Professional Documents

Culture Documents

Study The Influence of Air Gap Variation On Axial Forces in Axial Flux Permanent Magnet Motor Using 3D FEM

Uploaded by

أسامةبوعزيزOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study The Influence of Air Gap Variation On Axial Forces in Axial Flux Permanent Magnet Motor Using 3D FEM

Uploaded by

أسامةبوعزيزCopyright:

Available Formats

Study the Influence of Air-gap Variation on Axial Forces in Axial

Flux Permanent Magnet Motor Using 3D-FEM

Seyyed Mehdi Mirimani

1

, Abolfazl Vahedi

1

, Fabrizio Marignetti

2

1

Center of Excellence for Power Systems Automation and Operation, Dept. of Electrical Engineering of

Iran University of Science & Technology, Tehran, Iran

2

Department of Electrical and Information Engineering, University of Cassino and Southern Latium, Italy

Abstract This paper describes the effect of air-gap variation on performance

of a 28 pole axial flux permanent magnet motor (AFPM) with concentrated

stator winding. The AFPM is modeled using three-dimensional finite-element

method. This model includes all geometrical and physical characteristics of the

machine components. Use of this accurate modeling makes it possible to obtain

the demanded signals for a very high precision analysis. The rotor of machine

however is likely to be displaced from its original location and cause to air-

gap variation. It is found that the air-gap variation has a detrimental effect on

air-gap flux density and amount of axial forces. Reduction of air-gap increases

the air-gap flux density and consequently increases the amount of axial force

between rotor and stator. This extra force can cause bearing damages and

lifetime reduction.

Keywords: Axial flux permanent magnet (AFPM) motor, air-gap variation,

three-dimensional finite-element method (3D-FEM).

I. Introduction

Axial Flux Permanent Magnet Machines (AFPM) first appeared in the technical literature in

the mid 70s. Soon their fields of application spread widely. Axial flux permanent magnet

(AFPM) machines have been used increasingly in various applications due to their high

efficiency, compact construction and their higher torque at low speed [F. Caricchi et al, 1996],

[A. Parviainen et al, 2005]. AFPM topologies make it possible to design high pole machines.

Thus, it can be directly coupled to the turbines with low-speed, such as wind and hydro turbines

[Y. Chen et al, 2004], [S. M. Hosseini et al, 2008]. Their robust structure and compactness

present high-speed axial-flux machines qualified for distributed generating application [A. S.

Holmes et al, 2005]. It is also a suitable candidate for electric vehicle (EV) and traction [Y.-P.

Yang and D. S. Chuang, 2007].

Most of motors have inbuilt deformity due to manufacturing defects such as unbalance

structure, bearing deficiency and misalignment [Ungtae Kim and Dennis K. Lieu, 2005]. The

rotor of machine however is likely to be displaced from its original location. The displacement

can occur during normal machine operation or during abnormal and fault conditions within the

machine [Jawad Faiz and Siavash Pakdelian, 2006]. This displacement changes the air-gap

length and subsequently affects all the machine characteristics. This fault affects the normal

operation of the machine and leads to motor vibration and decrease the motor lifetime.

Analysis of air-gap deformity in radial flux motors has been the subject of many literatures [S.

Nandi et al, 2005], [Bashir Mahdi Ebrahimi et al, 2008], [Jawad Faiz and Siavash Pakdelian,

2008], [Jawad Faiz et al, 2008]. But, nothing has been reported on the analysis of air-gap

deformity in AFPMs.

' g

g

g

' g

Fig. 1. Schematic representation of rotor displacement in axial flux permanent magnet motor. (a) healthy motor (b)

motor with air-gap deformity.

' o

o

' g

g

Fig. 2. Schematic representation of static air-gap displacement in axial flux permanent magnet motor

However, like the conventional radial flux machines, Because of manufacturing imperfections,

the rotor air-gap variation is inevitable. Consequently, it is of great interest to investigate the

axial force, which tends to bearing defects.

In this paper, a surface mounted axial flux permanent magnet (AFPM) motor with air-gap

variation has been modeled using 3-dimentional finite element method. Magnetic flux density of

air-gap and axial forces between rotor and stator in healthy motor and in fault condition has been

calculated. It is observed that air-gap variation has significant effects on air-gap flux pattern and

axial force of the motor.

II. Air-gap Variation in AFPM

An issue coming up from the fabrication and normal operation of the motor is the displacement

of the rotor with respect to the stator. This fault appears due to inherent mechanical tolerances

and defects in the bearing system that supports the rotor [C. Peter Cho and Barry K. Fussell,

1993].

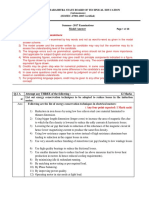

TABLE I

SPECIFICATION OF THE MOTOR

Quantity Value

Rated power(kW) 2.2

No load voltage(V) 210

Rated phase current(A) 3.5

Frequency(Hz) 300

Speed(rpm) 1285

Phase connection

Pole pairs 14

Air gap length(mm) 1.2

Rotor diameter(mm) 206

Remanence of magnets(T) 1.24

Thickness of magnets(mm) 3

Outer diameter of stator(mm) 200

Inner diameter of stator(mm) 116

Slot width(mm) 13.6

Slot height(mm) 40

Number of slots 24

Width of stator back iron(mm) 10.5

Width of rotor back iron(mm) 10

Wire diameter(mm) 1.5

Number of turns per coil 130

Phase resistance at 300Hz() 2.5

Stator inductance(mH) 10

Fig. 3. Three-dimentional FEM model of AFPM

Fig. 2 shows the rotor axial displacement. In such a case, air-gap length uniformly decreases

along the rotor. If the rotor shaft assembly is adequately rigid, then the level of air-gap

displacement remains constant. The air-gap displacement factor is defined as follows:

100

'

=

g

r

ADF

{1}

Where g' is the air-gap length in fault condition, and r is given by:

' g g r =

{2}

Where g is the air-gap length in healthy condition. Air-gap displacement degrees more than 50%

will not be considered in this paper.

III. Motor Specifications

Fig. 3 shows a three-phase, 210-V, 2200-W, 1850-rpm, -connected AFPM machine that was

modeled studying air-gap variation. It consists of a stator with 24 slots and 12 single layer

trapezoidally shaped coils with fractional winding. The Coils with a same color belong to one

phase. The rotor disc consists of 28 magnets of alternating polarity. The machine parameters are

given in Table I [Fabrizio Marignetti et al, 2006], [Fabrizio Marignetti et al, 2008].

IV. Finite Element Simulation

Many literates have demonstrated that accurately analyzing the behavior of Axial Flux PM

Machines is not an easy task because these types of machines are intrinsically 3-D machines

[Fabrizio Marignetti et al, 2008]. Three dimensional finite-element method (FEM) allows a

precise analysis of magnetic devices taking into account geometric details and magnetic

nonlinearity. So, it is an appropriate method for analyzing air-gap variation in AFPMs. Use of

this accurate modeling makes it possible to obtain the demanded signals for a very high precision

analysis. Three-dimensional finite-element analysis (3D-FEA) software FLUX2D/3D by

CEDRAT is used to simulate the motor [CEDRAT Group, 2009]. Fig.3 shows The FEM model

that was used in this paper.

Fig. 4. Three-dimensional mesh model.

Fig. 5. Flux density distribution in the stator

V. Primary Finite Element Results

The center of the stator is fixed at the origin of the global coordinate system, where magnetic

force is evaluated. The center of the rotor is located at the origin of the local coordinate system,

which rotate around the center of the global coordinate system, i.e., the center of the stator, by a

constant step angle. Investigation of airgap variation models was made with the assumptions of a

three-dimensional problem and nonlinear materials. A relatively large ADF of 50% of the

nominal air gap was selected to magnify its effects. Fig. 4 shows mesh diagram of the proposed

motor and as it shows, density of meshes increases near the air-gap in order to a precise

simulation. Whole nodes number is 460,000 in this simulation. This amount of nodes is very

high and will warrant the accuracy of simulation. Fig. 5 demonstrates the flux diagram of stator.

It shows that maximum flux density in hotspots is 2.147 T.

VI. Effect of Air-gap Variation in Air-gap Flux

One of the most important characteristics of the motor is Air-gap flux density. So, it was

simulated under no-load condition to monitor the effect of air-gap variation in this characteristic.

Fig.6 shows the axial component of the no-load air-gap flux density duo to permanent

magnets in healthy and fault conditions. Moreover, the z-component of the no-load air-gap flux

density was computed over a circumference in the middle of air-gap. Fig.7 reports the

waveforms. In addition, maximum flux density of air-gap was computed in different ADF.

Fig. 6. Axial component of the no-load air-gap flux density (a) healthy condition [ADF=0] (b) fault condition

[ADF=0.5]

-1.5

-1

-0.5

0

0.5

1

1.5

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

Angle(rad)

Z

-

c

o

m

p

o

n

e

n

t

o

f

f

l

u

x

d

e

n

s

i

t

y

(

T

)

-

SEF=0

SEF=0.5

Fig. 7. z-component of the no-load air-gap flux density over a circumference in the middle of air-gap

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0 0.1 0.2 0.3 0.4 0.5

ADF

m

a

x

i

m

u

m

v

a

l

u

e

o

f

a

i

r

g

a

p

f

l

u

x

-

-

d

e

n

s

i

t

y

(

T

)

Fig. 8. Maximum value of air-gap flux density

Fig. 9. Schematic representation of axial forces in axial flux permanent magnet motor

It is observed that centricity clearly affects the flux amplitude and its maximum value. The

reason is that the flux path reluctance is mainly determined by the length of the air gap. When the

rotor is acceded to the stator poles vertically, the length of gaps between rotor permanent

magnets and their corresponding stator teeth are reduced. So, as seen in Fig.6, Fig. 7 and Fig. 8

air-gap variation affects flux density considerably and the flux densities and their maximum

values rising in the air-gap.

7 . 25 =

magnets permanent

Fig. 10. Top view of permanent magnets

2140

2145

2150

2155

2160

0 5 10 15 20 25

Anglular position of rotor(degree)

A

x

i

a

l

f

o

r

c

e

(

N

)

Fig. 11. Axial force between rotor and stator

0

500

1000

1500

2000

2500

3000

3500

0 0.1 0.2 0.3 0.4 0.5

ADF

A

x

i

a

l

F

o

r

c

e

(

N

)

Fig. 12. Axial force between rotor and stator

VII. Effect of Air-gap variation in Axial Force Between Rotor and Stator

In axial flux permanent magnet machines, there is an axial force between rotor magnets and

stator teeth. Fig. 9 represents the Schematic of this axial force. Fig 10 shows that the period of

these force fluctuations is equal the angular distance between two identical permanent magnets.

It means that after this amount of rotation, a N pole replaces by another coming one and the

situation of permanent magnets toward the stator teeth becomes similar to the previous position.

The force fluctuations will repeat a same manner in other periods. The period is obtained as

follows:

=

2

360

p

{3}

Where p is number of machine poles. Fig. 11 shows the total magnetic force fluctuates of the

motor in one period. This trend will repeat in other periods. In order to have a simple view for

amount of this force under different ADFs, its mean values was compared.

It observed that rotor displacement, resulting in extra magnetic force between rotor and stator.

In fact, if the air-gap reduces, then the air-gap magnetic field increases. Consequently, attraction

force due to the magnet will be greater, therefore the bearings should withstand a higher amount

of axial forces. Fig. 12 shows mean value of axial force in different value of ADF. It shows that

the value of axial forces rises by increasing the ADF. This is to be expected, since the attractive

magnetic force on the rotor increases rapidly as the air gap decreases. Choice of the bearings for

the motor was done accordance with the primary airgap length and its related force. So, this

amount of stresses that act on the machine will decrease bearings lifetime and cause to bearing

damages.

VIII. Conclusion

The effect of air-gap variation on air-gap flux density and axial forces of a 28 pole AFPM is

investigated through 3-D finite-element analysis. The rotor of machine however is likely to be

displaced from its original location and cause to air-gap variation. It is found that the air-gap

variation has a detrimental effect on air-gap flux density and amount of axial forces. Reduction

of air-gap increases the air-gap flux density and consequently increases the amount of axial force

between rotor and stator. This extra force can cause bearing damages and lifetime reduction.

References

A. Parviainen, M. Niemel, J. Pyrhnen, and L. J. Mantere, Performance comparison between low-speed axial-flux and radial-flux

permanent magnet machines including mechanical constraints, in IEEE Int. Electric Machines and Drives Conf., IEMDC, May 2005.

A. S. Holmes, G. Hong, and K. R. Pullen, Axial-flux permanent magnet machines for micro power generation, J.Microelectromech.Syst.,

vol. 14 no. 1, pp. 5462, Feb. 2005.

Bashir Mahdi Ebrahimi, Jawad Faiz, M. Javan-Roshtkhari, and A. Zargham Nejhad, Static Eccentricity Fault Diagnosis in Permanent

Magnet Synchronous Motor Using Time Stepping Finite Element Method, IEEE Trans. Magnetics, vol. 44 no. 11, pp. 42974300,

November. 2008.

CEDRAT Group, France, Flux3D Users Guide, ver. 10.3 2009.

C. Peter Cho and Barry K. Fussell, Detent Torque and Axial Force Effects In A Dual Air-Gap Axial-Field Brushless Motor, IEEE

Transaction on magnetics, vol. 29 no. 6, pp. 24162418, Nov. 1993.

Fabrizio Marignetti, Giovanni Tomassi, Piergiacomo Cancelliere, Vincenzo Delli Colli, Roberto Di Stefano, Maurizio Scarano,

Electromagnetic and Mechanical design of a Fractional-slot- windings Axial-flux PM synchronous machine with Soft Magnetic Compound

Stator, in IEEE Industry Applications Conference, 2006.

Fabrizio Marignetti, Vincenzo Delli Colli, and Yuri Coia, Design of Axial Flux PM Synchronous Machines Through 3-D Coupled

Electromagnetic Thermal and Fluid-Dynamical Finite-Element Analysis, IEEE Trans. Industrial Electronics, vol. 55 no. 10, pp. 3591

3601, October. 2008.

Y. Chen, P. Pillay, and A. Khan, PM wind generator comparison of different topologies, in IEEE Inustrial Applications Annual Meeting,

October. 2004.

F. Caricchi, F. Crescimbini, F. Mezzetti, and E. Santini, Multistage axial flux PM machine for wheel direct drive, IEEE Trans. Ind. Appl.,

vol. 32 no. 4, pp. 882887, July./ August. 1996.

S. M. Hosseini, M. Agha-Mirsalim, and M. Mirzaei, Design, prototyping, and analysis of low cost axial-flux coreless permanent-magnet

generator, IEEE Trans. Magnetics, vol. 44 no. 1, pp. 7580, January. 2008.

Jawad Faiz, Bashir Mahdi Ebrahimi, Bilal Akin, and Hamid A. Toliyat ,Finite-Element Transient Analysis of Induction Motors Under

Mixed Eccentricity Fault, IEEE Trans. Magn., vol. 44 no. 1, pp. 20042008, January. 2008.

Jawad Faiz and Siavash Pakdelian, Finite-Element Analysis of a Switched Reluctance Motor Under Static Eccentricity Fault, IEEE Trans.

Magn., vol. 42 no. 8, pp. 20042008, August. 2006.

Y.-P. Yang and D. S. Chuang, Optimal design and control of a wheel motor for electric passenger cars, IEEE Trans. Magetics, vol. 43 no.

1, pp. 5161, January. 2007.

Jawad Faiz and Siavash Pakdelian, Diagnosis of Static Eccentricity in Switched Reluctance Motors Based on Mutually Induced Voltages,

IEEE Trans. Magnetics, vol. 44 no. 8, pp. 20292034, August. 2008.

S. Nandi, H. A. Toliyat, and X. Li, Condition monitoring and fault diagnosis of electrical motors-a review, IEEE Trans. Energy

Converters, vol. 20 no. 4, pp. 719729, December. 2005.

Ungtae Kim and Dennis K. Lieu, Effects of Magnetically Induced Vibration Force in Brushless Permanent-Magnet Motors, IEEE Trans.

Magnetics, vol. 41 no. 6, pp. 21642172, June. 2005.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Simulation & Modeling of BLDC MotorDocument20 pagesSimulation & Modeling of BLDC Motorsam clastineNo ratings yet

- Brushless Servo MotorsDocument4 pagesBrushless Servo Motorschidambaram kasiNo ratings yet

- BHEL Training Report On TURBO GENERATORDocument49 pagesBHEL Training Report On TURBO GENERATORArun Rana33% (3)

- y D Starter PDFDocument13 pagesy D Starter PDFnazar750No ratings yet

- Selection of Generator For The Micro Hydro Power PlantDocument5 pagesSelection of Generator For The Micro Hydro Power PlantMuhammad NomanNo ratings yet

- Electrical Handbook by KreatryxDocument309 pagesElectrical Handbook by KreatryxAjay TiwariNo ratings yet

- Course Notes - AC MOTORDocument21 pagesCourse Notes - AC MOTORHarold DuranoNo ratings yet

- Unit - V Synchronous Drives: 1 Variable Frequency ControlDocument22 pagesUnit - V Synchronous Drives: 1 Variable Frequency ControlHaripriya PalemNo ratings yet

- A Study of The Design For The Flux Reversal Machine 221201 011547Document4 pagesA Study of The Design For The Flux Reversal Machine 221201 011547Rana AtharNo ratings yet

- 4 Chimi WangmoDocument3 pages4 Chimi WangmoChimi Wangmo0% (1)

- Basic Elctrical Technology (ELE 101) PDFDocument2 pagesBasic Elctrical Technology (ELE 101) PDFRahul PinnamaneniNo ratings yet

- PUMP Testing SheetDocument3 pagesPUMP Testing SheetAlan Tan Y RNo ratings yet

- Chapter Four Stand by Generator Selection and Installation: Outage Transfer Switch Electrical Load Generator CircuitsDocument23 pagesChapter Four Stand by Generator Selection and Installation: Outage Transfer Switch Electrical Load Generator Circuitsmiheret tadesseNo ratings yet

- Lehe1126 01Document2 pagesLehe1126 01Matías MocilnikarNo ratings yet

- CAA Assistant Director Electrical Test Mcqs by NTS On 12-05-2019 PDFDocument6 pagesCAA Assistant Director Electrical Test Mcqs by NTS On 12-05-2019 PDFdani100% (1)

- Nema ManDocument416 pagesNema Manmetha.d8070No ratings yet

- Ans.-01 Why Single-Phase Induction Motors Are Not Self-Started?Document16 pagesAns.-01 Why Single-Phase Induction Motors Are Not Self-Started?DharamNo ratings yet

- The Golf GTEDocument12 pagesThe Golf GTEwattafilling100% (1)

- DC Ac MidtermDocument81 pagesDC Ac MidtermaaronjameseviscaynoNo ratings yet

- Review On Field Oriented Control of Indu PDFDocument12 pagesReview On Field Oriented Control of Indu PDFSHADAB SYEDNo ratings yet

- Lagerwey's Next Generation of Direct Drive: DurabilityDocument2 pagesLagerwey's Next Generation of Direct Drive: Durabilitytony_abNo ratings yet

- Unit-4-Electrical Machines: Lecture-3 Starting methods of 3-Φ Induction MotorDocument13 pagesUnit-4-Electrical Machines: Lecture-3 Starting methods of 3-Φ Induction MotorPratik SarkarNo ratings yet

- DCDocument3 pagesDCAkhilesh Kumar MishraNo ratings yet

- 2 - Hydro Power and Synchronous MachinesDocument49 pages2 - Hydro Power and Synchronous MachinesvignanbNo ratings yet

- Medium Voltage Induction Motor Protection and Diagnostics: Yi Du Pinjia Zhang Prof. Thomas G. HabetlerDocument61 pagesMedium Voltage Induction Motor Protection and Diagnostics: Yi Du Pinjia Zhang Prof. Thomas G. HabetlervladalucarDNo ratings yet

- File 11. Power Gen Course ExcercisesDocument9 pagesFile 11. Power Gen Course Excercisesnabil160874No ratings yet

- 2017 Summer Model Answer PaperDocument28 pages2017 Summer Model Answer Paper52. YASHRAJ RANSHURNo ratings yet

- Drawings 2Document56 pagesDrawings 2Aditya SinghNo ratings yet

- Working and Applications of ESC-Electronic Speed ControlDocument11 pagesWorking and Applications of ESC-Electronic Speed ControlNavin KhatriNo ratings yet