Professional Documents

Culture Documents

R.M.K. College of Engineering and Technology: Days Period I II III IV V VI VII Viii

Uploaded by

rkrajesh86Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R.M.K. College of Engineering and Technology: Days Period I II III IV V VI VII Viii

Uploaded by

rkrajesh86Copyright:

Available Formats

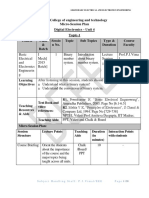

R.M.K.

COLLEGE OF ENGINEERING AND TECHNOLOGY

R S M Nagar,Puduvoyal 601 206

LECTURE PLAN 2014 - 2015 (Semester / Year)

Name of the Faculty

Department

Subject Code & Name

Individual Time Table

Rajesh K

Days

Period

: III

Branch

II

III

IV

VI

Tuesday

Wednesday

Year / Semester

VIII

Mechanical

ME2026/Unconventional

UC

Machining Process

Thursday

Friday

Saturday

VII

Year B / VI Sem

UC

UC

Mechanical

Tentative dates for Unit tests and Model Exam

Unit Test I

: 30-01-2015 to 05-02-2015

Unit Test II

: 12-03-2015 to 18-03-2015

Model Exam : 04-04-2015 to 13-04-2015

RMKCET/COM/F/15

UNIT I : INTRODUCTION TO UCM

Duration

Sl.

No

Fro

m

To

Planned

Lecture

Date

Topics to be covered

Teaching

Aids to be

used

Lecture

Date

Remarks by

the faculty

Steps taken to cover the

Signature

incomplete portions, &

of

Signature of the Staff

Principal

Member

1.

2.

Introduction to unconventional

machining processes

UCM needs and classification

3.

Brief introduction to the type of

energy source employed in AJM,

USM , WJM

4.

Brief introduction to the type of

energy source employed in EDM,

ECM, ECG

5.

Brief introduction to the type of

energy source employed in LBM,

PAM,EBM

No. of Hours Allotted: 05

Signature of HOD

Date:

No. of Hours Taken:

RMKCET/COM/F/15

UNIT II: MECHANICAL ENERGY BASED PROCESSES

Duration

Sl.

No

Fro

m

To

Planned

Lecture

Date

Topics to be covered

Teaching

Aids to be

used

Lecture

Date

Remarks by

the faculty

Steps taken to cover the

Signature

incomplete portions, &

of

Signature of the Staff

Principal

Member

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

No. of Hours Allotted: 05

Abrasive Jet Machining, Working

Principle equipment used

Abrasive Jet Machining ,Process

parameters

Abrasive Jet Machining, MRRVariation in techniques used,

Applications

Water Jet Machining, Working

Principle equipment used

Water Jet Machining- Process

parameters

Water Jet Machining ,MRRVariation in techniques used,

Applications

Ultrasonic Machining, Working

Principle equipment used

Ultrasonic Machining ,Process

parameters

Ultrasonic Machining, MRRVariation in techniques used,

Applications

Comparison of process capabilities

and parametric analysis

Signature of HOD

Date:

No. of Hours Taken:

RMKCET/COM/F/15

UNIT III: ELECTRICAL ENERGY BASED PROCESSES

Duration

Sl.

No

Fro

m

To

Planned

Lecture

Date

Topics to be covered

Teaching

Aids to be

used

Lecture

Date

Remarks by

the faculty

Steps taken to cover the

Signature

incomplete portions, &

of

Signature of the Staff

Principal

Member

16.

20.

Electric Discharge Machining

(EDM)- working Principle

Electric Discharge Machining

(EDM) equipments-Process

Parameters

MRR- electrode / Tool Power

Circuits

Characteristic of the Electric

Discharge Machining process

Dielectric, Flushing

21.

Wire cut EDM working Principles

22.

Process Parameters, equipments

23.

Characteristic of Machining

process, Applications.

17.

18.

19.

Signature of HOD

Date:

24.

No. of Hours Allotted: 05

No. of Hours Taken:

RMKCET/COM/F/15

UNIT IV: CHEMICAL AND ELECTRO-CHEMICAL ENERGY BASED PROCESSES

Duration

Sl.

No

Fro

m

To

Planned

Lecture

Date

Topics to be covered

Teaching

Aids to be

used

Lecture

Date

Remarks by

the faculty

Steps taken to cover the

Signature

incomplete portions, &

of

Signature of the Staff

Principal

Member

25.

26.

27.

28.

Chemical machining, working

Principle

Etchants, Maskant,

Techniques of applying maskants

Process Parameters MRR-

30.

Principles of ECM, Electrolysis,

Functions of Electrolyte and its

importance

ECM machine tool, equipments

31.

CAT - II

32.

Electrical circuit, MRR

33.

35.

Process Parameters of ECM,

parametric analysis

Principles of ECG, ECG Machine

Tool

Equipments, Process Parameters

36.

Electrical circuit, MRR

29.

34.

Signature of HOD

Date:

RMKCET/COM/F/15

37.

Process Parameters ,Process

characteristics

No. of Hours Allotted: 05

No. of Hours Taken:

UNIT V : THERMAL ENERGY BASED PROCESSES

Duration

Sl.

No

Fro

m

To

Planned

Lecture

Date

Topics to be covered

Teaching

Aids to be

used

Lecture

Date

Remarks by

the faculty

Steps taken to cover the

Signature

incomplete portions, &

of

Signature of the Staff

Principal

Member

38.

Laser Beam machining ,LBM

-working Principle

39.

Types of laser, Equipments

40.

Process Parameters ,Process

characteristics

41.

plasma Arc machining (PAM)

working Principle

42.

plasma Arc cutting system,

Equipments

43.

Process Parameters ,Process

characteristics

44.

Electron Beam Machining (EBM)working Principle

45.

Electron Beam machining system,

Equipments

46.

Process Parameters ,Process

Signature of HOD

Date:

RMKCET/COM/F/15

47.

No. of Hours Allotted: 05

characteristics

Beam control techniques

Comparison of process

capabilities, Applications.

No. of Hours Taken:

RMKCET/COM/F/15

You might also like

- Schaums Outline of Thermodynamics for Engineers, Fourth EditionFrom EverandSchaums Outline of Thermodynamics for Engineers, Fourth EditionRating: 5 out of 5 stars5/5 (5)

- Welding Code Exam Version D1.1Document13 pagesWelding Code Exam Version D1.1Liyakathalikhan Shahjahan100% (4)

- Smart Electrical and Mechanical Systems: An Application of Artificial Intelligence and Machine LearningFrom EverandSmart Electrical and Mechanical Systems: An Application of Artificial Intelligence and Machine LearningRakesh SehgalNo ratings yet

- Automotive Electrical and Electronics EngineeringDocument11 pagesAutomotive Electrical and Electronics EngineeringsrajapratyNo ratings yet

- Chemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningFrom EverandChemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningNo ratings yet

- GovernorsDocument85 pagesGovernorsrkrajesh86100% (2)

- Cement Seminars and Courses 2016Document68 pagesCement Seminars and Courses 2016Lucas Araújo100% (1)

- Fabrication TechnologyDocument11 pagesFabrication Technologyhiren mandaliaNo ratings yet

- VW 50060-1 - 2007-11 - (Cold Rolled-DUAL Phase Steel)Document5 pagesVW 50060-1 - 2007-11 - (Cold Rolled-DUAL Phase Steel)JORGE SOLISNo ratings yet

- Infrastructure in KarnatakaDocument47 pagesInfrastructure in KarnatakaAnandkumar PokalaNo ratings yet

- Sustainable Engineering Products and Manufacturing TechnologiesFrom EverandSustainable Engineering Products and Manufacturing TechnologiesNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- 4 Manufacturing Cost EstimationDocument22 pages4 Manufacturing Cost EstimationMuhammad Syafiq0% (1)

- Ucmp Crouse FileDocument37 pagesUcmp Crouse Filehari0118No ratings yet

- Me 2403 Power Plant Engineering - LectureplanDocument7 pagesMe 2403 Power Plant Engineering - LectureplanBIBIN CHIDAMBARANATHANNo ratings yet

- Sbtet Ap C-14 Syllabus Dmet C-14Document211 pagesSbtet Ap C-14 Syllabus Dmet C-14thirukumarNo ratings yet

- Pec IvDocument6 pagesPec Iv3111hruthvikNo ratings yet

- VIIIth Semester Scheme and SyllabusDocument21 pagesVIIIth Semester Scheme and SyllabusJitesh DewanganNo ratings yet

- M Tech - Manufacturing-Technology Course STR and SyllabusDocument23 pagesM Tech - Manufacturing-Technology Course STR and SyllabusarjunNo ratings yet

- RTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TDocument27 pagesRTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TxaloliNo ratings yet

- Couse File EDTCDocument20 pagesCouse File EDTCNitesh DixitNo ratings yet

- Class Com Circular 1eee II Year 22.1.15Document1 pageClass Com Circular 1eee II Year 22.1.15sulthan_81No ratings yet

- Kerala University Mtech - Me - Ind Refrigeration 2013 SchemeDocument59 pagesKerala University Mtech - Me - Ind Refrigeration 2013 SchemerebyroyNo ratings yet

- Manufacturing TechnologyDocument34 pagesManufacturing TechnologyGeorge OliverNo ratings yet

- B.Tech 4th Sem ME Final After ModificationDocument16 pagesB.Tech 4th Sem ME Final After Modificationphilip williamNo ratings yet

- M Tech Syllabus For Thermal EngineeringDocument43 pagesM Tech Syllabus For Thermal Engineeringwaku74No ratings yet

- LP Iii I Mech 55019 (2012-2013)Document22 pagesLP Iii I Mech 55019 (2012-2013)Rahul Kumar KNo ratings yet

- JNTU - H R05 Mechanical Syllabus BookDocument48 pagesJNTU - H R05 Mechanical Syllabus Bookchepurthi100% (2)

- Polytechnic Eee (Curriculum-09) SyllabusDocument216 pagesPolytechnic Eee (Curriculum-09) SyllabusKrishna PrasadNo ratings yet

- R16 B.Tech Mechanical EnggDocument34 pagesR16 B.Tech Mechanical EnggmechhodNo ratings yet

- ME Final Upto 4th Year Syllabus 04-06-13Document58 pagesME Final Upto 4th Year Syllabus 04-06-13zenithtutorials12No ratings yet

- RVR & JCCE MechanicalDocument211 pagesRVR & JCCE MechanicalMadhusudhan Rao KNo ratings yet

- B.Tech Mechanical Engineering 4 Semester: Assam Science and Technology University GuwahatiDocument17 pagesB.Tech Mechanical Engineering 4 Semester: Assam Science and Technology University GuwahatiPrasanta GogoiNo ratings yet

- Production EngineeringDocument39 pagesProduction EngineeringkeepingbusyNo ratings yet

- Visvesvaraya Technological University, Belgaum: M.TECH. Machine Design I SemesterDocument71 pagesVisvesvaraya Technological University, Belgaum: M.TECH. Machine Design I SemesterVasudeva BhattarNo ratings yet

- Vignan BTech Syllabus PDFDocument257 pagesVignan BTech Syllabus PDFdevyani_patilNo ratings yet

- R16 III & IV Years SyllabusDocument133 pagesR16 III & IV Years SyllabusAnonymous 5HYsyrddpNo ratings yet

- Plant Maintenance and Safety Course Code: 3341906Document8 pagesPlant Maintenance and Safety Course Code: 3341906Dhaval UpadhyayNo ratings yet

- 08AA603-Process Planning and Cost Estimation-Lesson PlanDocument3 pages08AA603-Process Planning and Cost Estimation-Lesson PlanMari MuthuNo ratings yet

- Final Practical Shedule April-May 2015Document6 pagesFinal Practical Shedule April-May 2015kks2810No ratings yet

- Syllabus R2013 PDFDocument105 pagesSyllabus R2013 PDFlogeshboy007No ratings yet

- Industrial Training DiaryDocument31 pagesIndustrial Training DiaryAaditya PalkarNo ratings yet

- AutomotiveDocument39 pagesAutomotiveyathin KLNo ratings yet

- Pec IiiDocument6 pagesPec Iii3111hruthvikNo ratings yet

- Curriculum 09 EeeDocument221 pagesCurriculum 09 EeeAjayVarma0% (1)

- Course File Contents New2Document1 pageCourse File Contents New2Rathan NNo ratings yet

- Signature: COMPETENCY MATRIX (ODD Sem 2013-2014)Document10 pagesSignature: COMPETENCY MATRIX (ODD Sem 2013-2014)rajasekaran2323No ratings yet

- Course File RRDocument32 pagesCourse File RRRaj RajendranNo ratings yet

- Visvesvaraya Technological University, Belgaum: M.TECH. Tool Engineering - (Tentative) I SemesterDocument6 pagesVisvesvaraya Technological University, Belgaum: M.TECH. Tool Engineering - (Tentative) I Semesteryathin KLNo ratings yet

- MiningDocument128 pagesMiningPrakash SundharamNo ratings yet

- TpeschemeDocument5 pagesTpeschemepachieduNo ratings yet

- Alagappa University - Time Table of B.Sc-Catering and Hotel Administration Examinations Apr-2013Document41 pagesAlagappa University - Time Table of B.Sc-Catering and Hotel Administration Examinations Apr-2013Siva MeruvaNo ratings yet

- 591 - Syllabus (4th Sem) Mechanical Engg. Dept.Document22 pages591 - Syllabus (4th Sem) Mechanical Engg. Dept.Rushikesh WakodeNo ratings yet

- Vimal BEEE Session Plan Unit 4 PDFDocument30 pagesVimal BEEE Session Plan Unit 4 PDFfvijayamiNo ratings yet

- 15 T.E. Mech Auto EnggDocument33 pages15 T.E. Mech Auto EnggNivedhan GandhiNo ratings yet

- Mce 211 Course Compact 2018 2019 SessionDocument9 pagesMce 211 Course Compact 2018 2019 SessionKEHINDE BABALOLANo ratings yet

- Me606 UcmDocument4 pagesMe606 Ucmnarayananx5No ratings yet

- APJ Abdul Kalam Technological University Thiruvananthapuram: Academic SectionDocument2 pagesAPJ Abdul Kalam Technological University Thiruvananthapuram: Academic SectionAthul RNo ratings yet

- RacDocument12 pagesRacRavindra_1202No ratings yet

- Basic Mechanical EngineeringDocument3 pagesBasic Mechanical EngineeringAkshay KharmateNo ratings yet

- Renewable Energy Production and Distribution Volume 2: Solutions and OpportunitiesFrom EverandRenewable Energy Production and Distribution Volume 2: Solutions and OpportunitiesMejdi JeguirimNo ratings yet

- Non-Destructive Testing and Condition Monitoring Techniques in Wind EnergyFrom EverandNon-Destructive Testing and Condition Monitoring Techniques in Wind EnergyNo ratings yet

- IEA Wind Recommended Practice for the Implementation of Renewable Energy Forecasting SolutionsFrom EverandIEA Wind Recommended Practice for the Implementation of Renewable Energy Forecasting SolutionsNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Som Unit 1 and 2 Question BankDocument7 pagesSom Unit 1 and 2 Question Bankrkrajesh86No ratings yet

- BeamsDocument5 pagesBeamsrkrajesh86100% (2)

- Automobile Engineering Question Bank For 5 UnitsDocument13 pagesAutomobile Engineering Question Bank For 5 Unitsrkrajesh86No ratings yet

- Simple Linear Regression: Interpreting Minitab OutputDocument4 pagesSimple Linear Regression: Interpreting Minitab Outputrkrajesh86No ratings yet

- Metrology Important QuestionsDocument2 pagesMetrology Important Questionsrkrajesh86No ratings yet

- IAT1 Question Paper Format (VII SEM)Document1 pageIAT1 Question Paper Format (VII SEM)rkrajesh86No ratings yet

- Foldable Motor BikeDocument11 pagesFoldable Motor Bikerkrajesh86No ratings yet

- Automobile Engineering Assignment QuestionsDocument5 pagesAutomobile Engineering Assignment Questionsrkrajesh86100% (1)

- Engineering ThermodynamicsDocument21 pagesEngineering Thermodynamicsrkrajesh86No ratings yet

- EMM Unit 2 Angular MeasurementDocument74 pagesEMM Unit 2 Angular Measurementrkrajesh86No ratings yet

- Electromagnetic EngineDocument35 pagesElectromagnetic Enginerkrajesh8650% (2)

- Certification 6G Aws D1Document19 pagesCertification 6G Aws D1RidwanKaryoNo ratings yet

- Hansen Aise Im Ch16Document55 pagesHansen Aise Im Ch16norsiah_shukeriNo ratings yet

- Equity LogisticsDocument23 pagesEquity LogisticsSalman Mohammed ShirasNo ratings yet

- BibliografiaDocument37 pagesBibliografiaJose GuerreroNo ratings yet

- Pyrolysis Technology, Equipment and Measuring Device: Syngas PyrolyzerDocument15 pagesPyrolysis Technology, Equipment and Measuring Device: Syngas PyrolyzerShantanuNo ratings yet

- T 3Document31 pagesT 3iwanmscNo ratings yet

- TriscuitsDocument4 pagesTriscuitsbf3649No ratings yet

- Green Lean Operationalisation of The Circular Economy Concept On Production Shop Floor LevelDocument11 pagesGreen Lean Operationalisation of The Circular Economy Concept On Production Shop Floor LevelNuriaNo ratings yet

- Corrosion Costs and Preventive Strategies in The United StatesDocument110 pagesCorrosion Costs and Preventive Strategies in The United StatesEduardo VillacrésNo ratings yet

- Hilti Product Technical GuideDocument16 pagesHilti Product Technical Guidegabox707No ratings yet

- Airlines' QualityDocument78 pagesAirlines' QualityToto H. SubagyoNo ratings yet

- Chapter 11Document10 pagesChapter 11CristiSantínNo ratings yet

- Evidence 4 PRODUCT DISTRIBUTIONDocument2 pagesEvidence 4 PRODUCT DISTRIBUTIONYAMILE HIGUITANo ratings yet

- Fuel Storage Tanks: Tank Protection Inside & OutDocument4 pagesFuel Storage Tanks: Tank Protection Inside & OutNazar Abdul KareemNo ratings yet

- PRESENTATION ON: - Supply Chain MangementDocument16 pagesPRESENTATION ON: - Supply Chain MangementSabah MemonNo ratings yet

- Sap MM FlowDocument20 pagesSap MM FlowVENKATESHNo ratings yet

- Alloy SteelDocument5 pagesAlloy SteelKun Hadipati Kusuma NegaraNo ratings yet

- The Introduction of Lean Manufacturing Concepts at QualcommDocument25 pagesThe Introduction of Lean Manufacturing Concepts at Qualcommcaran35No ratings yet

- Ch6 Raiborn SMDocument96 pagesCh6 Raiborn SMDominic SociaNo ratings yet

- C12A and Code Case.Document28 pagesC12A and Code Case.inorwoodNo ratings yet

- Different Forms IBRDocument5 pagesDifferent Forms IBRSourav DasNo ratings yet

- Supply Chain ManagementDocument71 pagesSupply Chain ManagementYopi TheaNo ratings yet

- Sika® Ceram-100P Tile AdhesiveDocument2 pagesSika® Ceram-100P Tile Adhesivedep_vinNo ratings yet

- 10 FlooringDocument39 pages10 FlooringHardesh NagarNo ratings yet

- Merge in TransitDocument29 pagesMerge in TransitMauricio FurtadoNo ratings yet