Professional Documents

Culture Documents

Carbon Fiber Composite

Uploaded by

Hendra GantinaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbon Fiber Composite

Uploaded by

Hendra GantinaCopyright:

Available Formats

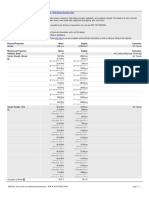

Overview of materials for Epoxy/Carbon Fiber Composite

http://matweb.com/search/DataSheet.aspx?MatGUID=39e40851fc164b...

Advertise with MatWeb!

Data sheets for over 105,000 metals, plastics, ceramics, and composites.

HOME SEARCH TOOLS SUPPLIERS FOLDERS ABOUT US FAQ LOG IN

Searches: Advanced | Category | Property | Metals | Trade Name | Manufacturer | Recently Viewed Materials

epoxy

Overview of materials for Epoxy/Carbon Fiber Composite

Categories: Polymer; Thermoset; Epoxy; Epoxy/Carbon Fiber Composite

Material

Notes:

This property data is a summary of similar materials in the MatWeb database for the category "Epoxy/Carbon

Fiber Composite". Each property range of values reported is minimum and maximum values of appropriate

MatWeb entries. The comments report the average value, and number of data points used to calculate the

average. The values are not necessarily typical of any specific grade, especially less common values and those

that can be most affected by additives or processing methods.

Vendors:

No vendors are listed for this material. Please click here if you are a supplier and would like information on how to

add your listing to this material.

Printer friendly version

Download as PDF

Download to Excel (requires Excel and Windows)

Add to Folder:

Export data to your CAD/FEA program

Physical Properties

Density

Water Absorption

Viscosity

Metric

1.15 - 2.25 g/cc

0.800 - 3.90 %

25000 - 450000 cP

5000 - 35000 cP

English

0.0415 - 0.0813 lb/in

0.800 - 3.90 %

25000 - 450000 cP

5000 - 35000 cP

@Temperature 60.0 - 60.0 C

@Temperature 140 - 140 F

Linear Mold Shrinkage

0.000 cm/cm

0.000 in/in

Average value: 0.000 cm/cm Grade Count:4

Mechanical

Properties

Hardness, Barcol

Tensile Strength,

Ultimate

Tensile Strength, Yield

Metric

English

Comments

60.0 - 65.0

50.0 - 2100 MPa

60.0 - 65.0

7250 - 305000 psi

Average value: 63.3 Grade Count:3

Average value: 760 MPa Grade Count:22

4.62 - 2650 MPa

2.965 - 2137 MPa

670 - 384000 psi

430.0 - 309900 psi

Average value: 1080 MPa Grade Count:40

Average value: 945 MPa Grade Count:19

@Temperature -59.0 - 177 C

@Temperature -74.2 - 351 F

0.500 - 11.0 %

6.60 - 520 GPa

5.30 - 140 GPa

0.500 - 11.0 %

957 - 75400 ksi

769 - 20300 ksi

@Temperature -55.0 - 177 C

@Temperature -67.0 - 351 F

110 - 2000 MPa

515 - 1448 MPa

16000 - 290000 psi

74700 - 210000 psi

@Temperature 71.0 - 90.0 C

@Temperature 160 - 194 F

6.41 - 199 GPa

37.0 - 191 GPa

930 - 28900 ksi

5370 - 27700 ksi

@Temperature 71.0 - 90.0 C

@Temperature 160 - 194 F

50.0 - 1720 MPa

7250 - 249000 psi

Average value: 829 MPa Grade Count:54

350 - 1786 MPa

50800 - 259000 psi

Average value: 888 MPa Grade Count:26

@Temperature -59.0 - 150 C

@Temperature -74.2 - 302 F

Elongation at Break

Modulus of Elasticity

Flexural Yield Strength

Flexural Modulus

Compressive Yield

Strength

1 of 3

0/0

Comments

Average value: 1.47 g/cc Grade Count:33

Average value: 2.87 % Grade Count:3

Average value: 242000 cP Grade Count:6

Average value: 20000 cP Grade Count:3

Average value: 1.94 % Grade Count:3

Average value: 105 GPa Grade Count:59

Average value: 86.9 GPa Grade Count:18

Average value: 915 MPa Grade Count:32

Average value: 967 MPa Grade Count:9

Average value: 75.9 GPa Grade Count:30

Average value: 101 GPa Grade Count:8

11/15/2014 8:03 PM

Overview of materials for Epoxy/Carbon Fiber Composite

Compressive Modulus

Shear Modulus

Shear Strength

http://matweb.com/search/DataSheet.aspx?MatGUID=39e40851fc164b...

8.20 - 138 GPa

36.0 - 119.3 GPa

1190 - 20000 ksi

5220 - 17300 ksi

@Temperature -59.0 - 130 C

@Temperature -74.2 - 266 F

3.00 - 5.00 GPa

2.00 - 2.40 GPa

435 - 725 ksi

290 - 348 ksi

@Temperature 130 - 130 C

@Temperature 266 - 266 F

30.0 - 120 MPa

26.2 - 124 MPa

4350 - 17400 psi

3800 - 18000 psi

@Temperature -55.0 - 177 C

@Temperature -67.0 - 351 F

Izod Impact, Notched

8.00 - 15.0 J/cm

15.0 - 28.1 ft-lb/in

Electrical Properties

Electrical Resistivity

Metric

100 - 1.30e+13 ohm-cm

Thermal Properties

CTE, linear

CTE, linear,

Transverse to Flow

Specific Heat Capacity

Thermal Conductivity

Maximum Service

Temperature, Air

Glass Transition Temp,

Tg

Processing

Properties

Processing

Temperature

Cure Time

Metric

-0.700 - 29.7 m/m-C

2.10 - 225 m/m-C

Average value: 72.5 GPa Grade Count:25

Average value: 84.5 GPa Grade Count:11

Average value: 3.83 GPa Grade Count:3

Average value: 2.20 GPa Grade Count:2

Average value: 74.6 MPa Grade Count:44

Average value: 57.4 MPa Grade Count:22

Average value: 10.4 J/cm Grade Count:4

English

Comments

100 - 1.30e+13 ohm-cm Average value: 1.00e+12 ohm-cm Grade Count:5

English

-0.389 - 16.5 in/in-F

1.17 - 125 in/in-F

Comments

Average value: 9.09 m/m-C Grade Count:10

Average value: 82.5 m/m-C Grade Count:3

1.00 - 1.20 J/g-C

0.239 - 0.287 BTU/lb-F

0.220 - 400 W/m-K 1.53 - 2780 BTU-in/hr-ft-F

120 - 300 C

248 - 572 F

Average value: 1.13 J/g-C Grade Count:3

Average value: 78.8 W/m-K Grade Count:12

Average value: 176 C Grade Count:9

76.1 - 170 C

169 - 338 F

Average value: 107 C Grade Count:7

Metric

English

Comments

127 - 166 C

260 - 330 F

Average value: 143 C Grade Count:7

5.00 - 10.0 min

5.00 - 10.0 min

0.0833 - 0.167 hour

0.0833 - 0.167 hour

Average value: 7.50 min Grade Count:3

Average value: 7.50 min Grade Count:1

@Temperature 138 - 138 C

@Temperature 280 - 280 F

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistent format. Users requiring

more precise data for scientific or engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent units. We advise

that you only use the original value or one of its raw conversions in your calculations to minimize rounding error. We also ask that you refer to MatWeb's terms of use regarding

this information. Click here to view all the property values for this datasheet as they were originally entered into MatWeb.

Users viewing this material also viewed the following:

Overview of materials for Epoxy, Molded, Glass Fiber Filler

Cytec Thornel P-55 Carbon Fiber/Epoxy Advanced Composite System

Overview of materials for Epoxy Cure Resin

Goodfellow Carbon/Epoxy Composite Sheet

Cytec Thornel P-120 Carbon Fiber/Epoxy Advanced Composite System

O1780 / 77904

Subscribe to Premium Services

Searches: Advanced Composition Property Material Type Manufacturer Trade Name UNS Number

Other Links: Advertising Submit Data Database Licensing Web Design & Hosting Trade Publications

Supplier List Unit Converter Reference Links Help Contact Us Site Map FAQ Home

2 of 3

11/15/2014 8:03 PM

Overview of materials for Epoxy/Carbon Fiber Composite

http://matweb.com/search/DataSheet.aspx?MatGUID=39e40851fc164b...

MatWeb.com

Follow

Like 1,709

Please read our License Agreement regarding materials data and our Privacy Policy. Questions or comments about MatWeb? Please contact us at

webmaster@matweb.com. We appreciate your input.

The contents of this web site, the MatWeb logo, and "MatWeb" are Copyright 1996-2014 by MatWeb, LLC. MatWeb is intended for personal, non-commercial use.

The contents, results, and technical data from this site may not be reproduced either electronically, photographically or substantively without permission from

MatWeb, LLC.

3 of 3

11/15/2014 8:03 PM

You might also like

- HDPE-MaterialData 78281Document2 pagesHDPE-MaterialData 78281tayyabmubarik2417No ratings yet

- Lushan L-5R Polyethylene Copolymer Adhesive For Steel Pipe CoatingDocument2 pagesLushan L-5R Polyethylene Copolymer Adhesive For Steel Pipe CoatingelsobkiNo ratings yet

- Overview of Materials For Polypropylene, Extrusion Grade: To View All Available Suppliers For This MaterialDocument2 pagesOverview of Materials For Polypropylene, Extrusion Grade: To View All Available Suppliers For This Materialvongoctu2016No ratings yet

- Overview of Materials For PVC, High Impact: To View All Available Suppliers For This MaterialDocument1 pageOverview of Materials For PVC, High Impact: To View All Available Suppliers For This Materialvongoctu2016No ratings yet

- Sandvik 316 Plate, Sheet and CoilDocument2 pagesSandvik 316 Plate, Sheet and CoilJesús Leal CarvajalinoNo ratings yet

- MaterialData 14827Document1 pageMaterialData 14827vakilgaurangiNo ratings yet

- Overview of Materials For PVC, Extruded: To View All Available Suppliers For This MaterialDocument2 pagesOverview of Materials For PVC, Extruded: To View All Available Suppliers For This Materialvongoctu2016No ratings yet

- Astm A228Document2 pagesAstm A228Rakesh S IndiaNo ratings yet

- PCB BookletDocument16 pagesPCB BookletsoybonNo ratings yet

- Special Metals NIMONIC® Alloy 90: Categories: Material NotesDocument3 pagesSpecial Metals NIMONIC® Alloy 90: Categories: Material NotesDragomirescu AlinaNo ratings yet

- Lead Free GuideDocument2 pagesLead Free Guidebeach_lover_1970No ratings yet

- Aluminum 2011 T6Document7 pagesAluminum 2011 T6Giovanni FantinatiNo ratings yet

- Aluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument3 pagesAluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum Alloyrezaeibehrouz100% (1)

- TitaniumDocument2 pagesTitaniumAbhishek JhaNo ratings yet

- MaterialData 81691Document2 pagesMaterialData 81691Carlos LorenzanaNo ratings yet

- Fault Analysis of High Voltage Power Transformer Using Dissolved Gas AnalysisDocument9 pagesFault Analysis of High Voltage Power Transformer Using Dissolved Gas AnalysisCarlos JaraNo ratings yet

- Aisi 316Document2 pagesAisi 316denihendrawanNo ratings yet

- AISI 4140 - 42Cr4Mo2Document2 pagesAISI 4140 - 42Cr4Mo2rajbir_singh75% (4)

- AMS 4640 - MatwebDocument1 pageAMS 4640 - Matwebanil610No ratings yet

- Corundum, Aluminum Oxide, Alumina, 99Document3 pagesCorundum, Aluminum Oxide, Alumina, 99Danielle FernandesNo ratings yet

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument3 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyBea Dri HdezNo ratings yet

- Caldon Lefm 240ci Ultrasonic Flow Meters: Integral Manifold DesignDocument6 pagesCaldon Lefm 240ci Ultrasonic Flow Meters: Integral Manifold DesignJim LimNo ratings yet

- TC Colorcode PDFDocument7 pagesTC Colorcode PDFPatrick MonteroNo ratings yet

- PERFORMANCE GUARANTEE REPORT Rev.0Document7 pagesPERFORMANCE GUARANTEE REPORT Rev.0Omar WardehNo ratings yet

- Energy Efficiency & ConservationDocument46 pagesEnergy Efficiency & ConservationOm PrakashNo ratings yet

- Ductile Iron Grade 60-40-18, Low Temperature ServiceDocument2 pagesDuctile Iron Grade 60-40-18, Low Temperature Servicevamsi patnalaNo ratings yet

- Zamak 5Document1 pageZamak 5san moedanoNo ratings yet

- Jain PE Gas Piping SystemDocument4 pagesJain PE Gas Piping Systemkishore@scribdNo ratings yet

- MaterialData - 14076 HDS H13Document2 pagesMaterialData - 14076 HDS H13Amol KulkarniNo ratings yet

- Aisi 1043 Steel - Hot Rolled Bar (Uns g10430)Document1 pageAisi 1043 Steel - Hot Rolled Bar (Uns g10430)feltofsnakeNo ratings yet

- OptiFuel Tech Offer 2022.2Document13 pagesOptiFuel Tech Offer 2022.2Andrew ShortlesNo ratings yet

- Sulzer Brochure CPE en LDocument19 pagesSulzer Brochure CPE en Lphantuan080213No ratings yet

- Overview of Materials For Thermoset Polyurethane Foam, UnreinforcedDocument4 pagesOverview of Materials For Thermoset Polyurethane Foam, Unreinforcedvaratharajan g rNo ratings yet

- Alluminium SheetsDocument7 pagesAlluminium SheetsVaibhav ShuklaNo ratings yet

- Actchem 85 RST: Product DataDocument1 pageActchem 85 RST: Product DatavladimirNo ratings yet

- Pulleys - Diameters and SpeedDocument7 pagesPulleys - Diameters and SpeedandysupaNo ratings yet

- FCCDocument69 pagesFCCanshug1016No ratings yet

- 4140 HTDocument2 pages4140 HTwillys8No ratings yet

- PP-R Pipe GradeDocument6 pagesPP-R Pipe GradeRAJESHNo ratings yet

- 1c6g5spkr 259575Document1 page1c6g5spkr 259575vladimirNo ratings yet

- Minfm35736 en 10273 Grade p295gh Normalized or Normalized Formed NDocument7 pagesMinfm35736 en 10273 Grade p295gh Normalized or Normalized Formed Nmh hNo ratings yet

- RefrateckDocument21 pagesRefrateckMagesh KumarNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data Sheetducchinh080No ratings yet

- Aisi E 52100 Steel: Advertise With Matweb!Document2 pagesAisi E 52100 Steel: Advertise With Matweb!ankitsarvaiyaNo ratings yet

- MEP Presentation - BSNLDocument64 pagesMEP Presentation - BSNLkamal_muralikumarNo ratings yet

- Qualitek 381F No Clean Flux: Technical Specifications Technical Data SheetDocument4 pagesQualitek 381F No Clean Flux: Technical Specifications Technical Data SheetteknoartistNo ratings yet

- Non-Oriented Fully Process Electrical Steel - ASTMDocument28 pagesNon-Oriented Fully Process Electrical Steel - ASTMhpham2005No ratings yet

- Andrew CF141T 50Document2 pagesAndrew CF141T 50sfynksNo ratings yet

- Understanding DGADocument37 pagesUnderstanding DGAdiakonos1984No ratings yet

- MaterialData 11916 2Document1 pageMaterialData 11916 2Muhammad Shena GumilangNo ratings yet

- Overview of Materials For Low Carbon Steel: CategoriesDocument6 pagesOverview of Materials For Low Carbon Steel: CategoriesAmin Ali AminNo ratings yet

- 35 Standard Gray Iron Test Bars, As CastDocument1 page35 Standard Gray Iron Test Bars, As CastEdward Elric2No ratings yet

- SensoNODE Pressure Sensor BulletinDocument2 pagesSensoNODE Pressure Sensor BulletinJaimeEnriquePadillaPobleteNo ratings yet

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- 16.efficiency Management Sytems PresentationsDocument67 pages16.efficiency Management Sytems Presentationsrahul100% (1)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- General Ser Vice Ball Valves: GB SeriesDocument13 pagesGeneral Ser Vice Ball Valves: GB SeriesRyan DuhonNo ratings yet

- 12th STD Chemistry Vol 2 EM WWW - Tntextbooks.inDocument328 pages12th STD Chemistry Vol 2 EM WWW - Tntextbooks.inSujatha VaradarajanNo ratings yet

- Separation: EngineeringDocument13 pagesSeparation: EngineeringandriNo ratings yet

- Project ANSYS WORMDocument5 pagesProject ANSYS WORMAditya DeyNo ratings yet

- Engineering Room Data SheetDocument1 pageEngineering Room Data SheetquycoctuNo ratings yet

- Science EarthquakeDocument3 pagesScience Earthquakexhem zeusNo ratings yet

- Direct Displacement-Based DesignDocument21 pagesDirect Displacement-Based DesignAmal OmarNo ratings yet

- Working Design of Single AnglesDocument2 pagesWorking Design of Single AnglesAnonymous 1BdR0EQgbu100% (1)

- Force in A Statically Determinate Cantilever TrussDocument12 pagesForce in A Statically Determinate Cantilever TrussIkhwan Z.86% (7)

- Seismic Reflection Data: What It Is, How It Can Be Used, & An Application at Elk Hills, CADocument25 pagesSeismic Reflection Data: What It Is, How It Can Be Used, & An Application at Elk Hills, CAvishnurajNo ratings yet

- Wnk2018 Article CFDAnalysisOfShip-To-ShipHydroDocument18 pagesWnk2018 Article CFDAnalysisOfShip-To-ShipHydroIszysax MediaNo ratings yet

- Вертикальный насос - GVSO - 0512 PDFDocument8 pagesВертикальный насос - GVSO - 0512 PDFMehmet ArvasiNo ratings yet

- Coupling Type TSEDocument4 pagesCoupling Type TSEAgus SunaryoNo ratings yet

- WWW - Jeeneetbooks.in: JEE (Main) 2021Document8 pagesWWW - Jeeneetbooks.in: JEE (Main) 2021VallabhNo ratings yet

- En 60068-2-27Document35 pagesEn 60068-2-27Raki Rock100% (1)

- Assignment Corrosion RustingDocument5 pagesAssignment Corrosion RustingADEBISI JELEEL ADEKUNLE100% (1)

- Maxifloor MFT 323 SL Epoxy CoatingDocument2 pagesMaxifloor MFT 323 SL Epoxy CoatinganggaNo ratings yet

- Tsymbal, Zutic - SpintronicsHandbook (2019)Document619 pagesTsymbal, Zutic - SpintronicsHandbook (2019)Alessandro Muzi FalconiNo ratings yet

- Project Zubair Mishrif DGS Expansion Technical Query N. 2510-TQ-C12-ENI-F-0003Document4 pagesProject Zubair Mishrif DGS Expansion Technical Query N. 2510-TQ-C12-ENI-F-0003mangesh patilNo ratings yet

- Mechanical Processes and Equipments MP - C9Document61 pagesMechanical Processes and Equipments MP - C9PHƯƠNG ĐẶNG YẾNNo ratings yet

- Design of Machine Elements - II (10me62)Document271 pagesDesign of Machine Elements - II (10me62)swetha shree chavan m100% (1)

- Special Relativity: What Time Is It?: Michael Fowler, Physics Department, UvaDocument6 pagesSpecial Relativity: What Time Is It?: Michael Fowler, Physics Department, UvaEdgar CalvaNo ratings yet

- Lecture 01Document31 pagesLecture 01nghaNo ratings yet

- HCH111, Ionic Equilibrium, 2022Document164 pagesHCH111, Ionic Equilibrium, 2022Kelvin pfebveNo ratings yet

- 06 Tutorial EM WavesDocument2 pages06 Tutorial EM WavesmukeshNo ratings yet

- Introduction To Ferrite Nano ParticlesDocument42 pagesIntroduction To Ferrite Nano Particleskhan126100% (2)

- Wadada Hydel Techgeneral 2021Document36 pagesWadada Hydel Techgeneral 2021Hamza IzharNo ratings yet

- Controlled Polymers For Pigment DispersantsDocument9 pagesControlled Polymers For Pigment Dispersantstrường phạmNo ratings yet

- Cooling TowersDocument2 pagesCooling TowersFrancis DacutananNo ratings yet