Threaded Fasteners Seminar:

Preload Loss and

Vibration Loosening

Jeff Jungmann,

Spiralock Corporation

�Fastener Selection

hUnderdesigned or overdesigned?

hToo small can be disastrous

hToo large adds weight, cost

hNot just size, but strength

hMaterial, property class, plating, friction

hCorrect selection requires understanding of joint

behavior

hInteraction of loads and deflections

hJoint response to mechanical & thermal loads, vibration

hHow to optimize joint for application?

2

Paper #

�Joint Loading Axial

hConcentric

hStress = Force/Tensile Area

hHow much load carried by bolt?

hStatic or dynamic force?

hBolt geometry has stress concentrations

hHigh stress areas more prone to failures

hFatigue

hHydrogen embrittlement

hStress corrosion cracking

3

Paper #

�Joint Loading Axial

hEccentric: Bending Moment

hNon-linear behavior

hMating surfaces can separate (gapping)

hCritical! Bolt carries entire load

hSeverity influenced by several factors:

hStiffness of fastened member

hBolt hole clearance

hBolt head diameter

hGrip length very critical, longer is better

4

Paper #

�Joint Loading Shear

hBolts typically not intended to

handle lateral loads

hFriction type

hDesign for clamp load to exceed slip load

hOften designed with multiple fasteners

hBearing type

hDirect load transfer between fastener and hole

hShoulder bolts

hLoad limit is shear strength of bolt threads

5

Paper #

�Joint Loading Torsional

hSolely a condition during tightening

Tb

hCombination of torsion and axial load

Tt

hTorsional preload is minimal, but relaxation occurs

directly after release of tool

hVery little torque energy goes to stretch the bolt

h50% lost to nut face

h40% lost to friction in threads

h10% creates load in pitch causing bolt to stretch

hIn many cases, fasteners see more strenuous

loading during installation than in service

6

Paper #

�Joint Loading Thermal

hFastener loads change as operating

temperature changes

hRegardless of external load!

hDissimilar metals = different rates of thermal

expansion

hWhen joint materials move more rapidly than

the fastener:

hCooling contraction causes loss of preload

hHeating expansion causes embedment, greater

tensile stress

7

Paper #

�Joint Loading Combined Effects

hKey considerations:

hFatigue limit - Goodman Diagram

hLimit alternating loads

hAxial load decreases force holding members

together

hNeed to determine neutral axis of joint to

analyze combined loads

hDecouple loads and resolve into x and y

components

8

Paper #

�Preferred Failure Mode

hBolts and nuts of equal grades designed to

have bolt fracture before nut strips

hVisible failure

hFemale threads always a compromise:

hEnough ductility to permit thread deflection

hSufficient strength to prevent stripped threads

hUse of softer materials requires length

correction for engagement

9

Paper #

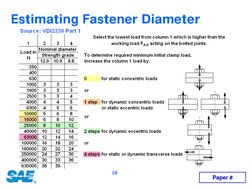

�Estimating Fastener Diameter

10

Paper #

�Joint Diagram

h Tightening sets up stress and strain in bolt & joint members

h Bolt length increases more than joint compresses

Force

Joint

compression

line

Compression

Joint thickness @

zero stress

Bolt

extension

line

Extension

11

Bolt length @

zero stress

Paper #

�Selecting Preload as % of Yield

%

Applications, important factors

100

Must know in-service loads; critical joints

85-95

Needs highly accurate installation method

65-75

Majority of fastener applications

50-60

Pressure vessels

35-40

Gasketed joints

10-20

Fastener serves as shear pin or positive stop

12

Paper #

�Hard Joint vs. Soft Joint

hHard Joint

hHigh preload

hFatigue resistant

hAssembly more rigid than fastener

hCan see large swings in joint tension

Force

Bolt

preload

Bolt Stretch

13

Joint

Compression

Extension

Paper #

�How Much Load Carried by Bolt?

hAdding load to bolt decreases clamping

force on joint

hBolt in a hard joint carries only a small

fraction of additional load

Force

Applied

Force, F

Bolt Stretch

14

Joint

Compression

Extension

Paper #

�Hard Joint vs. Soft Joint

hSoft Joint

hGasketed and noncritical joints

hFastener is more rigid than assembly

hBolt takes majority of applied load

hJoint member compression may be non-linear

Force

Non-linear

behavior

Bolt Stretch

15

Joint

Compression

Extension

Paper #

�How Much Load Carried by Bolt?

hBolt in a soft joint carries a larger

percentage of additional force

hRisk of fastener moving from elastic

region into yield

Force

Bolt Stretch

16

Applied

Force, F

Joint

Compression

Extension

Paper #

�Separation Load

hPoint where external load reduces clamp

force to zero

hAny additional increase in load is carried

100% by the bolt

hDangerous!

Force

Bolt Stretch

Joint

17

Compression

Extension

Paper #

�Joint Preload

hThree major sources of most fastener issues

hIncorrect clamp load for application

hService loads exceed design loads

hAssembly or service process causes large

deviations in clamp load

hPreload scatter

hLoss of clamp load in service

hRelaxation

hEnvironmental factors

hSelf-loosening

18

Paper #

�Preload Relaxation

hSeveral possible sources of deformation

hExceed pressure limits of contact areas

hGaskets

hApproach bolt yield

hEmbedment

hPlastic deformation occurs primarily at installation

hRough surfaces, threads, creep in soft materials

hRelaxation dependent on time, temperature,

and vibration

19

Paper #

�Preload Relaxation

hEffect of Embedding

h64% in 1st thread; 90% in first three threads

Remaining

preload after

embedment

Bolt Stretch

Joint Compression

Extension

Plastic

deformation

20

Paper #

�Environmental Factors

hChange in temperature causes change in length

hCoefficient of thermal expansion for steel is ~1/2

that of aluminum

hTemperature limits of materials:

hCarbon steel starts to anneal at 230 C (450 F)

hStainless steels begin to anneal at 480 C (900 F)

hHeat resistant alloys used in extreme environments

hCorrosion often begins at areas with high stress

concentration

21

Paper #

�Mechanism of Self Loosening

hScrew thread is an inclined plane

wrapped around a cylinder

hFriction holds block on plane

hSelf-locking is achieved when coefficient of thread

friction is tangent of thread helix angle

hDynamic friction only 10% of static friction; once

broken free it is easy to move

hVibration forces reduce friction force on threads,

allows fastener to slide in loosening direction

22

Paper #

�Effect of Thread Pitch

hMore force needed to pull out fine pitch wedge

hSmaller helix angle improves vibration resistance

Fc

23

Ff

Paper #

�Mechanism of Self Loosening

hSeveral mechanisms used to explain self-loosening

hImpact load causes assembly to resonate

hLocalized cyclic plastic deformation, esp. at 1st

engaged thread

hTorsional energy released

hBearing surface slips

hNut rotates in loosening direction

External

Load

Bending

Moment

Contact

Pressure

Variation

24

Micro-Slip

Between

Threads

Rotation

of the Nut

Paper #

�Thread Tolerances

hInherent radial clearance to allow free-spinning

assembly

hContributes to thread fit variations

hMotion (slip) permitted when preload is low or

external forces are very high

hAmount of motion limited by thread clearance

25

Paper #

�Locking Mechanisms

hAll-metal locknuts

hCotter pins

hNylon inserts

hLock wire

hTri-lobular bolts

hTab lock

hSplit washers

hBelleville washers

hToothed lockwashers hAdhesives

hSerrated nuts

hOpposing ramps

hJam nuts

hTapered threads

hSelf-locking threads

(Spiralock)

26

Paper #

�Vibration Loosening Test

hJunkers Test

hCam driven transverse movement

hMost severe condition to accelerate self-loosening

hTreats fastener like it is undersized for application

27

Paper #

�Vibration Test Variables

hComparison studies require apples-to-apples

test parameters

hAmplitude, Frequency, Preload, Hole clearance,

Bearing surface

28

Paper #

�Vibration Performance

29

Paper #

�Vibration Performance

30

Paper #

�Vibration Loosening Findings

hMajority of lock features only serve as fail-safe

method to prevent loss of fastener after selfloosening

hWorst condition for loosening is transversal vibration,

10-15 Hz

hNumber of cycles to complete loosening is inversely

proportional to the joint stiffness

hMost effective methods do not rely exclusively on

thread friction, but modify basic joint behavior

hAim to attain a level of initial bolt tension above

which self-loosening does not occur

31

Paper #

�Chemical Agents - Adhesives

hLiquid cures in absence of oxygen

hCreates permanent lock and seal by gluing threads

together

hFills gap wherever there is thread clearance

hCan not audit torque after installation

hOnce threads are broken free, must be reapplied

32

Paper #

�Opposing Cam Surfaces

hInterposing teeth have greater angle

than lead angle of thread

hCam washers use serrations to grip

bearing surfaces

hNo counter-rotation

hConsistent performance

hAdds extra components to joint

hWont grip hardened surfaces

33

Paper #

�Preload Locking Thread Form

hThread form integrated into

hole/fastener no extra parts

hMore even stress distribution

hSelf-centers bolt - no bending stress

hContinuous spiral line of contact

hRadial force 3x greater than

conventional threads

hTakes up all radial clearance

between threads

hFree spinning

34

Wedge Standard 60

ramp

Paper #

�Preload Locking Thread Form

hAxial Load vs. Radial Load

Self-locking thread has

3 times the radial locking load

35

Paper #

�Preload Loss Prevention Strategies

hDetermine needed clamp load first

hAchieve proper clamp load

hAvoid rough, irregular contact surfaces

hMinimize number of joint elements and materials

hUse longer bolts increase grip length

hMinimize hole clearances

hFine threaded fasteners are more resistant to

vibration than coarse threads

hReduce thread clearance (tighter tolerance fit) to

provide better loosening resistance

hChange mechanical behavior of joint

36

Paper #

�References

hBickford, John H. Introduction to the Design and

Behavior of Bolted Joints 1995, Marcel Dekker, Inc.

hBlendulf, Bengt. Fastening Technology &

Bolted/Screwed Joint Design. 2000.

hBolt Science. Vibration Loosening of Bolts and

Threaded Fasteners, Tutorial on Basics of Bolted

Joints. 2008.

hComer, Jess. Threaded Fasteners and the Bolted

Joint. 2004.

hJunker, G.H. New criteria for self-loosening of

fasteners under vibration, 1969, SAE Trans 78:314335.

37

Paper #