Professional Documents

Culture Documents

Silo Problems

Uploaded by

ghita_gabrielCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Silo Problems

Uploaded by

ghita_gabrielCopyright:

Available Formats

International Journal of Agronomy and Plant Production. Vol.

, 4 (8), 1997-2003, 2013

Available online at http:// www.ijappjournal.com

ISSN 2051-1914 2013 VictorQuest Publications

Grain Flow from Different Discharge Gates in a Grain Seeder

1

Davood Kalantari , Ali Hasanzadeh Tolouti

1- Assist. Prof. in Dep. of Mechanics of Agr. Machinery Engineering, Sari Agricultural and Natural Resources

University (SANRU), sari, Iran.

2- M.Sc. Student of Mechanics of Agr. Machinery, Department of Agricultural Machinery, Sari Agricultural and

Natural Resources University (SANRU), sari, Iran.

*Corresponding Author: Davood Kalantari

Abstract

An analytical and experimental study is performed in this paper for evaluation of discharge rate

of grain flow from different discharge gate of a grain seeder. Three different apertures (circular,

rectangular and square shape with the same area) have been considered in this study. Based on

the experimental and theoretical results obtained in this study, it is shown that the discharge

rate of the circular aperture is the maximum. In contrast, the squared aperture has a minimum

discharge rate. It is also found that with increasing the grain height in the tank, the discharge

rate does not change significantly. Regarding the non-uniform and oscillating discharge from a

squared aperture, it is not recommended to use for discharging grain materials from a reservoir,

grain drills or silos and storage tanks.

Keywords: grain, aperture, grain seeder, discharge rate, tank.

Introduction

Approximately 65-70 percent of carbohydrates, proteins, and also many vitamins of B class, mineral

materials and infrequent components of Iranians regimes are supplied through the cereals and their products,

(Rajabzadeh, 1997). This report indicates the importance of academic researches on grain production and

also grain drills. Senapativ et al (1992) compared 5 kinds of grain drills (Hashtjin, 2004). In their research, 11

factors were considered as comparative criterions in grain drills. These factors include: necessary force for

moving grain drills, farm efficiency, farm capacity, the uniformity of seed distribution, plant density per hectare,

operation costs per hectare, planting depth, capacity of alignment the space between rows, the number of

workers required to use grain drills, crop yield, possibility of simultaneous seed and fertilizer distribution in the

field. After evaluation of these factors and through consideration of the effect of each factor on grain drills

efficiency, the function of overall result of each grain drills was calculated and all of these results were

compared. Final results showed that combined drills (grain drills with seed and fertilizer tank) had the best

performance and is the most appropriate grain drills for Asian-India region.

Feeding devices of grain drills usually lie in the bottom of the tank. The location of apertures is different in

the tank (Mohsenin, 1986). In order to prevent arching in front of the hole due to internal friction between

seeds, some mixers have been installed inside the seed tank, (Hashtjin, 2004), and (Enstad, 1981).

Installation of the mixer inside the tank reduces the bulk density of grain and increases the flow ability of

grains. Continuous and uniform discharge of seed mass through the hole is a necessary condition for

consistent distribution of seed, (Heege, 1993). However due to the differences between the forms, size and

weight of grains among types of seeds and between their varieties, discharging process in grain drills has

become a complex issue, (Jenike, 1970), (Enstad, 1981), (Walters, 1973).

Regarding increasing importance of mechanization of grain farming in our country and due to the exact

determination of optimum planting rates per unit area, it is necessary to measure and control the seed

discharge rate from grain seeders, (Joftkar & Kalantari, 2011). Therefore an analytical and experimental study

is presented for evaluation of discharge rate of wheat grain from different interior hole of a storage tank of the

grain seeder. Three different apertures (circular, rectangular and square shape with the same area) are

considered in this study and their discharge rate are compared together and with the theoretical derivations.

Intl. J. Agron. Plant. Prod. Vol., 4 (8), 1997-2003, 2013

Material and Method

Physical and frictional characteristics of Alvand wheat cultivar used in the present experiments are listed

in table 1 in 12%-13% moisture content, (Razavi, 2006), (Razavi & Akbari, 2006).

bulk density (kg

Table 1: Physical, mechanical and frictional

properties of Alvand wheat in the humidity7936.164

12%, (Razavi, 2006).

1359126.24

true density(kg

filling repose angle(degree)

19.2

discharge repose angle (degree)

22.6

Poisson's ratio

0.180.02

module of elasticity (MPa)

22.24.4

diameter(mm)

dz

4.193

For measurement of grain discharge, a cylindrical tank with diameter of 35cm and a conical bottom with

angle of 45 were constructed from Galvanized iron as a model of a grain drill tank. The end of conical part

was built with three different interchangeable apertures: circular, square and rectangular gates with a same

2

cross sectional area of approximately 29 cm . For each measurement, wheat was filled inside the tank rang

ing from 35 cm to 130 cm height with seven height intervals of about 15 cm. Discharge rate of each gates was

measured by collecting the discharged grains in another container. Discharge rate was then calculated after

measuring the weight of collected grains inside the container and taking into account the time of discharge,

using Q=V/t. Through this method outlet discharge and coefficient of discharge () was calculated for each

height. SAS 9.1 software was used for statistical analysis. Mean comparisons were performed by using

Duncans multiple rage test.

Theatrical analysis of the problem

According to Fig. 1, seed mass is located in a pot with a circular hole of d in diameter located at the

bottom of it. Seeds flow out with a diameter of d1 (d1<d); thus the active bulk of seeds passing through the

circular aperture is equal to the ABDC (see Fig. 1), while the rest of seeds are stagnated in ABEF and CDGH

areas. Slope angle of falling surfaces near the aperture (discharge repose angle) is defined by ; = 45

/2

( being internal friction angle of seeds). The value of is given 32-34 for dried wheat, (Bernatski et al,

1998).

Figure 1. Discharge pattern of seeds from Reservoir

To estimate the flow rate of seeds passing the lower gate of the tank, a formula similar to the fluid flow can

be used, given by Bernatski et al (1998).

1998

Intl. J. Agron. Plant. Prod. Vol., 4 (8), 1997-2003, 2013

(1)

where is flow discharge coefficient which can be obtained by measurement. Discharge coefficient () is

defined as actual-to-theoretical amount of discharging grains from an aperture. The numerical value of this

index for soft seeds is considerably less than that of liquids. This is due to the more energy requirement in

seeds to overcome the internal friction in compare to the fluids.

is the bulk density of discharging seeds

through the aperture. The dynamic bulk density

is considerably less than the bulk density of static grains .

F1 is cross sectional area of the grain flow (using d1); which is less than geometrical area of the aperture (F),

and P is the static pressure directly above the aperture. For a practical use, the value of P can be estimated

by Bernatski et al (1998).

(2)

where

, see Fig. 1. After inserting the amount of P from (2) in (1) and using

, one obtains:

(3)

'

where c is flow coefficient for a circular aperture and d1=d-d represents the reduction of diameter during

'

the grain flow. According to research done by Bernakei et al (1998), d = (1.5- 3)dz; dz to be the seed diameter.

The above equation indicates that the stability of Q and therefore consistency of the grain flow depends on

'

the consistence of

and (d-d ). Based on Eq.3, it seems that by increasing the aperture diameter (d),

'

variation of

and (d-d ) reduces; therefore the grain flow rate (Q) remains consistent and more regular.

With the same procedure like above, the following expression (4) can be obtained to measure the grain

flow from a rectangular aperture.

(4)

The amount of

for a rectangular aperture is different to the amount of

for a circular aperture (r< ),

since arching of seeds occur at the corner of a rectangular aperture which reduces the amount of grain flow.

The frequency of arching depends on the type of grains inside the seed tank and the size of aperture.

After dividing the flow rate of a rectangular aperture to that of a circular aperture, one obtains

(5)

where in this equation

is the dimensionless shape factor of a rectangular aperture defined by:

(6)

By replacing

,

and

factor for a rectangular aperture in the form of:

in equation 6, we obtain a simple shape

(7)

The amount of output discharge rate for a square aperture can be obtained from (4) after substituting

'

'

and b d = a d .

(8)

1999

Intl. J. Agron. Plant. Prod. Vol., 4 (8), 1997-2003, 2013

Now through dividing the output discharge rate of a square section to that of a circular section, one

obtains

(9)

where

is dimensionless shape factor of the square aperture, defined by

(10)

In this experiments, dimension of rectangular aperture were selected a=6.8 cm, and b=4.3 cm. Average

'

seed diameter (dz) is 4.193 mm. Using an average value of d = 2dz from d' = (1.5 3)dz given by Bernakei et

al (1998) , we have:

,

,

A similar computation for the square aperture with 5.4 cm sides, yields

Dimensionless shape factor of the rectangular and squared apertures can be obtained after considering

the above obtained values in (7) and (10), respectively,

Now through substituting the calculated

in (5) and (10), we have:

Based on the experiments conducted in this study, the average discharge coefficient () for circular,

rectangular and square apertures obtained 0.245, 0.23 and 0.21 respectively. Considering these values, the

value of rectangular and squared aperture's discharge rate will be obtained 0.88 and 0.26 of that of the

circular aperture with the same cross sectional area, respectively.

Results and Discussion

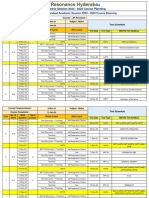

The analysis of variance (ANOVA) for the output discharge time, discharge rate and discharge coefficient

at different grain heights in the reservoir and different gates cross section are presented in Table 2.

The results shown in table 2 indicate that difference between output discharge time, discharge rate and

discharge coefficient for the various apertures (different cross sections: circular, rectangular and square) are

significant at the 1% probability.

On the other hand, influence of different grain height inside the reservoir on the three parameters of a)

discharge time, b) output discharge rate and c) discharge coefficient were not significant at the at the 1% or

5% probability, see table 2 and Fig. 2a, b, and c. This result is consistent with the obtained theoretical

derivations, i.e., Eqs.3, 4 and 8, since the parameter height of the grain inside the reservoir does not exist in

the obtained relations.

Meanwhile based on the results presented in the table 2, interaction of aperture cross section height of

the grain inside the reservoir for all of the investigated parameters were not significant. This means that 2

parameters "cross section" and "height of grains inside the seed tank" are independent from each other.

2000

Intl. J. Agron. Plant. Prod. Vol., 4 (8), 1997-2003, 2013

Table 2. Analysis of variance table, discharge time,

discharge and the discharge coefficient in three

Square average

Degree cross-sectional

area and height

Changes

in

of

Discharge

resources

freedom Discharge time Discharge

coefficient

ns

ns

ns

Repeat

2

1.081

0.007

0.0003

**

**

**

Cross section

2

42.014

0.077

0.0007

ns

ns

ns

height

2

2.3

0.0081

0.00018

Height

Cross

ns

ns

ns

4

10.396

0.016

0.0001

section

Test error

16

3.572

0.006

0.0001

Coefficient

of

10.24

9.24

13.73

variation

ns: Non significant, *: significant at the level of 5%, **: significant at the level of 1%

c

Figure 2. Influence of different grain height inside the seed tank on the output discharge for different cross

sections: a) circular, b) rectangular, and c) square.

Regarding the results presented in Fig. 3, it is shown that the discharge rate of the circular aperture is the

maximum. In contrast, the squared aperture has a minimum discharge rate. It is also shown in this figure that

discharge rate of the squared aperture fluctuates with decreasing the wheat height inside the reservoir. This

mean that an accurate control of grain flow from a squared aperture is difficult in practice.

2001

Intl. J. Agron. Plant. Prod. Vol., 4 (8), 1997-2003, 2013

Figure 3. Comparing the output discharge rate for different

apertures.

Discharge coefficient () which illustrated in Fig.4, depends on the output discharge rate, the surface

area, acceleration of gravity and biophysical properties of the grains inside the tank, see also Eq. 1. This

coefficient is also a measure of quality of the designed aperture. Due to a transcended flow from a circular

aperture, i.e., a larger discharge coefficient , the time duration for discharging wheat from a circular aperture

is less than the other two apertures. The square aperture needs the most duration of time and has a minimum

flow stability, i.e., fluctuating discharge coefficient shown in Fig.4.

Figure 4. Comparison of discharge coefficient () for different apertures.

According to Fig. 4, discharge coefficient is independent of the height of the grains inside the tank.

Considering that the heights and acceleration of gravity and the surface area are the same for three

apertures, discharge coefficient will be only a function of flow discharge from the aperture. It is also evident

from Fig.4 that flow discharge from a squared aperture is not uniform with changing the height of grains inside

the tank. This is a disadvantage of squared apertures since the amount of seeds per hectare varies with

decreasing the height of grains inside the reservoir during the planting operations, yielding non-uniformity of

seed distribution and plant density per hectare. Circular apertures have the advantage that controlling the

amount of seeds flowing downward is easier. However construction of a circular aperture with variable cross

section in practice maybe is difficult and expensive. In this case a rectangular aperture is recommended for

seed drills.

2002

Intl. J. Agron. Plant. Prod. Vol., 4 (8), 1997-2003, 2013

Conclusion

The theoretical derivations (Eqs. 3, 4, and 8) indicate that the discharge of grains from a seed tank is

independent of the grain height in the reservoir, which is in contrast to the fluid flow from a reservoir. This

result is also consistent with the results presented in table 2 and also with the observations illustrated in Fig.

3.

Considering the obtained results in this study, it is found that a circular aperture is the best case for

discharging of grains from a seed tank or a reservoir. Regarding this fact that the purpose of design and

manufacture of a grain drill is to careful distribution of the seeds in the farm, a circular or a rectangular

aperture can be used in order to design the seed tank of grain drills. In contrast, a square aperture is not

recommended due to disproportion of measured and computed discharge parameters. For the experiments

performed in this study, discharge rate from the squared aperture were highly sensitive to the height changes.

References

Bernatski H, 1997. Principles of grain drills mechanics. Wiley, New York. pp: 112.

Enstad G, 1981. A Novel Theory on the Arching and Doming in Mass Flow Hoppers. PhD Thesis.

Norwegian Institute of Technology. Bergen.

Hashtjin T, 2004. Agricultural products mechanics. Zanjan University Publications. pp: 509-520.

Heege H J, 1993. Seeding methods performance for cereals, rape, and beans. Transaction of The

ASAE. 36(3):653-661.

Jenike A, 1970. Storage and Flow of Solids, Bull. Exp. Station, Univ. Utah, Salt Lake City. 4(16), pp:

1240-1246.

Joftkar H, Kalantari D, 2011. The optimized storage condition of cereals in a storage silo. Fifth National

Conference of Agricultural Wastes. Tehran, Iran.

Mohsenin N, 1986. Physical Properties of Plant and Animal Materials. 2nd ed. New York Gordon And

Breach Science Publishers.

Rajabzadeh N, 1996. Preparation and keeping seed technology. Astane- Qodse-Razavi Publications.

pp: 40-150.

Razavi A, 2006. The study of physical characteristics of 4 Iranian improved wheat cultivars. The

Second National Food Industry Conference. Tehran, Iran.

Razavi A, Akbari R, 2006. Biophysical properties of agricultural products and foodstuffs. Mashhad,

Ferdousi University Publications. pp: 340-480.

Walters J, 1973. A theoretical analysis of stresses in axially-symmetric hoppers and bunkers. Wiley,

New York. pp: 779-789.

2003

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Tax Planing 2014Document370 pagesTax Planing 2014ghita_gabrielNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- CA Tax Planning For and Your Family 2017Document20 pagesCA Tax Planning For and Your Family 2017ghita_gabrielNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Kitchen Doors Buying Guide Fy10Document2 pagesKitchen Doors Buying Guide Fy10ghita_gabrielNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The-Wealthy-Barber-return Notes PDFDocument6 pagesThe-Wealthy-Barber-return Notes PDFghita_gabrielNo ratings yet

- Tenis de MasaDocument119 pagesTenis de Masaemilbuta2008No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Funds Integral Pro 1 enDocument151 pagesFunds Integral Pro 1 enghita_gabrielNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Dividend InvestingDocument71 pagesDividend Investingghita_gabriel100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Basic Inverter Training Course PDFDocument73 pagesBasic Inverter Training Course PDFghita_gabrielNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- PRO2 03eDocument7 pagesPRO2 03eghita_gabrielNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pressure Sensor SDE3-V1D-B-WQ4-2P-M8: Data SheetDocument1 pagePressure Sensor SDE3-V1D-B-WQ4-2P-M8: Data Sheetghita_gabrielNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- PRO2 02eDocument15 pagesPRO2 02eghita_gabrielNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Expansion Units: SpecificationsDocument3 pagesExpansion Units: Specificationsghita_gabriel100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 2SA1264Document3 pages2SA1264ghita_gabrielNo ratings yet

- Flasher BitsDocument1 pageFlasher Bitsghita_gabrielNo ratings yet

- PXR Temperature ControllersDocument5 pagesPXR Temperature Controllersghita_gabrielNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Servo Motor ControlDocument72 pagesServo Motor ControlTien-Thinh NguyenNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- PRO2 01eDocument14 pagesPRO2 01eghita_gabrielNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 3M.1 Inverter Powerflex 40: Nalysing and Understanding Other ComponentsDocument15 pages3M.1 Inverter Powerflex 40: Nalysing and Understanding Other Componentsghita_gabrielNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- mc14518bcp en PDFDocument8 pagesmc14518bcp en PDFdellcoNo ratings yet

- Tutorial + Solutions 27 August 2010Document2 pagesTutorial + Solutions 27 August 2010Jailene Gómez CollazoNo ratings yet

- Alkaline Titration Method for Hydrocyanic Acid in BeansDocument1 pageAlkaline Titration Method for Hydrocyanic Acid in BeansAngie Cerinza Acosta0% (1)

- Strength of Materials (Part I & II) - TimoshenkoDocument450 pagesStrength of Materials (Part I & II) - TimoshenkoJuan David Zapata Oliveros100% (1)

- Sizing A Supply/Return Register of DiffuserDocument2 pagesSizing A Supply/Return Register of DiffusermitasyahuNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Penetapan Kadar Sakarin, Asam Benzoat, Asam Sorbat, Kofeina, Dan Aspartam Di Dalam Beberapa Minuman Ringan Bersoda Secara Kro...Document13 pagesPenetapan Kadar Sakarin, Asam Benzoat, Asam Sorbat, Kofeina, Dan Aspartam Di Dalam Beberapa Minuman Ringan Bersoda Secara Kro...Wisnu WardhanaNo ratings yet

- BC 2.2 Ok PDFDocument16 pagesBC 2.2 Ok PDFsatydevsinghnegiNo ratings yet

- Spalart-Allmaras: Production or Strain/Vorticity-Based Production Under Spalart-Allmaras Production inDocument1 pageSpalart-Allmaras: Production or Strain/Vorticity-Based Production Under Spalart-Allmaras Production inGoutam AcharjeeNo ratings yet

- Material GradesDocument32 pagesMaterial GradesMarius PopaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- 37PHTOCHEMICALDHEEBAJCPRDocument7 pages37PHTOCHEMICALDHEEBAJCPRRifantyNo ratings yet

- Barley Straw: A Potential Method of Algae Control in PondsDocument4 pagesBarley Straw: A Potential Method of Algae Control in PondsArmando Chiclla SalazarNo ratings yet

- HMK95AADocument4 pagesHMK95AASamsung SamsungNo ratings yet

- Angewandte Chemie Intl Edit - 2021 - Jeong - Rapid Access To Ordered Mesoporous Carbons For Chemical Hydrogen StorageDocument9 pagesAngewandte Chemie Intl Edit - 2021 - Jeong - Rapid Access To Ordered Mesoporous Carbons For Chemical Hydrogen StorageHanfeng ZhouNo ratings yet

- DIN 50 929, Part 3, Page 3Document1 pageDIN 50 929, Part 3, Page 3Edson Erick Caceres ValenzuelaNo ratings yet

- PDF El Gran Libro de Los Conjuros Heciiiiiihizos Rituales y Sortilegios Spanish Edition 001 120 CompressDocument120 pagesPDF El Gran Libro de Los Conjuros Heciiiiiihizos Rituales y Sortilegios Spanish Edition 001 120 CompressRo MonaNo ratings yet

- FT 539G Eng 01Document4 pagesFT 539G Eng 01lmw_arunNo ratings yet

- Workshop 14 Radiation Enclosures: WS14-1 NAS104, Workshop 14, March 2004 2004 MSC - Software CorporationDocument24 pagesWorkshop 14 Radiation Enclosures: WS14-1 NAS104, Workshop 14, March 2004 2004 MSC - Software Corporationaiyubi2No ratings yet

- Sika Plast 257Document3 pagesSika Plast 257HasithaNo ratings yet

- Reaction of Hydrazine Hydrate and Hydrazine Hydrochloride With Dibenzoylmethane and Flavone Role of Solvent and PH OnDocument5 pagesReaction of Hydrazine Hydrate and Hydrazine Hydrochloride With Dibenzoylmethane and Flavone Role of Solvent and PH OnjamonlineNo ratings yet

- School Iron Supplement TrackingDocument7 pagesSchool Iron Supplement TrackingYoj Evol J. RomafNo ratings yet

- Chemistry Investigatory ProjectDocument23 pagesChemistry Investigatory ProjectAkashNo ratings yet

- C ClampDocument26 pagesC Clamparulmurugu100% (4)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- C 429 - 01 QzqyoqDocument8 pagesC 429 - 01 QzqyoqMarceloNo ratings yet

- Resonance Test PlanDocument15 pagesResonance Test Planbheemasaisurya976No ratings yet

- Amersham ECL Plus - RPN 2132Document32 pagesAmersham ECL Plus - RPN 2132SharkTooth FinesseNo ratings yet

- TX434SDocument2 pagesTX434Sbedjo8No ratings yet

- TrenchingDocument8 pagesTrenchingarnel_ado4412No ratings yet

- Pipe Stress Amp SupportDocument24 pagesPipe Stress Amp SupportShilpa GanganNo ratings yet

- Capacitors: An OverviewDocument60 pagesCapacitors: An OverviewKish ShenoyNo ratings yet

- Conversion PDFDocument2 pagesConversion PDFGavin TexeirraNo ratings yet

- Heat energy explained through particle motionDocument5 pagesHeat energy explained through particle motionRovejane S. SalvacionNo ratings yet