Introduction to Geometric

Dimensioning and Tolerancing (GD&T)

Based on ASME

Y14.5M 1994 standard

�Feature

A feature is a general term applied to a

physical portion of a part, such as a surface,

hole, slot, boss, tab, etc.

�Feature of Size

A feature of size (FOS) is one cylindrical or

spherical surface, or a set of 2 opposed

elements or parallel surfaces, associated

with a size dimension.

An axis, median plane or center point can be

derived from a feature of size.

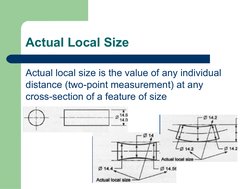

�Actual Local Size

Actual local size is the value of any individual

distance (two-point measurement) at any

cross-section of a feature of size

�Actual Mating Envelope (AME)

Defined according to the type of feature of

size being considered

AME of an external feature of size is a

similar perfect feature counterpart of the

smallest size that can be circumscribed

around the feature so that it just contacts the

surfaces at the highest points. Eg. Smallest

cylinder or two parallel planes at a minimum

separation

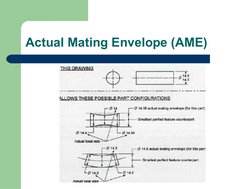

�Actual Mating Envelope (AME)

�Actual Mating Envelope (AME)

AME of an internal feature of size is a

similar perfect feature counterpart of the

largest size that can be inscribed within the

feature so that it just contacts the surfaces at

the highest points. Eg. Largest cylinder or

two parallel planes at a maximum separation

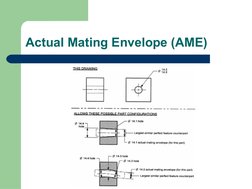

�Actual Mating Envelope (AME)

�Actual Mating Envelope (AME)

AME is a variable value: it is derived from an

actual part

If a feature of size is controlled by a

positional or orientation tolerance with the

MMC or LMC modifier, the AME is relative to

the appropriate datums

�Actual Mating Envelope (AME)

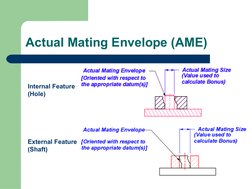

Internal Feature

(Hole)

External Feature

(Shaft)

�Feature Control Frame

A series of compartments containing symbols

and values that describe the geometric

tolerance of a feature. The order and purpose

of these compartments follow a consistent

standard.

�Feature Control Frame: Components

1.

2.

3.

Geometric characteristic being controlled.

Feature tolerance value

Datums to reference

�Datum Reference Frame (DRF)

Frame of reference to which all

requirements are attached.

In geometric tolerancing, we can relate

engineering, manufacturing and inspection

together by using this DRF.

Three planes are called primary plane,

secondary plane and tertiary plane.

�Datum Reference Frame (DRF)

�Datum Reference Frame (DRF)

Datums and DRF indicate the origin of a dimensional

relationship to a toleranced feature of a part.

True geometric counterpart (TGC) of datum feature

actually establishes the datum.

Being theoretical, measurements cannot be made

from the true geometric counterpart. Hence,

simulated datums are assumed to exist and be

simulated with manufacturing/inspection equipment.

Measurements then originate from the simulated

datums and not from the features themselves.

�Datum Reference Frame (DRF)

�DRF Defines Design Intent

�DRF Defines Design Intent

�Datum Features without Size

�Datum Features without Size

�Datum Features with Size

�Datum Features with Size: TGC

�Placement of Datum Feature Symbol

�Datum: Pattern of Features

The Y14.5 standard tells us we can use a

pattern of features to establish a datum or

datums.

�Datum: Pattern of Features

Unfortunately, the explanation in the Standard only covers a

pattern of holes at MMC. There is no support for using a

pattern of features of size RFS.

Where two parallel holes are used as a pattern to help

establish a datum reference frame, it is pretty certain that two

datum planes will result - one plane through the two holes and

a second plane midway between the holes.

Once more than two holes are used as a pattern to establish a

datum, the resulting datum reference frame is unclear.

Recommendation: Avoid using a pattern of more than two

holes to establish datums when referenced RFS.

�Single Datum from Two Features

�Datum Targets

�Datum Targets

�Taylor Principle

Also known as Envelope Principle or Rule

#1

Unless otherwise specified, the limits of size

of a feature prescribe the extent within which

variations of geometric form, as well as size,

are allowed. This control applies solely to

individual features of size.

Does not apply to features left in the "as

furnished" condition (eg. stock)

�Taylor Principle

�Basic Dimension

A theoretically perfect, linear or angular

dimension, which serves to specify

(1) The form, and the orientation and location of

tolerance zones relative to one another and

relative to specified DRFs

(2) The mutual orientation and location of

datums, and

(3) The mutual orientation and location of datum

targets.

�Symbology

�Straightness (Line element)

Tolerance zone between 2 parallel lines

Value must be smaller than size tolerance

Material modifier cannot be applied

Datum cannot be referenced

�Straightness (Axis/Median plane)

Tolerance zone is cylindrical or 2 parallel

planes.

Value must be smaller than size tolerance.

Material modifier can be applied.

Datum cannot be referenced.

�Straightness (Axis/Median plane)

Median plane or (median) axis is very difficult

(and hence expensive) to determine.

Can only be applied to features of size.

Differentiated from Straightness of line

elements by positioning the FCF differently.

�Straightness of Median Plane

�Straightness of Cylindrical Axis

�Straightness of Cylindrical Surface

�Flatness

Tolerance zone between 2 parallel planes

Material modifier cannot be applied

Datum cannot be referenced

0.0 0 1

p a r al l e l

p lanes

1.000 ' 0.002

0 .0 01

�Straightness/Flatness: Unit Basis

Flatness and straightness on a unit basis are

good controls to use when you don't want an

abrupt change in a surface.

If you don't limit the overall variation,

however, a larger than expected out of

flatness or straightness may result.

�Straightness/Flatness: Unit Basis

The maximum radius of

curvature allowed by the

flatness of 0.2/50 is:

R2 = 252 + (R - .2)2

R = 1562.6

Solving the other

triangle for B:

1562.62 - 1002 = B2

B = 1559.4

Therefore the maximum

out of flatness could be:

R - B = 3.2

�Straightness/Flatness: Unit Basis

To avoid this unintended accumulation of

tolerance, it is usually best to include an overall

flatness control when applying flatness or

straightness on a unit basis.

�Circularity (Roundness)

On a cylindrical/conical feature: Applies to a

cross-section obtained as a result of the

intersection by any plane perpendicular to a

common axis.

On a sphere: Applies to a cross-section

obtained as a result of the intersection by

any plane passing thru a common center.

�Circularity (Roundness)

Tolerance zone bounded by two concentric

circles.

Material modifier cannot be applied.

Datum cannot be referenced.

Value should be smaller than size

tolerance.

�Circularity (Roundness)

�Cylindricity

Tolerance zone bounded by two concentric

cylinders within which the surface must lie.

3D counterpart of 2D circularity.

Material modifier cannot be applied.

Datum cannot be referenced.

Value should be smaller than size tolerance.

�Cylindricity

�Perpendicularity

A surface, median plane, or axis at right

angles to the datum plane or axis.

Automatically controls flatness.

Datum must be referenced.

Datum may be modified.

Material modifier may be applied.

�Perpendicularity

�Perpendicularity Tangent Plane

�Perpendicularity Axis of Cylinder

�Angularity

A surface, median plane or axis at a specified

angle (other than 0 or 90) from a datum plane or

axis. Can have more than one datum specified.

�Parallelism

The condition of a surface equidistant at all

points from a datum plane, or an axis

equidistant along its length to a datum axis.

�Parallelism

�Runout or Circular Runout

A 2D geometric tolerance that controls the

form, orientation, and location (but not size)

of each element of a cylindrical part as it

rotates about a datum axis.

As the part rotates 360 about the datum

axis, the error must be within the tol limit.

Datum must be specified but material

modifier cannot be applied.

�Circular Runout

Circular runout does not protect

against barrelling or waisting

�Circular Runout

Circular runout does not protect against sphericity or

conicity. Nor does it locate the surface.

�Total Runout

A 3D geometric tolerance that controls the

form, orientation, and location (but not size)

of the entire length of a cylindrical part as it

rotates about a datum axis.

As the part rotates 360 about the datum

axis, the error must be within the tol limit.

Datum must be specified but material

modifier cannot be applied.

�Total Runout

Total runout controls cumulative variation of

circularity, cylindricity, straightness, coaxiality,

angularity, taper, and profile when it is applied

to surfaces constructed around a datum axis.

�Total Runout

When it is applied to surfaces constructed at

right angles to a datum axis, it controls

perpendicularity (and thereby flatness).

�Runout: Straightness of Shafts

Straightness of an axis on an RFS basis will be

functional but may cause problems in inspection.

The straightness control automatically provided by

Rule #1 and the size tolerance is an alternative.

Since size tolerances on shafts are usually tight to

assure good fit in bearings, this approach frequently

results in a straightness requirement that is tighter

than required. This is especially true when the

length/diameter ratio is large. Also, Rule #1 does not

apply for diameters left "as furnished".

Runout callout with datum targets is an alternative.

�Runout: Straightness of Shafts

The datum targets are located where the shaft contacts

the bearings. Circular runout controls the circularity and

concentricity of each slice of the feature. If the shaft is

out of straight, some slices will be eccentric to the

datum axis and will show up in the inspection.

�Position

A 3-D location tolerance that describes the

exact location with respect to a datum

reference.

Sometimes, when a pattern of features carry

a position tolerance, then a datum reference

may be omitted. It then controls the individual

features to each other.

�Position: Cylindrical Feature

For a cylindrical feature (of size), typically, a

symbol is specified with the tolerance,

indicating a cylindrical tolerance zone for the

axis of the actual mating envelope of the

feature.

2 datum planes may be referenced for

locating the feature in a plane perpendicular

to its axis. Another plane may be referenced

for perpendicularity.

Alternately, datum axes may be specified.

�Position: Cylindrical Feature

�Position: Cylindrical Feature

�Position: Single Planar Surface

For a single planar surface, the position

tolerance specifies a tolerance zone between

two parallel planes located to the datum and

oriented parallel to it, within which the

surface must lie.

An additional datum plane may be

referenced for perpendicularity.

Same as a profile of a surface control.

�Position: Single Planar Surface

�Position: 2 Opposed Planar Surfaces

For two opposed planar surfaces (planar

feature of size), the position tolerance

specifies a tolerance zone between two

parallel planes located to the datum and

oriented parallel to it, within which the

median of the actual mating envelope of the

feature of size must lie.

An additional datum plane may be

referenced for perpendicularity.

�Position: 2 Opposed Planar Surfaces

�Position

Material modifier may be applied for position

control of features of size.

Datum features of size, if specified, may be

modified.

�Composite Position Tolerance

�Composite Position Tolerance

�Composite Position Tolerance

�Compound Position Tolerance

�Projected Tolerance Zone

Generally used for threaded holes and holes that

will receive a pin (usually a press fit).

Concern is that the screw or pin projecting from

the hole might interfere with the surface of the

clearance hole in the mating part.

More important to know where stud or fastener

will be rather than where hole or tapped hole is.

Projected value is usually max thickness of the

mating part or max height of the pin or stud.

�Projected Tolerance Zone

�Concentricity

A 3-D location tolerance that describes the

location of opposing points in cylindrical

features with respect to a datum reference.

Controls median points. Hence, maybe

expensive to check.

Datum axis must be specified; cant be

modified.

Feature tolerance cant be modified.

Concentricity ignores the size, roundness

and cylindricity of the feature.

�Concentricity

�Symmetry

A 3-D location tolerance that describes the

location of opposing points with respect to a

datum reference.

Controls median points. Hence, maybe

expensive to check.

Datum plane must be specified; cant be

modified.

Feature tolerance cant be modified.

�Symmetry

�Symmetry vs. Position

�Profile

A tolerancing method of controlling irregular

surfaces, lines, arcs or normal planes.

Controls form, orientation, location and size.

Hence, it is the most powerful control.

The profile tolerance specifies a uniform

boundary along the true profile within which

the elements of the surface must lie.

�Profile

�Profile

Datums can be specified and modified.

Tolerance cannot be modified.

Profiles can be individual line elements

(Profile of a line) or the entire surface (Profile

of a surface)

Referencing datums (to lock all relevant

DOFs) for a profile of a line control is

equivalent to a profile of a surface.

�Profile

�Profile of a Line vs. Surface

�Profile of a Line vs. Surface

�Profile of a Surface - Composite

Acceptable

Configurations

Unacceptable Configurations

�Profile of a Surface - Composite

�Profile of a Surface - Composite

�Position to Control Location of

Irregular Features: Boundary Concept

�Position to Control Location of

Irregular Features: Boundary Concept

�Position to Control Location of

Irregular Features: Boundary Concept

�Material Condition Modifiers

Can only be applied to features of size

MMC: Condition when a feature contains the

maximum material within stated limits of size

LMC: Condition when a feature contains the

least material within stated limits of size

RFS: Indicates that a geometric tolerance

applies at any increment if size within limits

�Material Condition Modifiers

�Effect of MMC Modifier

Diameter

Feature Size

Diameter Tol

Zone Allowed

.260

.005

.261

.006

.262

.007

.263

.008

.264

.009

.265

.010

.266

.011

.267

.012

.268

.013

�Effect of LMC Modifier

Diameter

Feature Size

Diameter Tol

Zone Allowed

.268

.005

.267

.006

.266

.007

.265

.008

.264

.009

.263

.010

.262

.011

.261

.012

.260

.013

�Effect of No Material Modifier (RFS)

�Virtual Condition

A constant "worst case" imaginary boundary

defined by the collective effects of a feature's

size, geometric tolerance, and material

condition.

�Virtual Condition: Shaft

For an external feature of size, the virtual

condition is equal to the size at MMC plus the

size of the tolerance zone at MMC.

Virtual Size

Tolerance

Zone at MMC

MMC Size

�Virtual Condition: Hole

For an internal feature of size, the virtual

condition is equal to the size at MMC minus the

size of the tolerance zone at MMC.

Virtual Size

Tolerance

Zone at MMC

MMC Size

�Resultant Condition

A variable "worst case" boundary, opposite the

virtual condition, that equals the feature's

actual mating envelope and its location

tolerance.

�Resultant Condition: Shaft

For an external feature of size, the resultant

condition is the actual mating size minus the

actual size of the tolerance zone utilized.

Actual

Tolerance Zone

Utilized

Actual Mating

Envelope

Resultant Size

�Resultant Condition: Hole

For an internal feature of size, the resultant

condition is the actual mating size plus the

actual size of the tolerance zone utilized.

Actual Mating

Envelope

Resultant Size

Actual

Tolerance Zone

Utilized

�Inner/Outer Boundary

The combination of size and position tolerance

causes a feature of size to "act" larger and smaller

than the actual size from a fit and slop standpoint.

The smallest the feature may act is called the inner

boundary. It represents the closest the surface of

the feature may ever get to the basic location

relative to the referenced datums.

The largest the feature may act is called the outer

boundary. It represents the farthest the surface of

the feature may ever get from the basic location

relative to the referenced datums.

�Inner/Outer Boundary: Shaft

The smallest a shaft may act is called its inner

boundary. It represents the closest the surface of

the shaft may ever get to the basic location relative

to the referenced datums. This boundary often

affects the slop between mating parts.

The largest a shaft may act is called its outer

boundary. It represents the farthest the surface of

the shaft may ever get from the basic location

relative to the referenced datums. This boundary

often affects the fit of mating parts.

�Inner/Outer Boundary: Hole

The smallest a hole may act is called its inner

boundary. It represents the closest the surface of

the hole may ever get to the basic location relative to

the referenced datums. This boundary often affects

the fit of mating parts.

The largest a hole may act is called its outer

boundary. It represents the farthest the surface of

the hole may ever get from the basic location relative

to the referenced datums. This boundary often

affects the slop between mating parts or the wall

thickness on the component.

�Inner/Outer Boundary: Hole (Eg.)

IB

IB

OB

OB

IB

OB