Professional Documents

Culture Documents

Universidad de Oriente SEF 2009

Uploaded by

DevilSzexCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Universidad de Oriente SEF 2009

Uploaded by

DevilSzexCopyright:

Available Formats

APPENDIX B-1

FSAE STRUCTURAL EQUIVALENCY FORM

This form must be completed and submitted by all teams no later than the date specified in the

Action Deadlines on specific event website. The FSAE Technical Committee will review all

submissions which deviate from the FSAE rules and reply with a decision about the requested

deviation. All requests will have a confirmation of receipt sent to the team. Structural Equivalency

Forms (SEF) and supporting calculations must be submitted electronically in Adobe Acrobat Format

(*.pdf). The submissions must be named as follows: schoolname_sef.pdf using the complete school

name. Please submit to the person indicated in the Action Deadlines for each event.

University Name UNIVERSIDAD DE ORIENTE

Car Number(s) & Event(s) # 24 FORMULA SAE CALIFORNIA

Team Contact Simn Nuez E-mail Address fsaeudo@gmail.com

Faculty Advisor Flix Payares E-mail Address fpayares@gmail.com

Is proof of equivalency for your design required for any of the rules?

___Yes. Rule(s) deviated (indicate which below) __ No. Chassis did not deviate from baseline

requirements

Deviation

Requested

No

Deviations

Rule

No.

3.10

3.10.6

3.11

3.12

3.13

3.14

3.18

3.18.4

3.19.4

3.19.5

3.20.3

3.20.6

3.24

3.25

3.26

5.2.2

5.4.4

Rule Description

Design Description

Main Roll Hoop Material

Main Roll Hoop Attach. to Monocoque

Front Roll Hoop Material

Main Roll Hoop Bracing

Front Roll Hoop Bracing

Monocoque Bracing Attachment

Front Bulkhead

Monocoque Front Bulkhead

Front Bulkhead Support

Monocoque Front Bulkhead Support

Impact Attenuator Attachment

Impact Attenuator Anti-Intrusion Plate

Tube Frames Side Impact Structure

Composite Monocoque Side Impact

Metal Monocoque Side Impact

Monocoque Safety Harness Attach.

Shoulder Harness Bar

26.7 mm x 2.77mm Round

26.7 mm x 2.77mm Round

26.4 mm x 2 mm Round

26.4 mm x 2 mm Round

26.4 mm x 2 mm Round

Attachment Checklist (make sure all are included in your report)

Receipt, letter of donation or proof for non-steel materials (composite, honeycomb, resin, etc).

Properties for all non-steel materials

Holes drilled in any regulated tubing require a deviation, include area and moment of inertia

ATTACH PROOF OF EQUIVALENCY

Please see "Structural Equivalency Guide" on SAE website for more information about the proof of

equivalency.

TECHNICAL COMMITTEE DECISION/COMMENTS

______________________________________________________________________________

Approved by__________________________________________ Date_____________

NOTE: THIS FORM AND THE APPROVED COPY OF THE SUBMISSION MUST BE PRESENTED

AT TECHNICAL INSPECTION AT EVERY FORMULA SAE EVENT ENTERED

2008 SAE International. All Rights Reserved. Printed in USA.

2009 Formula SAE Rules

2009 STRUCTURAL EQUIVALENCY

STRUCTURAL EQUIVALENCY FOR MAIN ROLL HOOP AND FRONT

ROLL HOOP MATERIAL

Figure N 1. Circular Cross Section of the Main Roll Hoop and Front Roll Hoop

The properties of the selected material are:

1020 STEEL

Property

Elasticity Modulus

Poisson Coefficient

Shearing Modulus

Density

Ultimate Strength

Yield Strength

Thermal Conductivity

CAR NUMBER

24

Value

200 x 109

0,29

7,7 x 1010

7900

379 x 106

207 x 106

47

Units

N/m2

NA

N/m2

Kg/m3

N/m2

N/m2

W/(M,K)

2009 STRUCTURAL EQUIVALENCY

According to rule 3.3.3.1 the tubing size required is:

OD 1.0 inch (25.4 mm) x 0.095 inch (2.4 mm)

or OD 25.0 mm x 2.5 mm metric

Material: minimum 0,1% carbon.

For 1020 steel we have a Modulus of Elasticity

E = 200 GPa

- Calculating its Area Moment of Inertia

I

I

I xx

I yy

64

OD 4

0.0254

64

11.591 10

ID 4

0.0206

m4

Figure N 2. Rules cross section for Main Hoop

The Buckling Modulus is:

EI

200 109 Pa 11.591 10 9 m 4

EI

2318.397 Nm2

- The tubing geometry selected for our design is:

Round Tube

OD 26.7 mm x 2 mm metric

Calculating its Area Moment of Inertia

I

I

I xx

I yy

64

0.0267

64

14.37 10

OD 4

ID 4

0.02096

m4

The Buckling Modulus is:

EI

200 10 9 Pa 14.37 10 9 m 4

EI

2874.064 Nm2

Its proved now that our design achieves the restriction of the rule 3.3.3.1 by

having a greater Moment of Inertia and exceeds Buckling Modulus.

CAR NUMBER

24

2009 STRUCTURAL EQUIVALENCY

Comparison of the cross section (Bending Moment Analysis)

- For the rules circular cross section

A1

A1

OD

0.0254

4

A1

ID

0.0206

1.734 x10 4 m 2

- For the new circular cross section

A2

A2

4

A2

OD

0.0267

ID

0.02096

2.148x10 4 m 2

Therefore, we can conclude that

A2 > A1

Let compare now the normal stress due bending moment in both cross sections:

- For the rules circular cross section

Assuming we are working in extreme conditions for the ultimate stress that maximum

bending moment would be:

u

M max

Ic

c

379 x10 Pa 11.591x10 9 m 2

0.0127 m

6

M max

M max

345.904 Nm

- For the new circular cross section

Now if we calculate the maximum normal stress produced by this bending moment in

our new cross section

M max

I

345.904 Nm 0.0134 m

u

14.37 x10 9 m 4

u

322.555 x10 6 Pa

This way we prove that in a maximum condition for the cross section of the rule 3.3.3.1

our selected cross section wont reach the maximum stress.

CAR NUMBER

24

2009 STRUCTURAL EQUIVALENCY

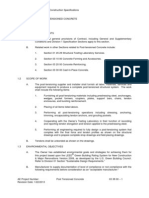

STRUCTURAL EQUIVALENCY FOR FRONT BULKHEAD, SIDE IMPACT

STRUCTURE AND FRONT BULKHEAD SUPPORT.

This report pretends to explain the reasons who lead our team to fill the structural

equivalency for the Front Bulk Head and the Side Impact Structure according to the

2009 FSAE rules (Show in fig. N 3)

Due to the several changes performed in our new chassis design, and considering the

note 2 of rule 3.3.1 that goes:

For a specific application, tubing of the specified outside diameter but with greater

wall thickness, OR of the specified wall thickness and a greater outside diameter

to those listed above, IS NOT a rules deviation requiring approval.

We have decided not to show any stress, buckling and/or simulation to prove out that

this new selected tube cross section is according to the SAE 2009 rules due to the higher

outer diameter and wall thickness of our circular cross section in comparison of the

tubing specified in the rules. All this considering that the new cross section chosen for

the team is the one you see in the next picture.

Front bulkhead cross

section

OD= 26.4 mm t= 2 mm

Side Impact & Front

Bulkhead Support cross

section

OD= 26.4 mm t= 2 mm

Figure N 3. Isometric view of 2009 Prototype.

Considering the new cross section of the Front Bulkhead Supports, we do not perform

any impact simulation in order to prove this frame geometry is safe enough due to

exceed cross section selected in our design.

CAR NUMBER

24

You might also like

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- CFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarDocument11 pagesCFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarGtatlisNo ratings yet

- Ackermann The Other Alignment PhenomenonDocument6 pagesAckermann The Other Alignment PhenomenonDevilSzexNo ratings yet

- 0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsDocument29 pages0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsmohdnazirNo ratings yet

- Rothe Erde GMBH Slewing BearingDocument6 pagesRothe Erde GMBH Slewing BearingMoustapha SeyeNo ratings yet

- API 4G - E5 Addendum 2Document4 pagesAPI 4G - E5 Addendum 2KATHERINE RIVERANo ratings yet

- Guides For Shoes CalculationDocument16 pagesGuides For Shoes CalculationgopaltryNo ratings yet

- Project Standards and Specifications Metallic Expansion Joint Rev01Document4 pagesProject Standards and Specifications Metallic Expansion Joint Rev01hiyeonNo ratings yet

- Revised RCSC Specification-Simplified, Clarified, Andimproved PDFDocument5 pagesRevised RCSC Specification-Simplified, Clarified, Andimproved PDFfarhadmrt6923No ratings yet

- Asme B 31J SifDocument6 pagesAsme B 31J SifVineesh Vs100% (1)

- R ProgrammingDocument163 pagesR Programmingvsuarezf2732100% (4)

- Structure Rehabilitation and Repair PDFDocument31 pagesStructure Rehabilitation and Repair PDFJerry Lee Moran MerkNo ratings yet

- Division 03 Concrete FinalDocument170 pagesDivision 03 Concrete FinalmasahinNo ratings yet

- PIP STF05520 Details For Pipe Railing For Walking and Working SurfacesDocument13 pagesPIP STF05520 Details For Pipe Railing For Walking and Working SurfacesVivian VijayNo ratings yet

- Etymologicon Universale v.1 PDFDocument682 pagesEtymologicon Universale v.1 PDFLeigh Smith100% (1)

- Hull: Options, Futures and Other Derivatives, Tenth Edition Chapter 15: The Black-Scholes-Merton Model Multiple Choice Test BankDocument4 pagesHull: Options, Futures and Other Derivatives, Tenth Edition Chapter 15: The Black-Scholes-Merton Model Multiple Choice Test BankKevin Molly KamrathNo ratings yet

- Controls' Gyratory compactors compliance and performanceDocument4 pagesControls' Gyratory compactors compliance and performancesebastian sepulvedaNo ratings yet

- Pipe Stress Analysis Using CAESAR IIDocument42 pagesPipe Stress Analysis Using CAESAR IIMEHMET ESENNo ratings yet

- Ac133 2014Document10 pagesAc133 2014Eddie ChanNo ratings yet

- Recognizing Quality HVAC TAB ReportsDocument80 pagesRecognizing Quality HVAC TAB ReportsdiningkoNo ratings yet

- Line Stop Welded To Shoe CalculationDocument16 pagesLine Stop Welded To Shoe CalculationmohdnazirNo ratings yet

- Pipe Stress Analysis Using CAESAR II PDFDocument42 pagesPipe Stress Analysis Using CAESAR II PDFdeni prastiko100% (1)

- AMS2303 - Steel Cleanliness, Aircraft Quality PDFDocument14 pagesAMS2303 - Steel Cleanliness, Aircraft Quality PDFRATHNAKUMARANo ratings yet

- Oct 18 SeatworkDocument24 pagesOct 18 SeatworkEasy WriteNo ratings yet

- 5-3 CEng Technical Report ExampleDocument18 pages5-3 CEng Technical Report ExampleBertrandMezatioNo ratings yet

- AS2327.1 2003 CompositeStructures SimplySupportDocument128 pagesAS2327.1 2003 CompositeStructures SimplySupportioana_marchis_86100% (1)

- SFD Ec3 Ec8Document79 pagesSFD Ec3 Ec8Rada IoanNo ratings yet

- Geometric Dimensioning AND Tolerancing (GD & T) : Prepared by Jignesh PatelDocument13 pagesGeometric Dimensioning AND Tolerancing (GD & T) : Prepared by Jignesh PatelunendratNo ratings yet

- Analysis of The Contact Pressure Between Cams and RollerDocument9 pagesAnalysis of The Contact Pressure Between Cams and Rolleranmol6237No ratings yet

- ETABS - Concrete Frame Design ManualDocument161 pagesETABS - Concrete Frame Design ManualvardogerNo ratings yet

- DLP Physics Form 4Document295 pagesDLP Physics Form 4Aini Othman100% (1)

- 031120-Permanent Concrete FormingDocument7 pages031120-Permanent Concrete FormingjimmydomingojrNo ratings yet

- Surface Vehicle Standard: Test and Test Procedures For SAE 100R Series Hydraulic Hose and Hose AssembliesDocument10 pagesSurface Vehicle Standard: Test and Test Procedures For SAE 100R Series Hydraulic Hose and Hose AssembliesMariano DomenechNo ratings yet

- Kawneer Trifab 400Document5 pagesKawneer Trifab 400WillBuckNo ratings yet

- AMS2304BDocument11 pagesAMS2304BmarcinNo ratings yet

- Report Futsal Court KemasekDocument24 pagesReport Futsal Court Kemasekaldeto71No ratings yet

- SYS Bolt ManualDocument64 pagesSYS Bolt ManualNoppolNorasriNo ratings yet

- International Journal of Engineering Research and DevelopmentDocument8 pagesInternational Journal of Engineering Research and DevelopmentIJERDNo ratings yet

- 2016 FSAE Structural Equivalency Spreadsheet V1.5Document138 pages2016 FSAE Structural Equivalency Spreadsheet V1.5PrasadHdNo ratings yet

- J1037 - 201504-Windshield Washer TubingDocument5 pagesJ1037 - 201504-Windshield Washer TubingJicheng PiaoNo ratings yet

- 047 Dalhousie-University FSAEM IAD124Document4 pages047 Dalhousie-University FSAEM IAD124Muhammad Hamish Khan NiaziNo ratings yet

- Draft Is 13098 - Tube For Pneumatic TyresDocument10 pagesDraft Is 13098 - Tube For Pneumatic Tyrest_solanki2001No ratings yet

- Aerospace Material Specification: Steel Cleanliness, Aircraft Quality Magnetic Particle Inspection ProcedureDocument14 pagesAerospace Material Specification: Steel Cleanliness, Aircraft Quality Magnetic Particle Inspection ProcedureGaryNo ratings yet

- 3 2 1Document12 pages3 2 1Izo SeremNo ratings yet

- PV Note AES4 20091006Document92 pagesPV Note AES4 20091006jamilNo ratings yet

- 77 GeipelDocument6 pages77 Geipelsaeed.work92No ratings yet

- Swd-Csa-A23.3-04 (Etabs2013)Document81 pagesSwd-Csa-A23.3-04 (Etabs2013)BJERNo ratings yet

- Sae J1231-2011Document14 pagesSae J1231-2011Ace LeeNo ratings yet

- Ac308 - 15 - Concrete Anchor Manufacturers AssociationDocument127 pagesAc308 - 15 - Concrete Anchor Manufacturers AssociationPaulo HenriqueNo ratings yet

- Standard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Document5 pagesStandard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Lupita RamirezNo ratings yet

- Design Issues in Mechanical Tolerance AnalysisDocument22 pagesDesign Issues in Mechanical Tolerance AnalysisKishor Kumar VishwakarmaNo ratings yet

- Controlling Flat-Rolled Shape - The FabricatorDocument10 pagesControlling Flat-Rolled Shape - The FabricatorsobheysaidNo ratings yet

- Sae j343 2010Document9 pagesSae j343 2010Danny AponteNo ratings yet

- RAPT Release NotesDocument25 pagesRAPT Release NotesSteve TaylorNo ratings yet

- Design and Testing of An Iso 5801 Inlet Chamber Test Rig and Related Issues With The StandardDocument12 pagesDesign and Testing of An Iso 5801 Inlet Chamber Test Rig and Related Issues With The StandardMarianaNo ratings yet

- Bridge Manual: 9.0 General 2 9.1 Concrete 3 9.2 Reinforcement Bars 4Document20 pagesBridge Manual: 9.0 General 2 9.1 Concrete 3 9.2 Reinforcement Bars 4Maan GalangNo ratings yet

- ASME Standards Technology, LLC Request For Proposals RFP-ASMEST-07-05 B31 (#2) - Impact Testing Exemption CurvesDocument14 pagesASME Standards Technology, LLC Request For Proposals RFP-ASMEST-07-05 B31 (#2) - Impact Testing Exemption CurvesvikramNo ratings yet

- 4 MKE OptimizacijaDocument9 pages4 MKE OptimizacijaLukaNo ratings yet

- 03 38 00 Post Tensioned ConcreteDocument15 pages03 38 00 Post Tensioned ConcretegullipalliNo ratings yet

- Sae j706 2017 Winche - CabrestanteDocument7 pagesSae j706 2017 Winche - CabrestanteCristian GordilloNo ratings yet

- Dubai Metro Viaduct CalculationsDocument51 pagesDubai Metro Viaduct CalculationsVanbaobbkk LeNo ratings yet

- Specs of 20m and 25m High Mast For Birgung ICPDocument16 pagesSpecs of 20m and 25m High Mast For Birgung ICPSANJeEVNo ratings yet

- Meshing 1Document20 pagesMeshing 1sb aliNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Impact Attenuator Design Meets FSAE RulesDocument4 pagesImpact Attenuator Design Meets FSAE RulesDevilSzexNo ratings yet

- How To Get Through Technical Inspection by Michael RoyceDocument66 pagesHow To Get Through Technical Inspection by Michael RoyceDevilSzexNo ratings yet

- Leon Cup Racer Technical Info 1Document5 pagesLeon Cup Racer Technical Info 1DevilSzexNo ratings yet

- Technical Manual Leon Cup Racer 2015Document49 pagesTechnical Manual Leon Cup Racer 2015DevilSzexNo ratings yet

- Standing Waves and Resonance ExplainedDocument26 pagesStanding Waves and Resonance ExplainedluisferpqNo ratings yet

- FAQs in C LanguageDocument256 pagesFAQs in C LanguageShrinivas A B0% (2)

- Relationships: Bamweyana Ivan LSG 2102Document17 pagesRelationships: Bamweyana Ivan LSG 2102Kiruhura TaremwaNo ratings yet

- Lab #1: Error: ME 422 Fall 2018Document5 pagesLab #1: Error: ME 422 Fall 2018jungleboymjaNo ratings yet

- Ved V. DatarDocument3 pagesVed V. DatarJoseph ChavoyaNo ratings yet

- Lab6Handout StrengthOfGravitationalForceDocument7 pagesLab6Handout StrengthOfGravitationalForceDuong Thi My LeNo ratings yet

- Problem SolvingDocument33 pagesProblem Solvingsathvik valivetyNo ratings yet

- SAP BI 7.0 - InfoCube PartitioningDocument5 pagesSAP BI 7.0 - InfoCube Partitioninghari_sadhu6210No ratings yet

- Core Java Ex 1Document157 pagesCore Java Ex 1lcbkraj2133No ratings yet

- kết quả chạy spss nckhDocument21 pageskết quả chạy spss nckhPHU LE GIANo ratings yet

- Asbio ManualDocument145 pagesAsbio ManualAbhijit DasNo ratings yet

- Tycssem5aiunit12345 (Munotes - In)Document55 pagesTycssem5aiunit12345 (Munotes - In)Chirag MummadiNo ratings yet

- Divide-and-Conquer Technique:: Finding Maximum & MinimumDocument8 pagesDivide-and-Conquer Technique:: Finding Maximum & MinimumFaria Farhad MimNo ratings yet

- 0580 w10 Ms 22Document4 pages0580 w10 Ms 22csmlcsNo ratings yet

- Vo MAT 267 ONLINE B Fall 2022.ddeskinn - Section 12.1Document2 pagesVo MAT 267 ONLINE B Fall 2022.ddeskinn - Section 12.1NHƯ NGUYỄN THANHNo ratings yet

- Introduction To General Relativity Solutions 31-35Document5 pagesIntroduction To General Relativity Solutions 31-35daveNo ratings yet

- Elementary Theory of StructuresDocument112 pagesElementary Theory of StructuresGodwin AcquahNo ratings yet

- Permutation MatrixDocument2 pagesPermutation MatrixrodwellheadNo ratings yet

- Hdca-5 TVDocument2 pagesHdca-5 TVDaniel ManoleNo ratings yet

- Excel Lesson 5Document28 pagesExcel Lesson 5Faisal QureshiNo ratings yet

- CL Second Verse Same As The First SeDocument18 pagesCL Second Verse Same As The First Seapi-2618943550% (1)

- Final Year Project Phase 1 ReportDocument25 pagesFinal Year Project Phase 1 ReportAman SharmaNo ratings yet

- Motion in Straight Line Particle Problems SPM Additional MathematicsDocument1 pageMotion in Straight Line Particle Problems SPM Additional MathematicsmaazioNo ratings yet

- Question 1Document3 pagesQuestion 1zattymyNo ratings yet

- PrenovaDocument17 pagesPrenovaErmitañoDelValleNo ratings yet