Professional Documents

Culture Documents

Scaffold Tips

Uploaded by

Indra YudaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scaffold Tips

Uploaded by

Indra YudaCopyright:

Available Formats

TIPS ON SCAFFOLD SAFETY

The following safety tips are offered by the engineering

department of bil-jax, inc. as guidelines in avoiding job-site

situations that could prove dangerous to scaffold workmen.

Courtesy of

Archbold, Ohio

POST WHERE WORKMEN CAN SEE

CHECK SAFETY CODES:

OSHA, state and local safety codes should be consulted; and

approval obtained from Building Safety and Industrial Commission on scaffold tips.

NAME

PHONE

INSPECT AND CHECK:

Take no chances. Inspect the scaffold set up after erection

and daily while in use. Don't remove or allow removal of, any

parts without the OK from the proper authorities. When wire

rope is used, inspect it on each job.

BEGIN WITH GOOD FOOTING:

Use base plates, sills or footers (or

combination) on solid ground; make

sure scaffold is leveled or plumbed.

REJECT DAMAGED PARTS:

Bent or otherwise damaged end frames or braces should not be

used. Put them aside for replacement. For repair, call bil-jax, inc.

DON'T SHORT-CHANGE BRACING:

Use bracing at all points provided; add extra braces if needed to

insure stability.

TIE SCAFFOLD TO THE BUILDING:

Scaffolding should be tied to the structure

using heavy wire or tie-in devices. The

first vertical tie should be at the maximum

height of 4 times the narrowest base

dimension. Additional ties are not to

exceed 26 feet vertically. Maximum horizontal distance between ties is not to

exceed 30 feet.

FIRE

DON'T OVERLOAD SCAFFOLDING:

Follow the safe load capacities as given

by the scaffold manufacturer. There's a

limit even to what steel can support. A 4to-1 safety factor must be figured on scaffolding.

POLICE

AMBULANCE

Do not use where user can come in contact with live power.

USE METAL CATWALKS, PLATFORMS;

Where available. If wood plank is used, it must be scaffold grade or

better. Inspect thoroughly before every job to make sure it is free from

breaks, knots, cracks or warpage. Decking should be full width.

DON'T RIDE MOVING SCAFFOLD;

and remember scaffold units are limited

in height to 4* times their narrowest

base dimension (unless base is widened by outriggers, or more end frames;

or tied into building.) Always keep casters locked. (except to re-spot)

*Exceptions: 3 times in CA, OH, OR, MT, ME

3 1/2 times in WA

DON'T CLIMB BRACES:

Use the steps provided on most steel

scaffolds to climb up to or down from

work levels. Use scaffold climbing

ladders where required.

PROTECT WORKING LEVELS:

Use overhead canopies to protect workers on lower work levels

when work is being done overhead. Rope off unsafe areas

underneath scaffold or provide wire mesh around work area.

Page 1 of 2

USE DOUBLE GUARD RAILS;

and toeboards on exposed sides at

platform heights of 6 feet or more.

Printed in U.S.A.

FORM 3-69TIPS/2-9CTI

SCAFFOLDING SAFETY GUIDELINES

as Recommended by SCAFFOLDING, SHORING & FORMING INSTITUTE

It shall be the responsibility of all employers and employees to read and comply with the following common sense guidelines which are

designed to promote safety in the erecting and dismantling of scaffolds. These guidelines do not purport to be all-inclusive nor to supplant or

replace other additional safety and precautionary measures to cover usual or unusual conditions. Local, State or Federal statu te or

regulations shall supersede these guidelines if there is a conflict and it is the responsibility of each employee to comply.

GENERAL GUIDELINES

I. POST THESE SCAFFOLDING SAFETY GUIDELINES in a conspicuous place and be sure that all persons who erect, dismantle or use

scaffolding are aware of them.

II. FOLLOW ALL STATE, LOCAL AND FEDERAL CODES, ORDINANCES AND REGULATIONS pertaining to scaffolding because they may

be more restrictive. For example, height or width requirements may vary.

III. SURVEY THE JOB SITEA survey shall be made of the job site for hazards, such as untampered earth fills, ditches, debris, high tension

wires, unguarded openings, and other hazardous conditions created by other trades. These conditions shall be corrected or avoided as noted

in the following sections.

IV. INSPECT ALL EQUIPMENT BEFORE USINGNever use any equipment that is damaged or defective in any way.

V. KEEP ALL EQUIPMENT IN GOOD REPAIRAvoid using corroded equipmentthe strength of corroded equipment is not known.

VI. INSPECT ERECTED SCAFFOLDS DAILYor at the beginning of every shift to be sure that they are maintained in safe condition.

VII. NEVER USE EQUIPMENT FOR PURPOSES OR IN WAYS FOR WHICH IT WAS NOT INTENDED.

VIII. REPORT ANY UNSAFE CONDITION. NEVER TAKE CHANCESDo not work on scaffolds if your physical condition is such that you feel

dizzy or unsteady in any way.

IX. WORKING UNDER THE INFLUENCE OF ALCOHOL OR ILLEGAL DRUGS IS STRICTLY PROHIBITED.

X. CONSULT YOUR SCAFFOLDING SUPPLIERNEVER TAKE CHANCESConsult manuals and instructions provided by the supplier;

scaffolding is his business.

GUIDELINES FOR ERECTION AND USE OF SCAFFOLDS

A. PROVIDE ADEQUATE SILLS for scaffold posts and use base plates.

B. USE ADJUSTING SCREWS or other approved conditions.

C. PLUMB AND LEVEL ALL SCAFFOLDS as the erection proceeds. Do not force

braces to fitlevel the scaffold until proper fit can be made easily.

D. BRACING. Each frame or panel shall be braced by horizontal bracing, cross

bracing, diagonal bracing or any combination thereof for securing vertical

members together laterally. All brace connections shall be made secure, in

accordance with manufacturers' recommendations.

E. DO NOT CLIMB CROSS BRACES. Use only an access (climbing) ladder,

access steps, frame designed to be climbed or equivalent safe access to

scaffold.

F. TIE RUNNING SCAFFOLD TO WALL or structure when the height exceeds*

four (4) times the minimum scaffold base dimension. The first vertical and

longitudinal tie shall be placed at this point. Vertical ties shall be repeated at

intervals not greater than 26 feet. Longitudinal ties shall be placed at each end

and at intervals not greater than 30 feet. Ties must prevent the scaffold from

tipping into or away from the wall or structure.

G. WHEN SCAFFOLDS ARE TO BE PARTIALLY OR FULLY ENCLOSED, specific

precautions must be taken to assure frequency and adequacy of ties attaching

the scaffolding to the building due to increased load conditions resulting from

effects of wind and weather. The scaffolding components to which the ties are

attached must also be checked for additional loads.

H. WHEN FREE STANDING SCAFFOLD TOWERS exceed* four times their

minimum base dimension vertically, they must be restrained from tipping.

I. DO NOT ERECT SCAFFOLDS NEAR ELECTRICAL POWER LINES UNLESS

PROPER PRECAUTIONS ARE TAKEN. Consult the power service company

for advice.

J. DO NOT USE ladders or makeshift devices on top of scaffolds to increase the

height.

K. DO NOT EXCEED MANUFACTURERS' RECOMMENDED LOAD RATING.

L. EQUIP AND MAINTAIN ALL PLATFORMS with proper guardrails, midrails,

and toeboards along all open sides and ends of scaffold platforms.

M. ALL BRACKETS shall be seated correctly with side brackets parallel to the

frames and end brackets at 90 degrees to the frames. Brackets shall not be bent

or twisted from normal position. Brackets (except mobile brackets designed to

carry materials) are to be used as work platforms only and shall not be used for storage

of material or equipment. When brackets are used, the scaffold shall be tied to the

structure or otherwise restrained to prevent tipping.

N. ALL SCAFFOLDING ACCESSORIES shall be used and installed in accordance with

the manufacturers' recommended procedure. Accessories shall not be altered in the

field. Scaffolds, frames and their components of various manufacturers shall not be

intermixed.

O. FOR PLANKING, THE FOLLOWING GUIDELINES APPLY:

1. Use only lumber that is properly inspected and graded as scaffold plank.

2. Planking shall have at least 12 inches of overlap and extend 6 inches beyond

center of support, or, be cleated at both ends to prevent sliding off supports.

3. Fabricated scaffold planks and platforms, unless created or restrained by hooks,

shall extend over their end supports not less than 6 inches nor more than 12

P.

Q.

R.

S.

inches.

4. Secure plank to scaffold when necessary.

FOR ROLLING SCAFFOLDS THE FOLLOWING ADDITIONAL GUIDELINES

APPLY.

1. CASTERS WITH PLAIN STEMS shall be attached to the panel or adjustment screw by pins or other suitable means.

2

.DO NOT EXTEND ADJUSTING SCREWS ON ROLLING SCAFFOLDS

MORE THAN 12 INCHES.

3. WHEELS OR CASTERS shall be provided with a locking device and kept

locked during erection and dismantling or any time scaffolds are not being

moved.

4. SECURE OR REMOVE ALL MATERIAL AND EQUIPMENT from platform

before moving scaffold.

5. USE HORIZONTAL DIAGONAL BRACING near the bottom and at 20 foot

intervals measured from the rolling surface.

6. DO NOT USE brackets or other platform extensions without consideration

of overturning effect.

7. THE HEIGHT OF A ROLLING SCAFFOLD excluding its uppermost

guardrails, must not exceed* four times its smallest base dimension unless

it is stabilized by an engineered counterweight system or some other

equivalent means.

8. CLEAT OR SECURE ALL PLANKS.

9. DO NOT ATTEMPT TO MOVE A ROLLING SCAFFOLD WITHOUT

SUFFICIENT HELPwatch out for holes in floor and overhead obstructionsstabilize against tipping.

10. DO NOT RIDE ROLLING SCAFFOLDS.

11. JOINTS shall be restrained from separation.

FOR "PUTLOGS" AND "TRUSSES" the following additional guidelines apply.

1. DO NOT CANTILEVER OR EXTEND PUTLOGS/TRUSSES as side brackets without thorough consideration for loads to be applied.

2. PUTLOGS/TRUSSES SHOULD BE EXTENDED AT LEAST 6 inches

beyond point of support.

3. PLACE RECOMMENDED BRACING BETWEEN PUTLOGS/TRUSSES

when the span of putlog/truss is more than 12 feet.

WHEN DISMANTLING SCAFFOLDING THE FOLLOWING ADDITIONAL

GUIDELINES APPLY:

1. CHECK TO SEE IF SCAFFOLDING HAS BEEN STRUCTURALLY ALTERED in any way which would make it unsafe, and if so, reconstruct where

necessary before commencing with dismantling procedures.

2. VISUALLY INSPECT PLANK prior to dismantling to be sure that they are

safe to work on.

3. COMPONENTS SHOULD BE LOWERED as soon as dismantled in safe

manner so as to protect personnel below.

4. DO NOT ACCUMULATE EXCESS COMPONENTS OR EQUIPMENT on

the level being dismantled.

5. DISMANTLED EQUIPMENT should be stockpiled in an orderly manner.

FOLLOW ERECTION PROCEDURES AND USE MANUALS.

* EXCEPTIONS: Three times in California, Ohio, Oregon, Montana, Maine; 3-1/2 times in Washington.

"These safety guidelines set forth common sense procedures for safely erecting and dismantling scaffolding equipment. However, equipment and scaffolding

systems differ, and accordingly, reference must always be made to the instructions and procedures of the supplier of the equipment. Since field conditions vary and

are beyond the control of the Institute, safe and proper use of scaffolding is the responsibility of the user and not the Institute."

Reprinting of this publication does not imply approval of product by the Institute or indicate membership in the Institute. Permission to reproduce in entirety can be

obtained from Scaffolding, Shoring & Forming Institute, 1230 Keith Bldg., Cleveland, Ohio 44115

Printed in the U.S.A.

Page 2 of 2

FORM NO. 3-61/5-01

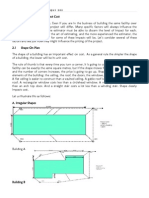

Climbing Ladder

Rolling Tower

Top Section

Bracket

6' Ladder

3' Ladder

Guard Rail & Posts

Steel Toeboard

Step Frame

Diagonal Brace

Hinge Pin

Rivet &

Cotter

Insert Pin

Pig Tail Pin

Spring

Rivet

Snap Pin

Drive Pin

NOTE: USE SUGGESTED

FRAME/INSERT IN ANY

COMBINATION.

Outrigger

Cat-A-Corner

Squaring Brace

Casters

ALL PHOTOS AND DRAWINGS ARE FOR ILLUSTRATION ONLY. FOLLOW ALL APPLICABLE ANSI AND

OSHA CODES AND REGULATIONS FOR USE OF THIS EQUIPMENT. DO NOT USE IN AREA WHERE USER

CAN COME IN CONTACT WITH LIVE POWER.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Factors Affecting Construction CostDocument8 pagesFactors Affecting Construction CostkazeNo ratings yet

- Security Alarm Services in Canada Industry ReportDocument32 pagesSecurity Alarm Services in Canada Industry ReportThe Hamilton Spectator100% (2)

- Safe Working at Heights Guide 1321Document52 pagesSafe Working at Heights Guide 1321Indra YudaNo ratings yet

- Scaffold TipsDocument2 pagesScaffold TipsIndra YudaNo ratings yet

- PSG Antropometri 2014Document58 pagesPSG Antropometri 2014Indra YudaNo ratings yet

- Trerapi Insulin Siip 2Document10 pagesTrerapi Insulin Siip 2Indra YudaNo ratings yet

- Al Qaffay Island Building Door & Window DetailsDocument1 pageAl Qaffay Island Building Door & Window DetailsSukant KamathNo ratings yet

- Floor Plan of CrematoriumDocument1 pageFloor Plan of Crematoriumjudy ramos0% (1)

- Horizon Linen Chutes Installation RequirementsDocument4 pagesHorizon Linen Chutes Installation Requirementshunkydee100% (1)

- rc38 Recs For Frost Protection Measures For Sprinklers PDFDocument12 pagesrc38 Recs For Frost Protection Measures For Sprinklers PDFNahado DMNo ratings yet

- Vitodens-200-W Technical Data ManualDocument44 pagesVitodens-200-W Technical Data ManualdupangNo ratings yet

- 2013 IA COAG Report National Infrastructure Plan LR PDFDocument140 pages2013 IA COAG Report National Infrastructure Plan LR PDFLauren FrazierNo ratings yet

- Deep Tunnels For Combined Sewer Overflow Storage and TransportDocument17 pagesDeep Tunnels For Combined Sewer Overflow Storage and TransportpabulumzengNo ratings yet

- Daftar Standard Di Elibrary RekindDocument48 pagesDaftar Standard Di Elibrary RekindHamzah ZuhdiNo ratings yet

- CYPECAD - User's ManualDocument141 pagesCYPECAD - User's ManualMajid AbujalilNo ratings yet

- Preparing To Build A Masonry OvenDocument28 pagesPreparing To Build A Masonry OvenSteve B. SalongaNo ratings yet

- Forced Vibration and Hygrothermal Analysis of CompDocument76 pagesForced Vibration and Hygrothermal Analysis of CompVignesh GuruNo ratings yet

- TDS - Pulmix 4033Document1 pageTDS - Pulmix 4033dipen royNo ratings yet

- Deterioration of Monuments and Their PreservationDocument11 pagesDeterioration of Monuments and Their PreservationPranav PadmavasanNo ratings yet

- Ijce V3i7p125Document8 pagesIjce V3i7p125paulocapchaNo ratings yet

- Technical Standard: (Signed Original On File) Sheet OFDocument7 pagesTechnical Standard: (Signed Original On File) Sheet OFd r hardyNo ratings yet

- Spec Flexgate ManualDocument2 pagesSpec Flexgate Manualsf wNo ratings yet

- Long Span StructureDocument17 pagesLong Span StructurePravah KhandekarNo ratings yet

- Sleek Wall-Hung Toilet with Tornado FlushDocument1 pageSleek Wall-Hung Toilet with Tornado Flushnishant81No ratings yet

- JTL Book Above Groung Discharge SystemsDocument54 pagesJTL Book Above Groung Discharge SystemsbendeniNo ratings yet

- Boedeker Plastics Polyurethane - Technical GuideDocument26 pagesBoedeker Plastics Polyurethane - Technical GuideJagdish PatelNo ratings yet

- Stair Case Design Single FlightDocument3 pagesStair Case Design Single Flightrahul100% (1)

- Precast Segmental Bridges in Riyadh Metro Project - Lines 1 & 2Document10 pagesPrecast Segmental Bridges in Riyadh Metro Project - Lines 1 & 2kutticute_877110165No ratings yet

- Spherical Roller Bearings for Vibrating EquipmentDocument2 pagesSpherical Roller Bearings for Vibrating EquipmentRodrigo Jechéla Barrios100% (1)

- Packing Plant PontianakDocument4 pagesPacking Plant PontianakRisaldi BahmarNo ratings yet

- Evaluation of Wave Barriers On Ground Vibration Reduction Through Numerical Modeling in AbaqusDocument1 pageEvaluation of Wave Barriers On Ground Vibration Reduction Through Numerical Modeling in AbaqusSIMULIACorpNo ratings yet

- On Industrial Visit: Presented By: K. Jagadesh 1225116215 MBA-B SectionDocument4 pagesOn Industrial Visit: Presented By: K. Jagadesh 1225116215 MBA-B SectionSaiVamsiNo ratings yet

- 10Document12 pages10rowatersNo ratings yet