c,

4000

'"

;;;

c

Cll )000

E

c

.J

2000

a '\

I VJL

10 0 0

.J'../'-.

.,

'"

es

"

2 Theta [deg)

C" costcoeme. Q" quartz. unmarked peaks receesem eccsee.

Fi,,-: un' 1. XRD :,palra (a' the dio!,o:.idt>jorlllill,!\ f fit aftt'r crystal/isatiol/ at 1150C (iJ) tilt' porcebnn tilt' aftt" siutt'rillS at

1215 C.

.e

o

30

Time(h)

t c

r-- - --- - - - ----- - - - --- - ----- - ---, 2

"'--- - - --- - - - - - - - - - - - - - - - - - - - - - -----' -to

80

u oo

1200

100 0

f5

80 0

' 00

"

w

c.

.,0

E

ace

0

0

Figure 2. Shrillkas t' bchm.'itlur the di0l':,idl' pMeda i".

1\ ,.. 102

Fig. 2 shows the shrinkage be haviour of the body. There are two vol ume expans ions:

one is at 573"C and the other sta rts at about 1000"C and conti nu es until the onset of

shrinkage at lI20"C. The expans ion seen at 573"C is d ue to the well kn own u-{) qu artz

tr ansformatio n whereas that starti ng at l OOO"C is tho ug ht to res ult from the vo lu me

expansion due to the forma tion of diopsidc from the reacti on of a mixture of qu artz,

magne sium and calcium oxi des. The amount of vo lume expansion d ue to di opsi de

formation is O. 5j{. Before thi s volume expansion, 0.3% volume shrinkage is also evidenced

at around 900"C in Fig. 2. This is att ribu ted to diopside crystallisation fro m the frit. The

di opside crystals formi ng from the fri t act as seeds for furt he r d iopside formation from the

reaction of quartz, magnesium and calcium oxides . Total linear shrinkage was observed

to be 9.5%. Th e SEM micrograph of the sintered tile afte r light etching wit h HF is shown

in Fig. 3. Diopside and quartz crysta ls are embedded in a glassy ma trix. The size of the

d iopsi de cr yst als is less than I .L1m. Some prope rties of the po rce lain ti le prod uced on an

ind ustr ial sca le are listed in Table 2.

Dry strength (kg/em') 13

Fired strength (kg/em') (ISO 10545-4) 615

Water absorption (%)( ISO 10545-3) O.O:!

Thermal expansion coefficient (ISO 10545-8) 6.76x l O-!l

Deep abrasion resistance {mm") (ISO 10545-6) 131

Chemical resistance (ISO 10545-13) UIIA

Colour L ~ 9 5 5 a- -0.56. b- 5.47

The fire d st rengt h of th e new ti le is so mewha t higher than that of commercial

porcelain tiles, which lies be tween 500-550 kg / cm. Th is can be att ributed to a large

am ount of di opside formati on in the composition. Whi ten ess of the tile is also qui te hi gh .

In order to observe the effectiveness of di opside crysta ls on whiteness, a diopside forming

compositio n and a trad itional porcel ain tile composition were prepared with the same

amount of 1'1.',0, (0.33jt,,) and TiO, (0.327<,). The colour values of the di opside form ing

composi tion were L=89,63, .1=-0.37, b=7,50, whereas those of th e tr aditi onal porcelai n tile

composi tion were L=8 1, 13, .1 =-1.21, b=7,96. Thi s is believed to be due to the fact that iron

ions are substi tuted for magne si um ions in the di opside latti ce and thus they have the

l'o- - I h1

Jill QUAU / 2002 CASTELLO" (SI'AI:-I)

valency of +2. [ron ions with --2 valency do not cause colouring. Deep abrasion resistance

is also better than that of comme rcial porcelain tiles, whi ch varies between 139-147 rnrn' .

Similarly to the mechani cal properti es, a large amount of di opside crys tals improves

abrasion resi stance.

CONCLUSIONS

A diopsi de based new porcelain tile has been developed . Thi s new tile can be

produced with high whiteness compa red to conve ntional tiles wh en the sa me amo unt of

impurities is present in the compos ition. Thus, relat ively impure raw mat eri als can be

tolerat ed when prod ucing tiles with hi gh whiteness. The new tile is mechani call y stronger

with higher abras ion resistance. Depending on the CaO/ MgO rati o in the starting

compos ition, diopside, di opside-wol lastoni te and woll astonite conta ini ng tiles can be

produced.

Po.; - 1M

You might also like

- Barrachina, 2018Document7 pagesBarrachina, 2018Iury MoraesNo ratings yet

- Production of Zircon-Free Opaque Wall Tile Frits and Their Use in Ceramic IndustryDocument7 pagesProduction of Zircon-Free Opaque Wall Tile Frits and Their Use in Ceramic Industrytaufiq_hidayat_1982No ratings yet

- This Content Downloaded From 200.129.187.61 On Tue, 02 Aug 2022 12:59:55 UTC:56 UTCDocument4 pagesThis Content Downloaded From 200.129.187.61 On Tue, 02 Aug 2022 12:59:55 UTC:56 UTCGuilherme Dos Santos MoreiraNo ratings yet

- Pyroxene-Based Glass-Ceramics As Glazes For Floor Tiles: Francisco Jose Torres, Javier AlarcónDocument7 pagesPyroxene-Based Glass-Ceramics As Glazes For Floor Tiles: Francisco Jose Torres, Javier AlarcónAHMED DERBESSNo ratings yet

- Hot Corrosion CeramicsDocument8 pagesHot Corrosion Ceramicsnipun718No ratings yet

- Crystallization of Belite - Melilite Clinker Minerals in The Presence of Liquid PhaseDocument5 pagesCrystallization of Belite - Melilite Clinker Minerals in The Presence of Liquid PhaseAnonymous NxpnI6jCNo ratings yet

- Id 131Document2 pagesId 131Vassia TsukalaNo ratings yet

- Propiedades Mecánicas y Químicas de Las Cerámicas de Vidrio de Disilicato de Litio Dopado Con ZR y P en Restauraciones Dentales.Document10 pagesPropiedades Mecánicas y Químicas de Las Cerámicas de Vidrio de Disilicato de Litio Dopado Con ZR y P en Restauraciones Dentales.Jose L LlanosNo ratings yet

- Kokubo, 1990, Apatite Coating On Ceramics, Metals and Polymers Utilizing A Biological ProcessDocument6 pagesKokubo, 1990, Apatite Coating On Ceramics, Metals and Polymers Utilizing A Biological ProcessEvaldo FilhoNo ratings yet

- A New Source For Production of Ceramic Filters - Carvalho, 2013Document3 pagesA New Source For Production of Ceramic Filters - Carvalho, 2013Naiane StocheroNo ratings yet

- Use of Acoustic Energy in Sand Casting oDocument4 pagesUse of Acoustic Energy in Sand Casting oMuhammad MujtabaNo ratings yet

- Precipitation in The Ni-Cu-Base Alloy Monel K-500Document13 pagesPrecipitation in The Ni-Cu-Base Alloy Monel K-500farhadeeNo ratings yet

- Structural Studies On I N D I U M Oxide, Tin Oxideandindium T I N Oxide Thin FilmsDocument25 pagesStructural Studies On I N D I U M Oxide, Tin Oxideandindium T I N Oxide Thin FilmsYasir AliNo ratings yet

- Rheology and Metal Forming of Fire-Refined CopperDocument6 pagesRheology and Metal Forming of Fire-Refined CoppervitordeleteNo ratings yet

- Hot Isostatic Pressing CeramicsDocument4 pagesHot Isostatic Pressing CeramicsradoslavoffNo ratings yet

- Bo Jap 02Document6 pagesBo Jap 02Vivek BelaNo ratings yet

- Chapter 2REVIEW OF RELATED LITERATUREDocument8 pagesChapter 2REVIEW OF RELATED LITERATUREmolecule atomNo ratings yet

- 2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainDocument8 pages2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainFURY FURIONNo ratings yet

- Sintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)Document13 pagesSintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)volkanNo ratings yet

- Faience: An Investigation of The Microstructures Associated With The Different Methods of GlazingDocument12 pagesFaience: An Investigation of The Microstructures Associated With The Different Methods of GlazingAlyaa GamalNo ratings yet

- Preparation of Glass-Ceramics From Red Mud in The Aluminium IndustriesDocument6 pagesPreparation of Glass-Ceramics From Red Mud in The Aluminium Industrieslamia97No ratings yet

- Lost Carbonate Sintering Process For Manufacturing Metal FoamsDocument4 pagesLost Carbonate Sintering Process For Manufacturing Metal FoamssadrezamanNo ratings yet

- Gold Jewellery Casting Technology Design and Defects EliminationDocument7 pagesGold Jewellery Casting Technology Design and Defects EliminationReinol Eko SianturiNo ratings yet

- Sulphur, Spurrite, and Rings in Cement Kilns PDFDocument4 pagesSulphur, Spurrite, and Rings in Cement Kilns PDFAnonymous NxpnI6jC100% (2)

- Sol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsDocument6 pagesSol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsahadsajjadiNo ratings yet

- Synthesis and Characterization of Nanocrystalline Powders For Partially Stabilized Zirconia CeramicsDocument5 pagesSynthesis and Characterization of Nanocrystalline Powders For Partially Stabilized Zirconia Ceramicsamirlove206No ratings yet

- Artículo Docente. Determinación de La Densidad de Un Líquido Con El Método Del PicnómetroDocument6 pagesArtículo Docente. Determinación de La Densidad de Un Líquido Con El Método Del PicnómetroAlejandro Vargas CalderonNo ratings yet

- Clay With SlagDocument8 pagesClay With SlagJose VargasNo ratings yet

- 2007 Bullentin Rel. 2 WearMechanism-DataDocument4 pages2007 Bullentin Rel. 2 WearMechanism-Data1977julNo ratings yet

- Properties of Porous Silica Glasses Prepared Via Sol Gel ProcessDocument5 pagesProperties of Porous Silica Glasses Prepared Via Sol Gel ProcessCaro CuadrasNo ratings yet

- Kurihara 1995Document7 pagesKurihara 1995ryzrouxNo ratings yet

- Precipitation Hardening in Aluminum Alloy 6022: W.F. Miao and D.E. LaughlinDocument6 pagesPrecipitation Hardening in Aluminum Alloy 6022: W.F. Miao and D.E. LaughlinKayode Remi-OlaniyanNo ratings yet

- Silicon Native OxideDocument11 pagesSilicon Native OxideAshwin ChockalingamNo ratings yet

- High Temperature Corrosion of Ni Based Alloy Inconel 740H in Simulated Coal-Ash and Flue-Gas EnvironmentsDocument7 pagesHigh Temperature Corrosion of Ni Based Alloy Inconel 740H in Simulated Coal-Ash and Flue-Gas EnvironmentsAnonymous lmCR3SkPrKNo ratings yet

- Cao, 2016Document16 pagesCao, 2016Iury MoraesNo ratings yet

- Sciencedirect: of MM CoDocument5 pagesSciencedirect: of MM CoSutan PauloNo ratings yet

- Deflocculation of Concentrated Aqueous Clay Suspensions With SodDocument5 pagesDeflocculation of Concentrated Aqueous Clay Suspensions With SodkhosrosaneNo ratings yet

- RetrieveDocument4 pagesRetrieveB.EKICINo ratings yet

- Velten Et Al-2002-Journal of Biomedical Materials ResearchDocument11 pagesVelten Et Al-2002-Journal of Biomedical Materials ResearchjeffreylopezNo ratings yet

- Chandamama, Mar 2011Document4 pagesChandamama, Mar 2011emediageNo ratings yet

- Spectroscopic Ft-Ir Study of Tio Films Prepared by Sol-Gel MethodDocument4 pagesSpectroscopic Ft-Ir Study of Tio Films Prepared by Sol-Gel Methodpneumann123No ratings yet

- Chen 2008Document5 pagesChen 2008Saiffudin AnwarNo ratings yet

- Ftir CaO PDFDocument4 pagesFtir CaO PDFbaharudin.alkimia13No ratings yet

- Egyptian FaienceDocument7 pagesEgyptian FaiencemaduroguyNo ratings yet

- Referensi 1 PDFDocument11 pagesReferensi 1 PDFAlbert Hendrico HutaurukNo ratings yet

- The Effect of Tio Addition On Glass Ceramic PropertiesDocument6 pagesThe Effect of Tio Addition On Glass Ceramic PropertiesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Synthesis of Zeolite LDocument13 pagesSynthesis of Zeolite LSivakumar RadhakrishnanNo ratings yet

- 10 1016@j Jeurceramsoc 2007 04 007Document9 pages10 1016@j Jeurceramsoc 2007 04 007gutierrezcamposd20No ratings yet

- Leucite Porcelain: E-Mail: Lezal@iic - Cas.czDocument4 pagesLeucite Porcelain: E-Mail: Lezal@iic - Cas.czAli AddieNo ratings yet

- Journal of Non-Crystalline Solids: Zhong-Jie Wang, Wen Ni, Yan Jia, Li-Ping Zhu, Xiao-Yan HuangDocument5 pagesJournal of Non-Crystalline Solids: Zhong-Jie Wang, Wen Ni, Yan Jia, Li-Ping Zhu, Xiao-Yan HuangBayu MuhammadNo ratings yet

- Cobre SelenioDocument5 pagesCobre SelenioMauricio E JimenezNo ratings yet

- Open-Pore Glasses and Glass-Ceramics by Sintering of Modified Pyrogenic Silicic AcidsDocument5 pagesOpen-Pore Glasses and Glass-Ceramics by Sintering of Modified Pyrogenic Silicic AcidsAli AddieNo ratings yet

- Kilikoglou Toughening of Ceramic Earthenwares by Quartz IncluDocument8 pagesKilikoglou Toughening of Ceramic Earthenwares by Quartz IncluMinerva DelgadoNo ratings yet

- Ceramics International: Yuanming Lai, Yiming Zeng, Xiaoli Tang, Huaiwu Zhang, Jiao Han, Zihan Huang, Hua SuDocument7 pagesCeramics International: Yuanming Lai, Yiming Zeng, Xiaoli Tang, Huaiwu Zhang, Jiao Han, Zihan Huang, Hua SuSamah SamahNo ratings yet

- Preparation and Characterisation of Self-Flowing Refractory Material Containing 971U Type MicrosilicaDocument6 pagesPreparation and Characterisation of Self-Flowing Refractory Material Containing 971U Type MicrosilicaAhmed Mostafa AL-AboudyNo ratings yet

- Nanoscience of Ancient PigmentDocument3 pagesNanoscience of Ancient Pigmental40No ratings yet

- 04-46 Analysis of Gold-Copper Braze Joint in Glidcop For UHV Components at The APS W.Toter S.SharmaDocument10 pages04-46 Analysis of Gold-Copper Braze Joint in Glidcop For UHV Components at The APS W.Toter S.SharmaKai XuNo ratings yet

- Dry Pressing Refractory Insulating BrickDocument25 pagesDry Pressing Refractory Insulating BrickPawan TiwariNo ratings yet

- B. Ersoy, T. Kavas, A. Evcin, S. Basßpınar, A. Sarıısßık, G. ÖnceDocument9 pagesB. Ersoy, T. Kavas, A. Evcin, S. Basßpınar, A. Sarıısßık, G. Önceİsmail ApaydınNo ratings yet

- Automatic Ingot Feeder For BoundaryDocument5 pagesAutomatic Ingot Feeder For Boundaryieee4mybusinessonlyNo ratings yet

- Crucible DataDocument32 pagesCrucible DataKeith HallNo ratings yet

- MetalsDocument7 pagesMetalschongkee56No ratings yet

- Recycling of Metals From Spent CatalystDocument6 pagesRecycling of Metals From Spent CatalystMohammad YoussefiNo ratings yet

- Alabandite Mineral Data1Document5 pagesAlabandite Mineral Data1BlacksacerdoteNo ratings yet

- Cement and Steel Rates For The Month of July 2013Document1 pageCement and Steel Rates For The Month of July 2013Guru PrasadNo ratings yet

- Properties of Stainless SteelsDocument22 pagesProperties of Stainless Steelsngoclinh87No ratings yet

- Gating System Design For Casting Thin Aluminium Alloy (Al-Si) PlatesDocument10 pagesGating System Design For Casting Thin Aluminium Alloy (Al-Si) PlatesKhin Aung ShweNo ratings yet

- 7075 Aluminium AlloyDocument3 pages7075 Aluminium AlloyjcetmechanicalNo ratings yet

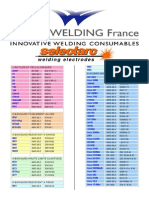

- Electrodes SelectarcDocument138 pagesElectrodes Selectarcfediss2014100% (2)

- Porosity Removal From AluminiumDocument63 pagesPorosity Removal From AluminiumSyeda NailaNo ratings yet

- Catalogo Alu MarketDocument40 pagesCatalogo Alu MarketMiguel Angel Diaz Escobar100% (2)

- Fabshield Offshore 71ni-1Document2 pagesFabshield Offshore 71ni-1Anonymous ejnktktkY7No ratings yet

- Control of SlagDocument12 pagesControl of SlagVinay RajputNo ratings yet

- Vautid 100Document4 pagesVautid 100emad sabriNo ratings yet

- Pulsed Mig Clad and Overlay WeldsDocument16 pagesPulsed Mig Clad and Overlay Weldscentaury2013No ratings yet

- The Tomtor Alkaline Ultrabasic Massif and Related REE-Nb DepositsDocument14 pagesThe Tomtor Alkaline Ultrabasic Massif and Related REE-Nb DepositsFabian MansillaNo ratings yet

- Stainless SteelDocument8 pagesStainless Steelsamitha505No ratings yet

- Manual de Soldadura Vol 3 Aws PDFDocument304 pagesManual de Soldadura Vol 3 Aws PDFColeccionadorMarvel100% (1)

- Solid StateDocument5 pagesSolid StateGadde Gopala KrishnaNo ratings yet

- MDRU PIMS Update 2014 PDFDocument2 pagesMDRU PIMS Update 2014 PDFVictor ValdiviaNo ratings yet

- A 732 - A732M - 02 Equivalencia Ic AstmDocument8 pagesA 732 - A732M - 02 Equivalencia Ic AstmorivaldopenaNo ratings yet

- Seminar ReportDocument19 pagesSeminar Reportvivekr84100% (1)

- On Crystal StructureDocument32 pagesOn Crystal StructureDeathEaterReturnNo ratings yet

- Welding Stainless Steel - Questions and Answers A Guide For Troubleshooting Stainless Steel Welding-Related Problems - AWS (2013)Document266 pagesWelding Stainless Steel - Questions and Answers A Guide For Troubleshooting Stainless Steel Welding-Related Problems - AWS (2013)arnoldbatista55100% (1)

- Outokumpu Stainless - Steel GradesDocument1 pageOutokumpu Stainless - Steel GradesNshuti Rene FabriceNo ratings yet

- Micro Analysis Crystals 1Document15 pagesMicro Analysis Crystals 1nikrouNo ratings yet

- Aluminum As Alloy and DeoxidantDocument5 pagesAluminum As Alloy and DeoxidantlarryjhNo ratings yet

- Heat TreatmentDocument20 pagesHeat Treatmentshanu100% (1)

- Geokimia 1Document24 pagesGeokimia 1Sasmi NopiyaniNo ratings yet