Professional Documents

Culture Documents

On The Choice of Tool Material in Friction Stir Welding of Titanium Alloys

Uploaded by

flasher_for_nokiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On The Choice of Tool Material in Friction Stir Welding of Titanium Alloys

Uploaded by

flasher_for_nokiaCopyright:

Available Formats

Proceedings of NAMRI/SME, Vol.

40, 2012

On the Choice of Tool Material in Friction Stir Welding of

Titanium Alloys

Gianluca Buffa, Livan Fratini and Fabrizio Micari

Dept. of Dept. of Chemical, Management, Computer Science and Mechanical Engineering

University of Palermo

Palermo, Italy

Luca Settineri

Department of Production Systems and Business Economics

Polytechnic University of Turin

ABSTRACT

Friction Stir Welding (FSW) is a solid state welding process patented in 1991 by TWI; initially adopted to weld aluminum

alloys, is now being successfully used also for magnesium alloys, copper and steels. The wide diffusion the process is having

is due to the possibility to weld both materials traditionally considered difficult to be welded or unweldable by traditional

fusion welding processes due to peculiar thermal and chemical material properties, and complex geometries as sandwich

structures and straightening panels. Recently, research is focusing on titanium alloys thanks to the high interest that such

materials are getting from the industry due to the extremely high strength-weight ratio together with good corrosion

resistance properties. At the moment, the main limit to the industrial applicability of FSW to titanium alloys is the tool life, as

ultra wear and deformation resistant materials must be used. In this paper a, experimental study of the tool life in FSW of

titanium alloys sheets at the varying of the main process parameters is performed. Numerical simulation provided important

information for the fixture design and analysis of results. Tungsten and Rhenium alloy W25Re tools are found to be the most

reliable among the ones considered.

KEYWORDS

Friction Stir Welding, Titanium Alloys, Tungsten alloys, tool life.

INTRODUCTION

During the last decade, the use of alloys characterized

by large resistance-weight ratios has been selected as the

best technical solution for automotive as well as aerospace

and aeronautical industries. However, besides the several

advantages they provide - as increase in the active and

passive safety, reduction of fuel consumption and

environmental impact - these materials present a few

drawbacks that must be properly taken into account. In

particular, they are often characterized by lower ductility

with respect to steels, anisotropy and are considered

difficult to be welded or non weldable.

At the moment, traditional fusion welding processes for

materials as aluminum, magnesium and titanium alloys is

often characterized by the insurgence of defects like

porosities and inclusions [1], [2]. In particular, as far as

titanium alloys are regarded, further issues are the elevated

distortion in the welded joints due to the high temperatures

reached and the phase change. Among the alternative

processes proposed, Friction Stir Welding (FSW) appears

as one of the most promising continuous joining techniques.

FSW is a solid state weld process invented in 1991 in which

the effectiveness of the obtained joint is strongly affected

by several geometrical and technological parameters; in

particular both rotating speed and feed rate have to be

properly chosen in order to obtain effective joints [3], [4].

During the process, the tool rotation speed (R) and feed rate

(Vf) are combined in a way that an asymmetric metal flow

is obtained. In particular, an advancing side and a retreating

side are observed: the former being characterized by the

positive combination of the tool feed rate and of the

peripheral tool velocity while the latter having velocity

vectors of feed and rotation opposite to each other. Hence

the tool action is the main responsible for both the material

softening and the material flow resulting in the weld of the

two workpieces. Based on the above description, it is clear

how the tool plays a key role in the process. In particular, it

must possess good mechanical properties at the

temperatures reached during the process, being thus

Proceedings of NAMRI/SME, Vol. 40, 2012

characterized by significantly larger melting temperature

and ultimate tensile strength with respect to the material to

be welded.

Nowadays, the process can be considered mature for

light materials as aluminum and magnesium alloys and it is

already being utilized for automotive, aeronautical, civil

and naval industrial applications for different joint

morphologies [5], [6], [7]. However, as far as titanium

alloys are regarded, difficulties arise for the application of

the process because of the chemical, mechanical and

thermal peculiar properties of these materials. Due to the

low thermal conductivity [7 W/mK], resulting in a non

uniform temperature distribution and in a significant

thermal gradient along the joint thickness, the effectiveness

of the joint can be compromised as most of the heat is

generated on the top surface of the joint, i.e. the contact

surface between the tool shoulder and the sheets. For such

reasons a specifically designed clamping fixture must be

designed. Additionally, the high reactivity of titanium with

atmospheric gas hydrogen, oxygen and nitrogen

requires a shield inert gas protection for the weld in order to

avoid the formation of very hard oxides on the top surface

of the sheets to be welded right where the tool is deforming

and welding the material.

Finally, due to the high temperatures and contact forces

between the sheets and the tool, the choice is limited to

ultra resistant, high melting and high cost tool materials. In

[8] friction stir welding of L80 steel was investigated with

experiments and modeling. Severe tool deformation and

some wear were observed when commercially pure

tungsten was used. Finite element analysis (FEA) was used

to predict the mushrooming of the tool. The temperature

histories in the weld region and tool forces were measured

and supplied to a finite element model. The simulated pin

deformation matched the experimental observation. Using

this model and optimization techniques, the required yield

strength of the pin material is estimated to be 400 MPa at

1000C to avoid mushrooming. At the moment, in spite of

the recent research efforts, this issue appears as the most

severe limitation to the industrial applicability of FSW to

titanium alloys as significant deformation can be found on

the tool itself even after only a few millimeters of weld

length.

In the recent years to two main categories of materials

have been utilized: ceramic and refractory metal alloys.

Among the former the most commonly utilized are

Polycrystalline cubic Boron Nitride (PcBN); although good

results have been reached, for a wide industrial utilization

of such materials the main limitations consist in the

extremely elevated costs as well as in the significant

brittleness that may lead to unexpected failures [9]. In [10]

friction stir welding was applied to commercial purity

titanium using a polycrystalline cubic boron nitride tool,

and microstructure and hardness in the weld were

examined. Additionally, the microstructural evolution

during friction stir welding was also discussed. The stir

zone consisted of fine equiaxed grains surrounded by

serrate grain boundaries, which were produced through the

allotropic transformation during the cooling cycle of

friction stir welding. The fine grains caused higher

hardness than that in the base material. A lath-shaped

grain structure containing Ti borides and tool debris was

observed in the surface region of the stir zone, whose

hardness was the highest in the weld. In [11] it is stated that

for ferrous alloys, FSW tool material development is at the

heart of the advancement of this novel joining technique.

Polycrystalline cubic boron nitride (PCBN) materials,

produced via high pressure and high temperature (HPHT)

process, have demonstrated good performance in FSW

applications. Thus, it is becoming more practical to friction

stir weld high melting temperature materials such as

stainless steels and alloy steels. The performance of FSW

materials is highly dependent on the design of material

system. This manuscript presents findings on correlations

between material properties and material design such as the

choice of binder phases and matrix and their subsequent

interactions with ultra-hard particles.

Among the refractory metal alloys researchers focused

their attention on Co based and, above all, W based alloys.

In this way a significant cost saving can be achieved,

opening the doors to a full industrial application of the

process. Unfortunately higher wear and deformation are

observed for these materials; hence a detailed investigation

on their performance during the welding process is needed.

In [12] the authors developed a new friction stir welding

(FSW) tool that enables welding of high-softeningtemperature materials, such as steels, and titanium alloys.

The new tool is made of a Co-based alloy strengthened by

precipitating intermetallics, Co3(Al,W), with an Ll2

structure at high temperatures. The Co-based alloy tool can

be manufactured at a low cost through a simple production

method consisting of casting, heat-treatment, and then

machining. It exhibits yield strengths higher than 500 MPa

at 1000C, so that it might have great potential as a FSW

tool for hard materials. In this study, the feasibility to use

the Co-based alloy tool to friction stir weld various highsoftening-temperature materials was examined through the

analysis of the changes in tool shape during the process and

the weld appearances produced. It should be observed that

there is a great emphasis on the development of friction stir

welding (FSW) tools that are resistant to wear while joining

high-temperature materials such as iron, titanium and

nickel-based alloys. Wear mechanisms may include

deformation, abrasive, and/or adhesive phenomena. In [13]

and [14] three different W based materials, were tested

performing, with the same tool geometry, FSW tests in the

worst, i.e. coldest, conditions on very thick high strength

steel (HSS) plates. The probability of adhesive wear

between tool and substrate material was evaluated using

computational thermodynamics and kinetics models.

Adhesive wear was described as diffusion couple between

tool and substrate materials. First, the combination of

Proceedings of NAMRI/SME, Vol. 40, 2012

tungsten tool and titanium base metal was evaluated. The

experimental data and calculations showed rapid rate of

cross-diffusion at FSW temperatures. Secondly, the

combination of tungsten tool and steel was evaluated. The

calculations showed minimal degradation due to crossdiffusion. However, microstructural characterization

showed alloying of steel with tungsten. Finally the

deformation of the welding tools was evaluated finding

minimum tool degradation for W25Re and W-Re-hafnium

carbon (HfC) tools.

In the paper a quantitative analysis of the tool life in

FSW of 3 mm thick Ti-6V-4Al titanium alloy sheets is

presented. Three different W based materials have been

selected, and each of them was tested under three different

process conditions till the complete failure of the tool

occurred. An already developed numerical model of the

process was utilized both to set up the welding fixture and

to provide explanations for the obtained results.

EXPERIMENTS

Ti6Al4V titanium alloy sheets 100 mm x 200 mm

and 3 mm thick were welded together under different

process conditions. In particular rotating speeds of 300, 700

and 1000 rpm were selected, based on a previously

developed campaign [15]. Fixed advancing speed equal to

35 mm/min, nuting angle equal to 2 and tool shoulder

sinking of 0.2 mm were considered for all the welds. The

tool sinking speed was kept constant and equal to 0.6

mm/min for all the welds. It is worthy notice that this

parameter is crucial for the tool life, being the sinking stage

the most dangerous for the tool as it is in contact with the

still cold titanium of the sheets. In this way three different

process conditions, characterized by an increasing Specific

Thermal Contribution (STC) given to the weld, were taken

into account.

Titanium

sheets

WC insert

Figure 1. Sketch of the utilized clamping fixture.

A tungsten insert was placed in the backplate along the

welding line in order to avoid carbon contamination with

the titanium sheets. In Figure 1 a sketch of the utilized

fixture is shown.

The tool geometry was the same for each tests at the

varying of both tool material and welding conditions ad was

characterized by a 16 mm shoulder and a 30 conical pin,

2.6 mm in height and 5 mm in major diameter. The pin had

a smooth lateral surface. Due to the relatively small sheet

thickness and consequent height of the pin the presence of

threads would have resulted in an increased complexity of

the tool manufacturing cycle, with limited enhancement of

the vertical component of the material flow an of the joint

quality. It should be noticed that the maximization of the

mechanical properties of the joints is not within the aims of

the present work.

Three different materials were utilized: K10, K10-K30

and W25Re. The firsts are two WC based materials, with a

certain percentage of cobalt, characterized by an ultrafine

grain microstructure. In general, smaller tungsten carbide

grain sizes allow for the manufacture of carbides with a

finer microstructure. A prerequisite for this is the

prevention of grain growth during the sintering process by

adding suitable doping components in the right amount,

adjusted to the cobalt content. The latter has been

determined based on the required performance

specifications for the carbide. Since the specific surface of

carbide depends reciprocally on its grain size, finelygrained carbide can absorb more binder than a coarselygrained TC. When considering the ISO hardness curve of

carbide in a diagram as a function of the carbide grain size

and its cobalt content, the curve behaves as a decreasing

polynomial function. An increase in cobalt content results

in increased toughness while hardness and wear resistance

are reduced. This opposite development of the two

desirable parameters, hardness and toughness, can be

countered by reducing the carbide grain size. The result is

an increased hardness on account of the finer basic grain of

the carbide which at the same time permits a high binding

metal content as the grain structure offers a large specific

surface, allowing for a high toughness. Consequently,

superfine grain carbide grades offer increased hardness

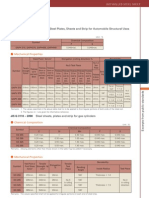

while almost maintaining toughness. In the next Table 1 the

composition, as weight percentage, and the main

mechanical properties of these two alloys, as given by the

supplier, are reported.

Proceedings of NAMRI/SME, Vol. 40, 2012

Table 1. chemical composition (wt%) and mechanical properties of the two WC based alloys utilized.

Material

K10

K10-K30

WC %

95.8

88.0

Co %

4.2

12.0

Density [g/cm3]

15.05

14.10

Hardness HV10

2300

1760

As far as the W25Re is regarded, the presence of 25%

of pure rhenium results in increased recrystallization

temperature, ductility and ultimate tensile strength with

respect to commercially pure tungsten, due to both solid

Transverse rupture strength (TRS) [MPa]

3700

4600

solution strengthening and grain size refinement [14]. In

Table 2 the mechanical properties - as provided by the

supplier - at both room and high temperatures are shown.

Table 2. chemical composition (wt%) and mechanical properties of W25Re

Material

W%

Re %

W25Re

75.0

25

Density

[g/cm3]

19.7

E

[Gpa]

410

Tensile strength (20C)

[MPa]

3800

As far as the utilized experimental procedure is

regarded, once selected the tool material, cooling conditions

and process parameters, i.e. tool rotating speed, several

welds, each about 180 mm in length, were performed till

the failure of the tool. In this way tool life diagrams were

built as will be shown in the next paragraphs. Figure 2

shows the final part of a weld characterized by 700 rpm; the

thermal flow conferred to the weld is visible even at naked

eye: the dotted line traces the boundaries of the Heat

Affected Zone (HAZ) which, in spite of the extremely poor

thermal conductivity of titanium, is quite large.

Tensile

[MPa]

330

strength

(1500C)

the rotating tool and two different configurations were

tested: in the first water is inserted in the cage, cooling the

top portion of the tool, i.e. the one farer from the pin, while

a shielding argon flow was given to the sheets in the

welding area. In the second configuration no water was

considered and the argon was introduced directly in the

cage in order to have a circumferential gas flow. Figure 3 (a

and b) shows a sketch of these configurations.

Tool cage

Heat affected zone

Tool holder

Tool

Argon

(a)

Figure 2. Final portion of the weld obtained with R = 700

rpm; different material color on the top surface indicates the

Heat Affected Zone.

In order to investigate the possibility to enhance the tool

life, the effect of water cooling of the tool was considered.

In particular a fixed cylindrical cage was placed around

Argon

Argon

Proceedings of NAMRI/SME, Vol. 40, 2012

Tool cage

Tool holder

Tool

Water

(b)

Argon

Sealing

o-ring

Argon

Figure 3. Sketches of the no water (a) and water (b) tool

cooling configurations.

NUMERICAL MODEL

The commercial FEA software DEFORM-3DTM,

Lagrangian implicit code designed for metal forming

processes, was utilized to investigate the FSW of Titanium

alloys. The numerical simulation was divided into two

stages: the sinking stage and the welding (advancing) one.

During the sinking stage, simulated to reach high enough

temperature level for the subsequent welding process, the

tool moves down vertically at 0.6 mm/sec with the assigned

rotating speed. Then, during welding or advancing stage,

the rotating tool moves along the welding line (seam). As

far as the thermal characteristics of the considered Ti-6Al4V alloy are regarded, constant values, taken from literature

[16], [17] were selected. In particular thermal conductivity

equal to 14 [N/sK] and heat capacity equal to 3.4

[N/mm2K] were utilized. This assumption makes the

thermal problem linear speeding up the numerical solution

at each time increment.

A temperature, strain and strain rate dependent rigidviscoplastic flow stress was used to model the plastic

behavior. Further details on the model and the material data

can be found in [18] and [19]. The tool and the components

of the clamping fixture, namely the backplate and the WC

insert, were modeled as rigid bodies and meshed, for the

thermal analysis, with about 5,000 and 15,000 and 8,000

tetrahedral elements, respectively. The upper part of the

clamping fixture (i.e. the actual clamping system) was

modeled through proper boundary conditions given to the

work-piece. A single block continuum model is used to

model the workpiece in order to avoid contact instabilities

due to the intermittent contact at the sheet-sheet interfaces.

The sheet blanks were meshed with about 20,000

tetrahedral elements with single edges of about 0.75mm; in

this way about four elements were placed along the sheet

thickness. A non-uniform mesh with adaptive re-meshing

was adopted with smaller elements close to the tool and a

re-meshing referring volume was identified all along the

tool feed movement [20]. In Figure 4 a close up of the

single block sheet at the end of the sinking stage is shown.

The contact conditions at the tool-workpiece interface

were modeled through a constant interface heat exchange

coefficient of 11[N mm-1 s-1 C-1] and a constant shear

friction factor equal to 0.3. The latter was chosen in such a

way to maximize the fitting of the numerical results with

experiments. Details on the contact modeling can be found

in [18] and [20].

As far as the modeling of the two different tool cooling

conditions is regarded, the no water case study was

modeled prescribing, for the whole lateral surface of the

tool, a convectional heat exchange with forced gas (see

again Figure 2a) characterized by a coefficient of 2 [N mm-1

s-1 C-1]. On the other hand, the water cooled case study was

modeled by dividing the tool lateral surface into three areas:

in the top area thermal exchange with water was considered

through a convection coefficient equal to 15 [N mm-1 s-1 C1

]; for the central area no heat exchange with environment

was assigned, being in direct contact with the sealing o-ring

needed in order to avoid water leaking on the sheets to be

welded (see again Figure 2b); finally, forced air convection

was modeled in the bottom area of the tool by a thermal

exchange coefficient equal to 2 [N mm-1 s-1 C-1] [17]. In the

following Figure 5 (a and b) the model of the tool is

presented and a sketch of the different areas considered for

thermal exchange phenomena is shown.

Figure 4. Sketch of the continuum sheet model at the

beginning of the welding stage.

Proceedings of NAMRI/SME, Vol. 40, 2012

Sealing

o-ring

Argon

Argon

(a)

(b)

Figure 5. Tool model and sketch of the different areas

considered for thermal exchange phenomena modeling:

water cooling (a) and no water (b) case studies.

RESULTS

The effectiveness of the tool water cooling was assessed

at the beginning of the experimental campaign with the aid

of the numerical tool. Two simulations, characterized by

tool rotational speed of 700 rpm, were run at the varying of

the thermal exchange conditions as described in the

previous paragraph. Figure 6 shows the obtained

temperature profiles in a longitudinal section of the tool

taken once the process reached the steady state, that is after

the tool advanced for about 22 mm.

As it can be observed form the above figure, although

the maximum temperature reached is quite high, the top

area of the tool remains cold due to the very poor thermal

conductivity of the WC based alloys. Based on this

observation it was deduced that the possible use of a

coolant chiller would not result in a significant reduction on

the tool temperature. In order to perform a quantitative

comparison between the two case studies, the temperatures

along the tool axis (see the black arrow in Figure 6) have

been collected for both the water and the no water case

study. In the next Figure 7 the obtained curves are shown.

As it could be expected after the analysis of Figure 6, no

significant difference can be observed all along the tool

length; just close to the top of the tool a slightly lower

temperature is calculated for the water case study. Based on

these preliminary results, just one set of experiments was

performed at the varying of the tool cooling conditions. In

particular the K10-K30 tool and rotating speed of 700 rpm

were utilized. Almost identical results were obtained in

terms of tool life, as suggested by the results obtained with

the numerical model, and hence, for the following

experiments, just the no water configuration was taken into

account.

Water

No water

1200

1000

Temperature[ C]

Water

800

600

400

200

0

10

15

20

25

30

35

[C]

Distance from the top of the tool [mm]

Figure 6. Temperature profiles in a tool longitudinal

section after the process reached the steady state (tool

rotation 700 rpm, no water case study).

Figure 7. Temperature profiles in a tool longitudinal

section for the water and no water case studies.

As briefly mentioned in the introduction paragraph, the

experimental strategy was to select a tool material and a

process condition, i.e. a tool rotating speed value, being

constant all the other process parameters. Then, several

sheets were welded together, with the given configuration,

till the complete failure of the tool. In this way a certain

number of welds, each of them equal to about 180 mm of

weld length, were performed and the tool life was measured

in terms of meters of welding. The same set up was utilized

Proceedings of NAMRI/SME, Vol. 40, 2012

for all the three tool materials and the three process

conditions, obtaining a total of nine different combinations.

In Figure 8 the resulting diagrams are shown.

Tool life [m]

300

700

(a)

(b)

(c)

1000

35

30

25

20

15

10

5

0

K10

K10-K30

W25Re

Tool material

Figure 8. Tool life total weld length to failure - at the

varying of tool material and process conditions (tool

rotating speed).

A few important observations can be drawn from the

above figure. First, for the K10 material, no data

corresponding to a rotational speed of 300 rpm is present,

indicating that tool failure occurred during the first weld. It

should be noticed that the test characterized by the K10 tool

material and rotational speed of 300 rpm was repeated three

times and always gave the same result in terms of tool early

failure (the failure mode will be better discussed in the

following). This is due to the combination of two factors:

the brittle behavior of this alloy and the cold weld

conditions. As a matter of fact, the lowest rotational speed

corresponds to the lowest STC conferred to the joint, and,

consequently, to a insufficient softening effect of the

titanium sheets as related to this peculiar tool material. By

increasing the STC and keeping the same tool material, a

few sheets could be successfully welded. However, the

overall tool life is very poor, showing the lowest values

among the three materials, and resulting in unacceptable

values for industrial applicability.

As far as the other two materials are regarded, a

significant increase is observed in the tool life. More in

details, all the values obtained at the varying of the tool

rotating speed with the K10-K30 tool are larger than the

maximum obtained with the K10 tool. An analogous

improvement is found when comparing the W2Re tool and

K10-K30 one.

The above described different behavior of the three

materials corresponds to three different failure modes.

Regardless of the process conditions under which they were

utilized, each of the three materials showed the same

morphology at the end of its service. In Figure 9 (a to c) the

pictures of the three broken tools are presented.

Broken pin

Figure 9. Broken tools at the end of their life: (a) K10, (b)

K10-K30 and (c) W25Re.

As it can be seen, the two WC based alloys exhibit a

completely different behavior: K10 shows a typical brittle

fracture due to excess of combined torque, compressive

force, and bending solicitation. Although this alloy is

characterized by larger hardness with respect to the K10K30 alloy, it also shows a reduced Transverse Rupture

Strength (TRS) (see again Table 1), which can be easily

connected to fracture toughness. The extreme mechanical

solicitations the tool undergoes to, together with small

vibrations due to random material inhomogeneities and

machine not perfect stiffness, leaded to an early failure.

This phenomenon, as already discussed, is emphasized and

taken to the extreme when the cold process conditions are

selected and no weld can be completed.

As far as the K10-K30 alloy is regarded, a ductile

failure mode is observed. Severe deformation progressively

occurs in the shoulder, where, at the end of the tool life, a

significant mushrooming effect is found. Additionally, the

final out of service of the tool is reached when the pin,

previously mushroomed as well, is completely torn away

from the shoulder surface. Finally, visible sign of titanium

adhesive wear are found on the shoulder surface. As a

consequence of the above observations, it arises that the

quality of the welds progressively decreases as the tool

accumulates meters of weld length.

Finally, observing the W25Re tool after failure, no

evident sign of either deformation or adhesive wear is

found. On the contrary, a fracture at mid height of the pin is

visible, resulting in insufficient penetration in the titanium

sheets and in the so called tunnel defect in the welded

joints. In this way it can be stated that the tool went out of

service. However, it should be observed that the broken pin

does not show visible signs of deformation and

mushrooming (Figure 10).

Proceedings of NAMRI/SME, Vol. 40, 2012

As a consequence, the quality of the welds performed

with this tool is kept about constant during its service. Such

consideration was substantiated by both optical analysis of

the joints and mechanical testing of a few samples

randomly taken during the experimental campaign.

As far as the influence of the process conditions is

regarded, for all the three materials, the shortest life was

found in correspondence of the lowest STC, i.e. with a tool

rotation of 300 rpm. On the other hand, the maximum weld

length was measured with the intermediate STC value.

When the maximum STC was utilized, i.e. when the tool

rotates at 1000 rpm, weld length values in between the two

extremes were observed. In order to explain such behavior

the numerical model was utilized to calculate both the

welding forces and the temperatures reached in the tool.

Thermal data of WC alloys were used for the temperature

calculations. Analogous results were found for the W25Re.

Figure 11 shows the evolution of the vertical force, the

main component in FSW processes, during the weld. It

should be observed that the second major component, i.e.

the advancing one, is usually one order of magnitude lower

than the vertical force [20].

340 rpm

700 rpm

Vertical force [KN]

120

90

60

30

0

10

20

700 rpm

1000 rpm

1400

1200

1000

800

600

400

200

0

0

10

15

20

25

30

Distance from the top of the tool [mm]

Figure 12. Calculated temperature along the tool axis at the

varying of the rotational speed.

1000 rpm

150

340 rpm

Temperature [C]

Figure 10. W25Re tool at about half of its life cycle (12

m). 700 rpm case study.

The three curves show a decreasing trend till about 40

seconds, corresponding to a tool translation of about 22

mm. As previously mentioned, this is approximately the

distance after which the process reaches the steady state

and, from this moment on, the forces will be quite constant.

As expected, the forces exerted on the tool decrease at the

increasing of the tool rotation due to the increased thermal

flow and, as a consequence, to the enhanced sheets material

softening. However, quite large values are calculated even

for the 1000 rpm case study. Additionally, it can be

observed that at the beginning of the advancing stage, the

magnitude of the forces is significantly larger than the one

calculated for the steady state. This indicates that the final

part of the sinking stage as wells as the initial part of the

welding stage are the process phases during which the tool

experiences the most severe solicitations, ranging the

vertical force between 85 kN and 140 kN. As a matter of

fact, for each of the considered materials and for each of the

considered process conditions, all the tools breakage

occurred during these two phases.

30

40

Time [sec]

Figure 11. Calculated vertical force vs. time at the varying

of the rotational speed.

Figure 12 illustrates the temperatures profiles calculated

for the tool along its axis (see again the black arrow in

Figure 6). Starting from the top surface, temperature

assumes similar values for the three configurations. On the

contrary, getting closer to the shoulder surface and the pin,

an appreciable difference is observed, reaching a maximum

value of about 300 between the coldest and the hottest

weld.

It is worthy notice that an increase in the tool rotation,

i.e. an increase in the maximum temperature, results in an

increased thermo-mechanical solicitation and may lead to a

failure of the tool. On the other hand, as observed in Figure

11, at the increasing of the tool rotation the reaction force

transmitted by the sheets to the tool decreases.

Proceedings of NAMRI/SME, Vol. 40, 2012

These two contrasting effect are summarized in Figure

13, where the maximum temperatures observed in the tool

are plotted together with the steady state force value at the

varying of the tool rotational speed. As anticipated, the

thermal and mechanical solicitations have opposite trends at

the increasing of the tool rotation. A qualitative curve,

taking into account the combined effect of softening and

actual load decreasing was added to the figure in order to

better highlight the presence of a peculiar rotational speed

value indicated as R* in the figure - minimizing the

overall thermo-mechanical solicitation on the tool. It should

be noticed that no actual minimization procedure was

carried out in this research.

From the above observation it is clear why all the

utilized tools showed the maximum weld length in

correspondence of the intermediate STC value in spite of

the significant reduction in the vertical force observed in

Figure 11.

Thermo-mechanical load on tool

R*

Figure 13. Maximum tool temperature and steady state

vertical force vs. tool rotation; qualitative overall thermomechanical solicitation on the tool.

SUMMARY & CONCLUSIONS

In the paper an experimental campaign aimed to the

identification of the most suited tool material for Friction

Stir Welding of titanium alloys was developed. 3 mm thick

Ti-6Al-4V titanium alloy sheets were welded together

under three different process conditions. The same tool

design was utilized for all the tests, the effectiveness of

water cooling was assessed and three different ultra

resistant refractory metal alloys were tested.

From the numerical and experimental obtained results

the following main conclusions can be drawn:

Water cooling on the lateral surface of

refractory metal tools does not produce any

significant change in the calculated tool

temperature and no beneficial effect is

observed for the tool life. This is due to the

extremely low thermal conductivity of these

materials. By adopting this tool cooling

configuration, the use of a coolant chiller

would not result in any appreciable

improvement in the heat removal.

All the tools failures were observed between

the end of the sinking stage and the first few

mm of welding. According to the numerical

results, these is the process

Although characterized by a large hardness

value, the K10 material revealed as inadequate

for FSW of titanium alloys as brittle fractures

occur. No weld could be obtained with the low

rotational speed and unsatisfying tool life

values were observed at the increasing of the

tool rotation;

More encouraging results were obtained with

the K10-K30 alloy, characterized by increased

fracture

toughness,

although

severe

deformation was observed in the tool shoulder

and pin during the tool life cycle. This aspect

may seriously compromise the soundness of

the obtained joints;

The best results, both in terms of tool life and

weld quality, were obtained with the W25Re

tool. Satisfying tool life was obtained and no

visible sign of degradation was observed

during the life cycle;

All the tools showed the largest weld length for

an intermediate tool rotation value due to the

concurrent effect of the force acting on the tool

itself and the temperatures it experiences

during the process.

After the preliminary screening of tool materials here

presented, in the future the authors will focus their research

activity on the W25Re alloy. Further developments include

a quantitative analysis of the abrasive and adhesive wear on

the W25Re tool as well as an implementation of the wear

phenomenon in the numerical model.

REFERENCES

[1] Liu, H.J., Fujii, H., Maeda, M., Nogi, K., 2003,

Tensile properties and fracture locations of frictionstir-welded joints of 2017-T351 aluminum alloy, J.

of Mat. Proc. Tech., 142: 692696

[2] Winter, E.F.M., Sharp, M.L., Nordmark, G.E.,

Banthia, V.K., 1990, Design considerations for

aluminium spaceframe automotive structures, SAE

technical series, Report No 905178.

Proceedings of NAMRI/SME, Vol. 40, 2012

[3] Rhodes, C.G., Mahoney, M.W., Bingel, W.H.,

Spurling, R.A., Bampton, C.C., 1997, Effects of

Friction Stir Welding on Microstructure of 7075

Aluminum, Scripta Materialia, 36: 69-75

[4] Guerra, M., Schmidt, C., McClure, L.C., Murr, L.E.,

Nunes, A.C., 2003, Flow patterns during friction stir

welding, Mater Charact, 49: 95-101

[5] Fratini, L., Buffa, G., Shivpuri, R., 2010,

Mechanical and metallurgical effects of in process

cooling during friction stir welding of AA7075-T6

butt joints, Acta Mater., 58: 2056

[6] Fratini, L., Buffa, G., Micari, F., Shivpuri, R., 2009,

On the material flow in FSW of T-joints: Influence

of geometrical and tecnological parameters, Int. J. of

Adv. Manuf. Technol., 44: 570

[7] Buffa, G., Campanile G., Fratini, L., Prisco, A.,

2009, Friction stir welding of lap joints: Influence of

process parameters on the metallurgical and

mechanical properties, Mater. Sci. and Eng. A, 519:

19.

[8] Gan, W., Li, Z.T., Khurana, S., 2007, Tool

mushrooming in friction stir welding of L80 steel,

TMS Annual Meeting, 279-283.

[9] Mahoney, M., Nelson, T., Sorenson, C., Packer, S.,

2010, Friction Stir Welding of Ferrous Alloys:

Current Status, Materials Science Forum, 638-642:

41-46.

[10] Zhang, Y., Sato, Y.S., Kokawa, H., Park, S.H.C.,

Hirano, S., 2008, Stir zone microstructure of

commercial purity titanium friction stir welded using

pcBN tool, Materials Science and Engineering A,

488 (1-2): 25-30.

[11] Liu, Q., Steel, R., Peterson, J., Horman, S., Collier,

M., Marshall, D.B., Davis, J.B., (...), Mahoney, M.,

2010, Advances in friction stir welding tooling

materials development, Proceedings of the

International Offshore and Polar Engineering

Conference, 4: 298-302.

[12] Sato, Y.S., Miyake, M., Kokawa, H., Omori, T.,

Ishida, K., Imano, S., Park, S.H.C., Hirano, S., 2011,

Development of a cobalt-based alloy FSW tool for

high-softening-temperature materials, 2011 TMS

Annual Meeting , 3-9.

[13] Thompson, B.T., Babu, S.S., Lolla, T., 2011,

Application of diffusion models to predict FSW tool

wear Proceedings of the International Offshore and

Polar Engineering Conference , 520-526

[14] Thompson, B., Babu, S.S., 2010, Tool degradation

characterization in the friction stir welding of hard

metals, Welding Journal (Miami, Fla), 89 (12): 256s261s.

[15] Fratini, L., Micari, F., Buffa, G., Ruisi, V.F., 2010,

A new fixture for FSW processes of titanium alloys,

CIRP Annals - Manufacturing Technology,

59(1):271-274

[16] Hot Working Guide A compendium processing

maps (1997) ASM Interantional.

[17] Deform 3D user manual. SFTC.

[18] Fratini, L., Beccari, S ., Buffa, G., 2005, Friction Stir

Welding FEM model improvement through inverse

thermal characterization, Transactions Of The North

American Manufacturing Research Institution Of

SME 33: 259-266

[19] Buffa, G., Fratini, L., Micari, F., 2011, Mechanical

and Microstructural Properties Prediction by

Artificial Neural Networks in FSW Processes of

Dual Phase Titanium Alloys, Proceedings of

NAMRC 39 Conference.

[20] Buffa, G., Hua, J., Shivpuri, R., Fratini, L., 2006, A

continuum based fem model for friction stir welding

- Model development, Mat. Sci. and Eng. A, 419/12: 389-396.

You might also like

- Frank C. Porter Corrosion Resistance of Zinc and Zinc Alloys 1994Document532 pagesFrank C. Porter Corrosion Resistance of Zinc and Zinc Alloys 1994Carlos Bermejo Alvarez100% (1)

- Fratini 2010Document4 pagesFratini 2010HahaNo ratings yet

- Interfacial Microstructure and Mechanical Properties of Diffusion BondedDocument8 pagesInterfacial Microstructure and Mechanical Properties of Diffusion BondedfarahNo ratings yet

- Farayibi2020 Article HardCladdingBySupersolidusLiquDocument19 pagesFarayibi2020 Article HardCladdingBySupersolidusLiqugau3koNo ratings yet

- Surface Roughness Modelling in Super Duplex Stainless Steel TurningDocument16 pagesSurface Roughness Modelling in Super Duplex Stainless Steel TurningfatinNo ratings yet

- An Overview of Friction Stir Welding (FSW) : A New PerspectiveDocument4 pagesAn Overview of Friction Stir Welding (FSW) : A New PerspectiveinventyNo ratings yet

- Investigation of Weld Defects in Friction-Stir Welding and Fusion Welding of Aluminium AlloysDocument10 pagesInvestigation of Weld Defects in Friction-Stir Welding and Fusion Welding of Aluminium AlloysV.v. TaguisNo ratings yet

- A Review On Friction Stir Welding of Dissimilar Materials Between Aluminium Alloys To CopperDocument7 pagesA Review On Friction Stir Welding of Dissimilar Materials Between Aluminium Alloys To CopperInternational Journal of Latest Research in Engineering and TechnologyNo ratings yet

- Tandem MIG process-WAAM in Stainless Steel-2018Document12 pagesTandem MIG process-WAAM in Stainless Steel-2018fereidoon marefatNo ratings yet

- Process Optimization of Preheated Friction Stir Welded Ferrous and Non Ferrous MaterialsDocument6 pagesProcess Optimization of Preheated Friction Stir Welded Ferrous and Non Ferrous MaterialsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diffusion Bonding of Ti6Al4V To Al O Using Ni/Ti Reactive MultilayersDocument12 pagesDiffusion Bonding of Ti6Al4V To Al O Using Ni/Ti Reactive MultilayersMarcionilo Neri da Silva JúniorNo ratings yet

- 1 s2.0 S0043164818313139 MainDocument13 pages1 s2.0 S0043164818313139 Mainyasemin gencbayNo ratings yet

- Research Paper On Friction Stir Welding PDFDocument4 pagesResearch Paper On Friction Stir Welding PDFeh1dvt0m100% (1)

- Friction Stir Welding Thesis PDFDocument8 pagesFriction Stir Welding Thesis PDFcarolinalewiswashington100% (2)

- Process Simulation of Aluminium Sheet Metal Deep Drawing at Elevated TemperaturesDocument8 pagesProcess Simulation of Aluminium Sheet Metal Deep Drawing at Elevated TemperaturesRashed alganmNo ratings yet

- FW 3 PDFDocument16 pagesFW 3 PDFdaniel 119360020No ratings yet

- Research Paper On Friction Stir WeldingDocument9 pagesResearch Paper On Friction Stir Weldingfzmgp96k100% (1)

- Dissimilar Welding of Titanium Alloys To Steel PDFDocument6 pagesDissimilar Welding of Titanium Alloys To Steel PDFrpadhra8803No ratings yet

- An Investigation Into Microstructure and MechanicaDocument10 pagesAn Investigation Into Microstructure and MechanicaGowri Shankar WuritiNo ratings yet

- Analysis of Process Parameters Effect On Friction Stir Welding of Aluminium 5083 and 6082Document9 pagesAnalysis of Process Parameters Effect On Friction Stir Welding of Aluminium 5083 and 6082Sreeharan Nagamani BNo ratings yet

- Materials 15 00412Document16 pagesMaterials 15 00412Murat CKNo ratings yet

- Research On The Friction Stir Welding of Titanium Grade 1Document5 pagesResearch On The Friction Stir Welding of Titanium Grade 1Sameer MDNo ratings yet

- Metals: Joining Ti6Al4V To Alumina by Diffusion Bonding Using Titanium InterlayersDocument17 pagesMetals: Joining Ti6Al4V To Alumina by Diffusion Bonding Using Titanium InterlayersMarcionilo Neri da Silva JúniorNo ratings yet

- Ultrasonic Welding of Dissimilar Metals, AA6061 and Ti6Al4VDocument6 pagesUltrasonic Welding of Dissimilar Metals, AA6061 and Ti6Al4Vkaliappan45490No ratings yet

- A Study On Rotary Friction Welding of Titanium AllDocument10 pagesA Study On Rotary Friction Welding of Titanium AllmadhukarNo ratings yet

- Welding Research Paper TopicsDocument8 pagesWelding Research Paper Topicscaqllprhf100% (1)

- Metals: Diffusion Bonding of Ti6Al4V To Al O Using Ni/Ti Reactive MultilayersDocument12 pagesMetals: Diffusion Bonding of Ti6Al4V To Al O Using Ni/Ti Reactive MultilayersMarcionilo Neri da Silva JúniorNo ratings yet

- J Proeng 2014 10 271Document6 pagesJ Proeng 2014 10 271dstifterNo ratings yet

- Effects of Temperature On Interfacial Evolution AnDocument23 pagesEffects of Temperature On Interfacial Evolution AnYvon WongNo ratings yet

- Coeficiente de Fricción LinealDocument9 pagesCoeficiente de Fricción LinealTaguis VelascoNo ratings yet

- Friction Stir Welding of Structural Steel S235 and S355Document7 pagesFriction Stir Welding of Structural Steel S235 and S355Ramona SzaboNo ratings yet

- Finite Element Modelling and Validation of Thermomechanical Behaviour For Layered Aluminium Parts Made by Composite Metal Foil ManufacturingDocument18 pagesFinite Element Modelling and Validation of Thermomechanical Behaviour For Layered Aluminium Parts Made by Composite Metal Foil ManufacturingNigus TeklehaymanotNo ratings yet

- Friction Stir Welding Thesis 2011Document4 pagesFriction Stir Welding Thesis 2011melissajacksonminneapolis100% (2)

- Materials in Metal FormingDocument42 pagesMaterials in Metal Formingasif100% (1)

- High Speed Machining of Aero-Engine AlloysDocument11 pagesHigh Speed Machining of Aero-Engine AlloysEng M G ElkhateebNo ratings yet

- A Review: Dissimilar Material Joining of Metal To Polymer Using Friction Stir Welding (FSW)Document5 pagesA Review: Dissimilar Material Joining of Metal To Polymer Using Friction Stir Welding (FSW)IJSTENo ratings yet

- Microstructure and Micro-Hardness Analysis of Friction Stir Welded Bi-Layered Laminated Aluminum SheetsDocument8 pagesMicrostructure and Micro-Hardness Analysis of Friction Stir Welded Bi-Layered Laminated Aluminum SheetsMangesh LingampalleNo ratings yet

- Advanced Powder Metallurgy TechnologiesDocument3 pagesAdvanced Powder Metallurgy TechnologiesAbhinav JoshiNo ratings yet

- 1 s2.0 S0007850613000577 MainDocument4 pages1 s2.0 S0007850613000577 MainBilay CernaNo ratings yet

- Jin 2017Document14 pagesJin 2017abdul basitNo ratings yet

- Cryogenic Cooling and Tool Life Improvement PaperDocument16 pagesCryogenic Cooling and Tool Life Improvement PaperAlvin EliasNo ratings yet

- FSW SeminarDocument23 pagesFSW SeminarMahaManthraNo ratings yet

- Research Paper FSWDocument10 pagesResearch Paper FSWsahith palikaNo ratings yet

- A Brief Review On Machinability of Titanium and Its Alloys For Nuclear ApplicationDocument3 pagesA Brief Review On Machinability of Titanium and Its Alloys For Nuclear ApplicationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Brief Review On Machinability of Titanium and Its Alloys For Nuclear ApplicationDocument3 pagesA Brief Review On Machinability of Titanium and Its Alloys For Nuclear ApplicationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- J Matpr 2017 07 083Document8 pagesJ Matpr 2017 07 083anandhunehNo ratings yet

- A Review of High Speed Machining of Titanium AlloysDocument0 pagesA Review of High Speed Machining of Titanium AlloysGeoffrey ArmstrongNo ratings yet

- Titanium Alloys and Their Machinability PDFDocument13 pagesTitanium Alloys and Their Machinability PDFznovak77No ratings yet

- Murshid Imam-2017Document22 pagesMurshid Imam-2017Shine KunnathNo ratings yet

- Friction Stir WeldingProcessing of Various MetalsDocument45 pagesFriction Stir WeldingProcessing of Various MetalsVikram JainNo ratings yet

- Effects of Titanium (Ti) Addition On Wear Behaviour of Powder Metallurgy (P/M) Plain Carbon SteelDocument11 pagesEffects of Titanium (Ti) Addition On Wear Behaviour of Powder Metallurgy (P/M) Plain Carbon SteelkrishnaNo ratings yet

- E3sconf Icmpc2023 01214Document13 pagesE3sconf Icmpc2023 01214BALOGUNNo ratings yet

- Wear Analysis of Chromium Carbide Coating On A516 WCB Steel by Plasma Spraying TechniqueDocument12 pagesWear Analysis of Chromium Carbide Coating On A516 WCB Steel by Plasma Spraying TechniqueIJRASETPublicationsNo ratings yet

- 19 Ijmperdapr201719Document10 pages19 Ijmperdapr201719TJPRC PublicationsNo ratings yet

- Materials Science & Engineering A: I. Mejía, A.E. Salas-Reyes, J. Calvo, J.M. CabreraDocument19 pagesMaterials Science & Engineering A: I. Mejía, A.E. Salas-Reyes, J. Calvo, J.M. CabreraCésar CastañedaNo ratings yet

- IOParcheivedDocument16 pagesIOParcheivedImdad JalaliNo ratings yet

- Low Cost Friction Stir Welding A ReviewDocument10 pagesLow Cost Friction Stir Welding A ReviewWeld TechNo ratings yet

- Materials 13 04965Document14 pagesMaterials 13 04965paulo passeiosNo ratings yet

- Analysis of Stainless Steel Welded Joints A Comparison Between Destructive and Non-Destructive TechniquesDocument7 pagesAnalysis of Stainless Steel Welded Joints A Comparison Between Destructive and Non-Destructive TechniquesKhalid M. HafezNo ratings yet

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysFrom EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysNo ratings yet

- Laboport: Mini Diaphragm Vacuum Pumps and CompressorsDocument2 pagesLaboport: Mini Diaphragm Vacuum Pumps and Compressorsflasher_for_nokiaNo ratings yet

- Thermowell For Thermometers ManualDocument40 pagesThermowell For Thermometers Manualflasher_for_nokiaNo ratings yet

- HDLS Series Switches: Installation Instructions For TheDocument4 pagesHDLS Series Switches: Installation Instructions For Theflasher_for_nokiaNo ratings yet

- LC1D115P7: Product Data SheetDocument3 pagesLC1D115P7: Product Data Sheetflasher_for_nokiaNo ratings yet

- TD 670 676 680 8PG BW Oct2015Document8 pagesTD 670 676 680 8PG BW Oct2015flasher_for_nokiaNo ratings yet

- Sample Only: Api 6A, Api Q1Document6 pagesSample Only: Api 6A, Api Q1flasher_for_nokiaNo ratings yet

- Doniflon 2010: Properties Appropriate Industries & ApplicationsDocument2 pagesDoniflon 2010: Properties Appropriate Industries & Applicationsflasher_for_nokiaNo ratings yet

- Parts Manual For F1600 1300Document23 pagesParts Manual For F1600 1300flasher_for_nokiaNo ratings yet

- Assessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density LogsDocument7 pagesAssessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density Logsflasher_for_nokiaNo ratings yet

- Data Sheet P 550: Technical InformationDocument1 pageData Sheet P 550: Technical Informationflasher_for_nokiaNo ratings yet

- Twelve Point Flange Screws: Earnest Technical BulletinDocument1 pageTwelve Point Flange Screws: Earnest Technical Bulletinflasher_for_nokiaNo ratings yet

- Mabanol Xenon Alpha Synth 5W-40: Synthetic High Performance Engine OilDocument1 pageMabanol Xenon Alpha Synth 5W-40: Synthetic High Performance Engine Oilflasher_for_nokiaNo ratings yet

- Mud Pump Consumables - enDocument24 pagesMud Pump Consumables - enflasher_for_nokia100% (1)

- Duraflo Composite Oemduea Mongoose PsDocument2 pagesDuraflo Composite Oemduea Mongoose Psflasher_for_nokiaNo ratings yet

- HpuDocument1 pageHpuflasher_for_nokiaNo ratings yet

- rfb7 de en PDFDocument2 pagesrfb7 de en PDFflasher_for_nokiaNo ratings yet

- Wheel Track Suspension List USADocument29 pagesWheel Track Suspension List USAflasher_for_nokiaNo ratings yet

- Marco Material Datasheet B1001Document2 pagesMarco Material Datasheet B1001flasher_for_nokiaNo ratings yet

- Mabanol Xenon Alpha Synth 5W-40 EDocument12 pagesMabanol Xenon Alpha Synth 5W-40 Eflasher_for_nokiaNo ratings yet

- Journal of Materials Processing Technology: Chen Hua, Hao Lu, Chun Yu, Jun-Mei Chen, Xiao Wei, Ji-Jin XuDocument11 pagesJournal of Materials Processing Technology: Chen Hua, Hao Lu, Chun Yu, Jun-Mei Chen, Xiao Wei, Ji-Jin Xuflasher_for_nokiaNo ratings yet

- Chapter 3BDocument1 pageChapter 3Bflasher_for_nokiaNo ratings yet

- Is 4454 Spring Steel WireDocument2 pagesIs 4454 Spring Steel Wireprasad.s.n KumarNo ratings yet

- Daily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDocument1 pageDaily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDeniz AydinNo ratings yet

- Summer Internship 2Document13 pagesSummer Internship 2JatinNo ratings yet

- Bend Testing - TWIDocument8 pagesBend Testing - TWIFarid Ahmed KhwajaNo ratings yet

- A 709/A 709M - 01b: N 1 - Where ". - ." Appears in This Table, There Is No RequirementDocument1 pageA 709/A 709M - 01b: N 1 - Where ". - ." Appears in This Table, There Is No Requirementle hoang vietNo ratings yet

- Monel Alloy 400 PropertiesDocument16 pagesMonel Alloy 400 PropertiesVelibor StokicNo ratings yet

- Investigation Into The Effect of Tool-Chip Contact Length OnDocument5 pagesInvestigation Into The Effect of Tool-Chip Contact Length OnAbid HussainNo ratings yet

- GostDocument4 pagesGostPinkuNo ratings yet

- The Family Tree of Stainless SteelDocument14 pagesThe Family Tree of Stainless Steelnike_y2kNo ratings yet

- UTP MaintenanceDocument28 pagesUTP MaintenanceAnonymous PkAjjOZBNo ratings yet

- Minfc25885 Is 733 Grade 63400Document4 pagesMinfc25885 Is 733 Grade 63400pavankumarankad81No ratings yet

- Steel Heat Treatment HandbookDocument832 pagesSteel Heat Treatment HandbookSiampol Feepakphor100% (2)

- Welding ElectrodeDocument2 pagesWelding ElectrodePaul PhiliphsNo ratings yet

- Saph 440Document1 pageSaph 440rinkumax2003100% (1)

- Gmaw and FcawDocument3 pagesGmaw and FcawMadidj_2014No ratings yet

- Mirrax Esr Heat Treatm - RecDocument4 pagesMirrax Esr Heat Treatm - RechamidharvardNo ratings yet

- Press Tool Technical RequirementsDocument6 pagesPress Tool Technical RequirementsVenkateswaran venkateswaranNo ratings yet

- Dental Amalgam: by Kazhan Omer AbdulrahmanDocument32 pagesDental Amalgam: by Kazhan Omer AbdulrahmanSyedMubeenYaserNo ratings yet

- Mecon Limited: Indian Iron Ore Scenario: Low Grade Iron Ore BeneficiationDocument19 pagesMecon Limited: Indian Iron Ore Scenario: Low Grade Iron Ore BeneficiationKalai SelvanNo ratings yet

- Welding Variables WeldersDocument5 pagesWelding Variables WeldersAkhilesh KumarNo ratings yet

- Anvil Restoration: © Robb Gunther and Karl SchulerDocument2 pagesAnvil Restoration: © Robb Gunther and Karl SchulerKelly CooverNo ratings yet

- HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Document4 pagesHPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Er Umesh RohitNo ratings yet

- Chapter 4 - Material Removal Processes (Cutting-Tool Materials and Cutting Fluids)Document8 pagesChapter 4 - Material Removal Processes (Cutting-Tool Materials and Cutting Fluids)emadaddin alezzaniNo ratings yet

- Research Article: Effect of Austempering and Martempering On The Properties of AISI 52100 SteelDocument7 pagesResearch Article: Effect of Austempering and Martempering On The Properties of AISI 52100 SteelVIDALNo ratings yet

- Detection of NMI in SteelDocument13 pagesDetection of NMI in SteelShahidNo ratings yet

- 26-Hardox 600 The - Ultimate Wear Plate PDFDocument4 pages26-Hardox 600 The - Ultimate Wear Plate PDFlazaroccsNo ratings yet

- Metal CastingDocument11 pagesMetal Castingআজিজুর রহমান চৌধুরীNo ratings yet

- Sae Astm Aisi ChartDocument1 pageSae Astm Aisi ChartOmar Jesus CocaNo ratings yet